Valve airtightness test bench

A technology of air tightness and test bench, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, machine/structural component testing, etc. It can solve problems such as difficulty in valve air tightness testing, Achieve the effects of improving judgment efficiency, simple equipment operation, and avoiding difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

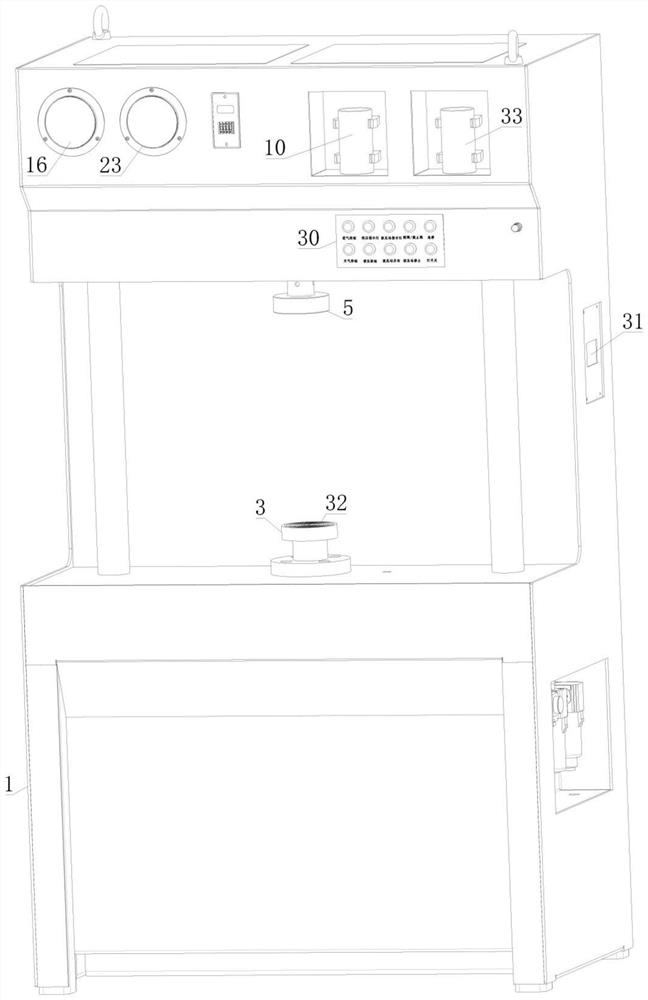

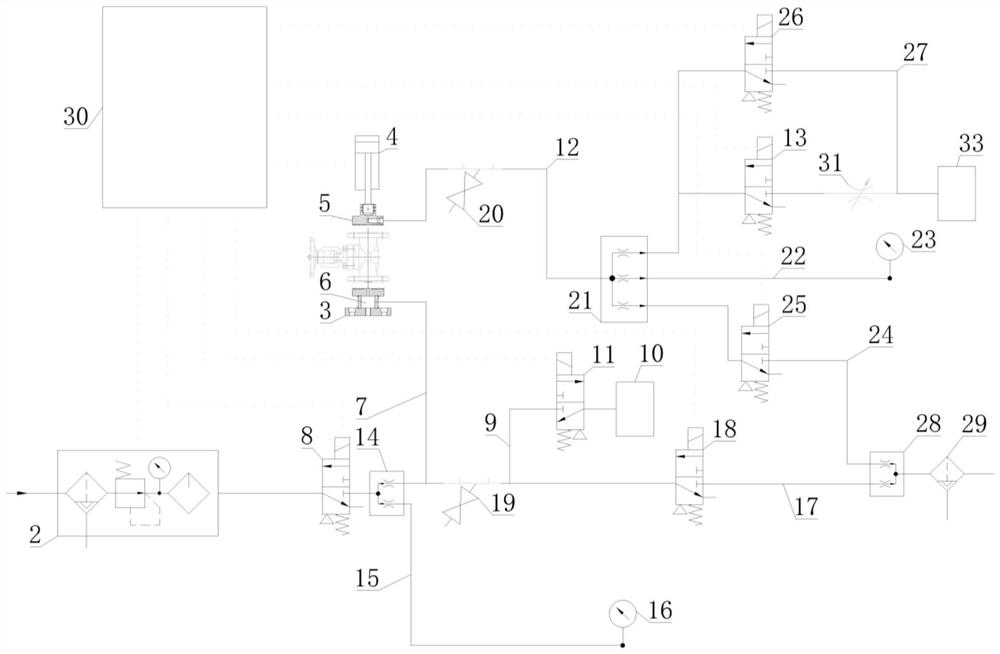

[0022] combined with figure 1 and 2 , this embodiment provides a valve airtightness test bench, including a bench body 1, and the structure of the bench body 1 can be various, as long as the functional requirements are met. In this example, combined with the figure 1 In this embodiment, the stand body 1 is specifically a cuboid cabinet-like structure, and a recessed gap is provided on the front surface of the middle part, and the bottom of the gap is a horizontal operating surface, so as to facilitate equipment operation in it. In this embodiment, the sides are respectively provided with columns for supporting and connecting the upper and lower ends thereof, so as to achieve the purpose of supporting;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com