Cleaning device with edge and omnidirectional obstacle detection

A technology for obstacle detection and cleaning devices, applied in cleaning devices, cleaning equipment, window cleaning, etc., can solve the problems of high module cost, reduce labor intensity and danger of manual glass cleaning, and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

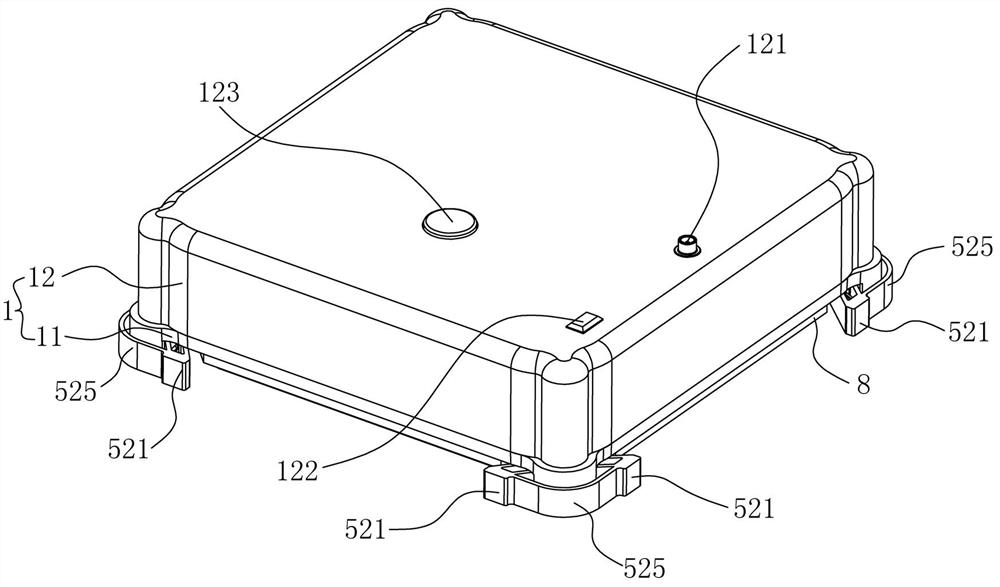

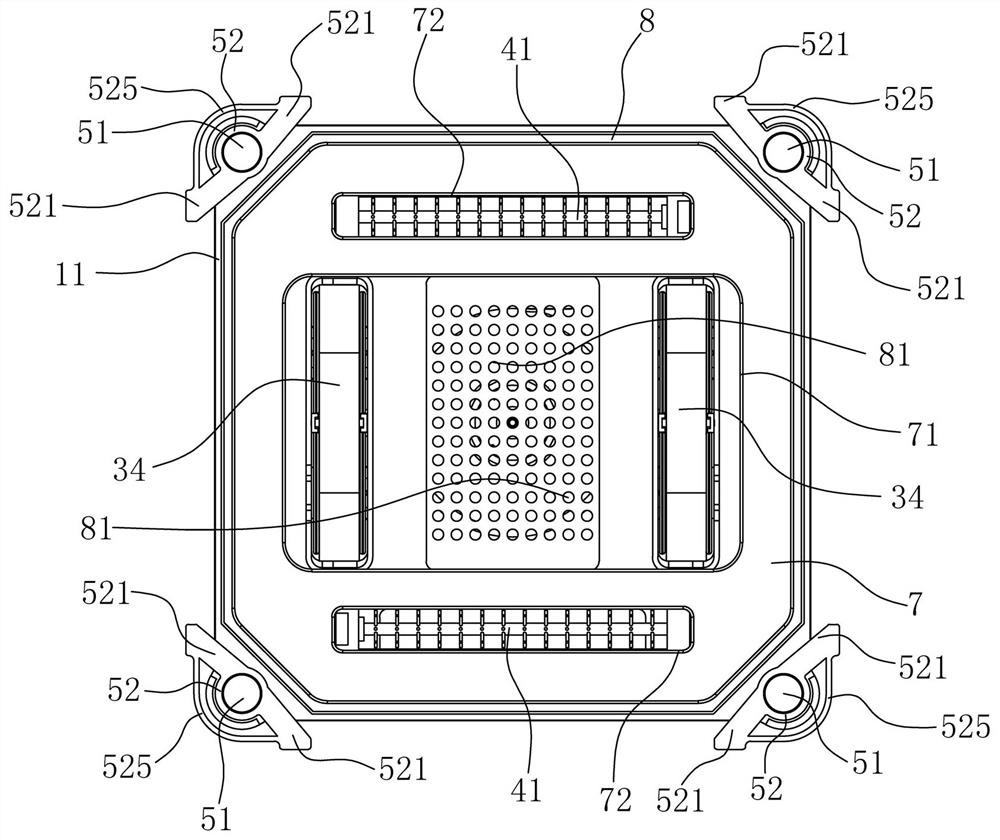

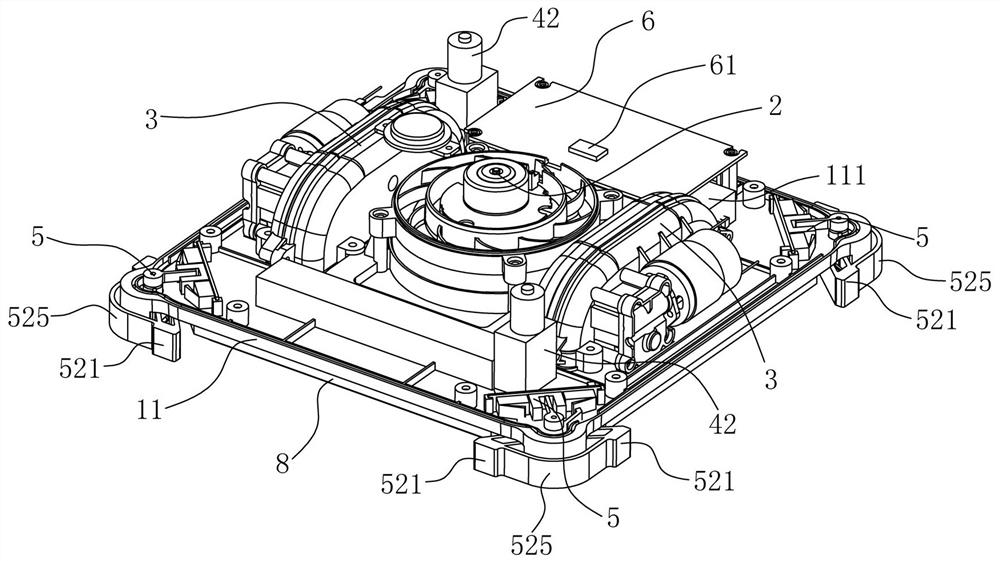

[0037] Such as Figure 1-11 As shown, the present invention relates to a cleaning device with edge and omnidirectional obstacle detection, including a casing 1, and a negative pressure part 2 is provided on the inner bottom of the casing 1, and the negative pressure part 2 is used to adsorb the casing 1 on To flatten the surface of the object, the symmetrical two sides of the negative pressure part 2 are respectively provided with a mobile unit 3, and the mobile unit 3 is used to drive the displacement of the casing 1 on the flat object surface, and the two symmetrical sides of the negative pressure part 2 are respectively provided with There is a cleaning unit 4, and the cleaning unit 4 is used to clean the solidified dirt on the surface of the flat object. The casing 1 is provided with an edge and an omnidirectional obstacle detection unit 5 at least at two opposite corners thereof. The obstacle detection unit 5 is used to judge whether the current displacement direction, th...

specific Embodiment 2

[0051] Such as Figure 9-10 As shown, the present invention discloses a cleaning device with edge and omnidirectional obstacle detection, and its edge and omnidirectional obstacle detection unit 5 includes an edge lifter 51 that passes through the base 11 and is sleeved on