Patents

Literature

67results about How to "Achieve attraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

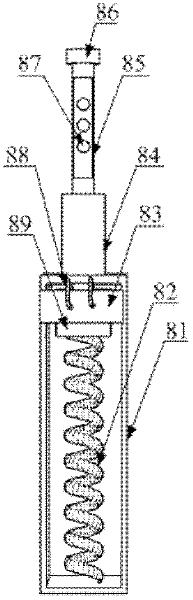

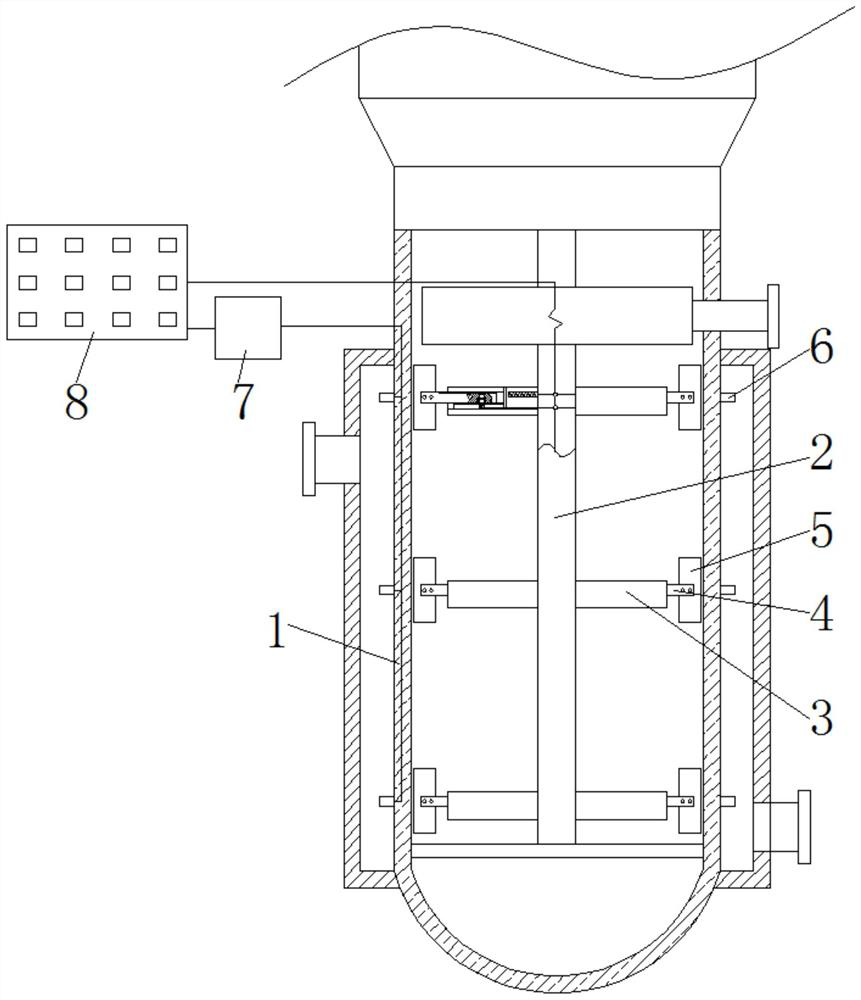

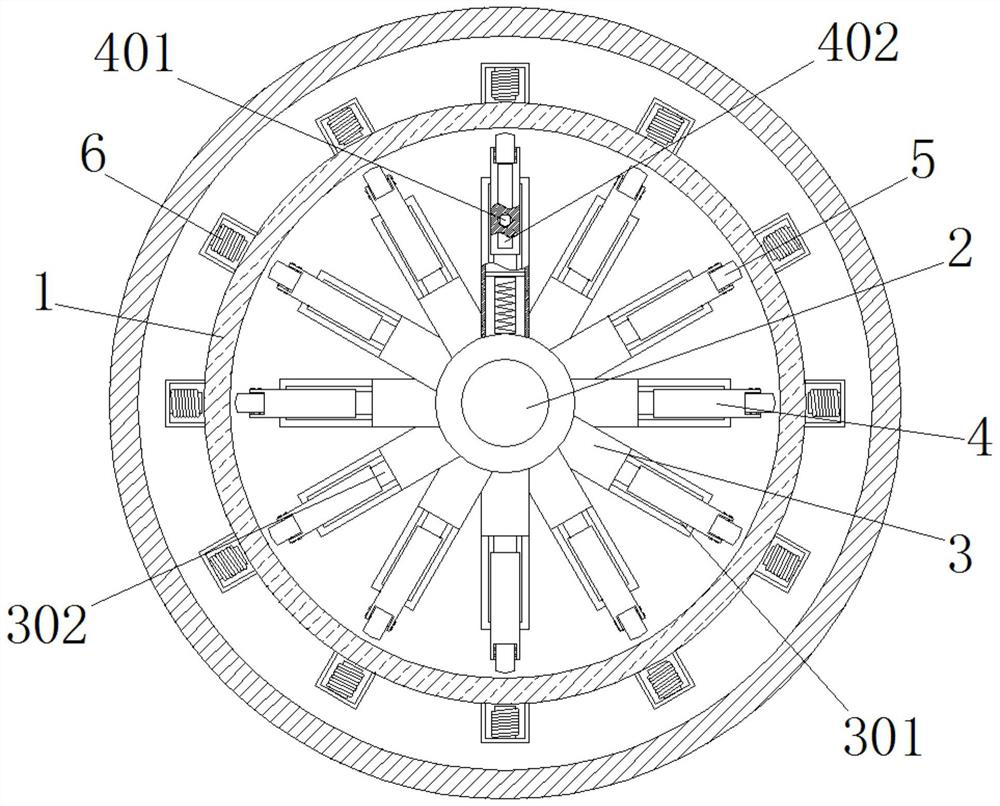

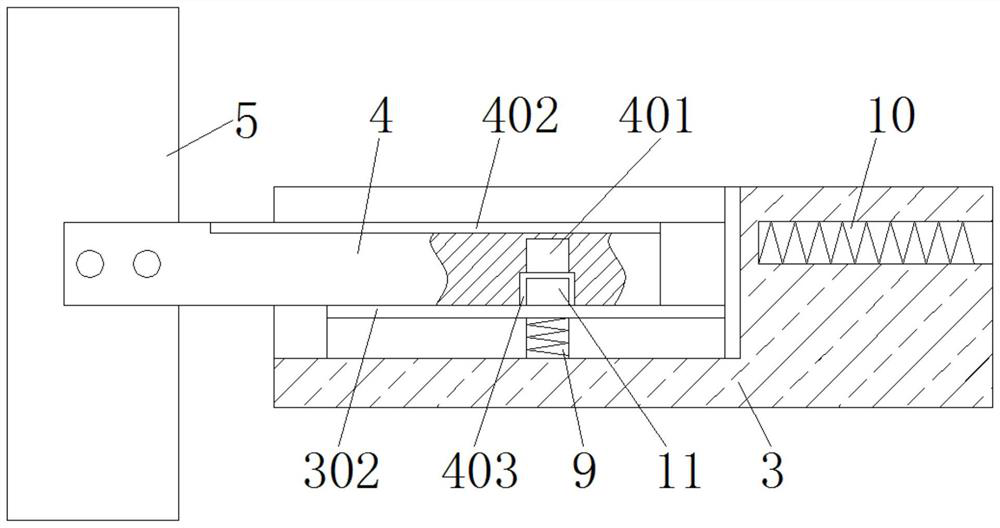

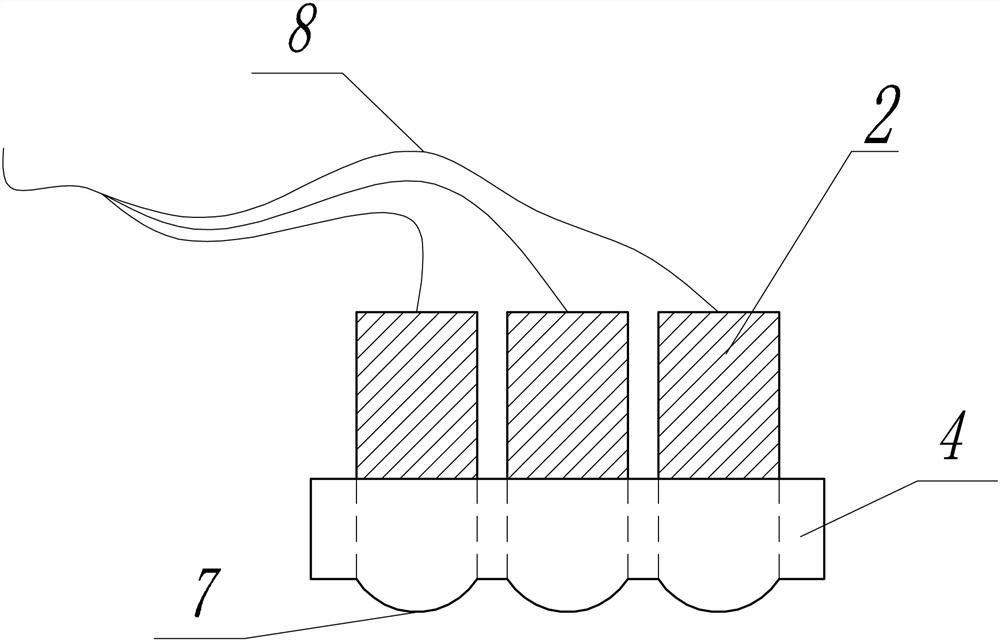

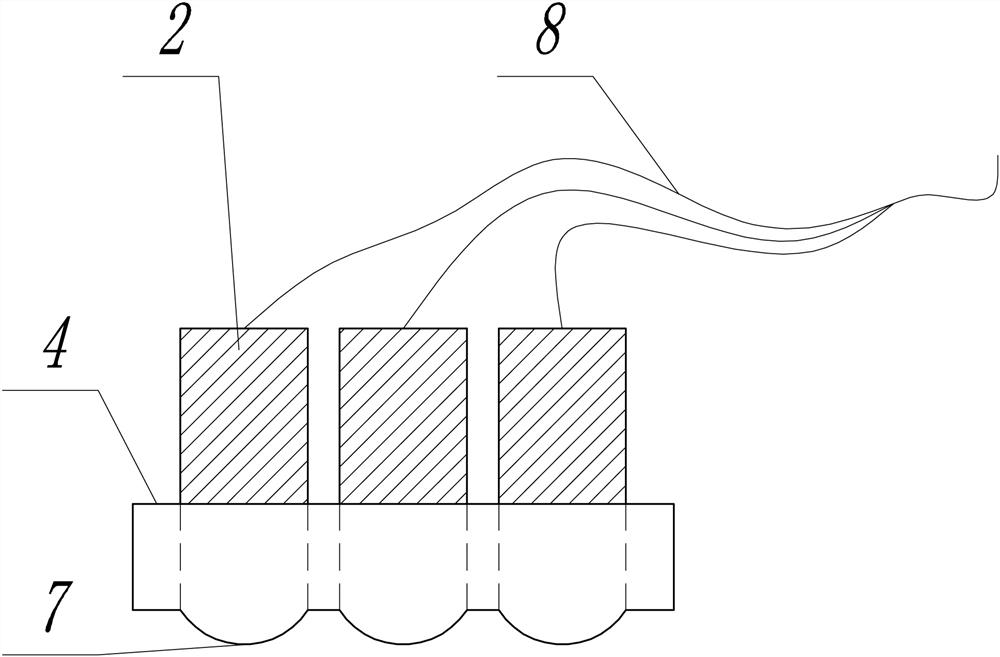

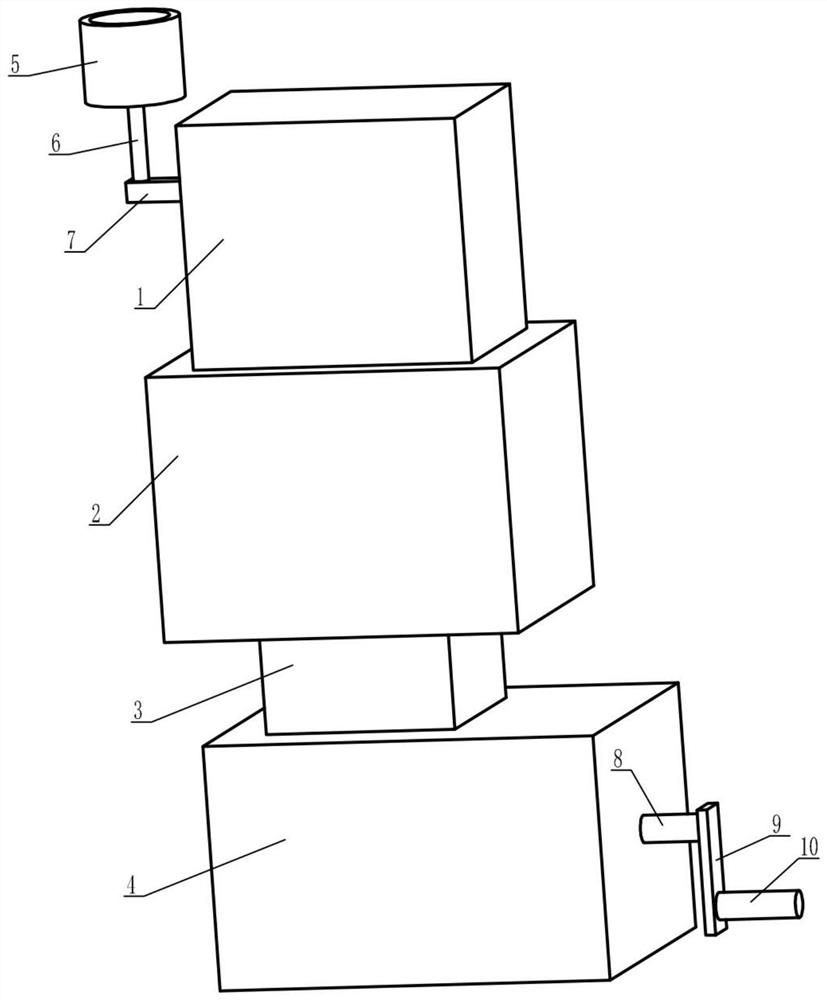

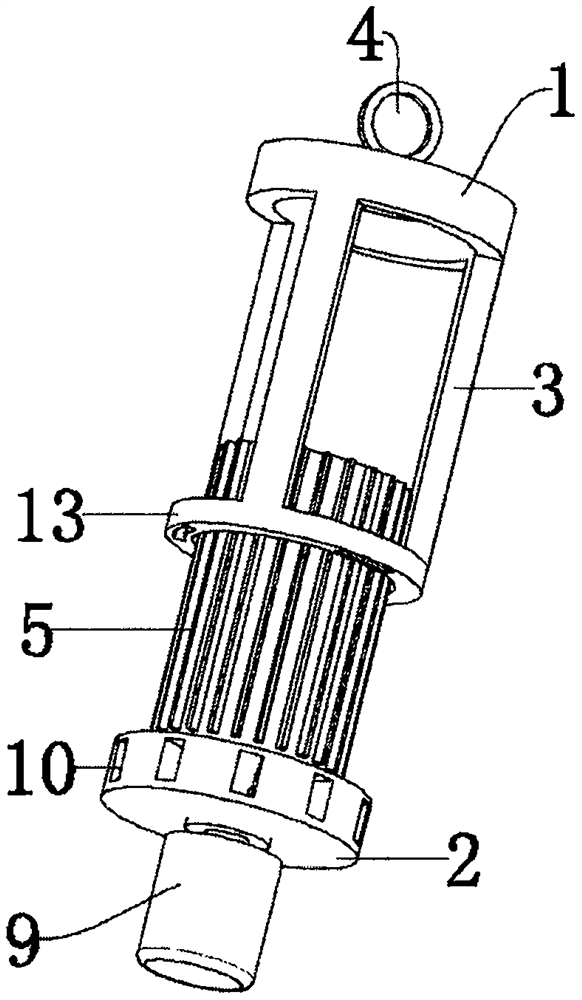

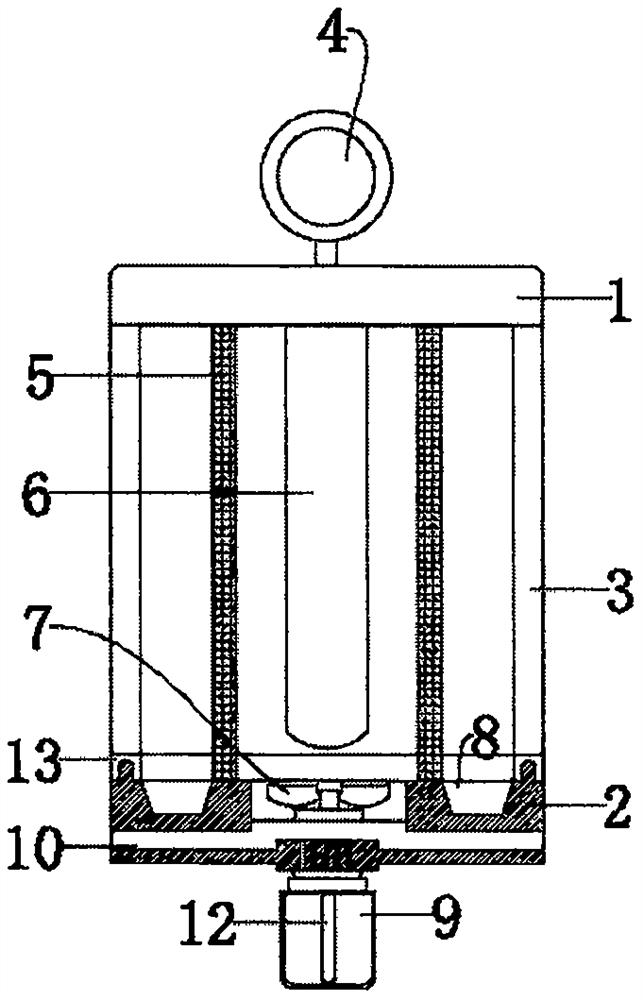

Electric wire smoldering smoke particle collection equipment

InactiveCN102288454ARealize acquisitionRealize automatic collectionWithdrawing sample devicesElectrical conductorHypobaric chamber

The invention provides smoldering smoke particle collecting equipment for an electrical conductor, which comprises a smoke generating device, a smoke collecting cover and a ventilating pipe, wherein the smoke generating device is provided with a power supply; the smoke collecting cover is arranged on the smoke generating device and further forms a smoke collecting chamber with the smoke generating device; the ventilating pipe is communicated with the smoke collecting chamber; the smoke collecting cover and the ventilating pipe are both provided with a smoke particle collector; the smoke particle collectors comprise collecting barrels, electromagnets, protecting sleeves and movable rods; springs and iron columns are arranged in the collecting barrels; one ends of the springs are connected with the bottom ends of the collecting barrels; the iron columns are connected with the springs; the electromagnets are connected with the power supply and are further all positioned at the other endsof the springs together with the iron columns; the protecting sleeves are connected with the collecting barrels; the movable rods are sleeved in the protecting sleeves in a sliding way and are further connected with the iron columns; and the movable rods are provided with smoke particle collecting meshes. By using the smoldering smoke particle collecting equipment for the electrical conductor, which is provided by the invention, the automatic collection of the smoldering smoke particles of the electrical conductor is achieved; a conventional manual collecting way is avoided; and the collection of the smoke particles in the environments of some environment simulating experimental devices (such as a hypobaric chamber and a drop tower) and the like, which are not applicable to manual collection, is achieved.

