Rubber cement mixing device and method capable of removing bubbles

A mixing device and degassing technology, which is applied to chemical instruments and methods, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problems of reduced product drainage, limited mixing range, whitening phenomenon, etc., to achieve Strong practicability, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

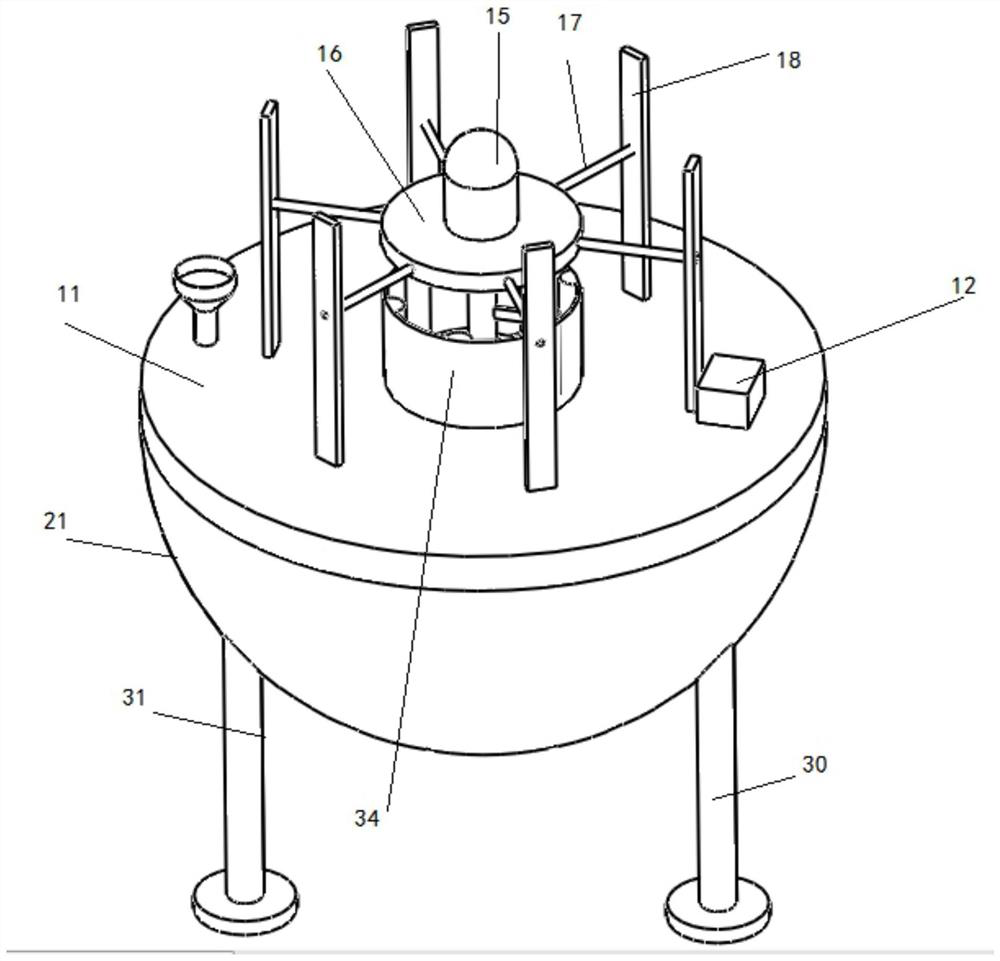

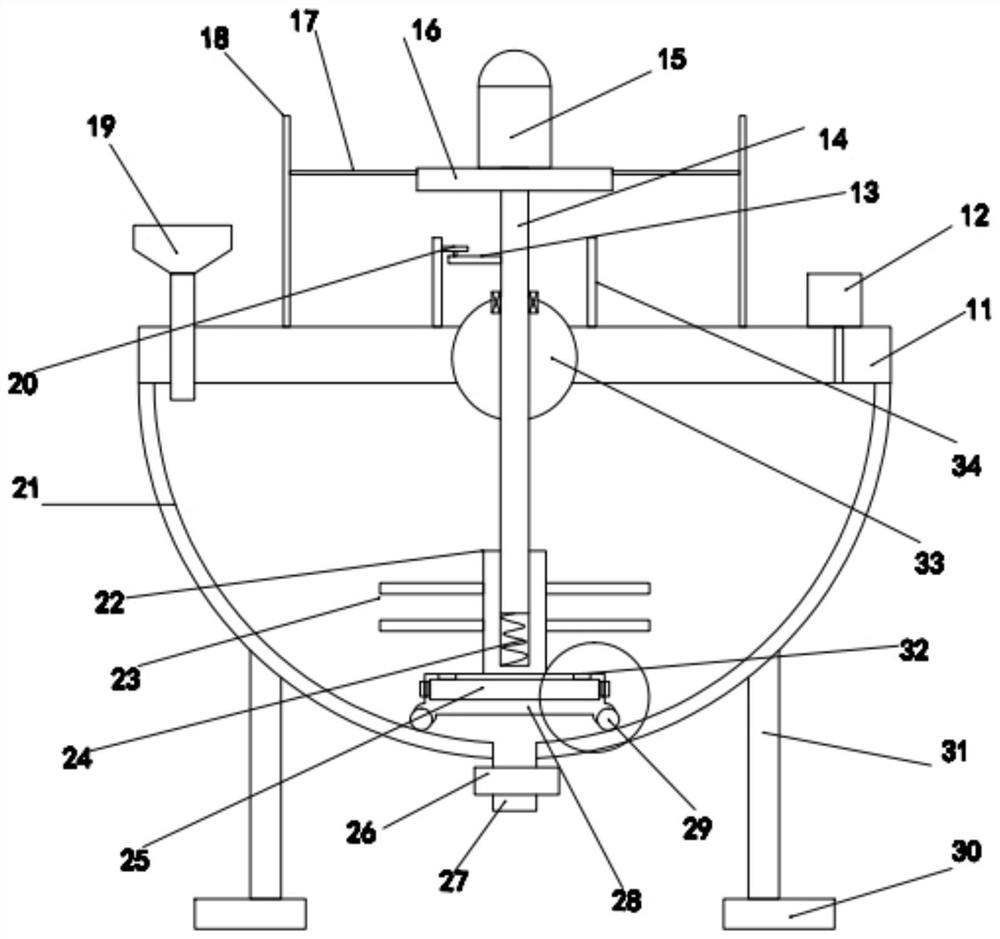

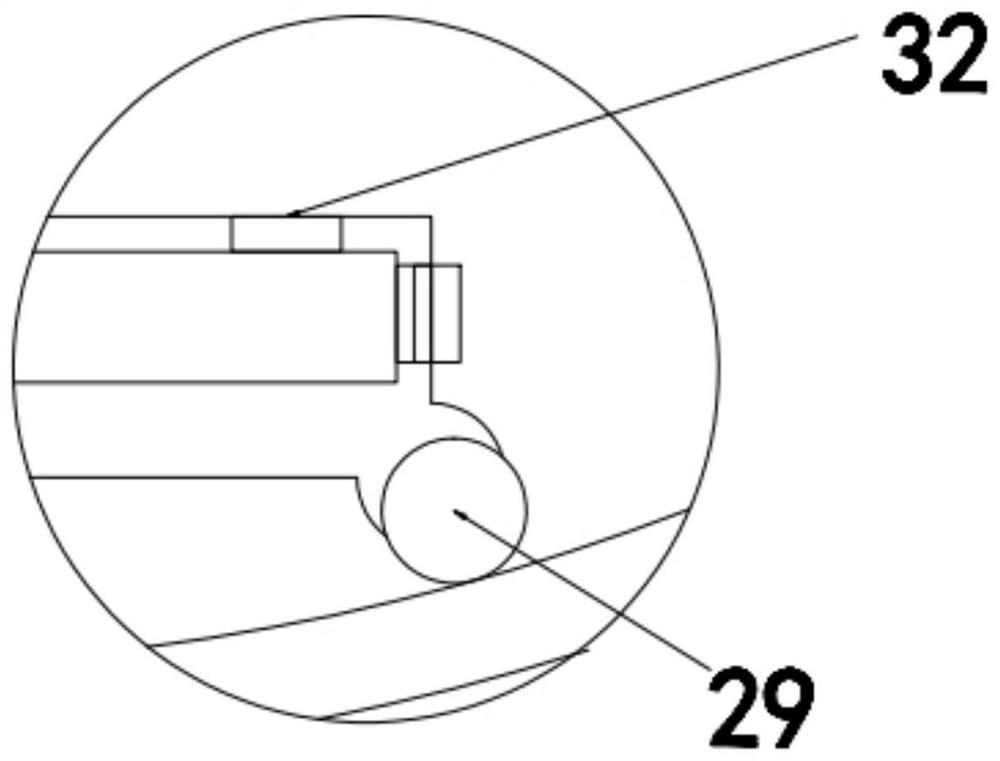

[0020] see Figure 1-Figure 4 , in the embodiment of the present invention, a kind of degassing glue mixing device includes a mixing tank 21 for storing glue, the upper port of the mixing tank 21 is provided with a top plate 11, and the top plate 11 is provided with There is a feeding hopper 19 for feeding, the feeding hopper 19 is provided with a solenoid valve, the bottom of the mixing tank 21 is provided with a feeding pipe 27 for discharging, and the feeding pipe 27 is provided with a discharge valve 26 , the lower end of the mixing tank 21 is distributed with a plurality of legs 31 in an array, the lower end of the legs 31 is provided with a support block 30, and the top plate 11 is provided with an air suction port, and the air suction port is connected to a device for taking out air. The negative pressure pump 12, by constructing a negative pressure structure inside the mixing tank 21, can release the gas inside the rubber material, and the upper end of the top plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com