the edge lifter 51 The return spring 53, the edge sensing block 54 fixed on the edge lifting part 51, the edge sensing part 56 arranged on at least one side of the edge sensing block 54, the collision block 52 sleeved on the bottom surface of the corner of the base 11, and the connection The obstacle sensing block 55 on the collision block 52, at least two obstacle sensing parts 57 located on one side of the obstacle sensing block 55, and the limit elastic block 5a located on the other side of the obstacle sensing block 55, the collision block 52 is used to drive The obstacle sensing block 55 rotates, and the limit spring block 5a is used to reset the rotating obstacle sensing block 55. The collision bumps 5...

specific Embodiment 3

[0059] Such as Figure 10-11 As shown, the present invention discloses a cleaning device with edge and omnidirectional obstacle detection. The edge and omnidirectional obstacle detection unit 5 includes an edge lifter 51 that passes through the base, and is sleeved on the edge lifter 51. return spring 53, edge sensing block 54 fixed on the edge lifting part 51, edge sensing part 56 arranged on at least one side of the edge sensing block 54, collision block 52 arranged on at least one side of the bottom surface of the corner of the base, connecting Composed of an obstacle sensing block 55 on the collision block 52, an obstacle sensing portion 57 on one side of the obstacle sensing block 55, and a limit spring 525 on the other side of the obstacle sensing block 55, the collision block 52 is used to drive the obstacle sensing The block 55 rotates, and the limit spring 525 is used to reset the rotating obstacle sensing block 55. One side of the collision block 52 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com