A kind of oled device manufacturing method and oled device

A device manufacturing method and device technology, which are applied in the fields of semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as hindering electron or hole injection, weak carrier injection capability, and difficulty in realizing OLED devices, etc. Achieve the effect of improving lifespan, eliminating impurities and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

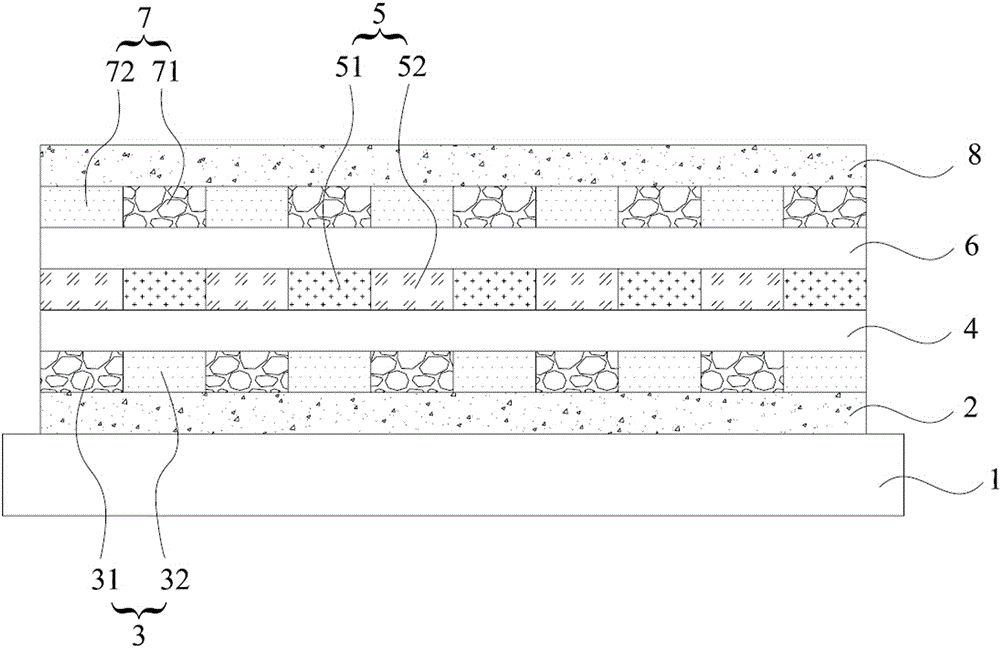

[0067] An OLED device, comprising a substrate 100 and at least one pixel located on the substrate 100, the pixel comprising:

[0068] anode 200;

[0069] cathode 800;

[0070] An organic functional layer located between the anode 200 and the cathode 800; the organic functional layer includes a first injection layer 300, a first transport layer 400, a light emitting layer 500, a second transport layer 600 and a second Injection layer 700; wherein,

