A kind of coal water slurry preparation method and its equipment

A technology for coal-water slurry and coal slime, which is applied in combustion methods, combustion equipment, lighting and heating equipment, etc., can solve the problems of large investment, high power consumption, difficulty, etc., and achieve high crushing efficiency, convenient maintenance and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

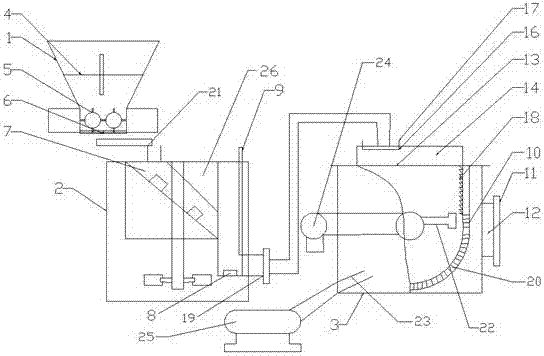

[0034] A method for preparing coal water slurry and its equipment, including: a special arch-breaking double-roller tooth feeding buffer bin 1, a special ingredient mixing tank 2, a special slurry breaking machine 3, and a special arch-breaking double-roller tooth feeding buffer bin 1 The metering belt conveyor 21 is connected with the coal mixing chute 7 of the special batching mixing tank 2, the discharge port 19 of the special batching mixing tank 2 is connected with the feed port 16 of the special slurry breaking machine 3, and the discharge port of the special slurry breaking machine 3 The hopper 23 is connected with a ball mill 25 .

Embodiment 2

[0036] A coal water slurry preparation method and its equipment, wherein: the upper part of the special arch-breaking double-roller tooth feeding buffer bin 1 is provided with an arch-breaking device 4, and the bottom of the special arch-breaking double-roller tooth feeding buffer bin 1 is equipped with an adjustable High-speed double roller teeth 5 and split gate 6.

[0037] All the other are with embodiment 1.

Embodiment 3

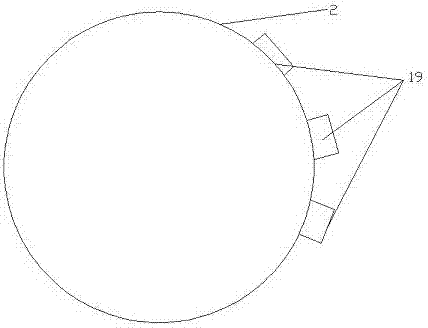

[0039] A method for preparing coal water slurry and its equipment, wherein: a special batching mixing tank 2 is provided with a coal mixing chute 7, a feeding chute 26 and an overflow gate 9, and the inside of the coal mixing chute 7 is provided with a permanent magnet 8. The ingredient mixing barrel 2 is provided with three discharge ports 19 .

[0040] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com