Cement paving device for building

A technology for cement installation and construction, which is applied in cement mixing installations, buildings, building structures, etc., can solve the problems of easy falling, uneven cement paving, and reduced wall laying efficiency, and achieve the effect of avoiding solidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

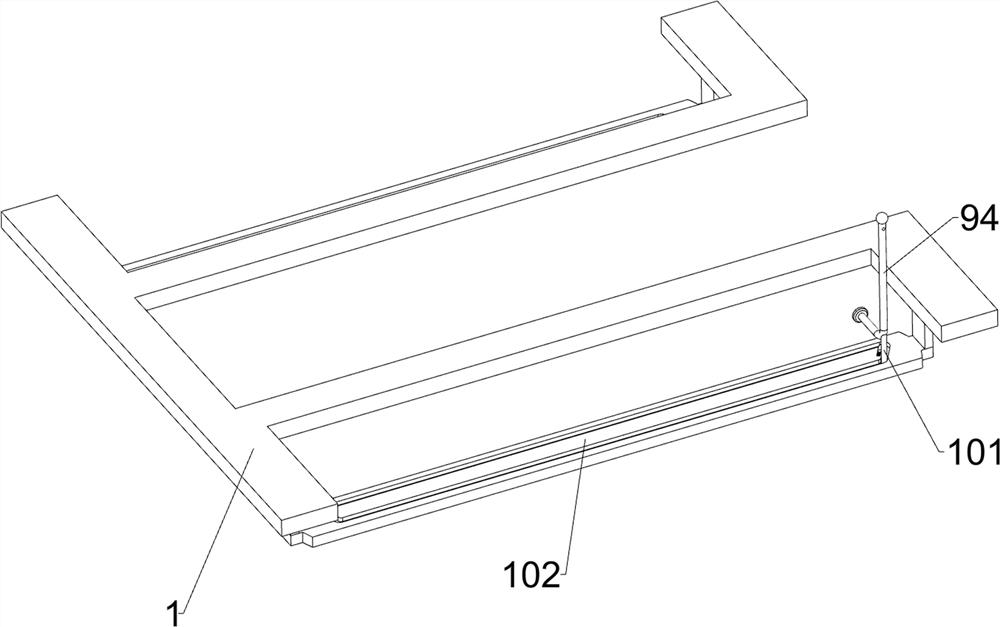

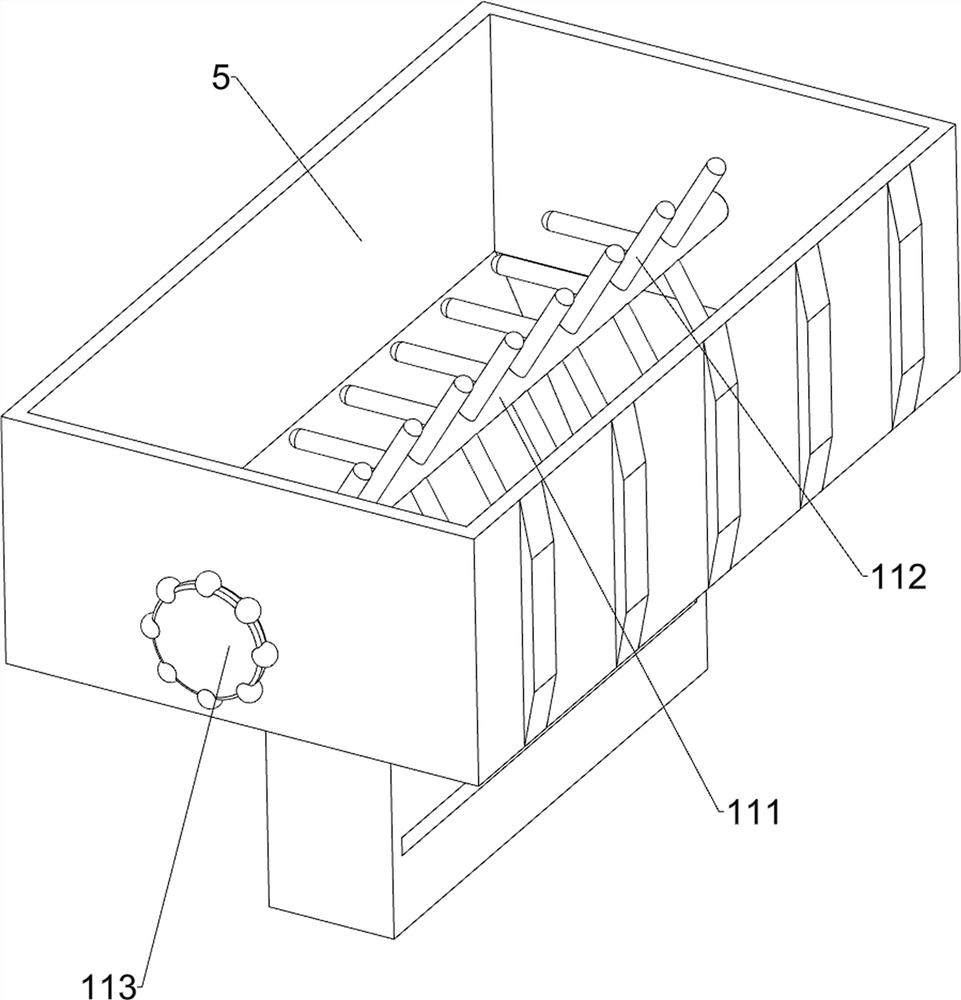

[0027] A cement paving device for construction, such as Figure 1-9 As shown, it includes a base 1, a guide rod 2, a sliding sleeve 3, a first mounting block 4, a hopper 5, a baffle plate 6, a driving mechanism 7 and a lifting mechanism 8, and the front and rear parts of the base 1 are provided with guide rods 2, and the guide rods Sliding sleeves 3 are provided on the rod 2, first mounting blocks 4 are provided on the sliding sleeves 3, a hopper 5 is provided between the front and rear first mounting blocks 4, and a hopper 5 is provided between the right parts of the two guide rods 2. There is a baffle 6, and the baffle 6 is slidingly matched with the hopper 5. The base 1 is provided with a driving mechanism 7, and the base 1 is provided with a lifting mechanism 8.

