Fire hammer with glass cutter

A glass knife and fire hammer technology, used in life-saving equipment, building rescue, etc., can solve the problem that the safety hammer cannot easily break the glass of the car, and achieve the effect of improving the success.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

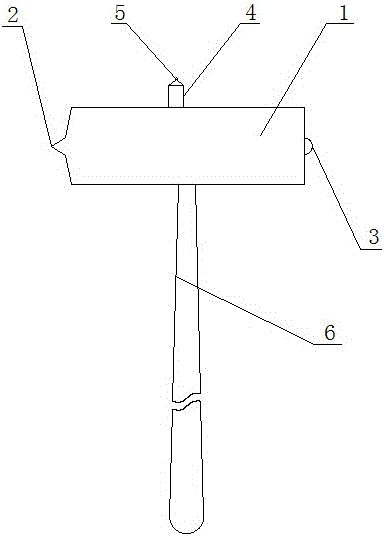

[0016] combined with figure 1 As shown, a fire hammer with a glass knife, the fire hammer includes a hammer body 1 and a hammer handle 6, the hammer body 1 is in the shape of a cylinder, one end surface of the hammer body 1 is provided with a cone 2, and the other A spherical piece 3 is arranged on the end face, a glass knife 4 is arranged on the side, and a diamond 5 is installed on the top of the glass knife 4 .

[0017] In order to increase the quality of the fire hammer and the inertia of hammering, in the embodiment, the hammer body 1, the cone 2, the spherical part 3 and the glass knife 4 are integrally formed, and the material is tungsten steel, and the material of the hammer handle 6 is cast iron.

[0018] Because the hardness of diamond 5 is very high, the protective film and the glass surface can be scratched easily, and the glass that is scratched by hammering the cone body 2 installed on the hammer body 1 is that the glass will be very easy due to the stress conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com