Vibration filtering type cast-in-situ bored pile concrete pouring height control device and method

A bored pile, height control technology, applied in the direction of measuring devices, sheet pile walls, buildings, etc., can solve the problems of precise control, insufficient pouring volume, waste, etc., and achieve the effect of ensuring the accuracy of early warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

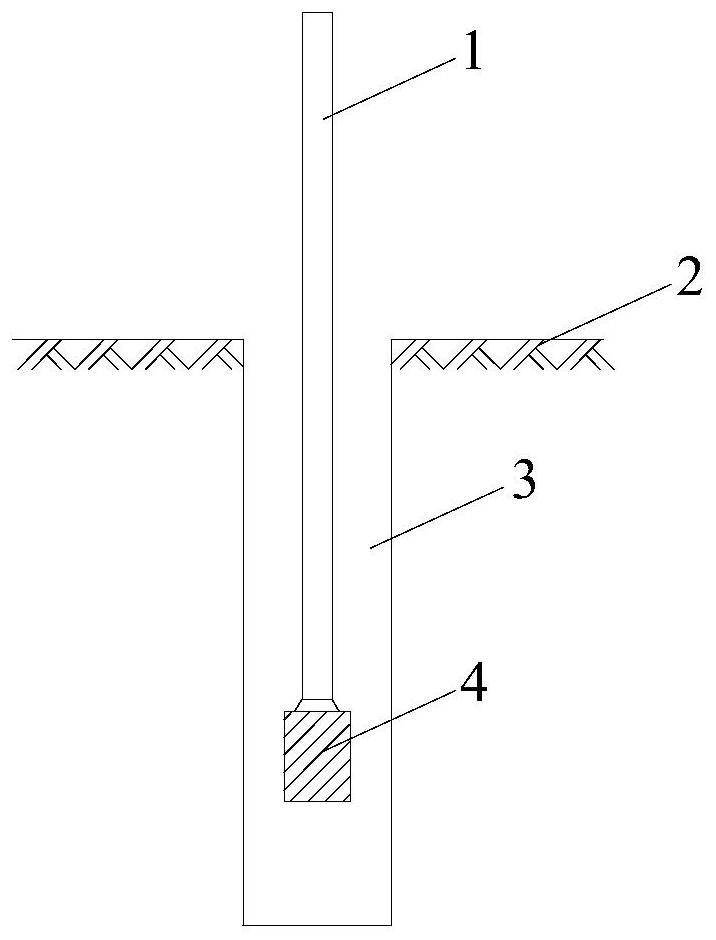

[0028] In this embodiment, a shock-filtering type bored pile concrete pouring height control device is disclosed, including: a connected probe rod, a detection and early warning mechanism and a signal receiving device;

