Laser-perforated hollow filter tip detection device and method

A technology of laser drilling and detection devices, which is applied in the direction of measuring devices, optical testing of defects/defects, and material analysis through optical means, and can solve the problems of missed detection and high probability of false detection, unqualified waste cigarettes, and filter penetration. Improve the background contrast, facilitate fault judgment, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

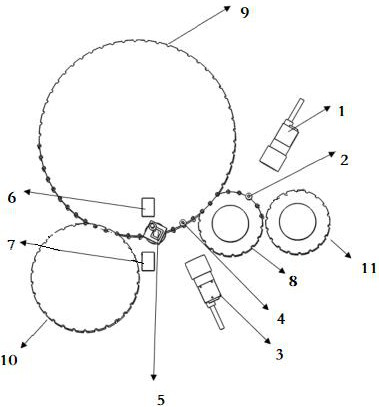

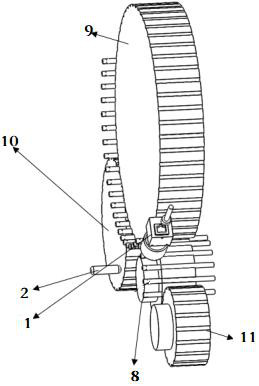

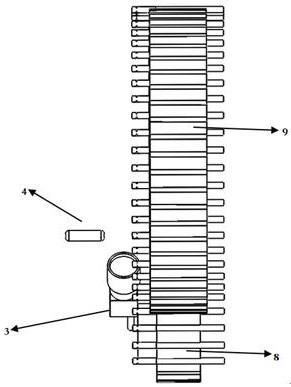

[0025] Such as Figure 1-8 As shown, a laser perforated hollow filter detection device includes an image acquisition system, an image processing system, and a rejection alarm system; the image acquisition system collects the upper laser hole image of the filter tip, the lower laser hole image, the hollow filter tip end image; the image processing system processes the image acquisition system to collect images, counts the appearance defects of the laser perforated hollow filter tip, and sends out rejection and alarm signals; the removal alarm system drives the original machine after receiving the rejection and alarm signals The equipment rejects cigarettes with defects i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com