Butt joint structure and butt joint method for extra-high voltage bushing and lead device of converter transformer

A UHV and commutation technology, applied in the field of transformers, can solve problems such as other structural damage, inability to align at one time, size deviation, etc., achieve precise alignment, eliminate deviation and damage, and improve installation quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

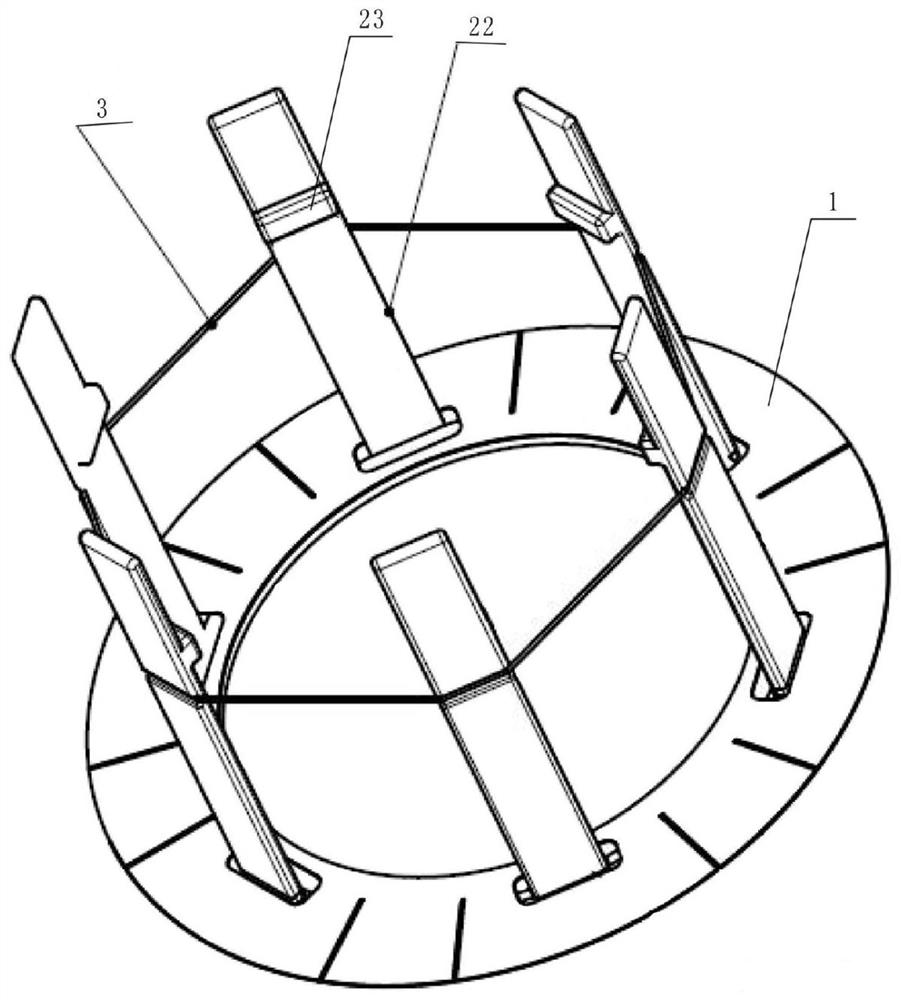

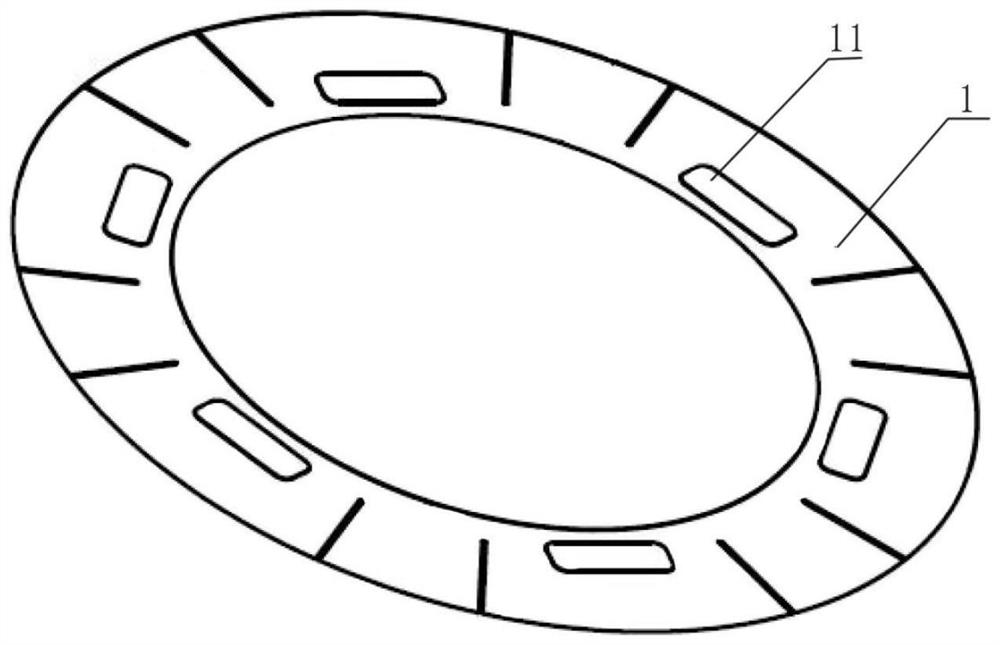

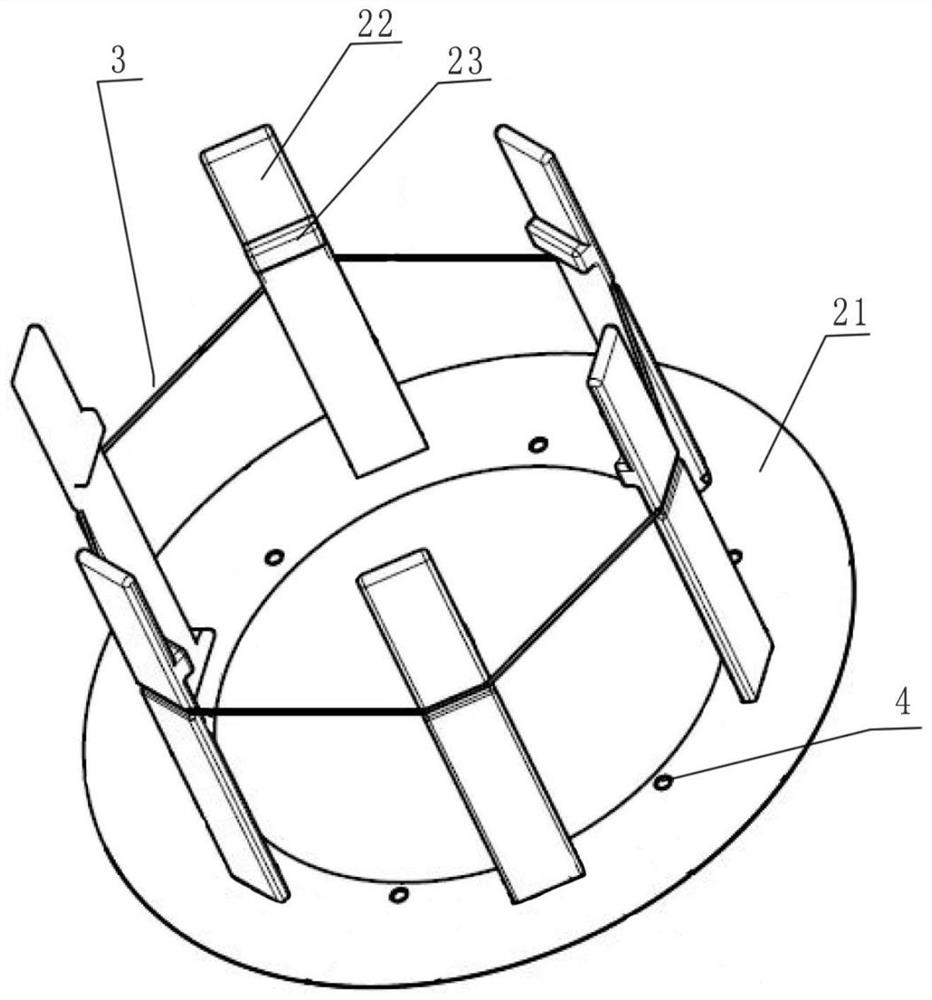

[0011] see Figure 1 to Figure 3 , the butt joint structure of the UHV bushing of the converter and the lead wire device includes an insulating cardboard 1 and a bracket, both of which are insulated. The insulating cardboard 1 is in the shape of a ring-shaped plate with a central hole in the middle and is made of insulating paper. This insulating material is commonly used in transformers and is often used as shielding insulation for transformers. The insulating cardboard 1 is provided with six rectangular through-holes 11, and the six through-holes 11 are evenly arranged along the circumferential direction of the insulating cardboard 1. The distance from each through-hole 11 to the central axis of the insulating cardboard 1 is equal, and two adjacent The included angle formed by the through hole 11 and the central axis of the insulating cardboard 1 is equal. The insulating cardboard 1 has good insulating performance, and can effectively shield the electric strength of AC and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com