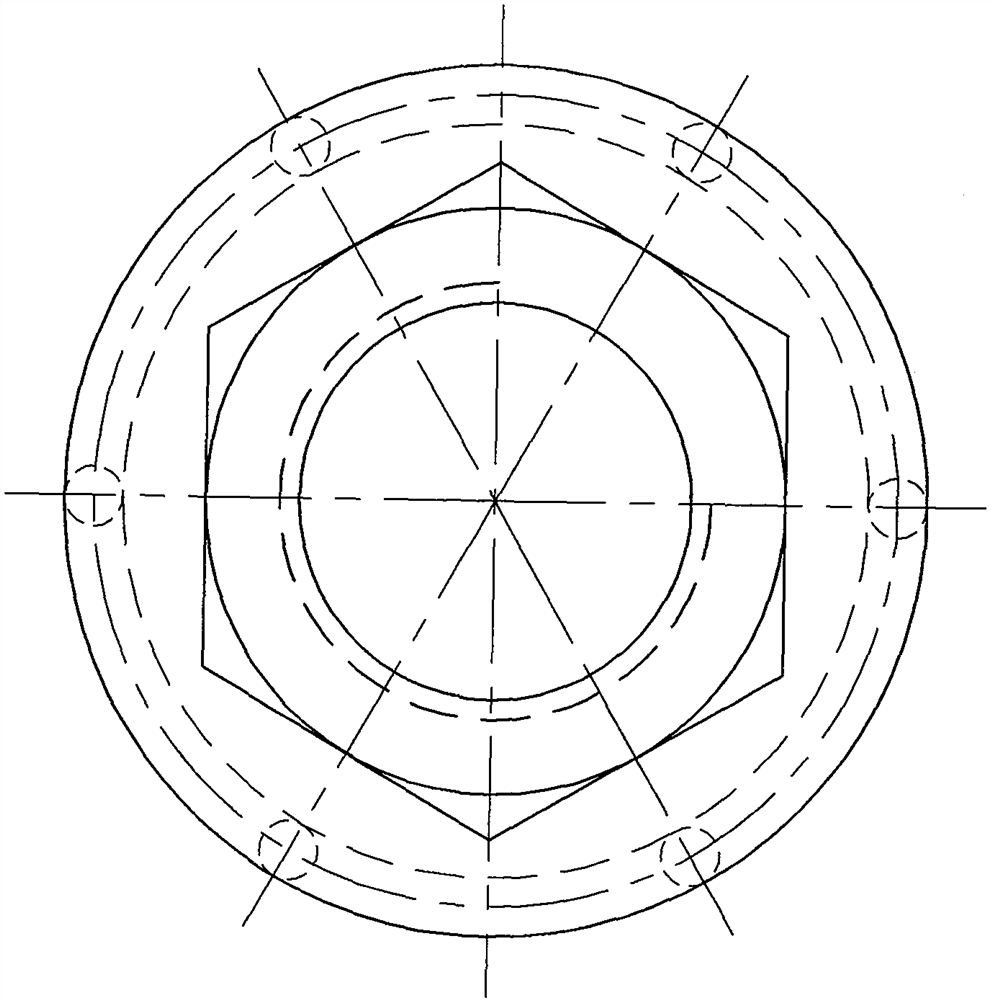

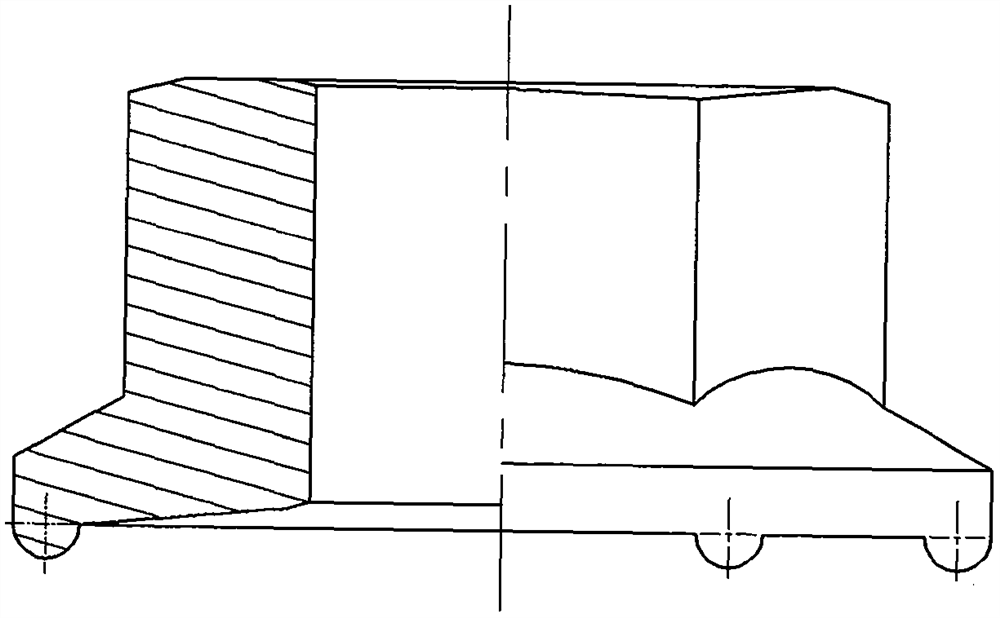

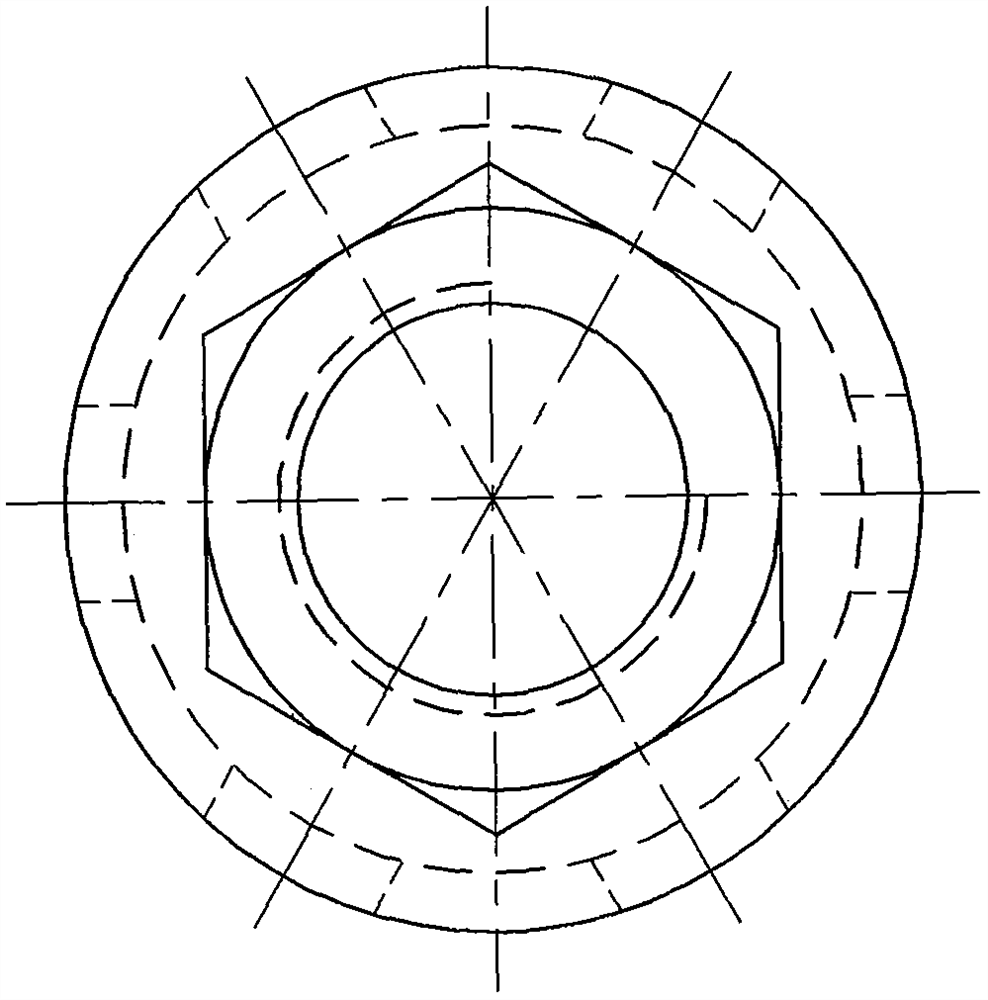

Flange bump, circumferential arc and high-tooth lock bolt and nut

A technology of anti-loosening bolts and nuts, which is applied in the fields of bolts, high-tooth anti-loosening nuts, circumferential arcs, and flange bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] National standard nuts and national standard flange nuts have good connection performance, but their anti-seismic and anti-loosening capabilities are limited. With the reloading and high-speed operation of various mechanical equipment, the loosening of nuts and bolts becomes more and more prominent. Increase the diameter of the flange surface of the flange nut, add bumps, circumferential arcs, and high teeth on the outermost edges of the flange nuts and bolts, so that the bottom surface of the flange and the workpiece are completely suspended, and the flange bumps, circumferential arcs 1. The high teeth contact the workpiece first. When the outer edge is under the local force of the bumps, circumferential arcs, and high teeth, the deformation will be large. The edge of the flange surface that does not contact the workpiece will also disperse part of the force and store elasticity at the same time. potential energy. The tall tooth itself is thin and tall, with an aspect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com