[0028] When using the device, the staff moves the equipment to the bricks where cement needs to be laid, and then the staff pours the mixed concrete into the hopper 5. After completion, the staff drives the hoppe...

Embodiment 2

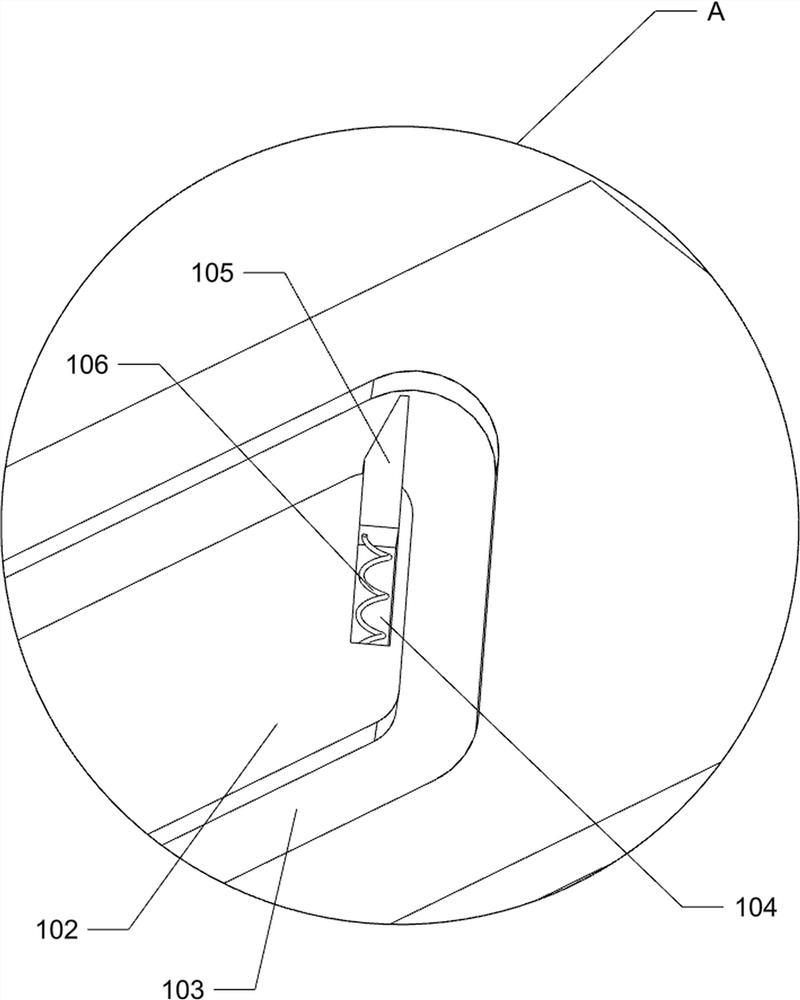

[0034]On the basis of Example 1, such as figure 1 , Figure 4 and Figure 5 As shown, also includes clamping mechanism 9, and clamping mechanism 9 includes the 3rd mounting block 91, cross bar 92, second spring 93, L shape bar 94 and fixing block 95, all is provided with on the first mounting block 4 The third mounting block 91, the third mounting block 91 is provided with a cross bar 92, the cross bar 92 is slidably provided with an L-shaped bar 94, and a second spring is wound between the L-shaped bar 94 and the cross bar 92 93, the lower part of the L-shaped bar 94 is provided with a fixed block 95.

[0035] When using this device, the staff pulls the L-shaped bar 94 to slide outward on the cross bar 92, the second spring 93 is deformed, and the outward sliding of the L-shaped bar 94 drives the fixed block 95 to move outwards and no longer clamps the brick. , the staff fixes the L-shaped rod 94 with a tool, and when the hopper 5 moves to the left to a certain distance, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com