Sliding trigger type bored pile concrete pouring height control device and method

A technology of height control and concrete, which is applied in the direction of sheet pile wall, building, foundation structure test, etc., can solve the problems of position deviation, excessive concrete filling, waste, etc., to prevent position deviation, avoid false alarm, Guaranteed precise control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

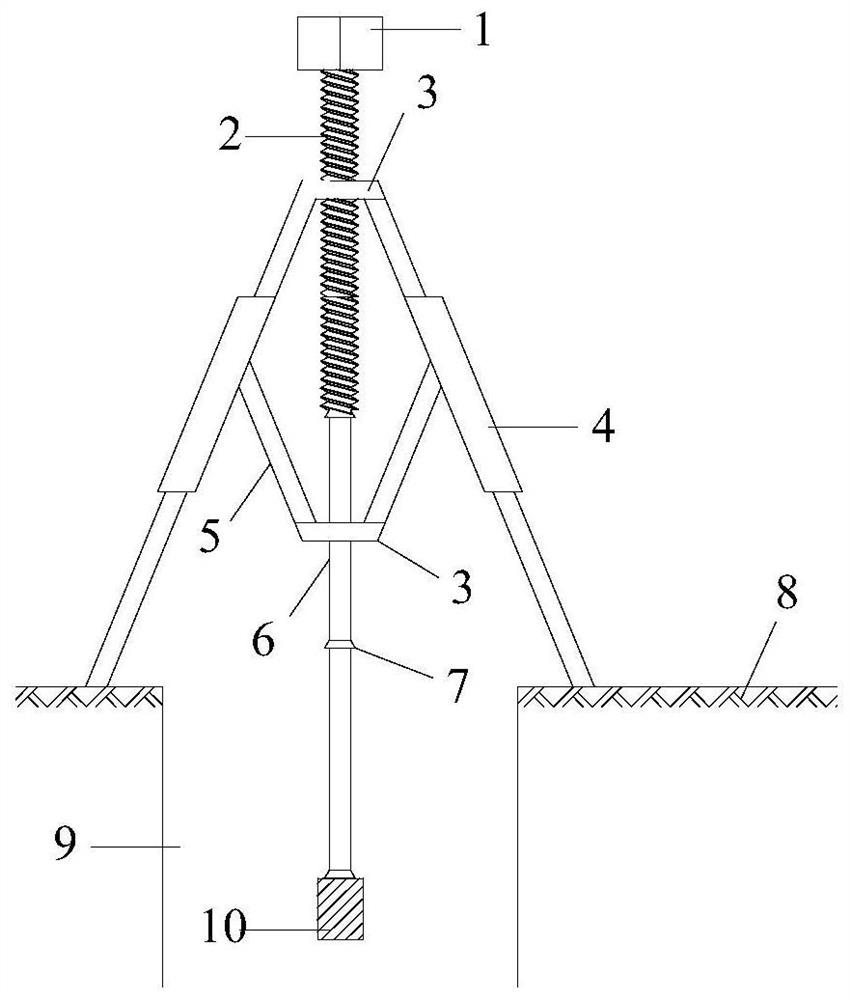

[0029] In this embodiment, a sliding trigger type bored pile concrete pouring height control device is disclosed, including: a detection sensing device, a probe rod connected to the detection sensing device, a support structure connected to the probe rod, and an alarm;

