Self-adaptive inflow control device, intelligent well completion pipe string and well completion method

An inflow control and self-adaptive technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as inability to separate reservoir layers, poor sand control effect, easy sand control failure, etc. Reliable sealing performance, good water blocking and oil stabilizing effect, and good sand control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention proposes an adaptive inflow control device, an intelligent completion pipe string and a well completion method, which can effectively realize reservoir sand control, water control and stable production, and has the advantages of reasonable pipe string structure, effective design method, and reliable interval isolation performance. It has the functions of multi-layer and segmental sand control, production stimulation and segmental adaptive water control and oil stabilization, and can effectively guide the optimization design and field application of multi-layer fracturing and packing intelligent completion, and has a very broad application prospect.

[0066] Below in conjunction with accompanying drawing, the present invention is described in further detail:

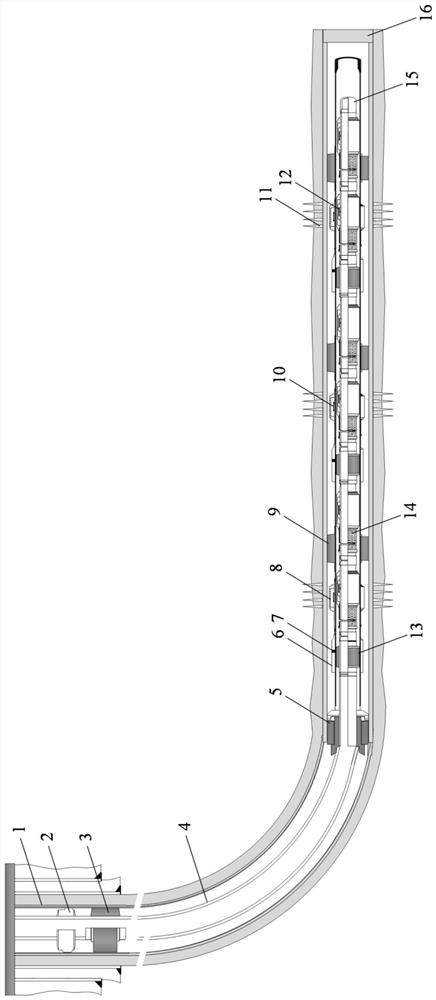

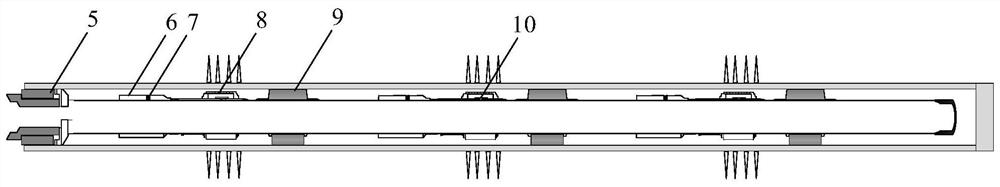

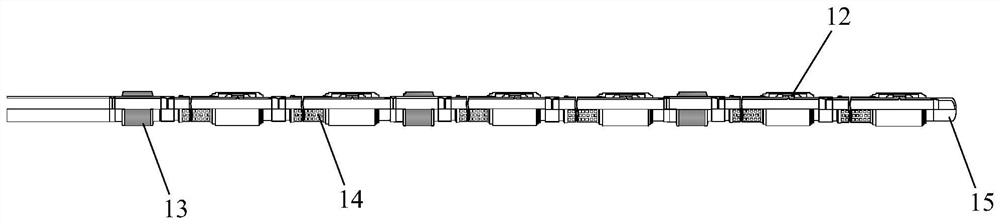

[0067] Such as figure 1 As shown, the intelligent well completion string of the present invention includes: a multi-layer fracturing packing string and an adaptive water control string located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com