Owner:UNIV OF SCI & TECH OF CHINA

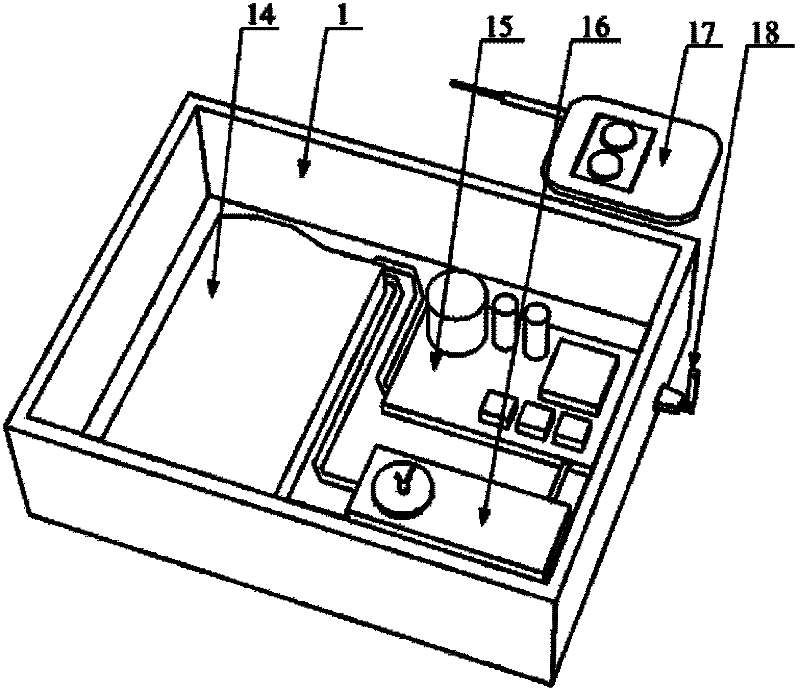

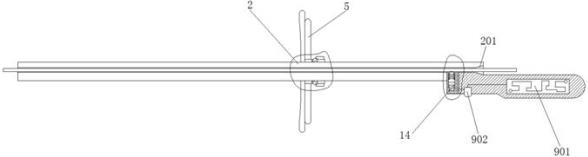

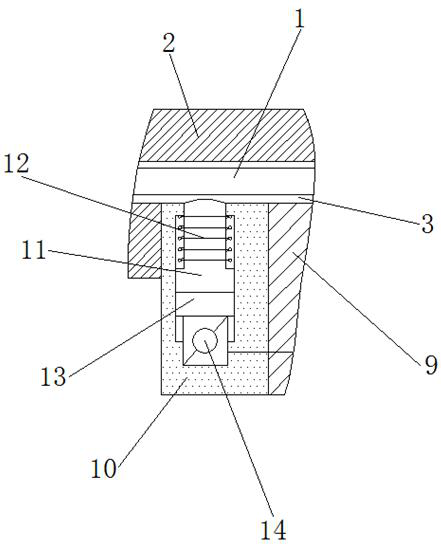

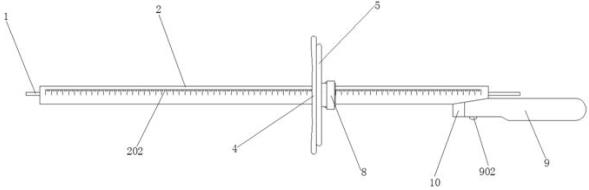

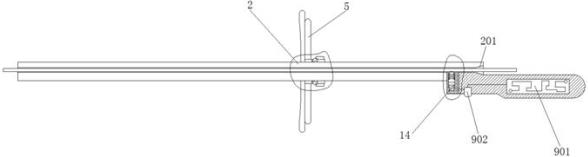

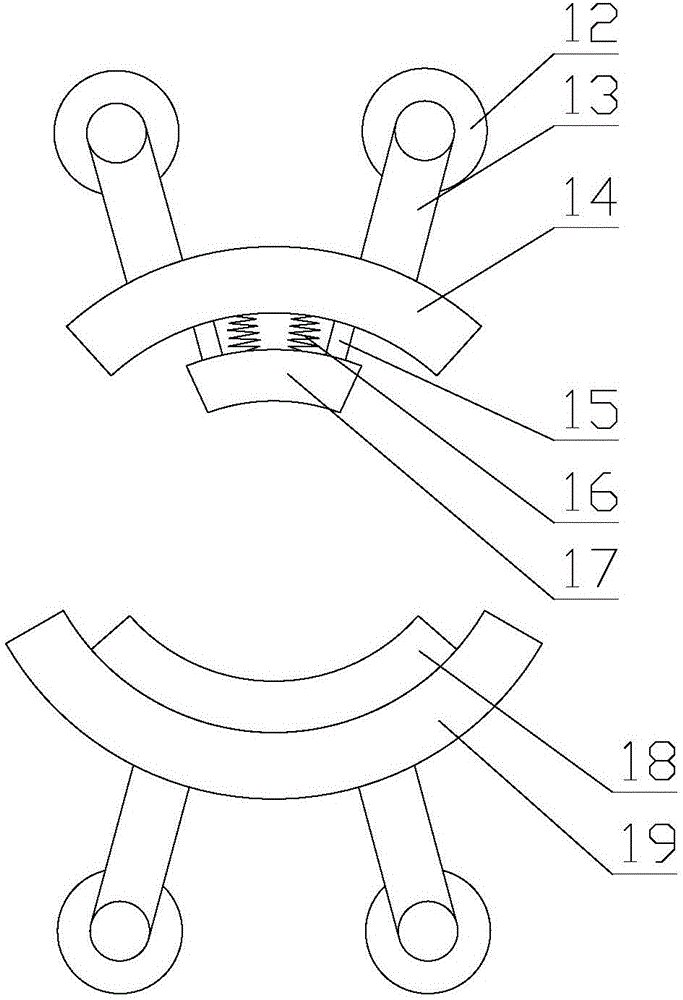

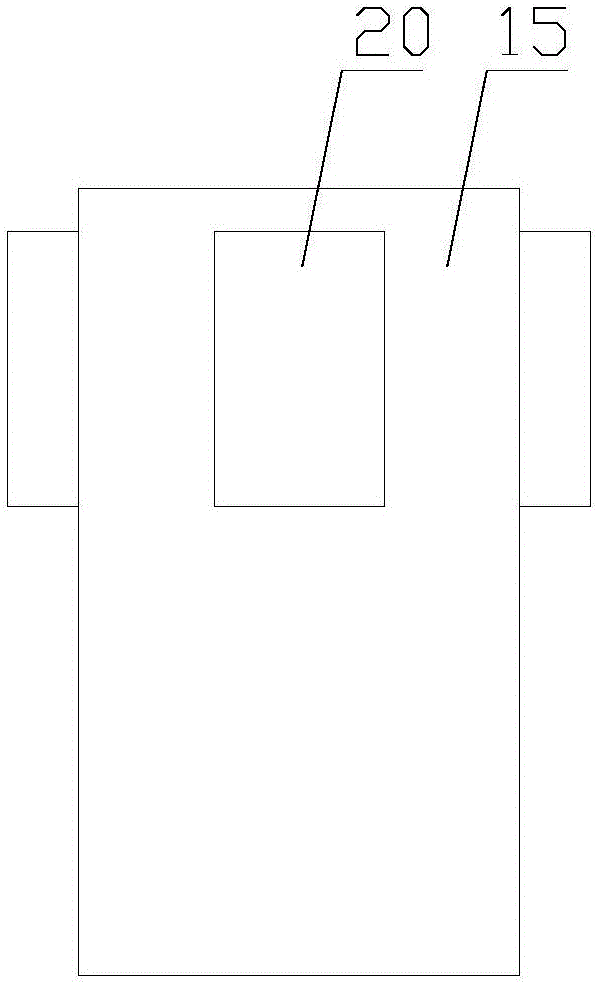

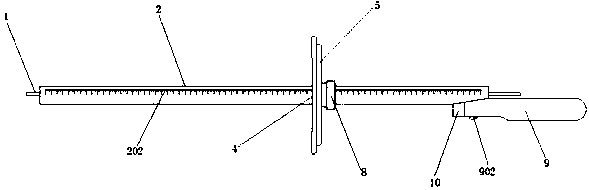

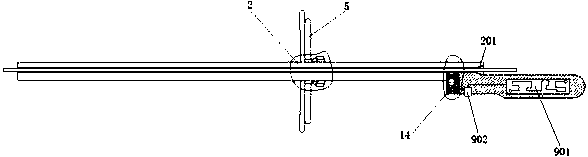

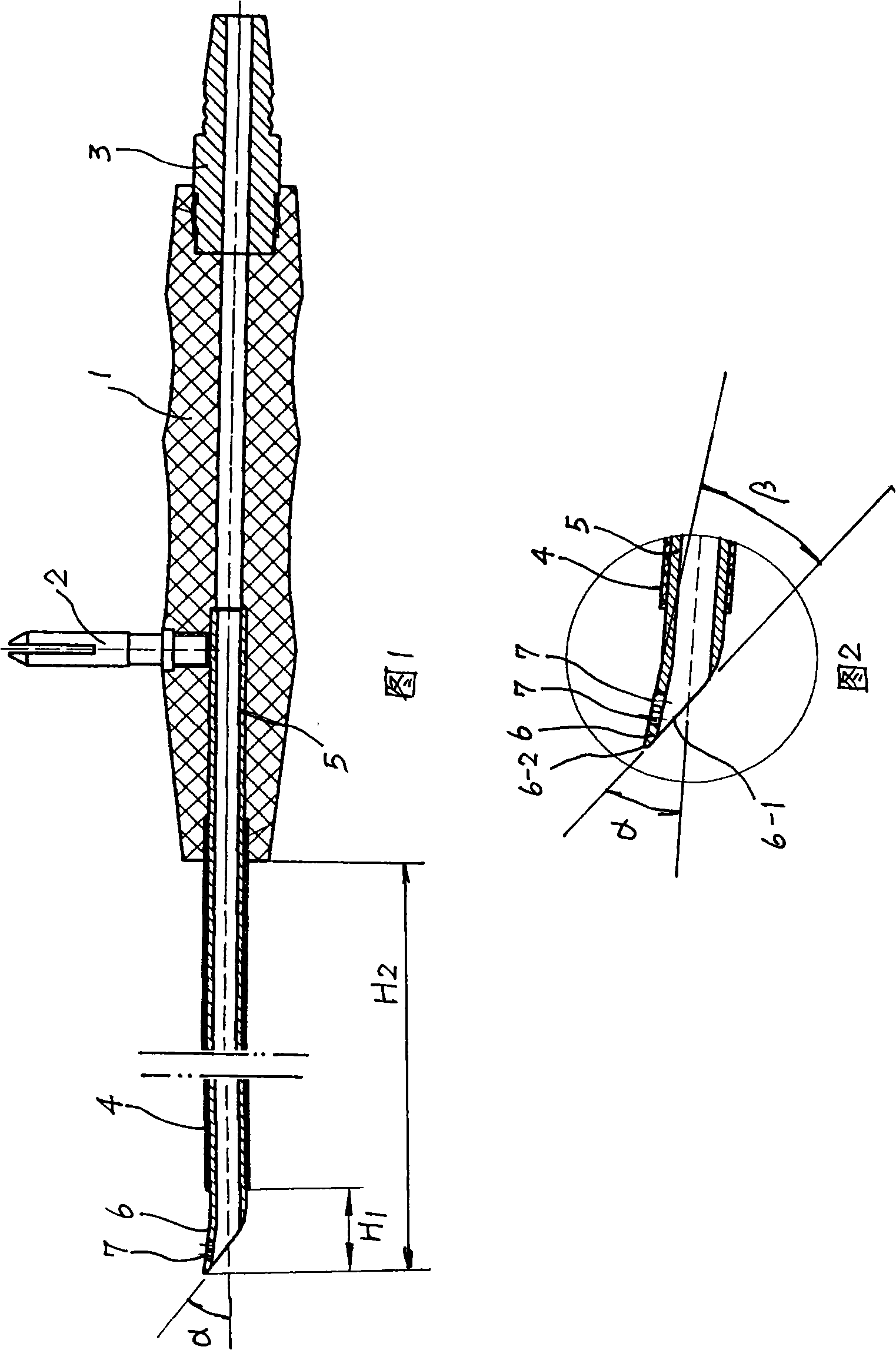

Adjustable microcatheter for cerebrovascular intervention and use method thereof

InactiveCN112169137AAchieve clampingGuaranteed positioningGuide wiresEngineeringIntensive care medicine

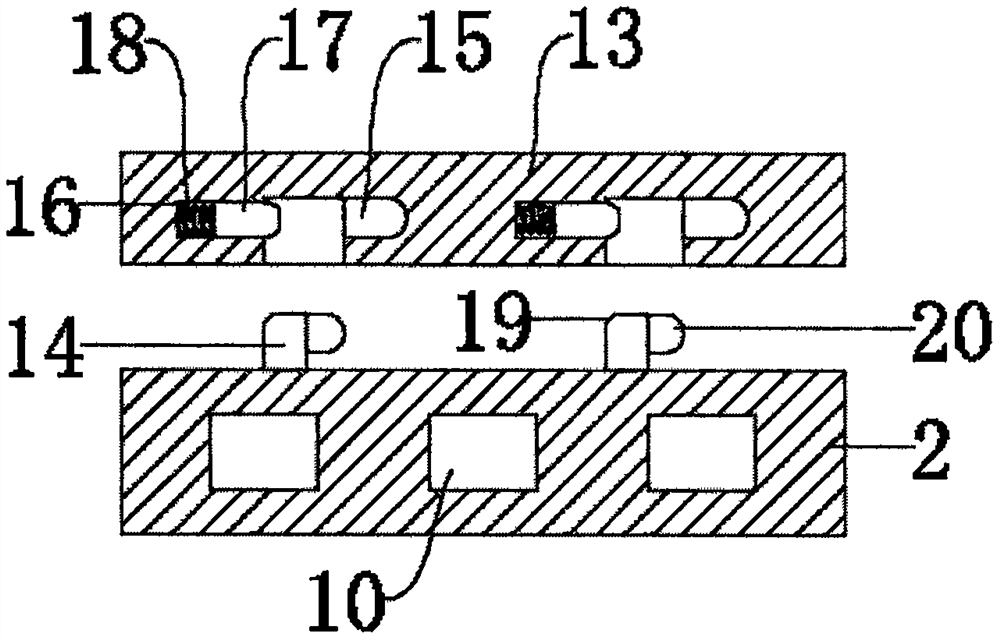

The invention discloses an adjustable microcatheter for cerebrovascular intervention and a use method thereof. The adjustable microcatheter comprises a guide wire, and further comprises a catheter body, an avoidance hole, a patch, a soft cushion, a clamping sleeve, clamping plates, a threaded sleeve, a handle, an insulating sleeve, a push plate, a spring, a conductive block and an electromagnet. The adjustable microcatheter for cerebrovascular intervention is easy to operate and powerful in function. Firstly, the catheter can be positioned and fixed through the catheter fixing type design, andthe stability and safety in a subsequent operation process are ensured; and secondly, the guide wire in the catheter can be positioned through the cooperation effect of a clamping type guide wire mechanism, the accuracy of treatment operation is improved, the operation burden of medical staff is relieved, and the purpose of satisfactory clinical application and popularization is finally achieved.