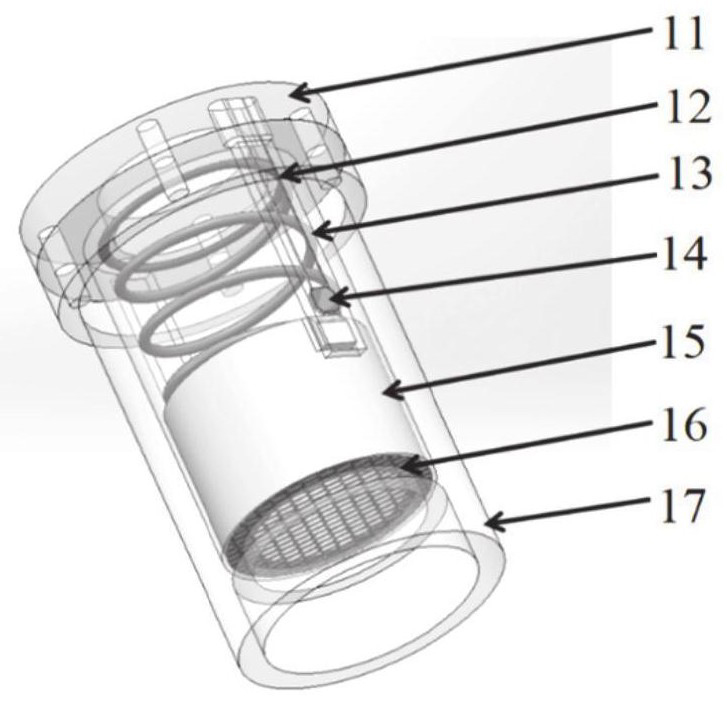

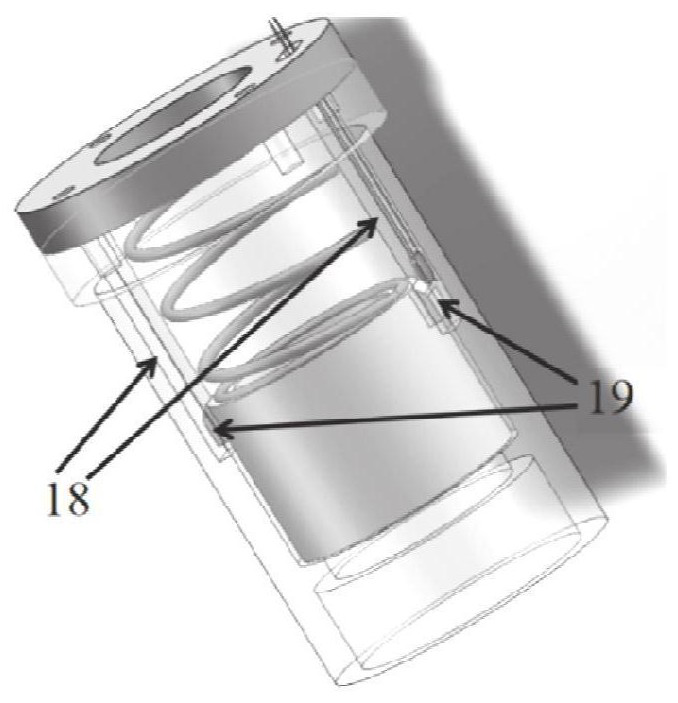

[0030] The detection and sensing device includes an outer shell and an inner part that can move relative to the outer shell. A switch is arranged on the outer shell. The switch is connected to the alarm. A protrusion corresponding to the position of the switch is set on the inner part. The inner part moves so that the protrusion touches the switch and the alarm Sound the alarm.

[0031] Further, the probe rod includes a connected threaded rod and a universal rod, the general rod is connected to the detection and sensing device, and the threaded rod is connected to the supporting mechanism.

[0032] Further, the support structure includes a probe rod holder and a support frame supporting the probe rod holder, a...

Embodiment 2

[0064] In this embodiment, a method for controlling the concrete pouring height of a slide-triggered bored pile is disclosed, including:

[0065] fixed support structure;

[0066] Lower the detection sensing device to the predetermined depth of the pile hole;

[0067] During the grouting process, the protrusion moves towards the switch direction;

[0068] When the concrete grout reaches a predetermined depth, the protrusion touches the switch, and the alarm sends out an alarm.

[0069] A method for controlling the concrete pouring height of a slide-triggered bored pile disclosed in this embodiment will be described in detail.

[0070] A. According to the construction requirements and grouting parameters, select a suitable sliding damper to ensure that the displacement of the inner cylinder caused by the fluctuation of the mud is filtered out, and the size of the bottom mesh of the inner cylinder is replaced to ensure that the coarse aggregate in the concrete slurry cannot pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com