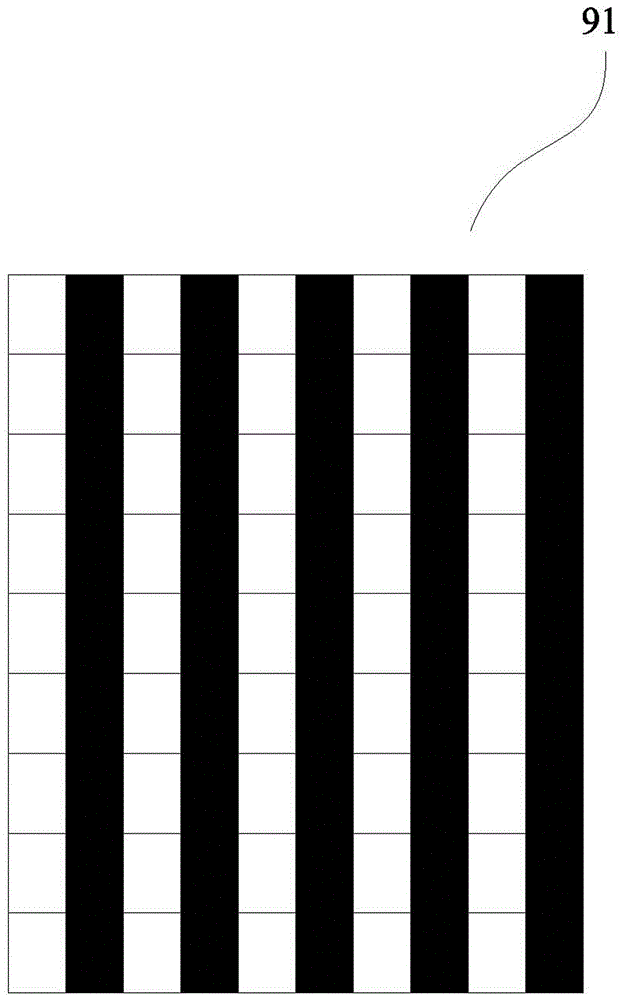

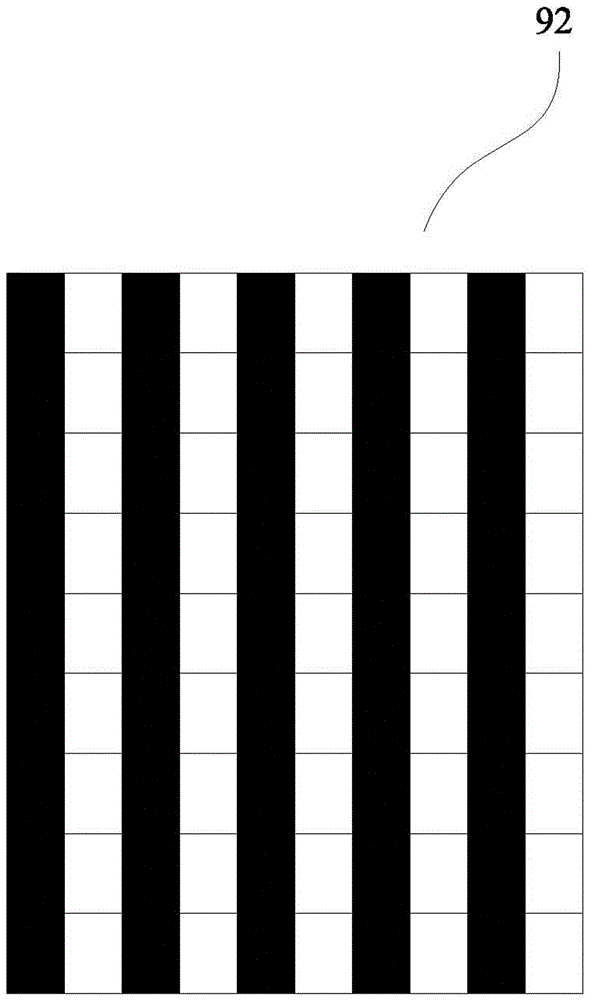

[0071] The first injection layer 300 includes five first hole injection strips 310 and five first electron injection strips 320, the first hole injection strips 310 and the first electron injection strips 320 are arranged in parallel adjacent to each other;

[0072] The second injection layer 700 includes five second hole injection strips 710 and five second electron injection strips 720, the second hole injection strips 710 and the second electron injection strips 720 are arranged in parallel adjacent to each other, the The seco...

Embodiment 2

[0090] An OLED device, comprising a substrate 100 and at least one pixel located on the substrate 100, the pixel comprising:

[0091] anode 200;

[0092] cathode 800;

[0093] An organic functional layer located between the anode 200 and the cathode 800; the organic functional layer includes a first injection layer 300, a first transport layer 400, a light emitting layer 500, a second transport layer 600 and a second Injection layer 700; wherein,

[0094] The first injection layer 300 includes five first hole injection strips 310 and five first electron injection strips 320, the first hole injection strips 310 and the first electron injection strips 320 are arranged in parallel adjacent to each other;

[0095] The second injection layer 700 includes five second hole injection strips 710 and five second electron injection strips 720, the second hole injection strips 710 and the second electron injection strips 720 are arranged in parallel adjacent to each other, the The seco...

Embodiment 3

[0113] Please refer to Figure 6 , an OLED device, comprising a substrate 100 and at least one pixel located on the substrate 100, the pixel comprising:

[0114] anode 200;

[0115] cathode 800;

[0116] An organic functional layer located between the anode 200 and the cathode 800; the organic functional layer includes a first injection layer 300, a first transport layer 400, a light emitting layer 500, a second transport layer 600 and a second Injection layer 700; wherein,

[0117] The first injection layer 300 includes five first hole injection strips 310 and five first electron injection strips 320, the first hole injection strips 310 and the first electron injection strips 320 are arranged in parallel adjacent to each other;

[0118] The second injection layer 700 includes five second hole injection strips 710 and five second electron injection strips 720, the second hole injection strips 710 and the second electron injection strips 720 are arranged in parallel adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com