Owner:万海伟

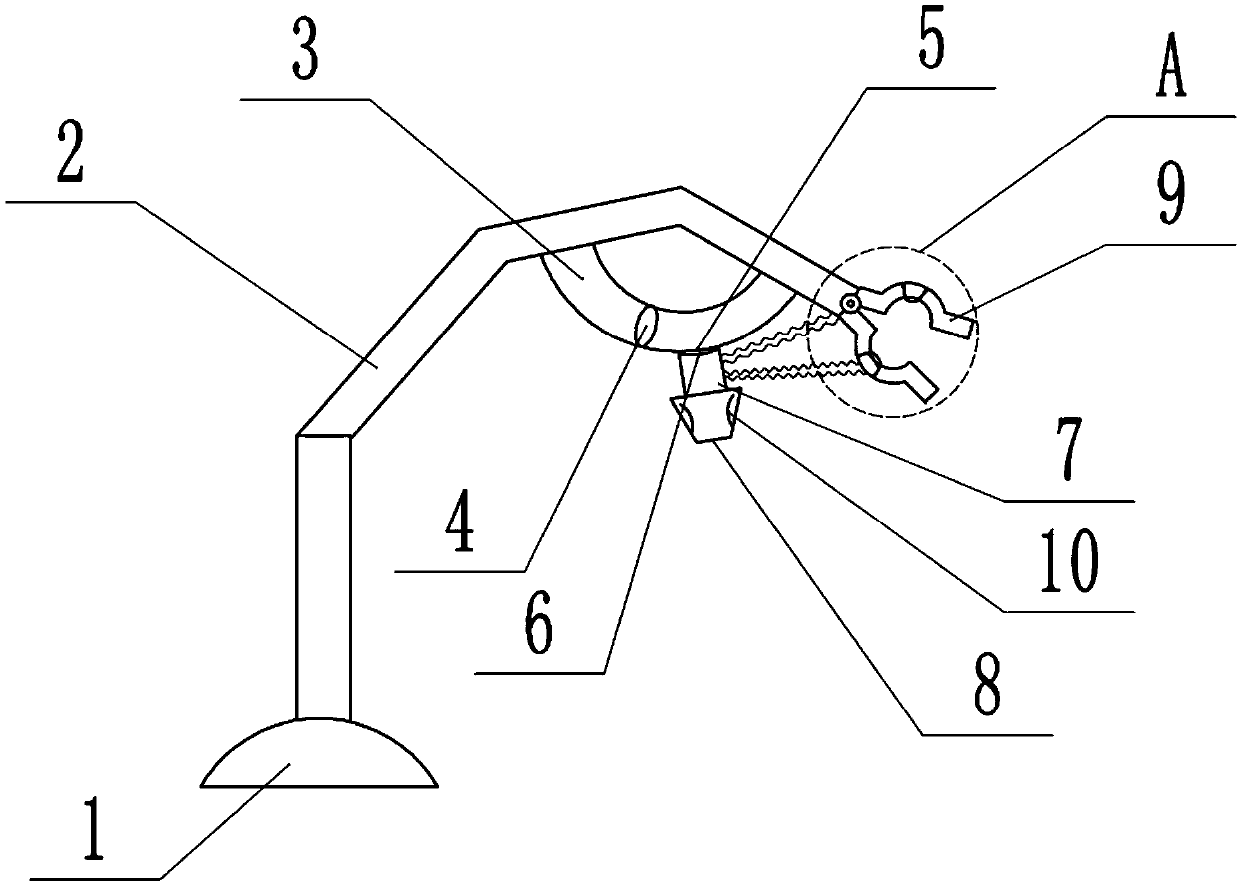

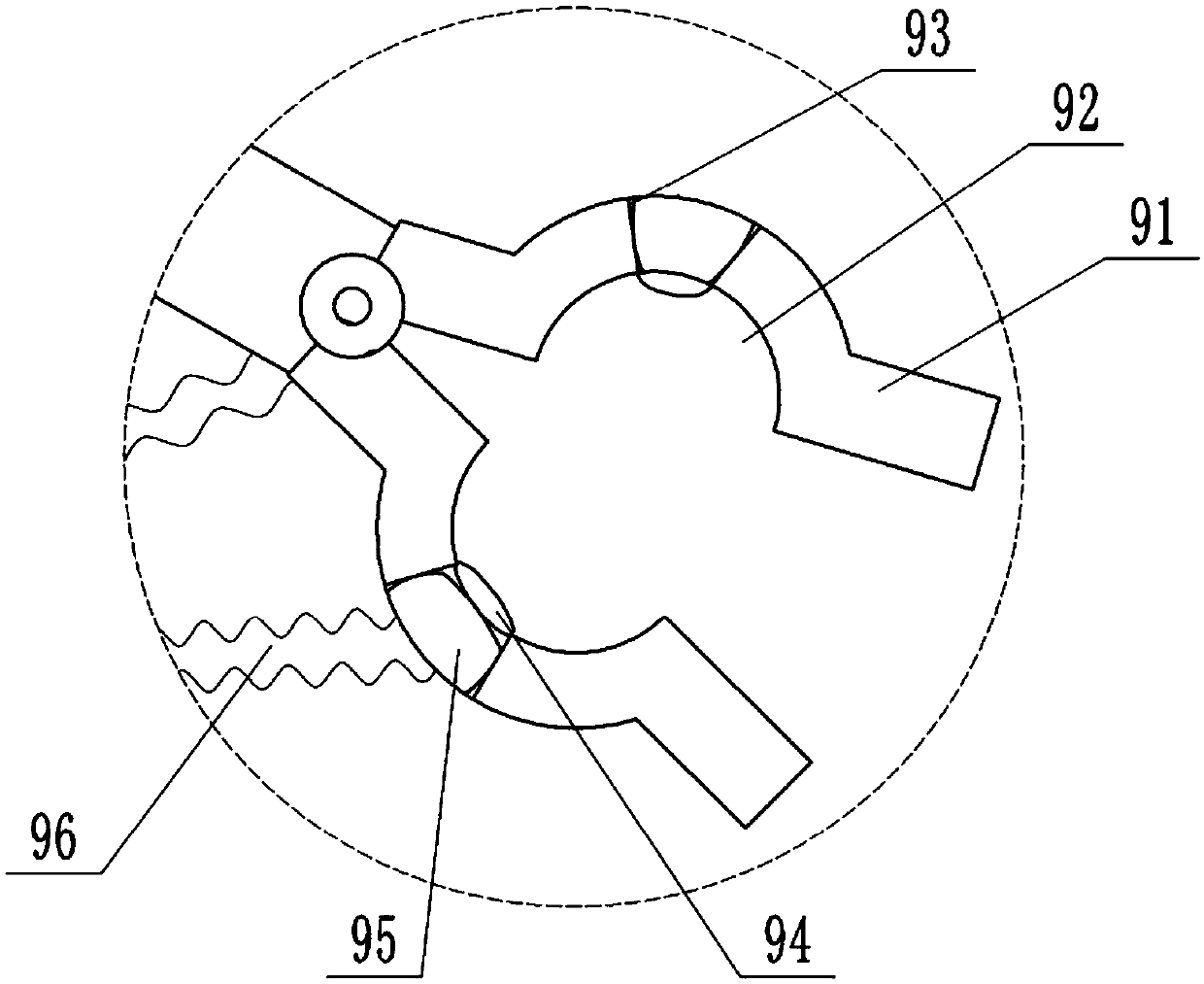

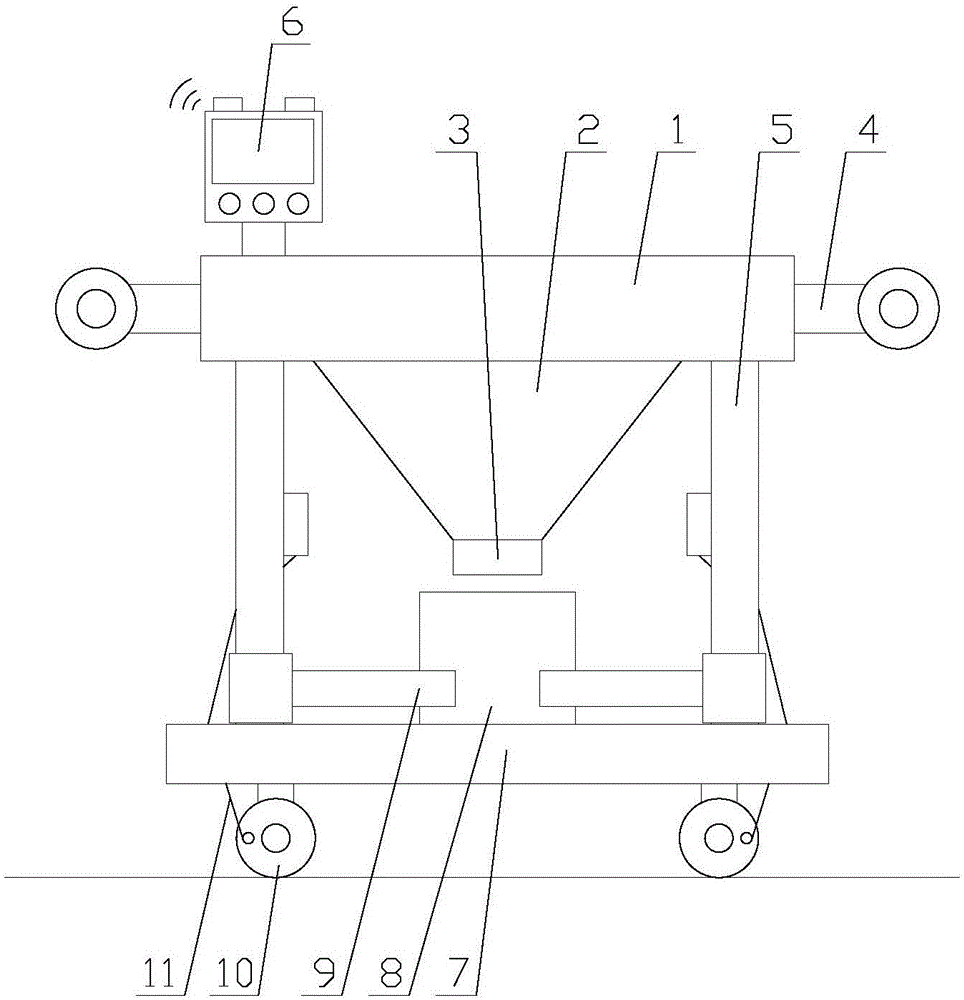

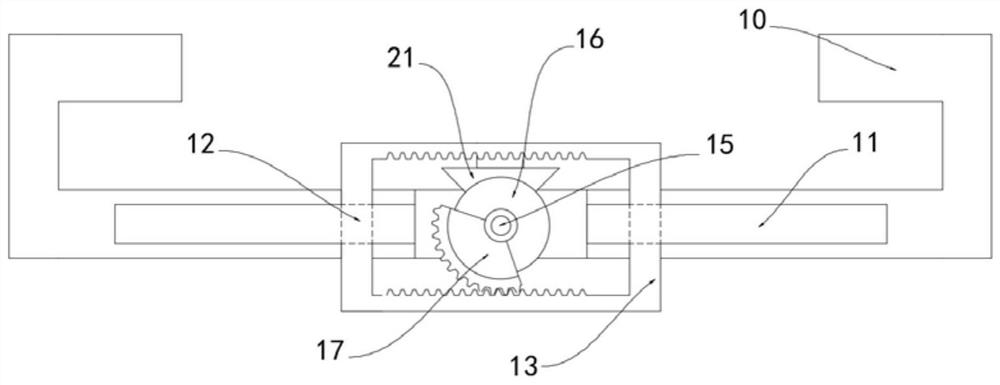

Industrial robot traction demonstration system

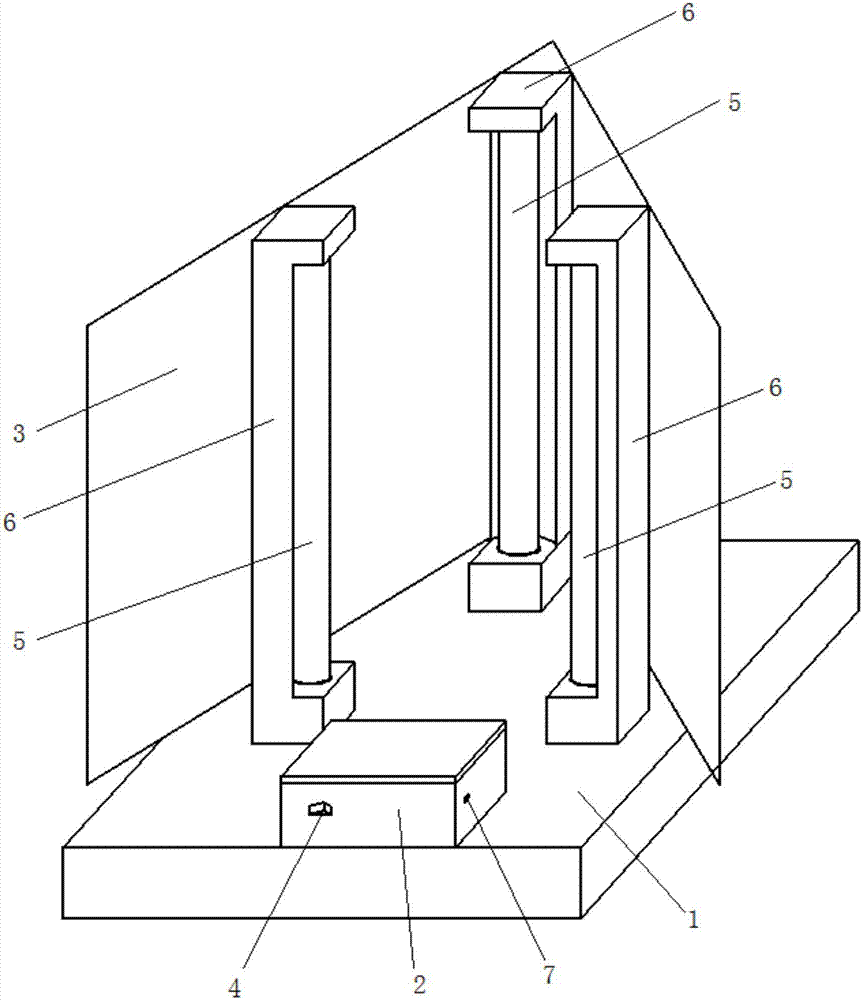

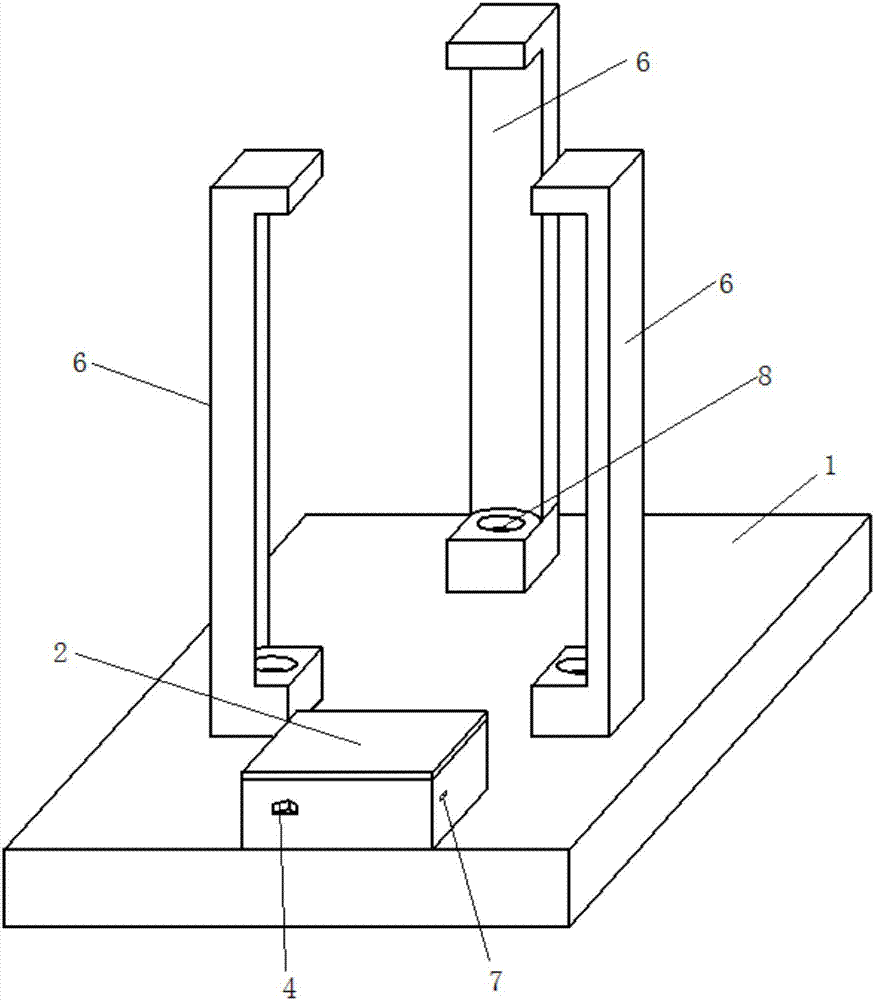

ActiveCN108673480ABlock circulationGuarantee the safety of lifeProgramme-controlled manipulatorGripping headsMagnetic valveControl theory

The invention discloses an industrial robot traction demonstration system, and relates to the field of robots. The industrial robot traction demonstration system comprises a mechanical arm with multiple degrees of freedom; the mechanical arm comprises a base and a plurality of movable arms; a movable joint is arranged between every two adjacent movable arms, and the movable arms are sequentially connected with the base by the movable joints; a U-shaped bag is arranged between every two adjacent movable arms, and two ends of each U-shaped bag are correspondingly in fixed connection with the twoadjacent movable arms; each U-shaped bag is internally provided with a magnetic valve dividing the U-shaped bag into two parts; a though hole is formed in the side, away from the base, of each U-shaped bag; a film is arranged at each through hole; a strip-shaped pipe is connected with the film at each U-shaped bag; a cone-shaped cover shell is in sleeving connection with the end, away from the corresponding U-shaped bag, of each strip-shaped pipe; and each cone-shaped cover shell is internally provided with a spring piece. According to the industrial robot traction demonstration system, the problem of danger caused by sudden power-off during traction demonstration of an existing robot is solved; and an industrial robot traction demonstration system capable of sending a warning during thesudden power-off of a robot to guarantee safety of workers near the robot is achieved.

Owner:WENZHOU UNIVERSITY

Adjustable microcatheter for cerebrovascular intervention and use method thereof

InactiveCN112169135AAchieve clampingGuaranteed positioningGuide wiresIntensive care medicineGuide wires

The invention discloses an adjustable microcatheter for cerebrovascular intervention and a use method thereof. The adjustable microcatheter comprises a guide wire, and further comprises a catheter body, an avoidance hole, a patch, a soft cushion, a clamping sleeve, clamping plates, a threaded sleeve, a handle, an insulating sleeve, a push plate, a spring, a conductive block and an electromagnet. The adjustable microcatheter for cerebrovascular intervention is easy to operate and powerful in function. Firstly, the catheter can be positioned and fixed through the catheter fixing type design, andthe stability and safety in a subsequent operation process are ensured; and secondly, the guide wire in the catheter can be positioned through the cooperation effect of a clamping type guide wire mechanism, the accuracy of treatment operation is improved, the operation burden of medical staff is relieved, and the purpose of satisfactory clinical application and popularization is finally achieved.

