Roll shifting operation method of skin pass mill

An operation method and the technology of the tempering machine, applied in the direction of contour control, etc., can solve the problems of frequent roll changing of work rolls, wear of the position where the work rolls contact with the edge of the steel belt, etc., so as to improve the operation rate, product quality and low cost , Delay the effect of rapid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] The present invention comprises the following steps:

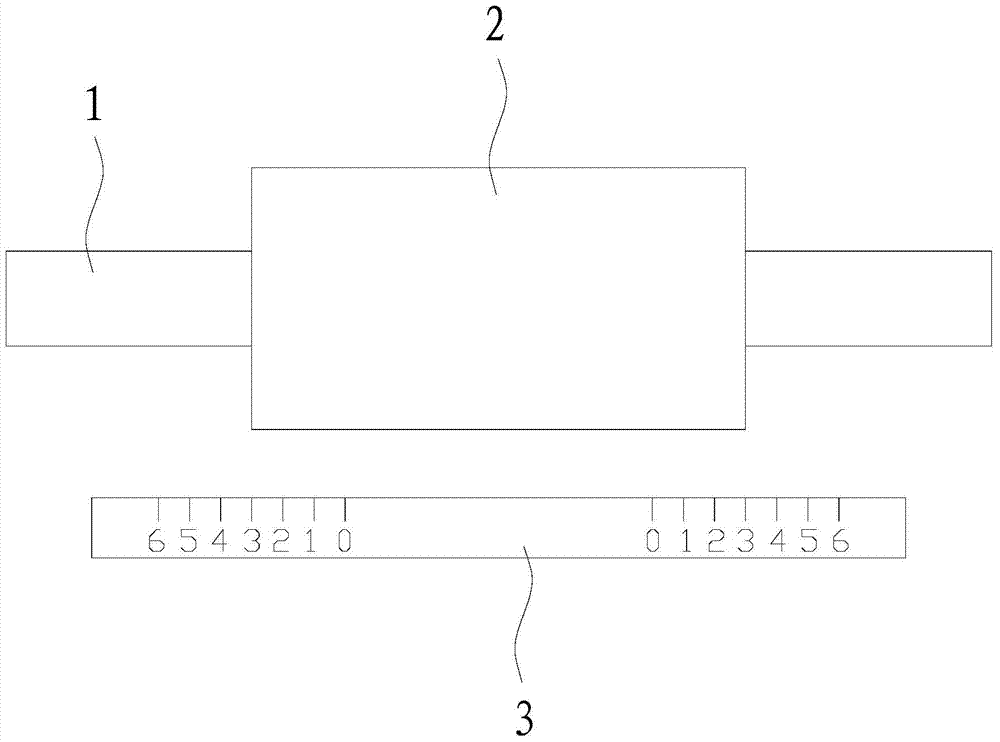

[0017] Ⅰ. Set the scale line 3 on the display of the uncoiler, take the central point of the display as the symmetrical point, set the scale line 3 on both sides symmetrically, and the scale line area is within the contact wear range between the work roll 1 and the steel coil 2. Such as figure 1 As shown, the display of the uncoiler is mainly used to display the position of the steel coil 2 on the work roll 1, but the traditional display has no scale lines, and the operator cannot intuitively determine the specific position of the steel coil 2. Therefore, the scale line 3 is set on the display. The scale line 3 is symmetrical to the center point of the display, and the scales on both sides are symmetrically distributed, that is, when the steel coil 2 is in the middle of the work roll 1, the center line of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com