Weft-knitted single-sided and double-sided socks and shoes and production methods thereof

A sock shoe, one-sided technology, applied in the direction of shoe uppers, footwear, boot legs, etc., can solve the problems of pressing the instep, difficulty in shoe insertion, and limited height of the instep, so as to achieve smooth foot entry, avoid pressure on the instep, and 3D structure solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 A weft single siphose shoe

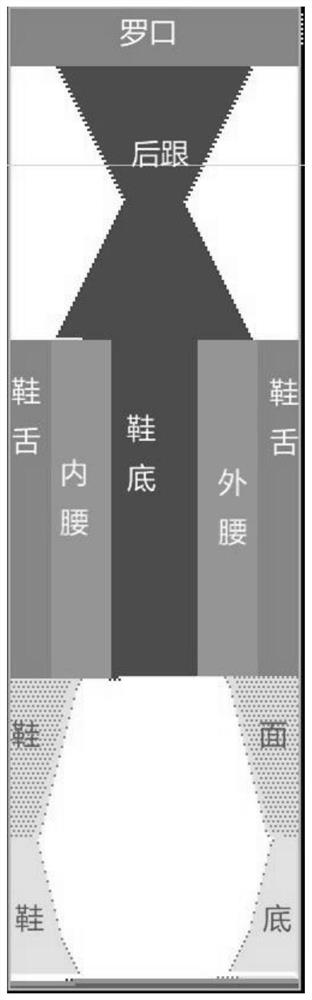

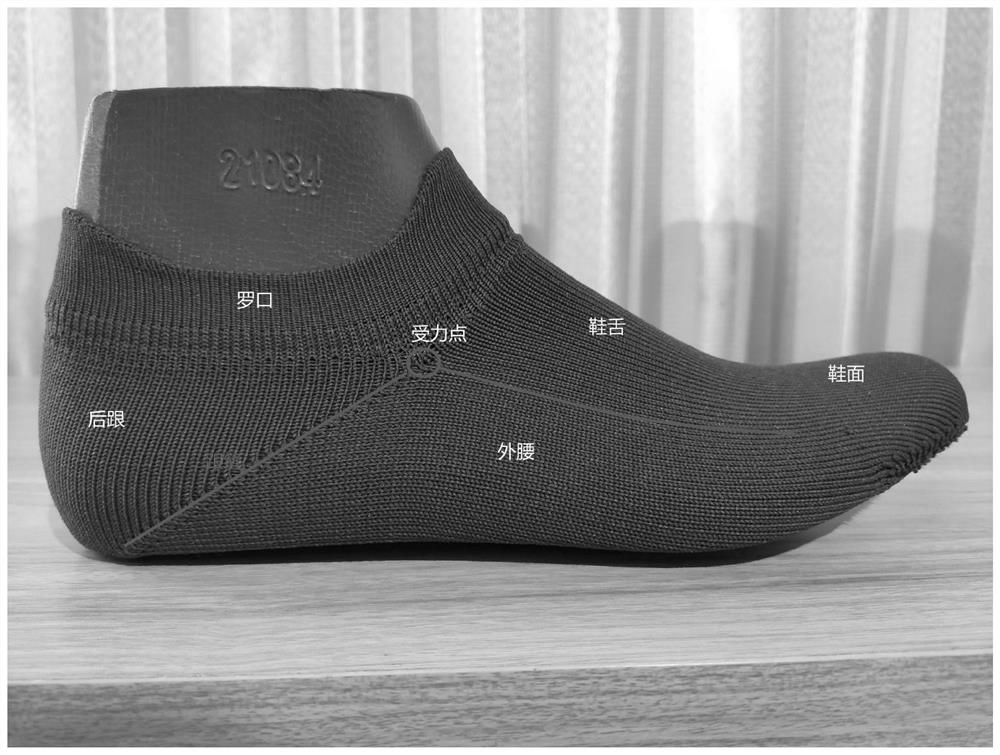

[0041] See image 3 Schematic diagram of the structure of the weft single siphoshime Figure 4 Weft widop fabric tile map of weft single siphoshs; Figure 4 Tile schematic socks, socks, socks, sock socks, composed of shallow mouth shoe 1 and laminated shoe 2 connected above shallow mouth shoe cover, said shallow shoe cover 1 pair of foot tip, foot bottom, heel and Package on both sides of the foot bows; the laminated shoe 2 is wrapped on the back and ankle portion.

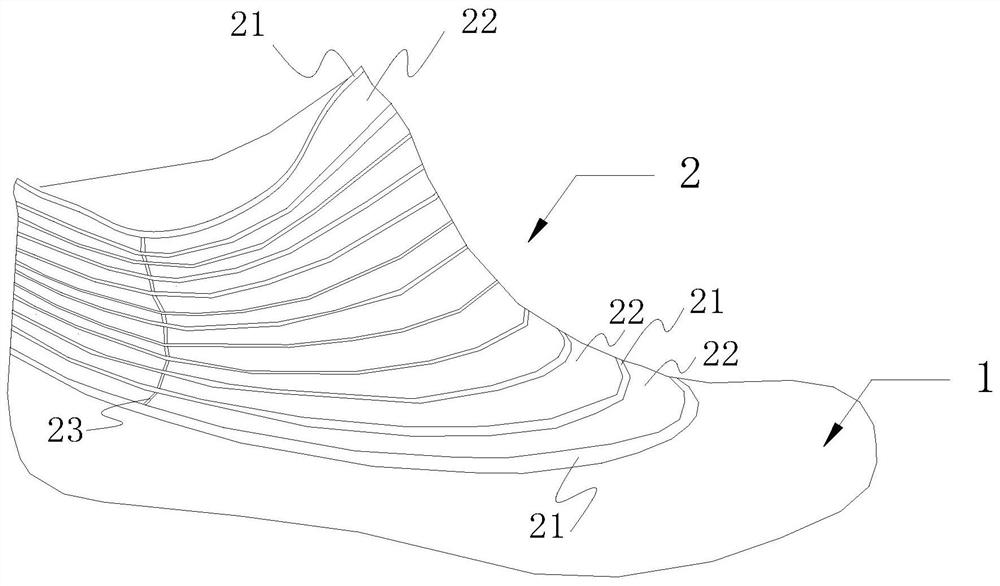

[0042] The laminated shoe 2 of the present embodiment includes 12 frames 21 and 11 drawings 22; the tensile ring 22 and the skeleton ring 21 are arranged longitudinally, and one stretch between the two adjacent bone ring 21 is provided. Circle 22. In the present embodiment, the bone ring 21 and the tensile ring 22 are numbered from the lower to the upper surface, closest to the ground, is the first bone shelf 21 or the first stretching ring 22.

[0043] See Figure 6 The skele...

Embodiment 2

[0053] Example 2 A weft double sock sock

[0054] Weft double socks shoes are fabricated with single-sided round weft machines, double-sided socks include inside socks shoes and external socks, and the inner socks shoes and outer socks are connected to the weft fabric. Symmetry structure, The mirror unit is a single sided sock sock in Example 1 using an inner sock sock shoes and an outer socks to share a shoe-roll skeleton ring, which uses one-in-one knitted inside socks and outer socks, and the inside socks shoes Enter the outer socks and connect with the outer shoe cover; Figure 9 The latitude widow fabric pair of weft-knitted double-sock shoes according to the embodiment of the present invention is shown. Figure 9 The socks and socks of the socks are shown in 5 drawings; in Example 2 is 11 drawings in Example 2).

[0055] In addition to the inner socks, the structure and weaving of the outer socks and outer socks are consistent with Example 1. Topped the woven inner sock socks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com