Owner:万海伟

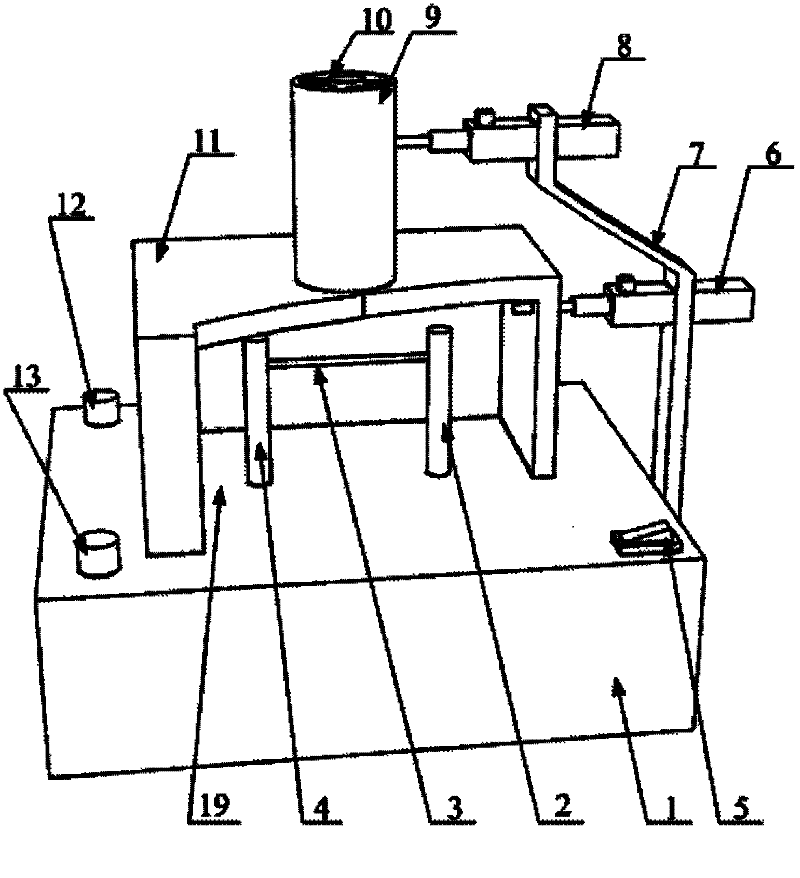

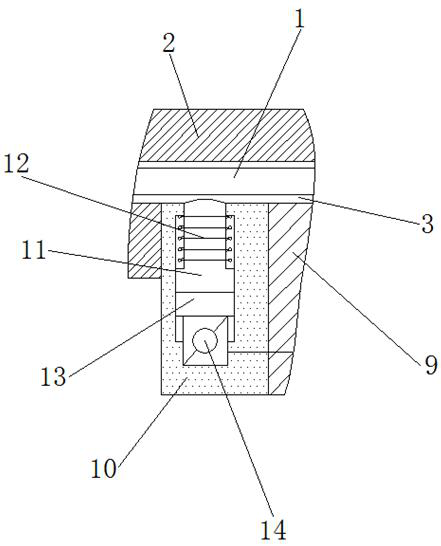

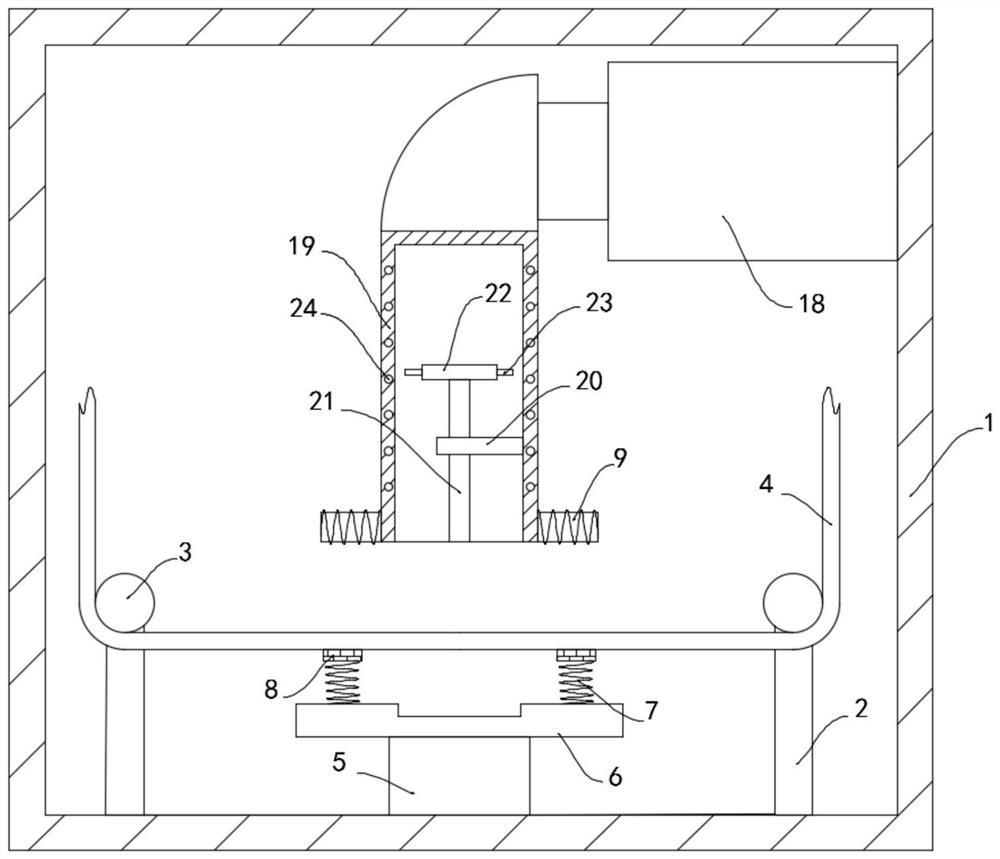

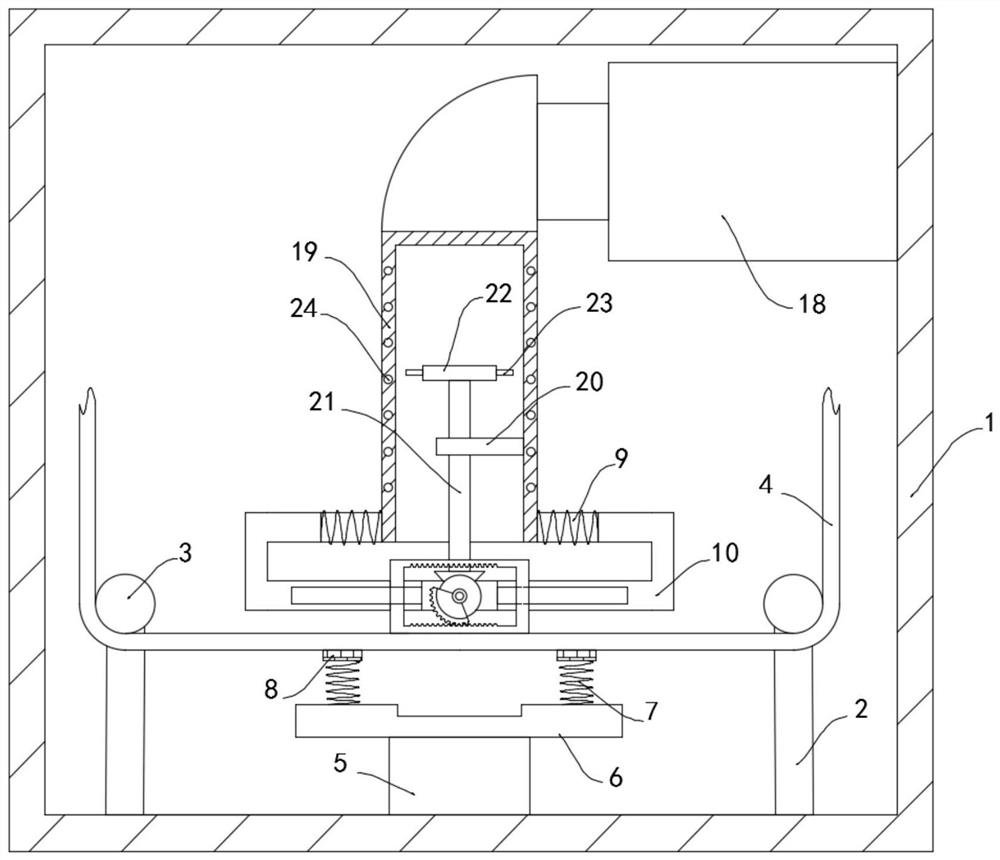

Medical debridement equipment based on Internet of Things

The invention relates to medical debridement equipment based on the Internet of Things. The medical debridement equipment based on the Internet of Things comprises a base, a workbench, a support column, a water channel, a water collection mechanism and a mobile mechanism. The water collection mechanism comprises a water collection bucket and a fixing assembly, the fixing assembly comprises a first fixing unit and a second fixing unit, the mobile mechanism comprises a universal wheel and an extension and retraction assembly, the extension and retraction assembly comprises a traction unit and a rotation unit, and the traction unit comprises a traction block and a traction line. According to the medical debridement equipment based on the Internet of Things, the first fixing ring and the second fixing ring can encircle the water collection bucket, then an electromagnetic coil is electrified and disconnected, the attraction to a magnet is achieved, and thus fixing and loosening of the water collection bucket are achieved; the magnet is pulled to the original position through a first spring, thus clamping of the water collection bucket is achieved, and the practicability of equipment is improved; besides, the traction block drafts the traction line, a turning wheel rotates, the purpose of retracting the universal wheel inside the base can be achieved, the second spring can pull the turning wheel to return the original position at the same time, and the practicability of the equipment is improved.

Owner:安溪钟泰专利技术转移有限公司

Textile fabric heat pump dryer

PendingCN112728908ASave energyAchieve attractionDrying gas arrangementsDrying chambers/containersEngineeringDry box

The invention belongs to the field of dryers, and particularly relates to a textile fabric heat pump dryer which comprises a drying box body. Two symmetrically-arranged supports are fixedly connected to the lower wall of the inner side of the drying box body, transmission wheels are rotatably connected to the side walls of the supports, and the two transmission wheels are jointly in transmission connection with cloth. A heat pump machine is fixedly connected to the inner side wall of the drying box body, an air outlet pipe fixedly communicates with the side wall of the heat pump machine in a sealed manner, multiple spiral coils are embedded in the side wall of the air outlet pipe, a supporting block is fixedly connected to the inner side wall of the air outlet pipe, and a rotating shaft is rotatably connected to the side wall of the supporting block. A fan is coaxially and fixedly connected to the upper end of the rotating shaft, a permanent magnet is embedded in the fan, iron cores are fixedly connected to the two sides of the air outlet pipe, and wires are wound around the iron cores. The textile fabric heat pump dryer has the advantages that by arranging the permanent magnet and the spiral coils, the situation that the cloth is blown up by wind, and consequently drying efficiency is affected is avoided, and by arranging an incomplete gear and a push plate, product quality is improved.

Owner:兰建德

Adjusting micro guiding pipe for cerebrovascular intervention

The invention discloses an adjusting micro guiding pipe for cerebrovascular intervention. Micro guiding pipe comprises a guiding wire, a guiding pipe body, an avoiding hole, an application soft cushion, a clamping sleeve, a clamping plate, a threaded sleeve, a handle, an insulation sleeve, a push plate, a spring, an electric guiding block and an electromagnetic block. The micro guiding pipe has the advantages of simple operation and powerful function, the positioning and fixing of the guiding pipe can be firstly achieved through a guiding pipe fixing type design, the stability and safety in subsequent operation process is ensured, the positioning of a guiding wire in the guiding pipe can be achieved to improve the accuracy of treatment operation and reduce the operation burden of a medicalworker, and the purpose of excellent clinical popularization is finally achieved.

Owner:JIANGSU YUANCHUANG MEDICAL TECH

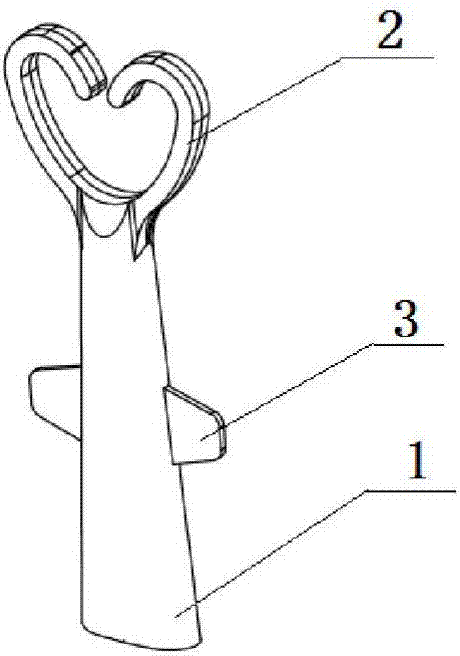

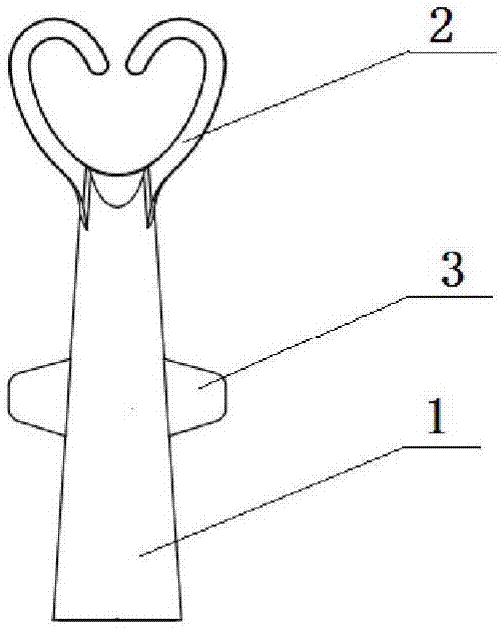

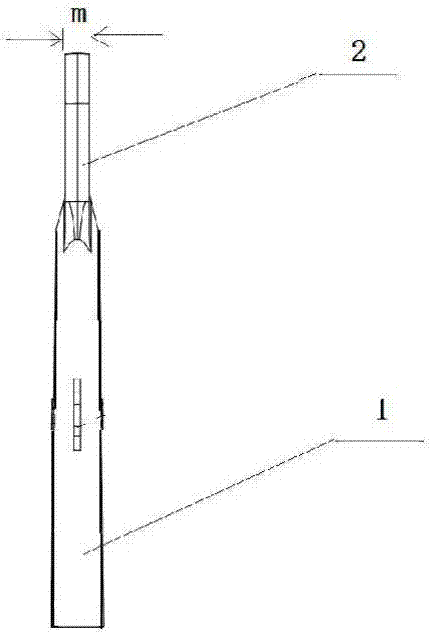

Controlled-release device for slowly releasing volatile substance and manufacturing method thereof

InactiveCN106900677AAchieve attractionTo avoidAnimal repellantsHorticulture methodsEngineeringVolatile substance

The invention relates to a controlled-release device for slowly releasing a volatile substance. The device comprises a body and a hanging part, the body comprises a sealing cavity, the capacity of the sealing cavity is 0.05-15 milliliters, the sealing cavity is filled with the volatile substance, the wall thickness of the body is 0.25-1.25 milliliters, and the body, the hanging part and a wing part are integrally formed by a macromolecule polymeric material which is capable of making the volatile substance be infiltrated into air from the sealing cavity. Compared with the prior art, the controlled-release device for slowly releasing the volatile substance can achieve a longer-acting controlled-release and completely releasing technical effect, and thus is more suitable for being regarded as a releaser of a repellent for interfering insect mating in field and can be used for being regarded as a lure core for monitoring, killing and luring and killing insects. The invention further relates to a manufacturing method of the controlled-release device, wherein the step of filling and sealing at a normal temperature is included.