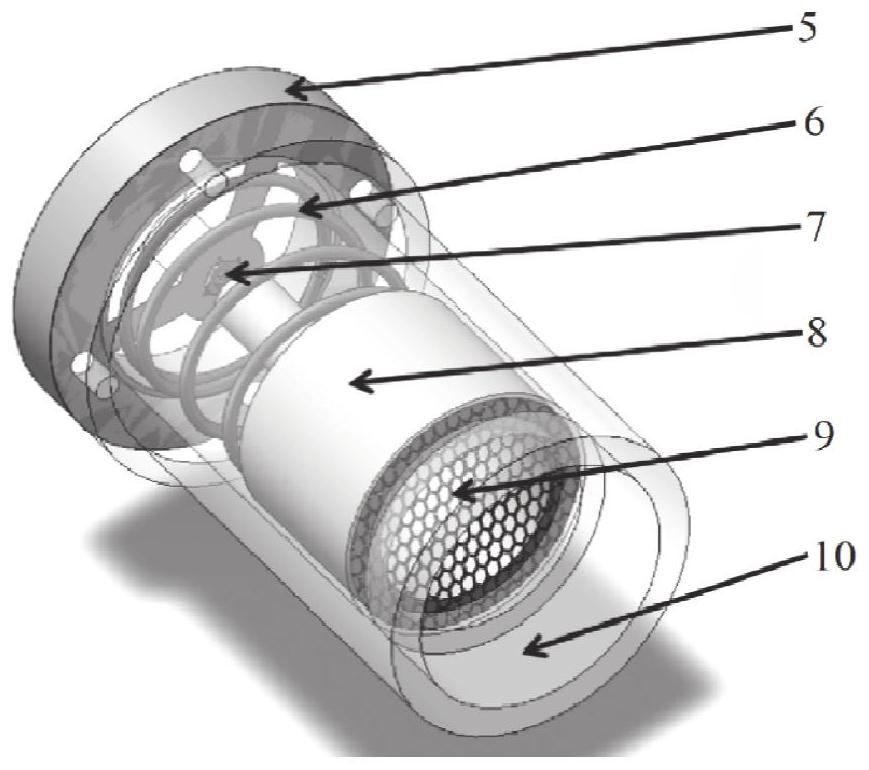

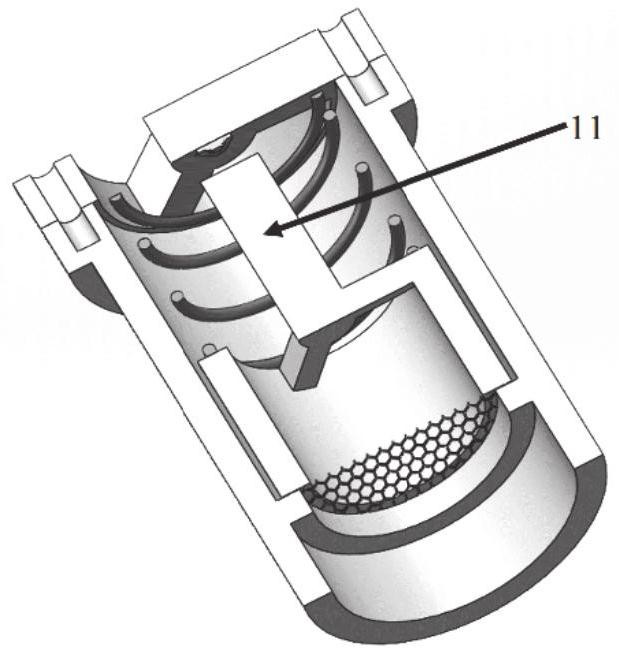

[0029] The detection and early warning mechanism includes an outer cylinder and an inner cylinder arranged in the outer cylinder, a top cover is provided at one end of the outer cylinder, a positioning rod is connected to an end of the inner cylinder facing the top cover, and an inner cylinder bottom net is provided at an end of the inner cylinder away from the top cover, An early warning signal generator is arranged on the end face of the top cover facing the inner cylinder, the early warning signal generator is connected to the signal receiving device, the inner cylinder and the positioning rod can move in the outer cylinder, so that the positioning rod contacts the early warning signal generator, and the early warning signal is triggered The device sends out...

Embodiment 2

[0055] In this embodiment, a method for controlling the pouring height of concrete of a shock-filtering bored pile is disclosed, including:

[0056] Lower the detection and early warning mechanism to a predetermined depth;

[0057] During the grouting process, the bottom net of the inner cylinder drives the positioning rod to move towards the top cover;

[0058] When the concrete slurry reaches the predetermined depth, the positioning rod contacts the early warning signal generator, triggering the early warning signal generator to send out an alarm signal;

[0059] When the signal receiver receives the alarm signal, the grouting is stopped.

[0060] A method for controlling the concrete pouring height of a vibration-filtering bored pile disclosed in this embodiment will be described in detail.

[0061] The concrete pouring height of the pouring pile is controlled by a shock-filtering type bored pile concrete pouring height control device.

[0062] The process of controlling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com