Disinfection control method of gas water heater and gas water heater

A gas-fired water heater and control method technology, applied in the directions of disinfection, fluid heater, heating, etc., can solve the problem that harmful bacteria are difficult to be killed, achieve high sterilization temperature, and ensure the effect of sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066]The following examples illustrate the invention, but the invention is not limited by these examples. Modifications to the specific implementation of the present invention or equivalent replacement of some technical features without departing from the spirit of the present invention should be included in the scope of the technical solution claimed in the present invention.

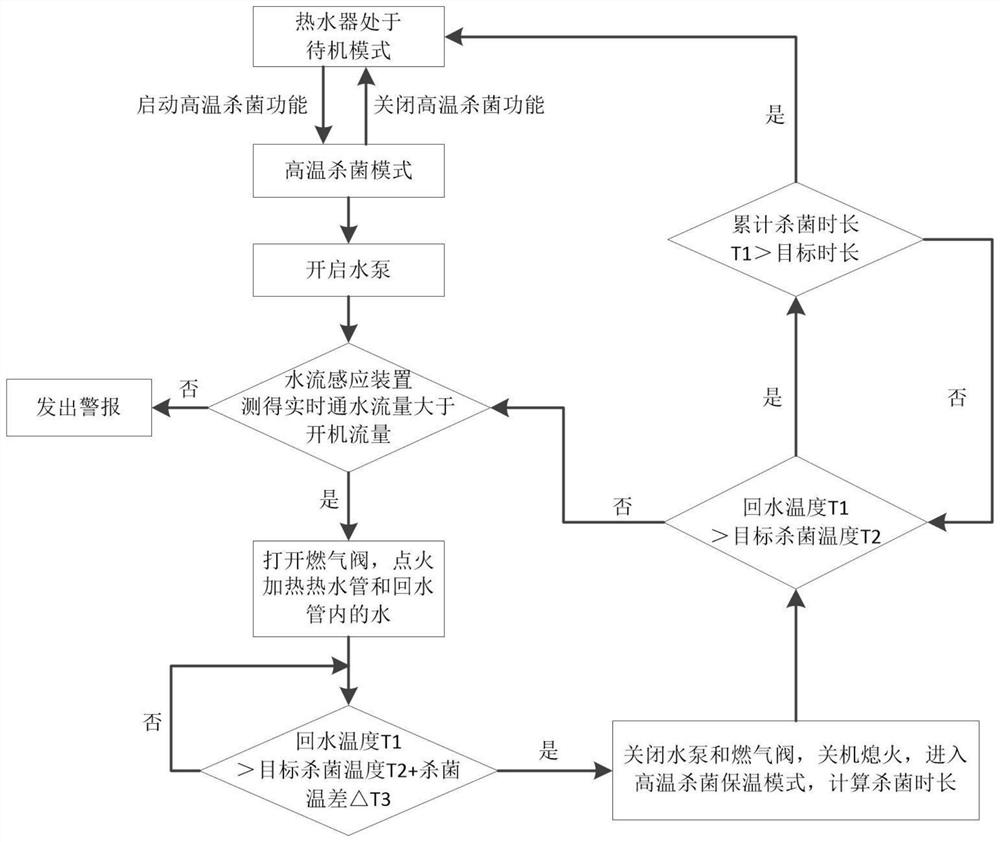

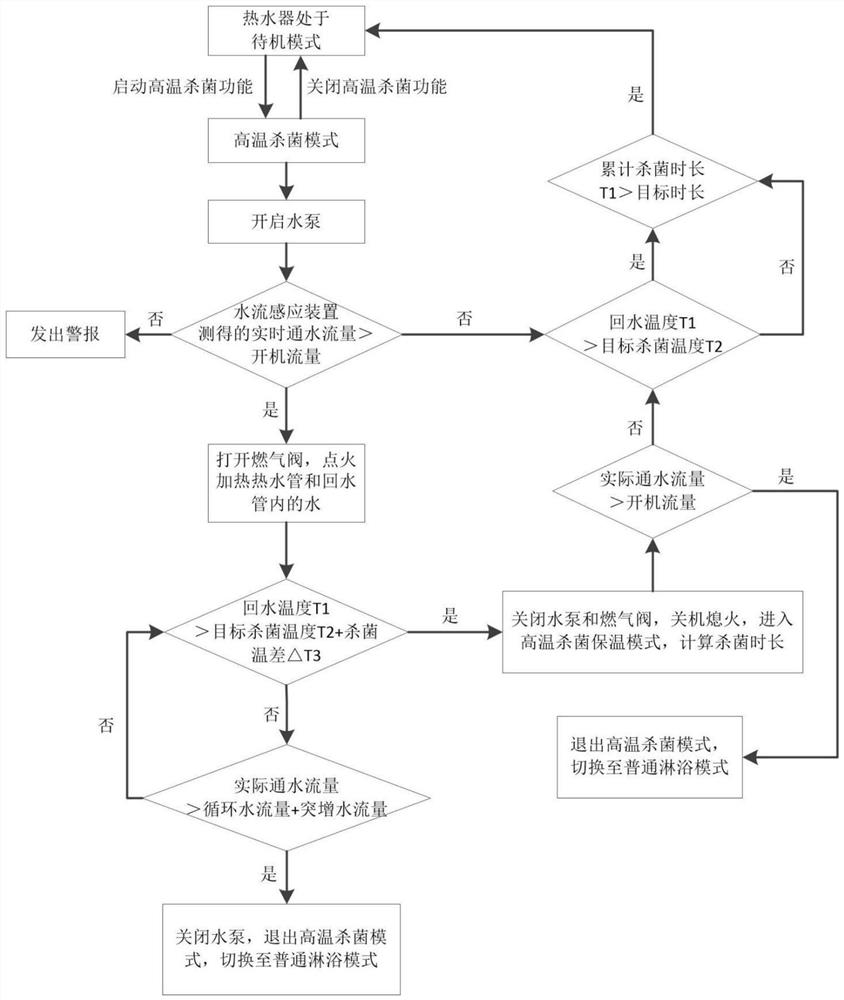

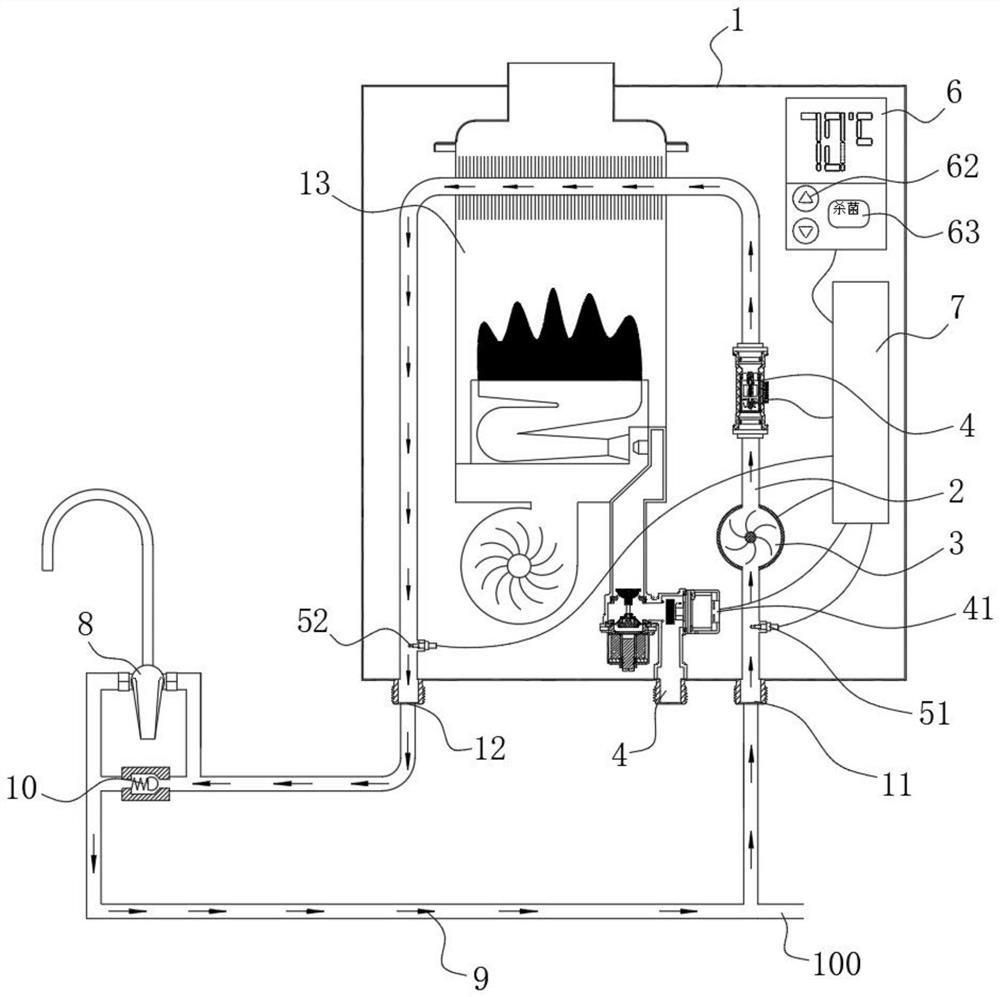

[0067] Such as Figure 1-Figure 3 As shown, the present invention provides a disinfection control method for a gas water heater, comprising the following steps:

[0068] S1: The water heater is in standby mode;

[0069] S2: Start the high-temperature sterilization function and enter the high-temperature sterilization mode;

[0070] S3: Turn on the water pump 3 installed on the hot water pipe 2 in the gas water heater;

[0071] S4: The water flow sensing device 4 installed on the hot water pipe 2 detects the real-time water flow rate of the water inlet of the hot water pipe 2, and then judges whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com