Owner:NANJING SINO GREEN BIOTECH

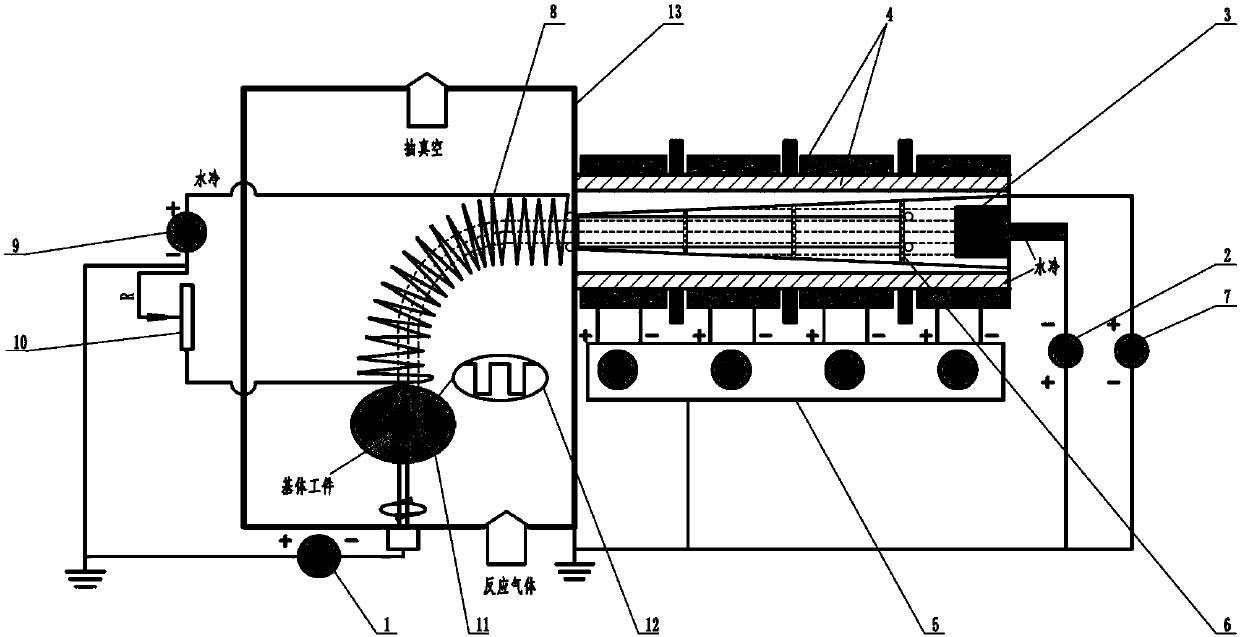

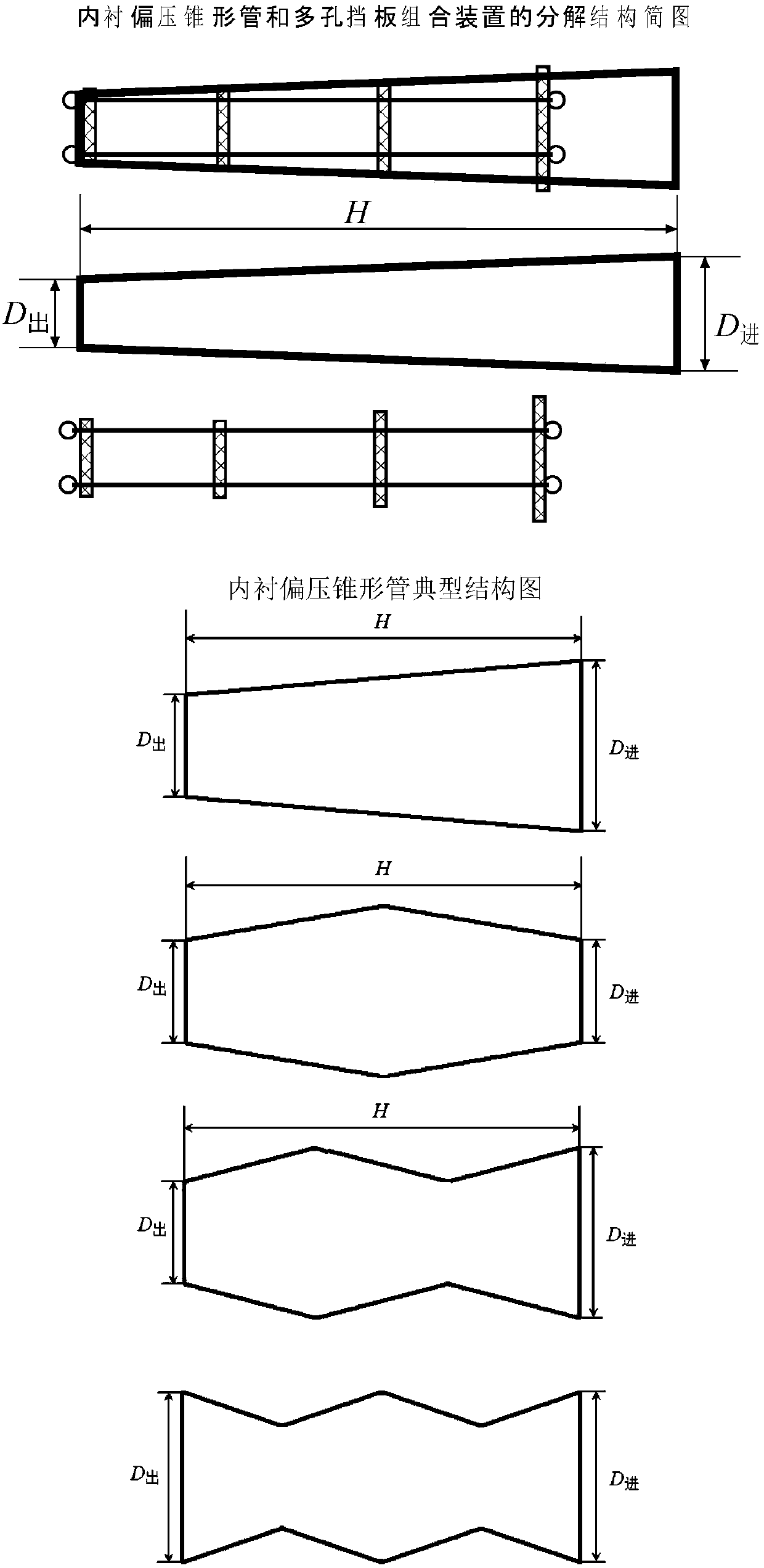

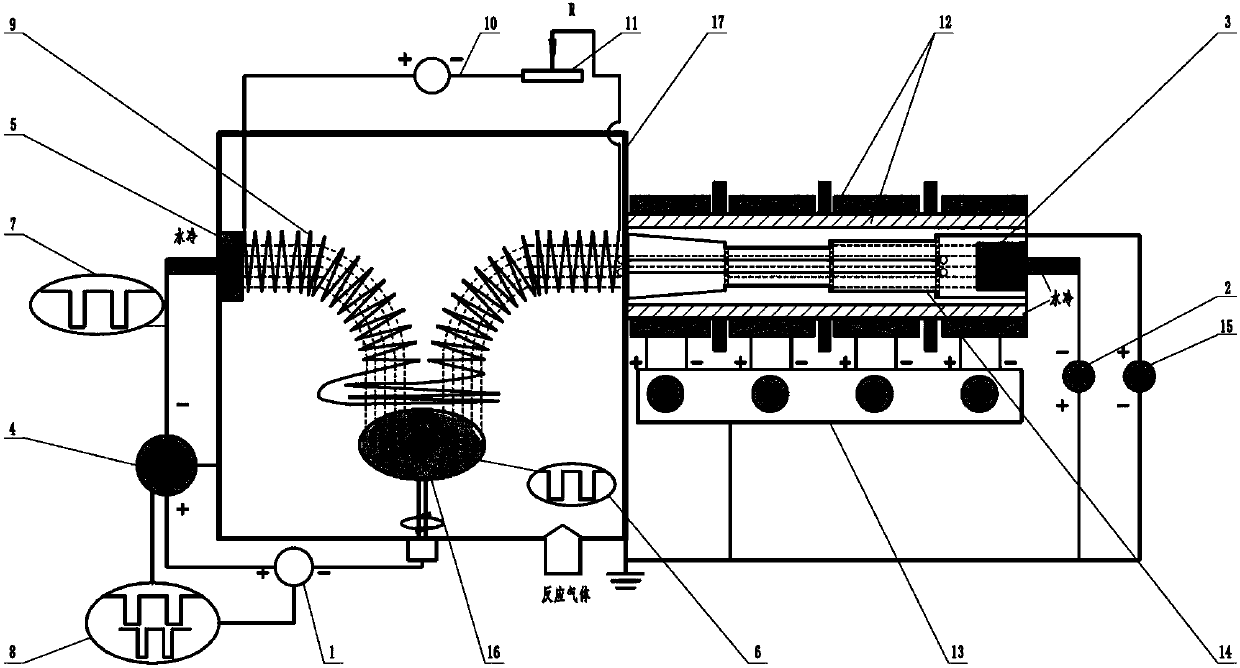

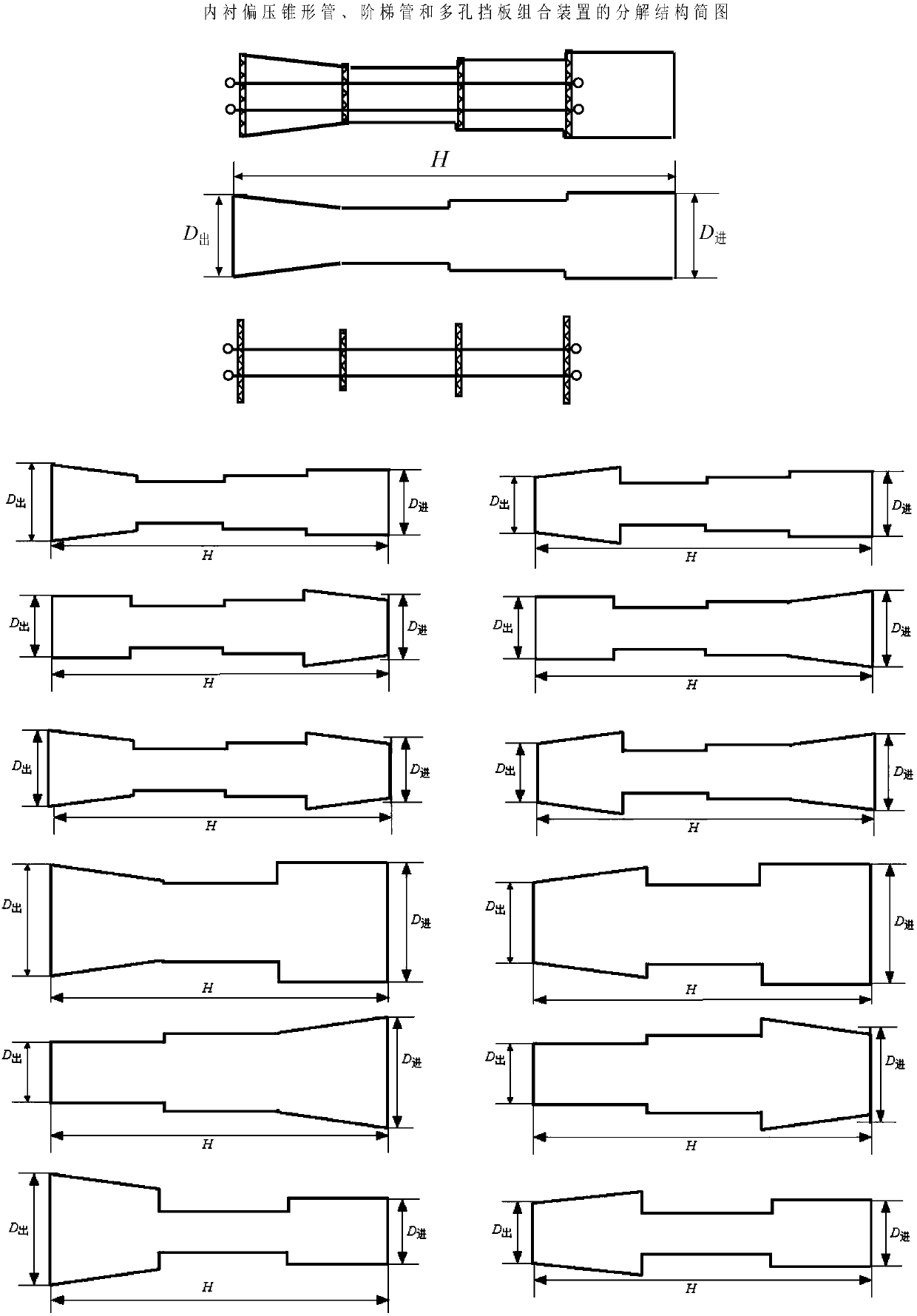

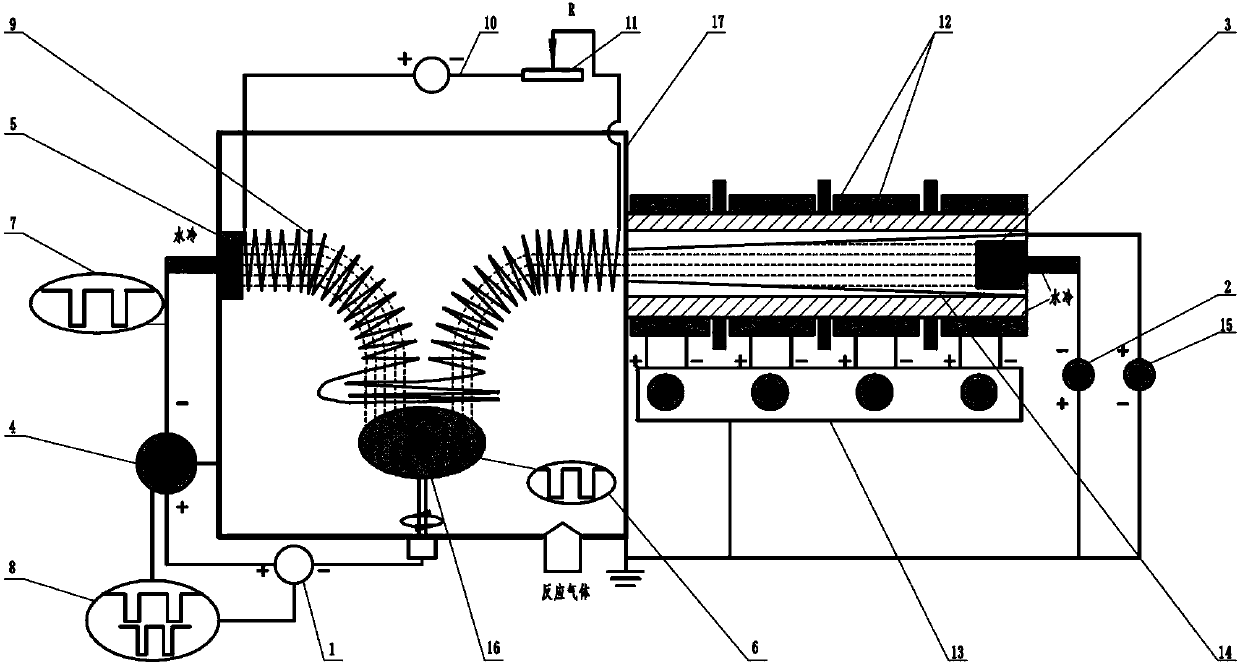

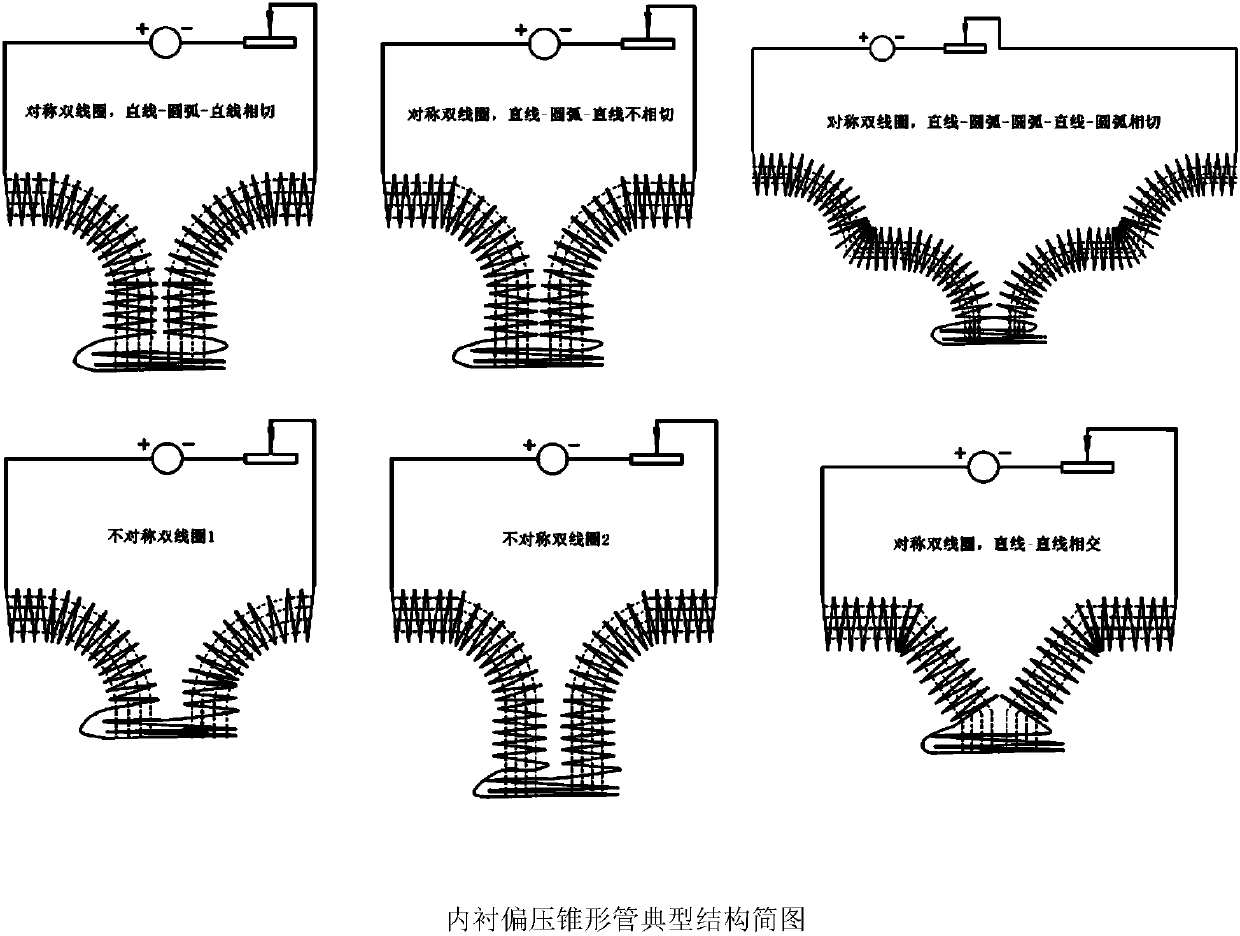

