Premixing burner for heat generator

A technology of pre-mixed combustion and heat generator, applied in the direction of burner, combustion chamber, combustion method, etc., can solve the problems of incomplete mixing, large gap, fluctuation, etc., and achieve the effect of improving the expansion angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

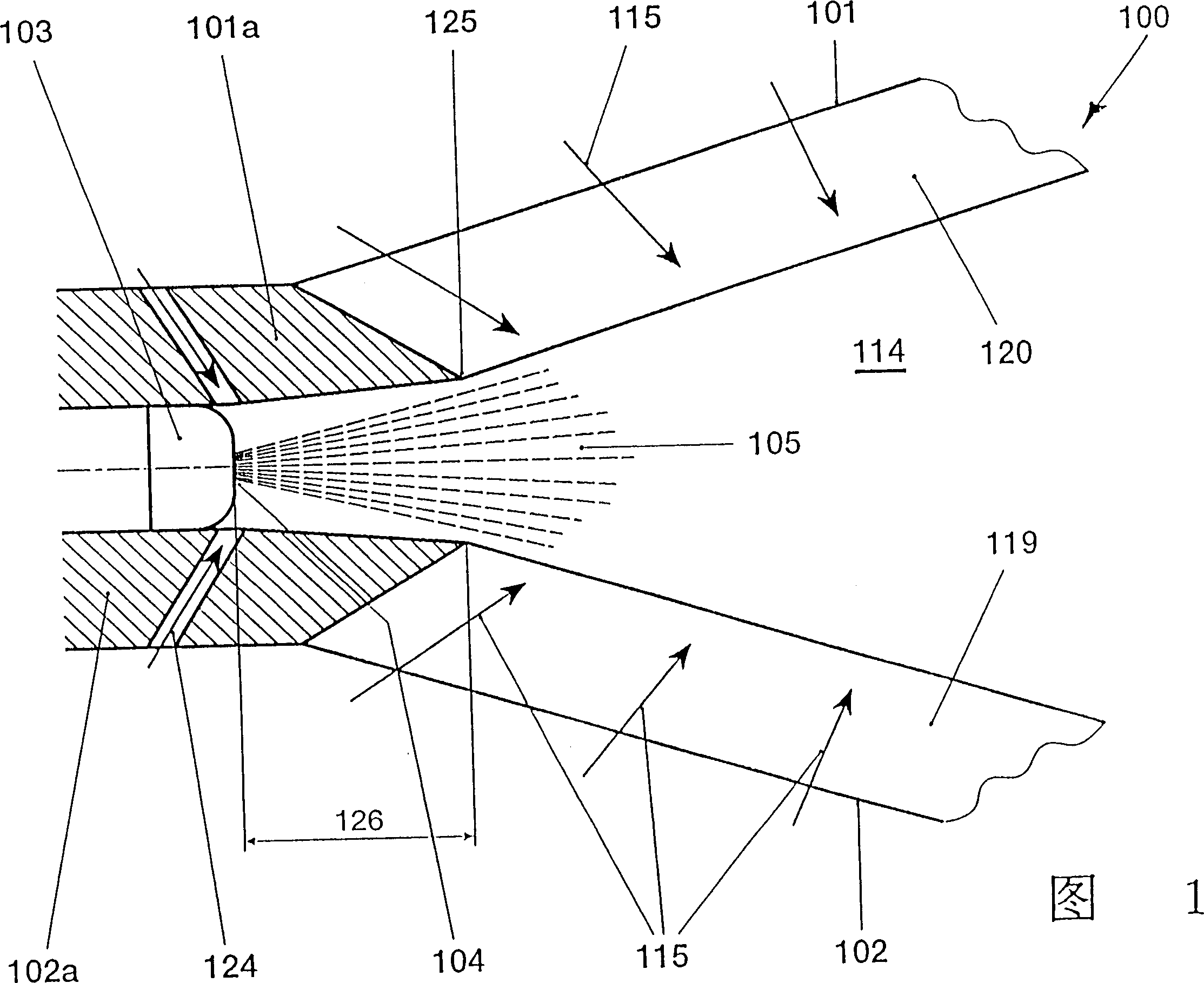

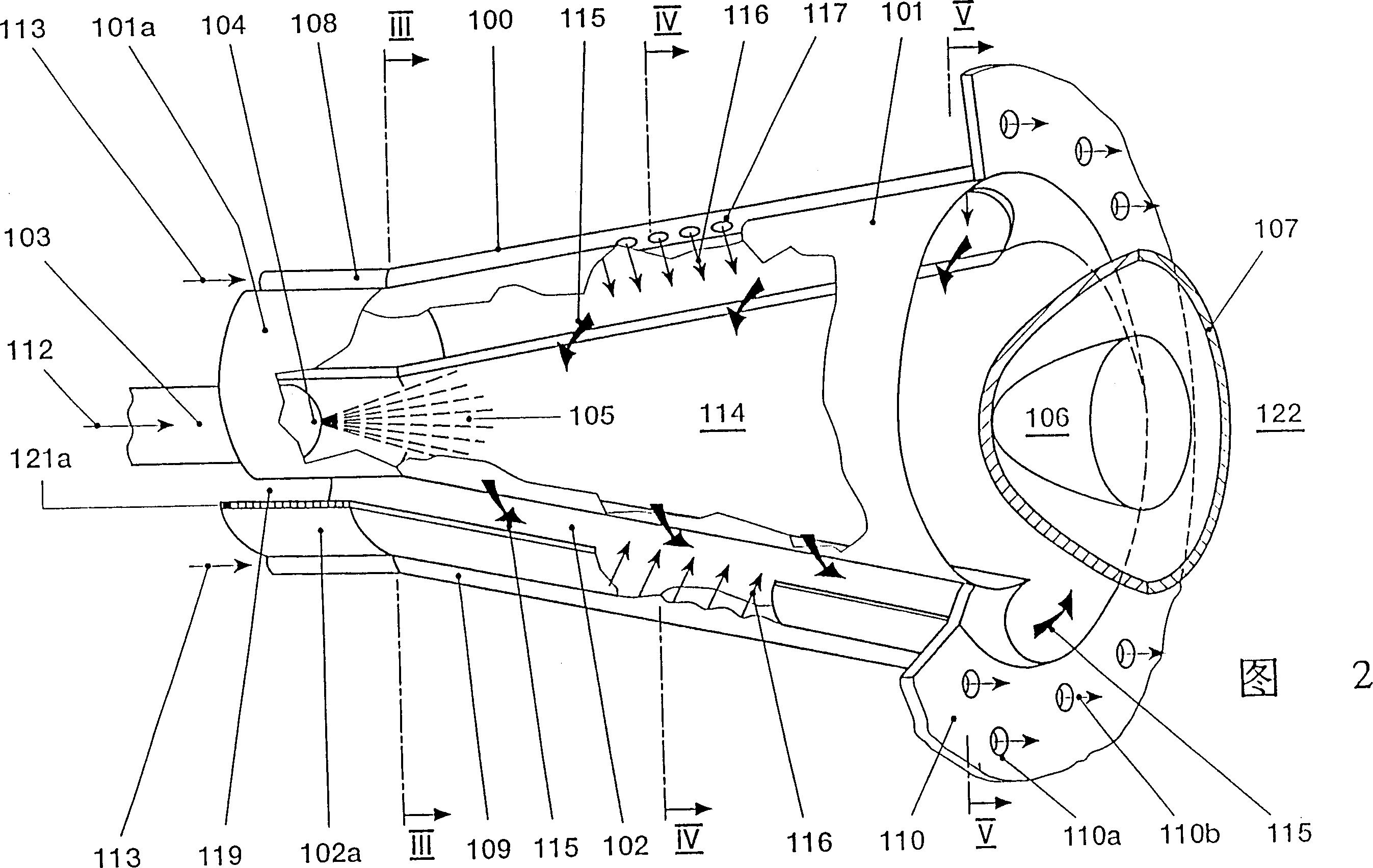

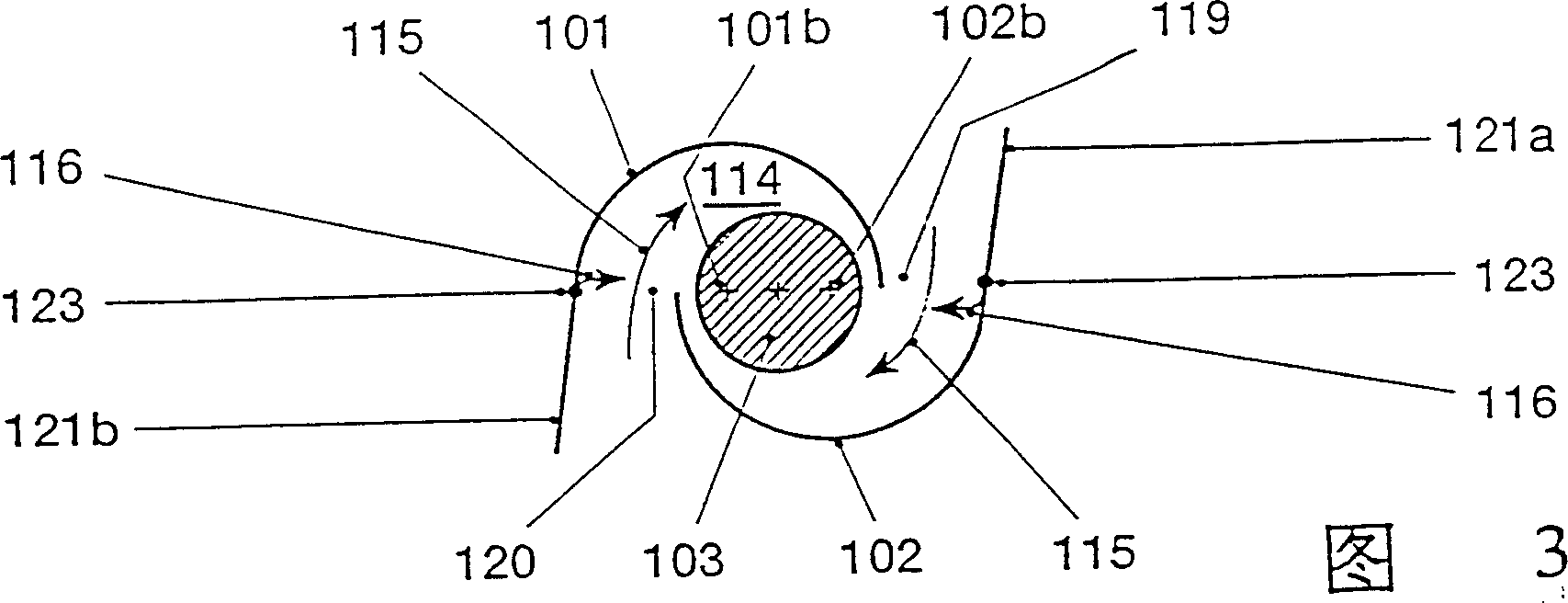

[0019] Figure 1 shows a schematic diagram of a premixing burner and is described in detail below with reference to Figures 2-5. 1 mainly shows a schematic diagram of a centrally positioned first fuel nozzle 103 that is offset upstream and rearwardly by a distance 126 with respect to the starting point 125 of the conical flow cross-section, which distance corresponds to the selected injection Angle 105 is about. As a result of this offset, the nozzle opening 104 of the first fuel nozzle 103 is located in the region of the head-fixed housings 101a, 102a. The fuel jet 105 generated by the backward displacement of the first fuel nozzle 103 enters the range covered by the main flow of combustion air in the burner inner chamber 114 with a larger conical radius, so the fuel jet 105 is no longer in this range as A dense solid, but breaks down into droplets, which easily pass through the combustion air stream. The flow of combustion air 115 into this fuel jet 105 is no longer hindere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com