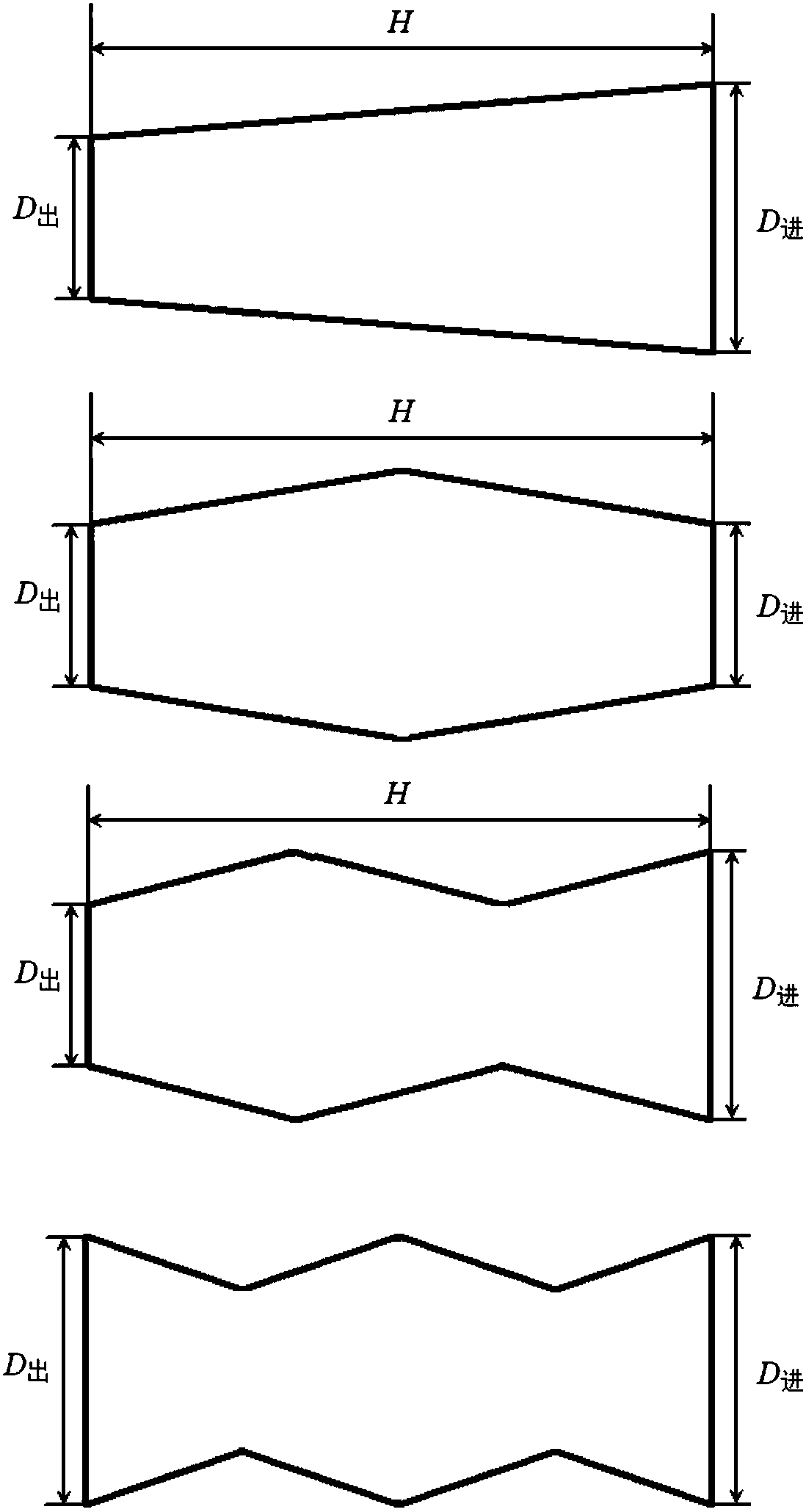

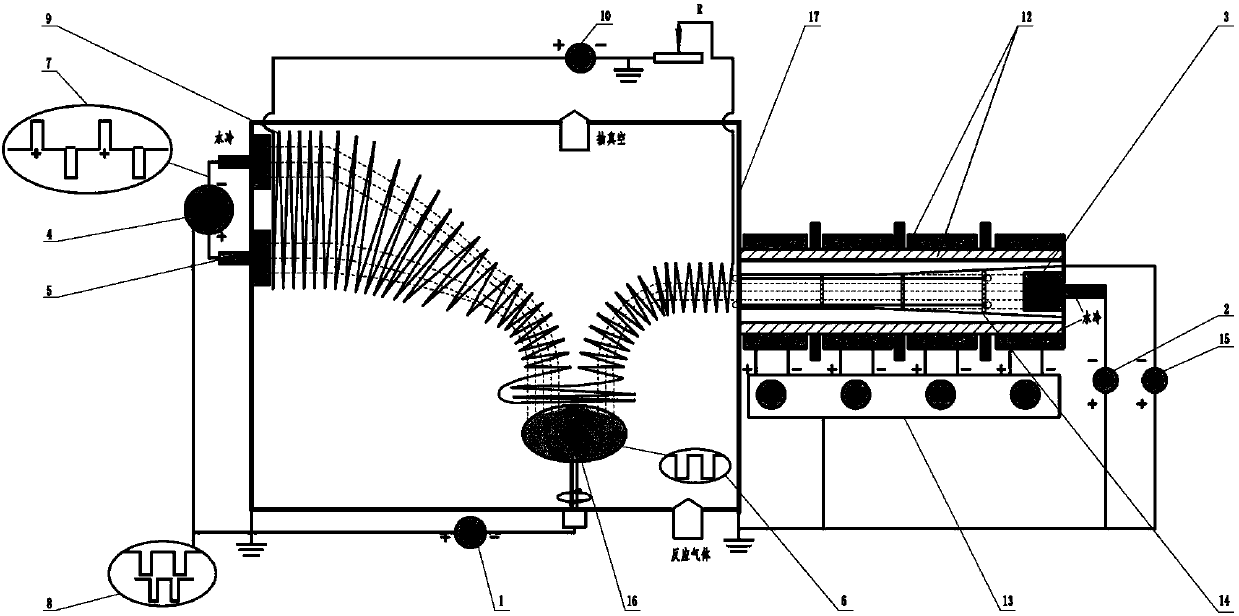

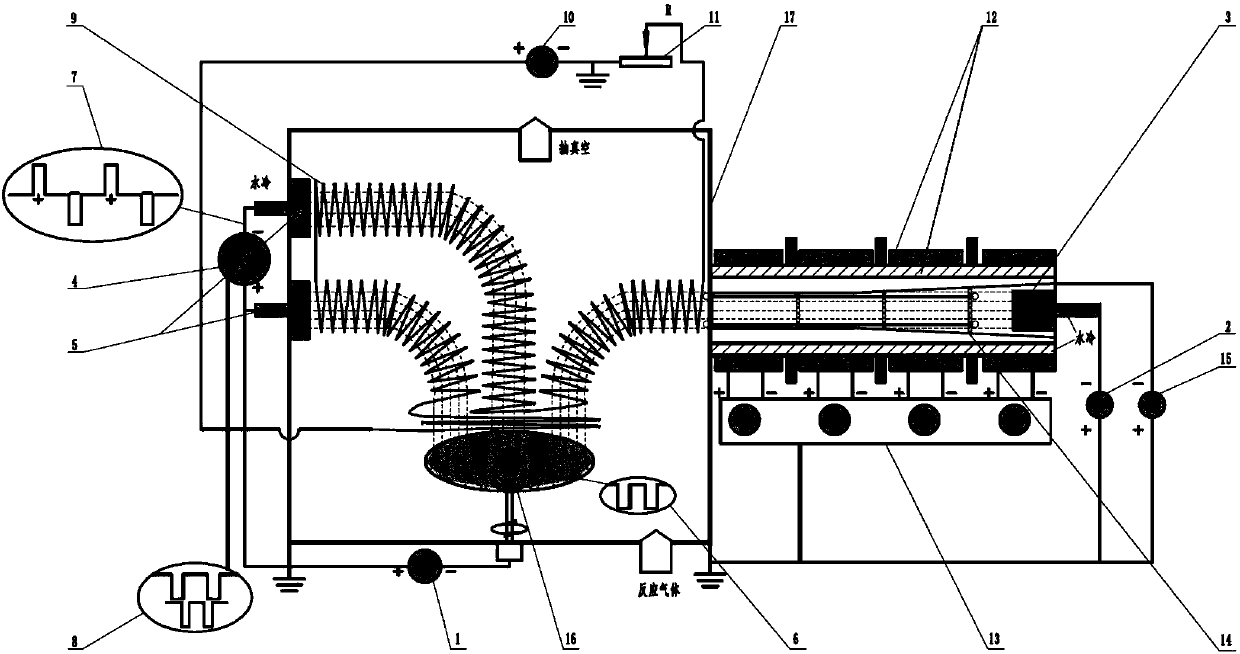

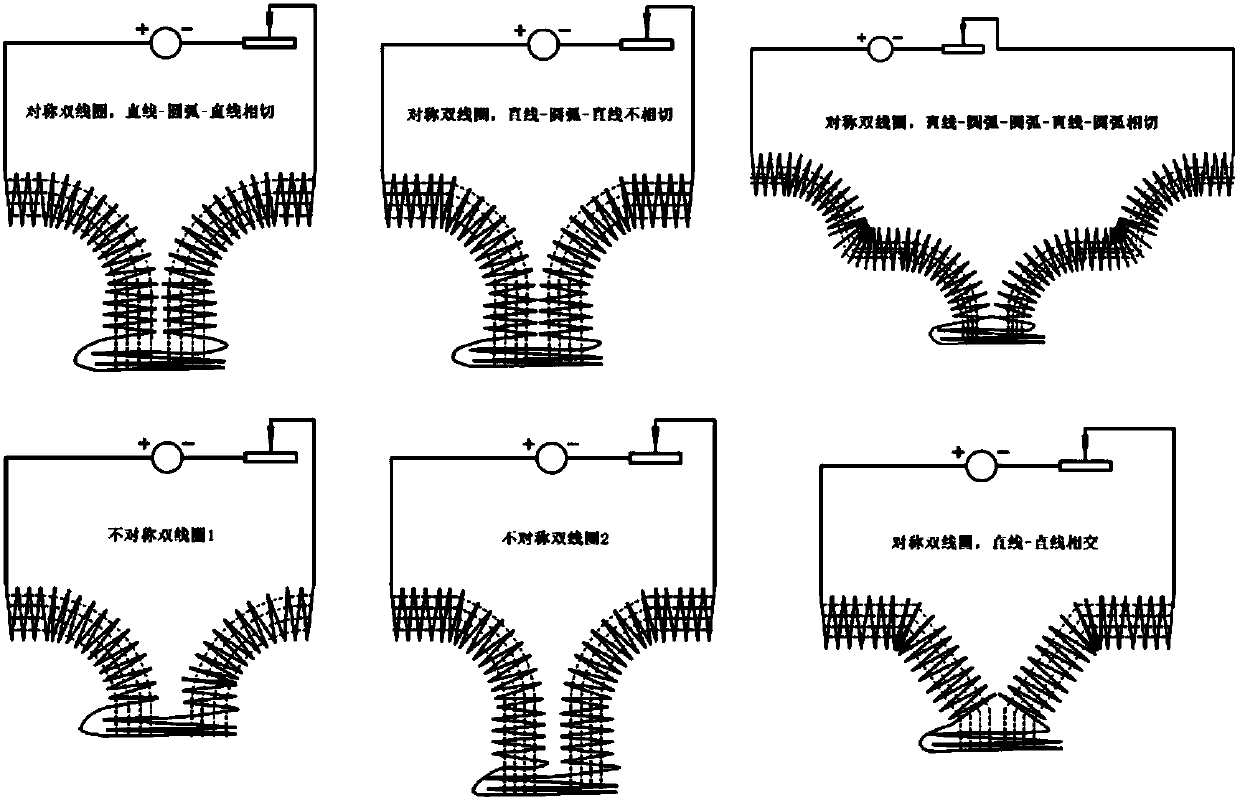

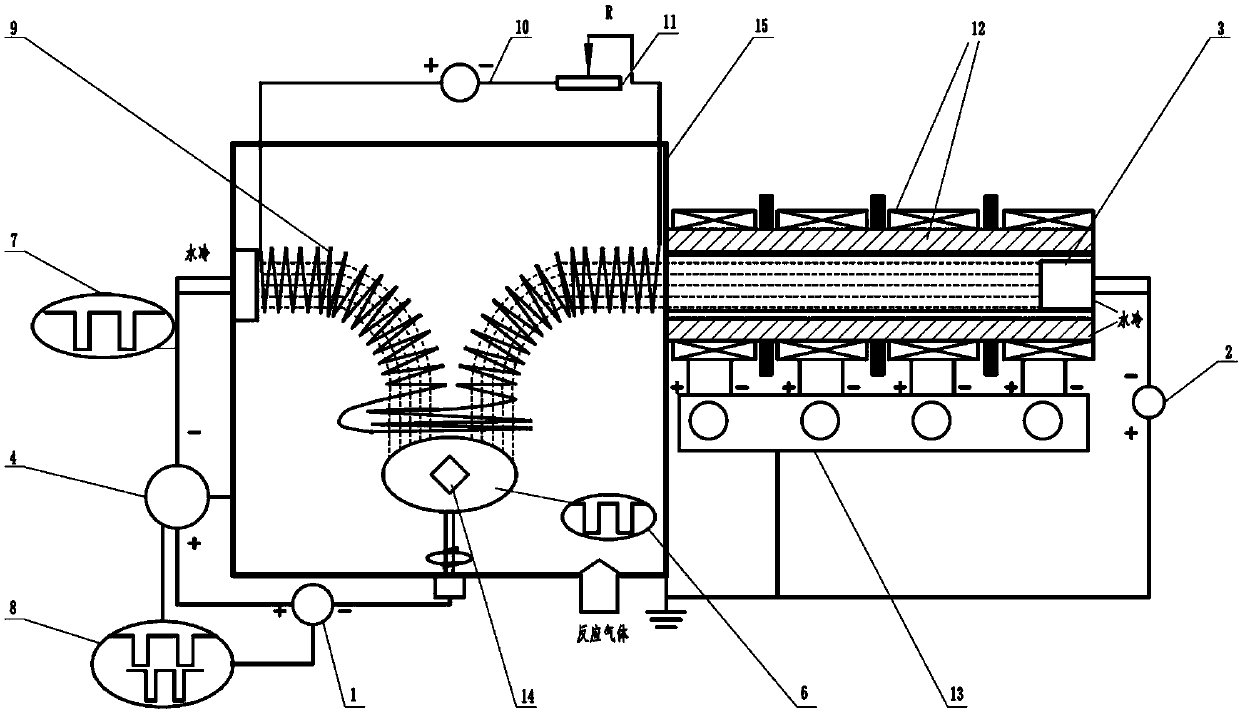

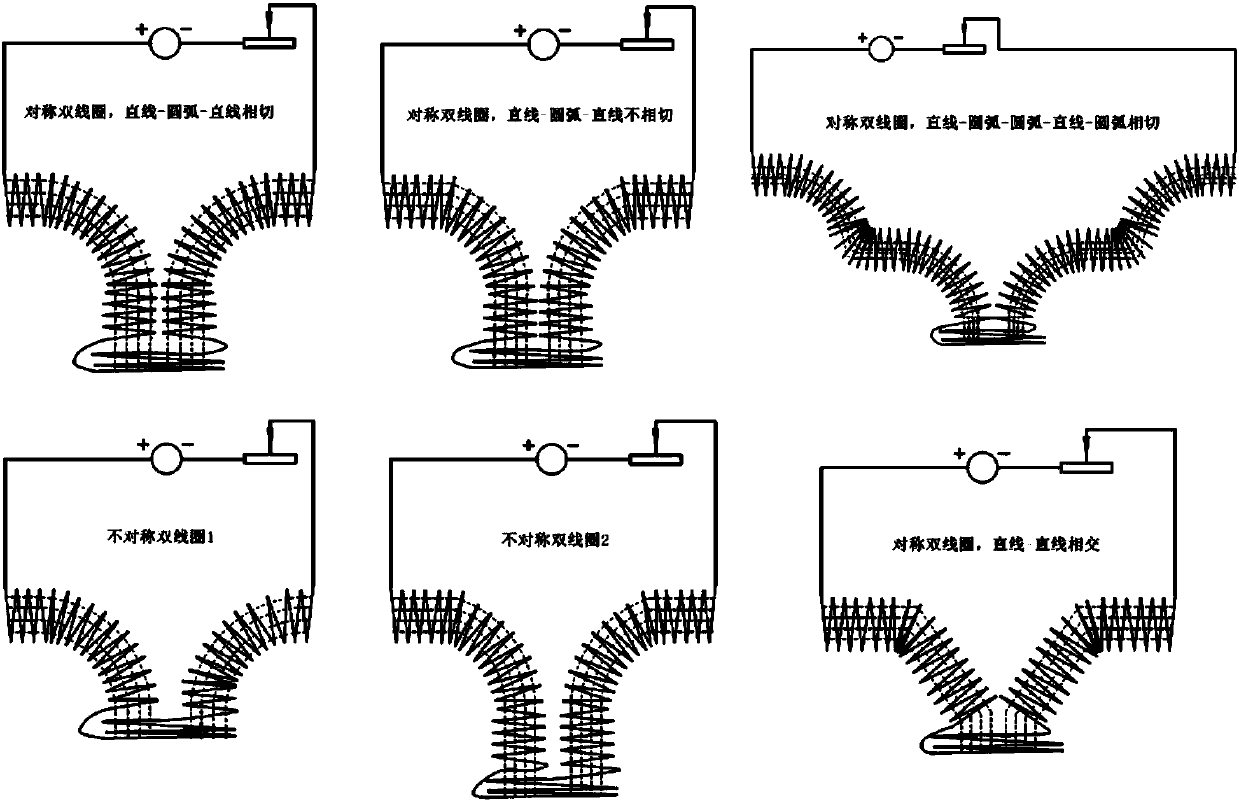

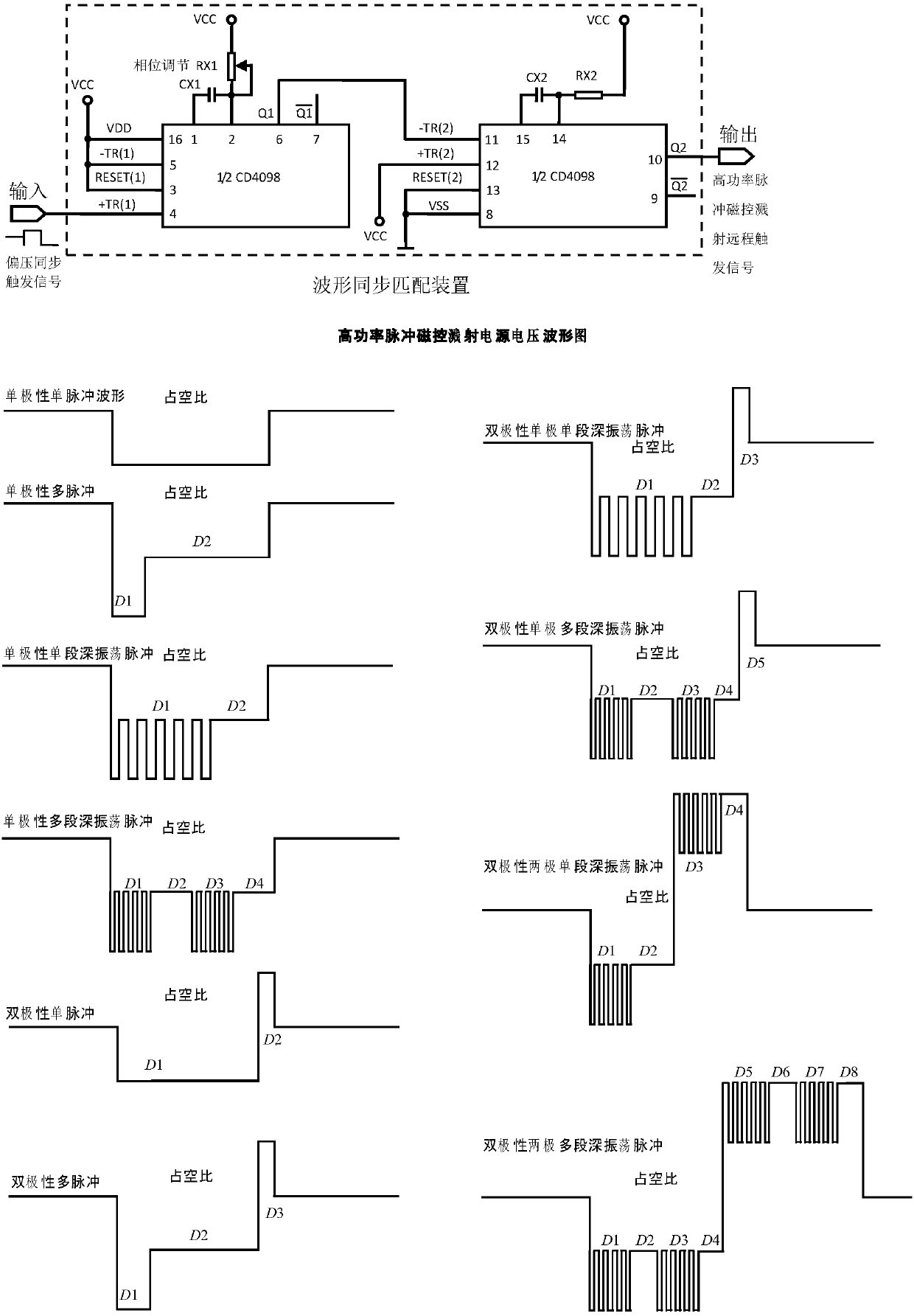

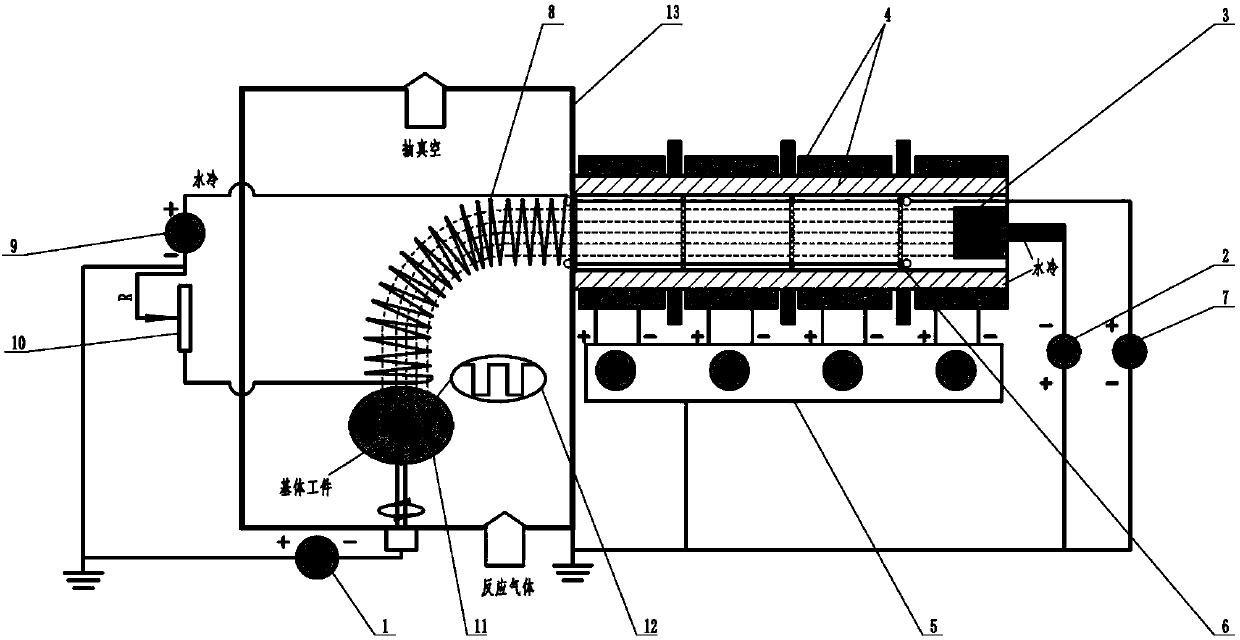

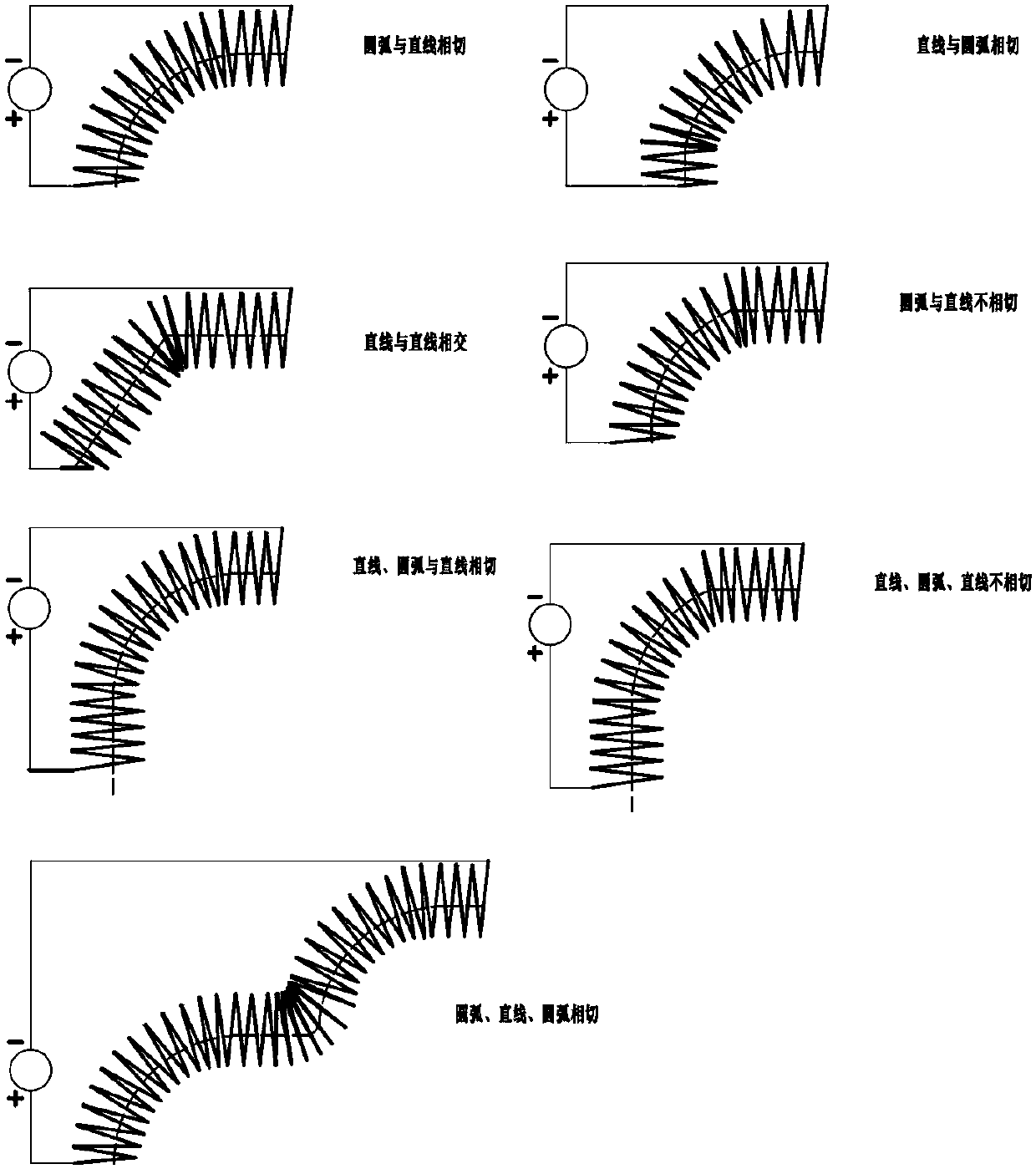

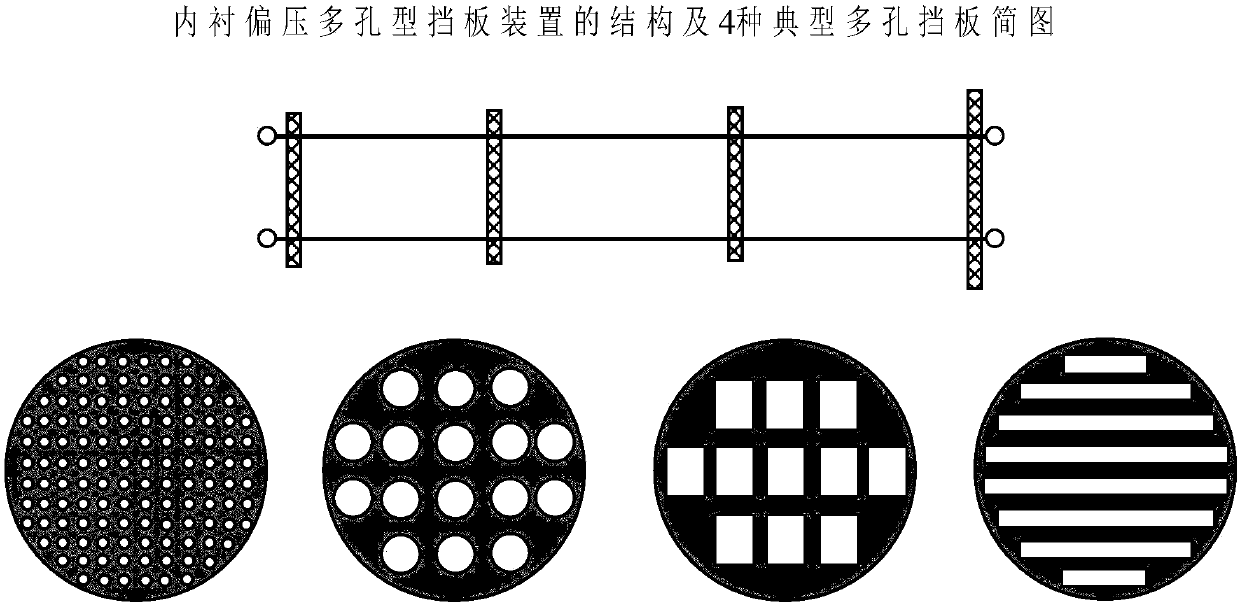

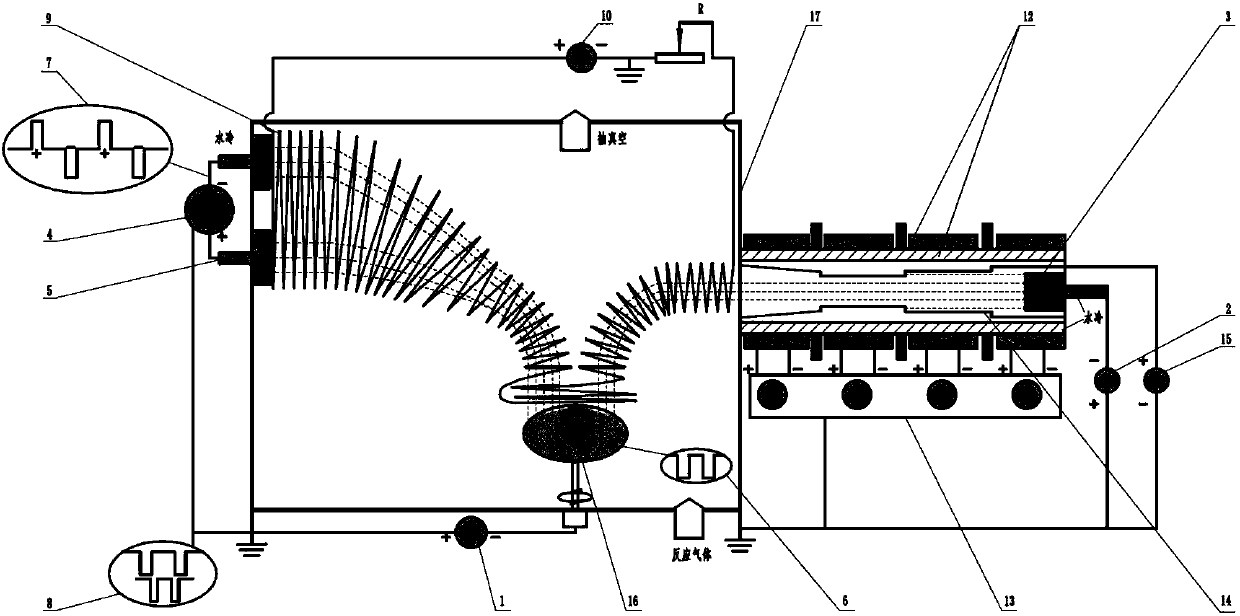

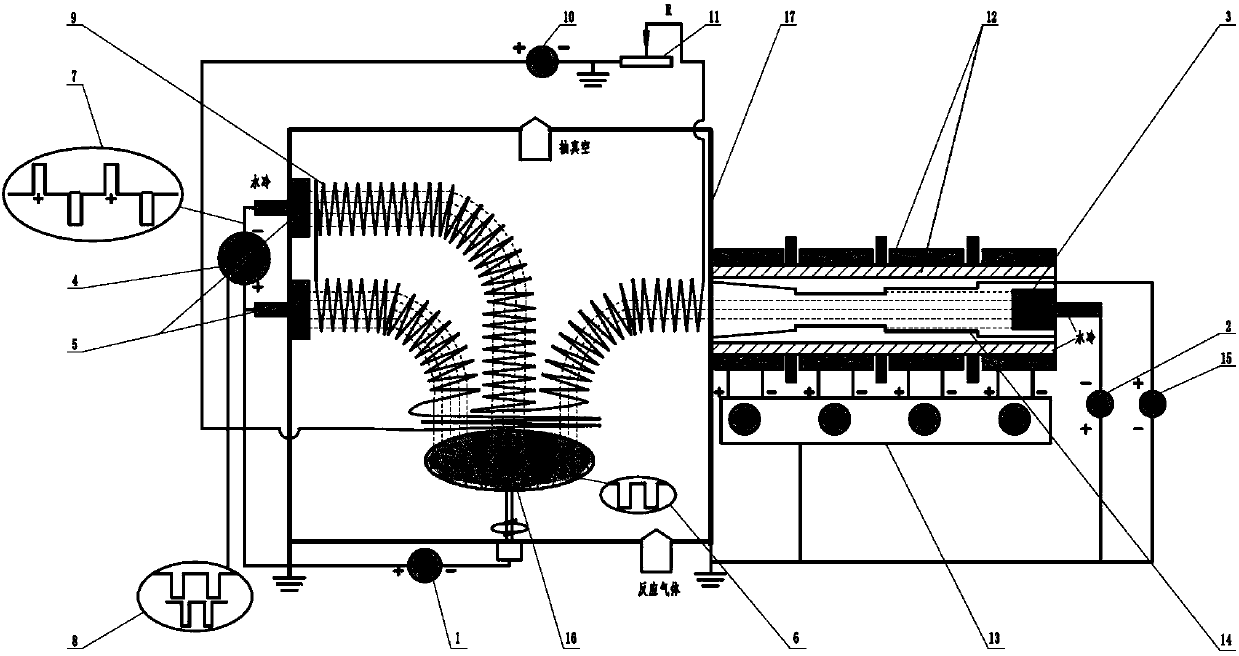

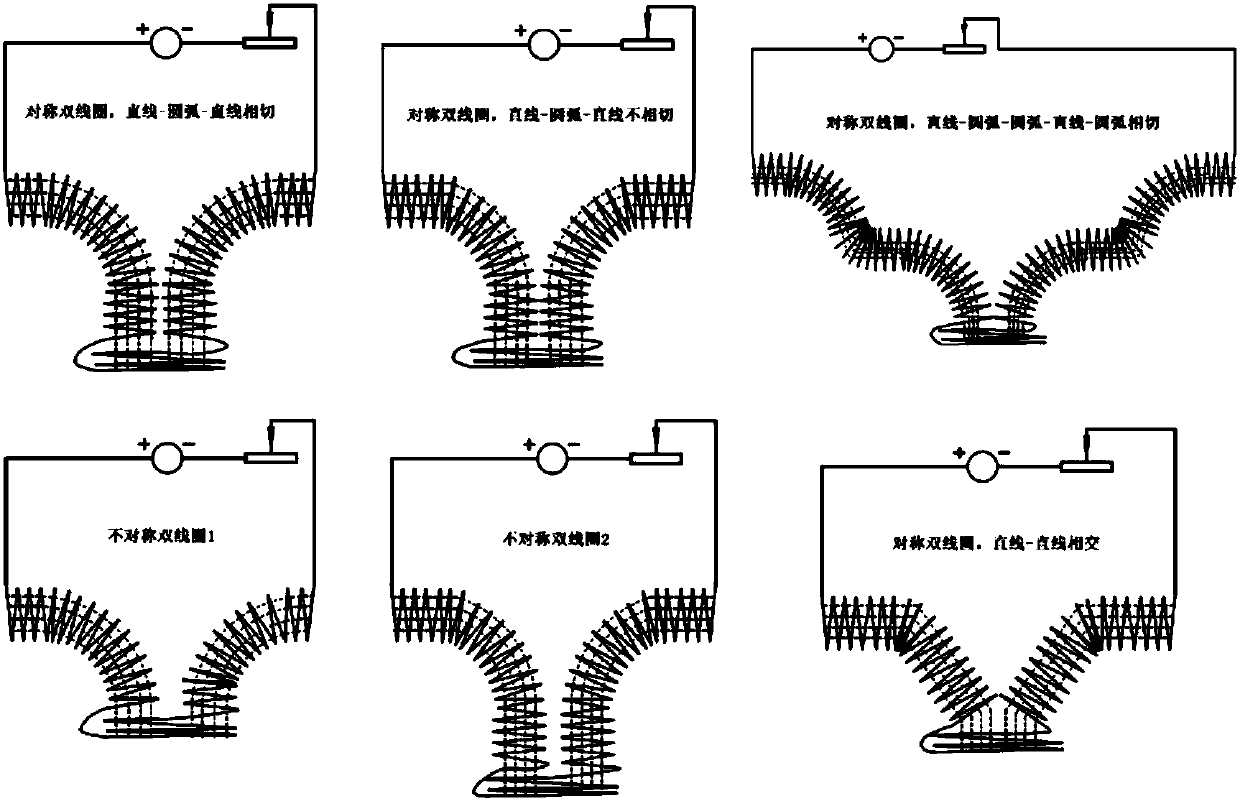

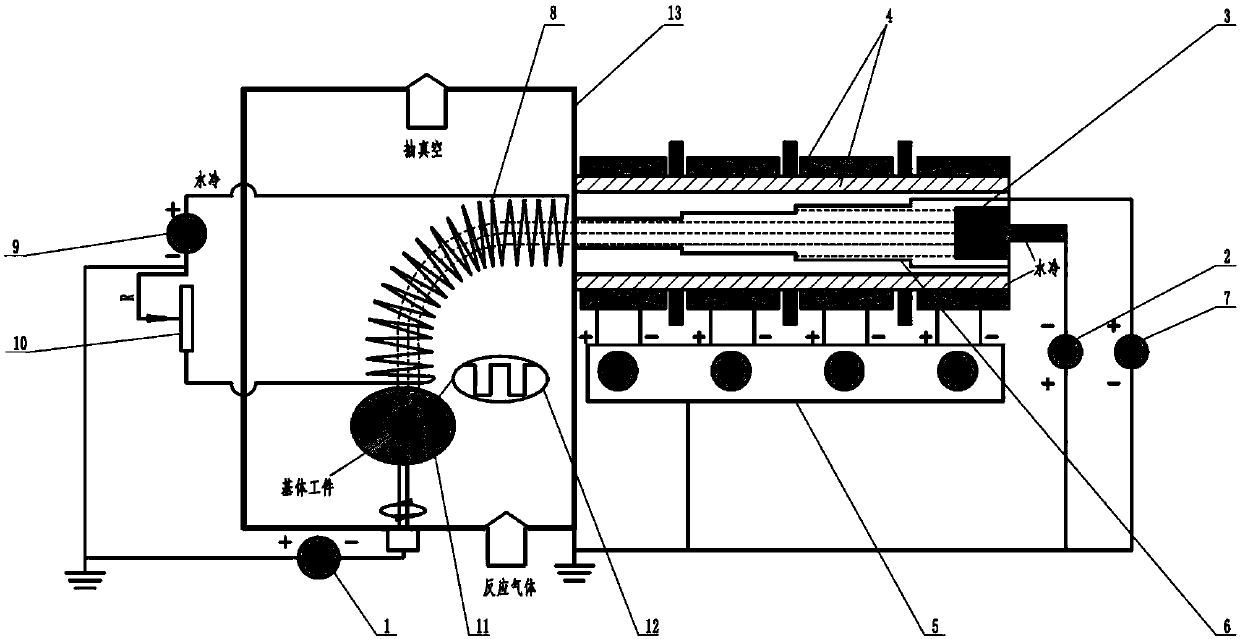

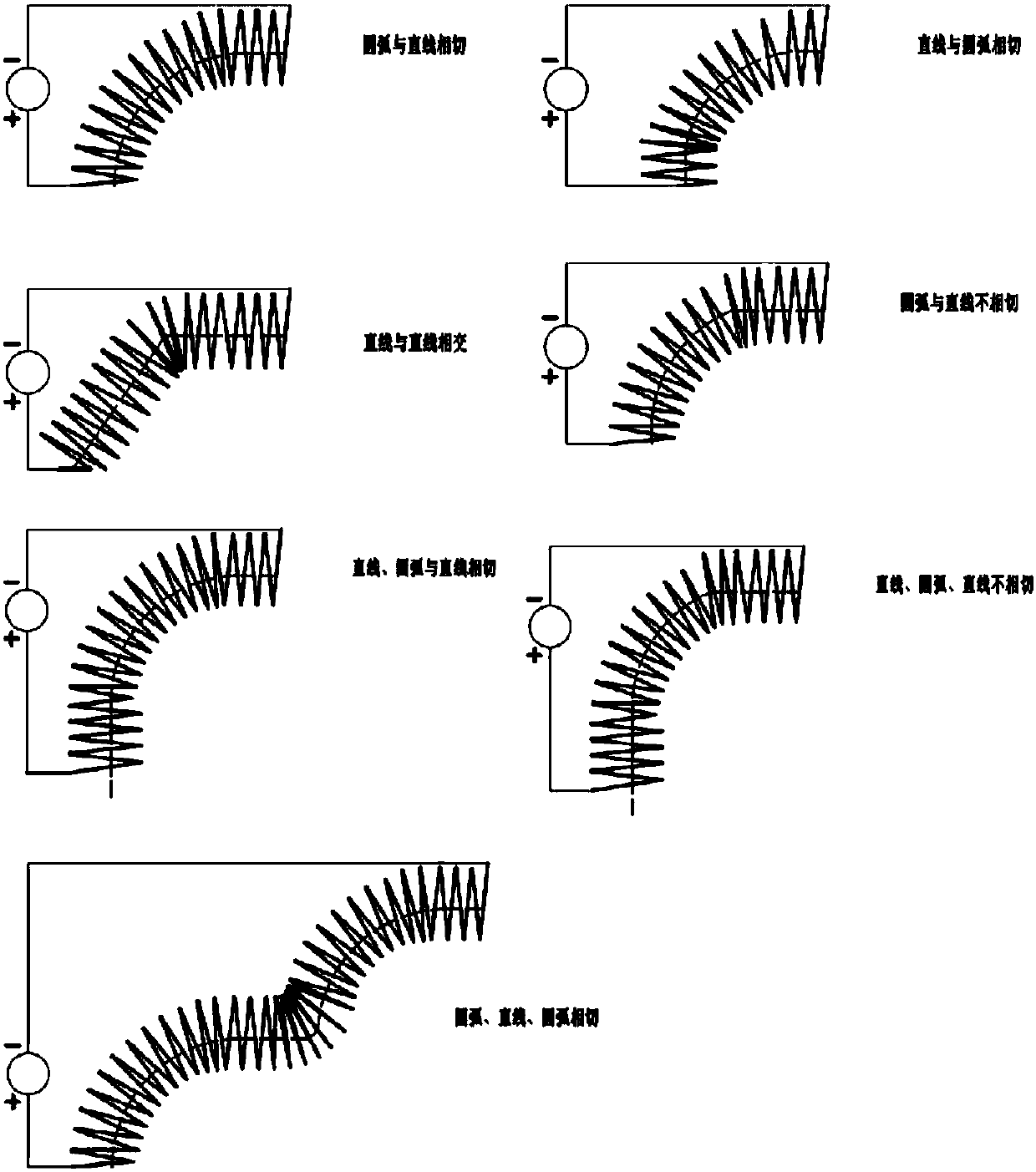

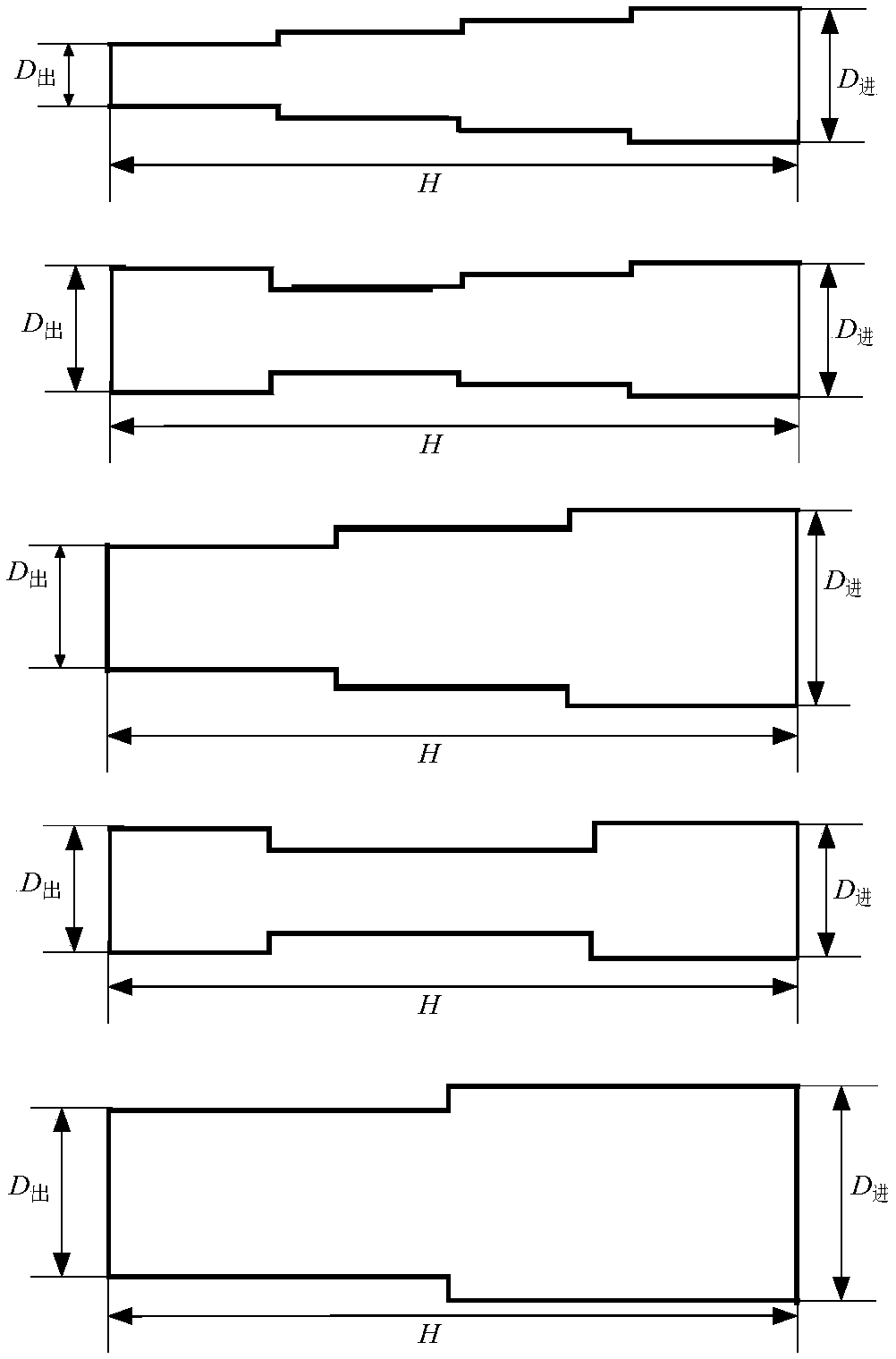

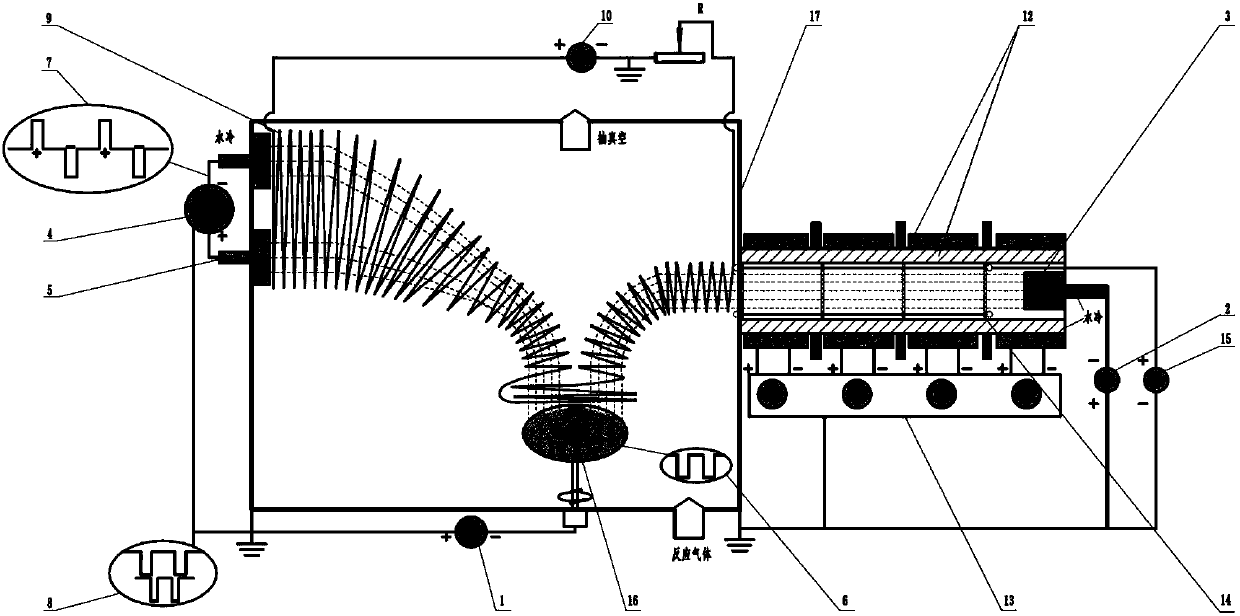

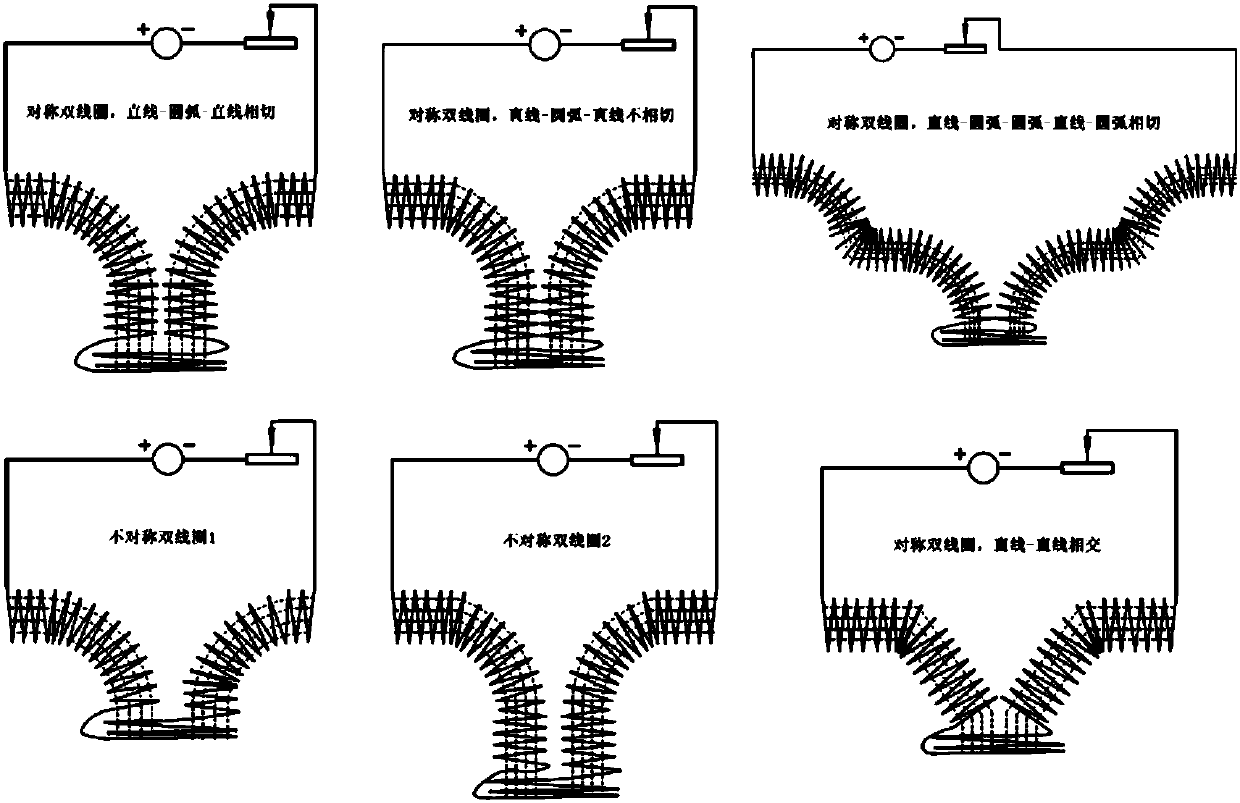

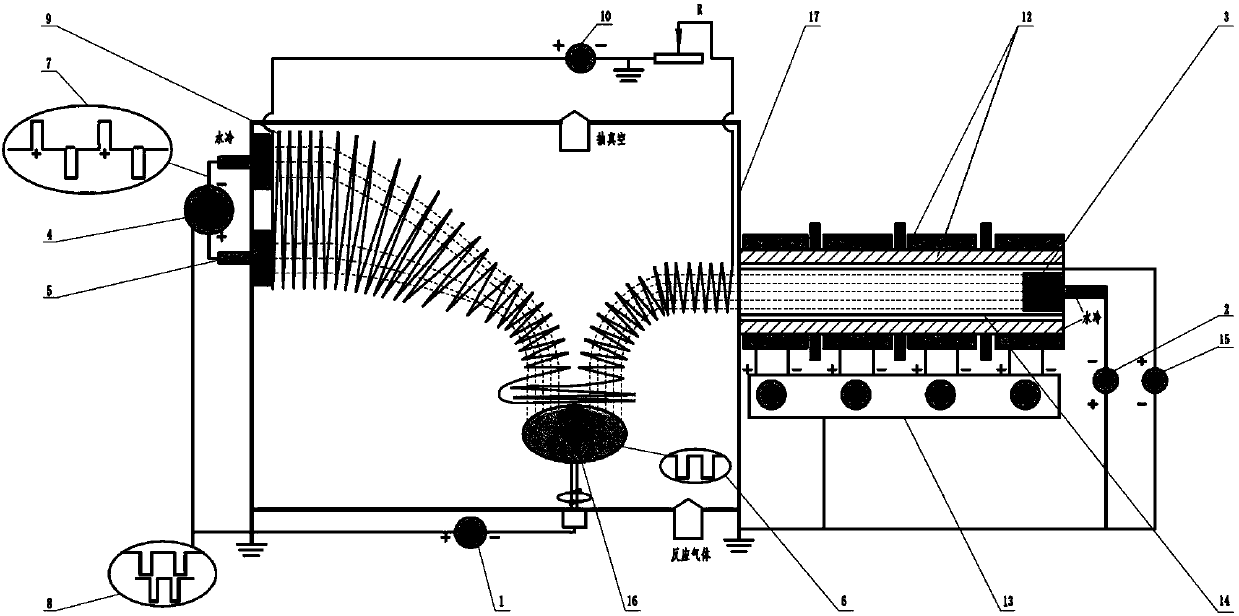

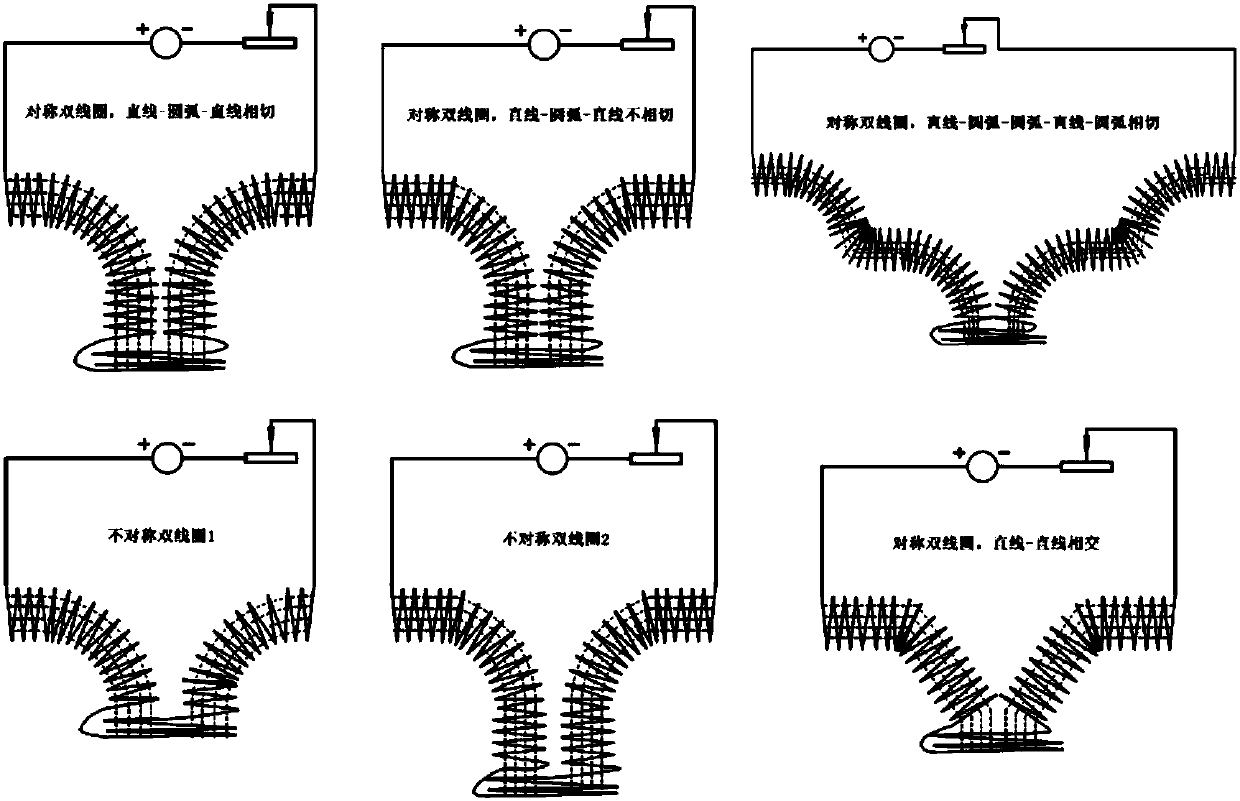

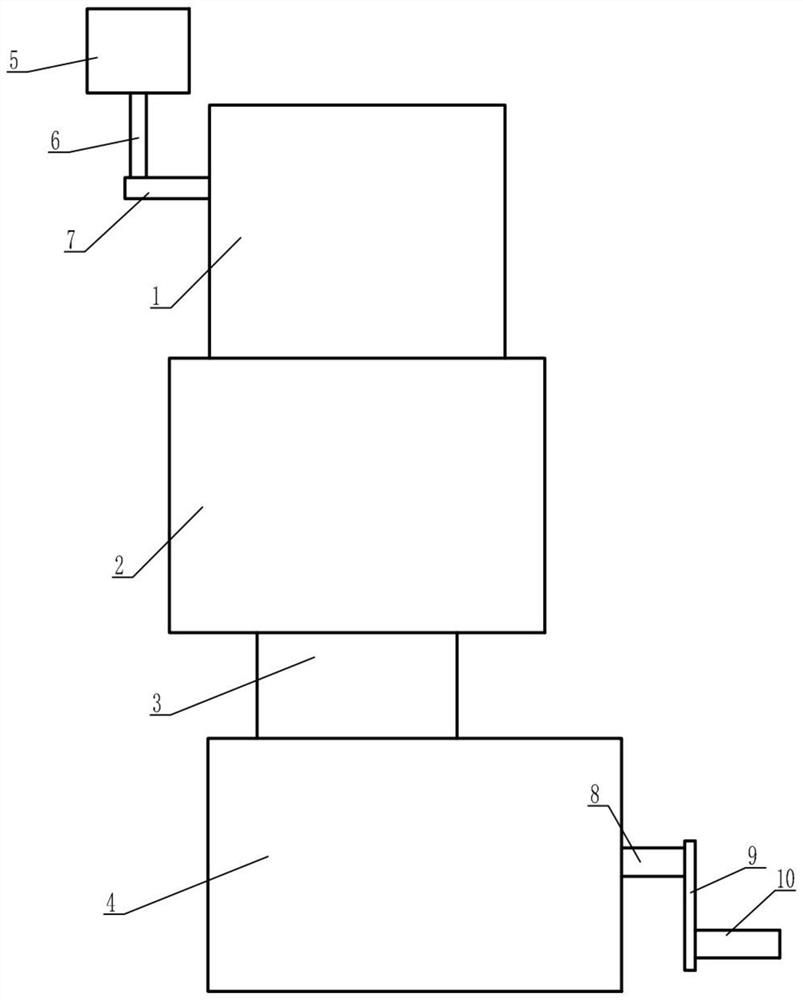

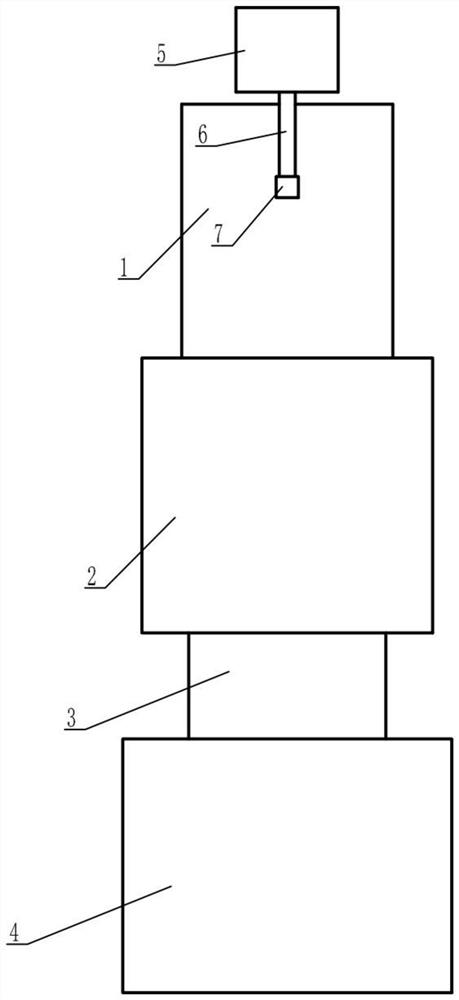

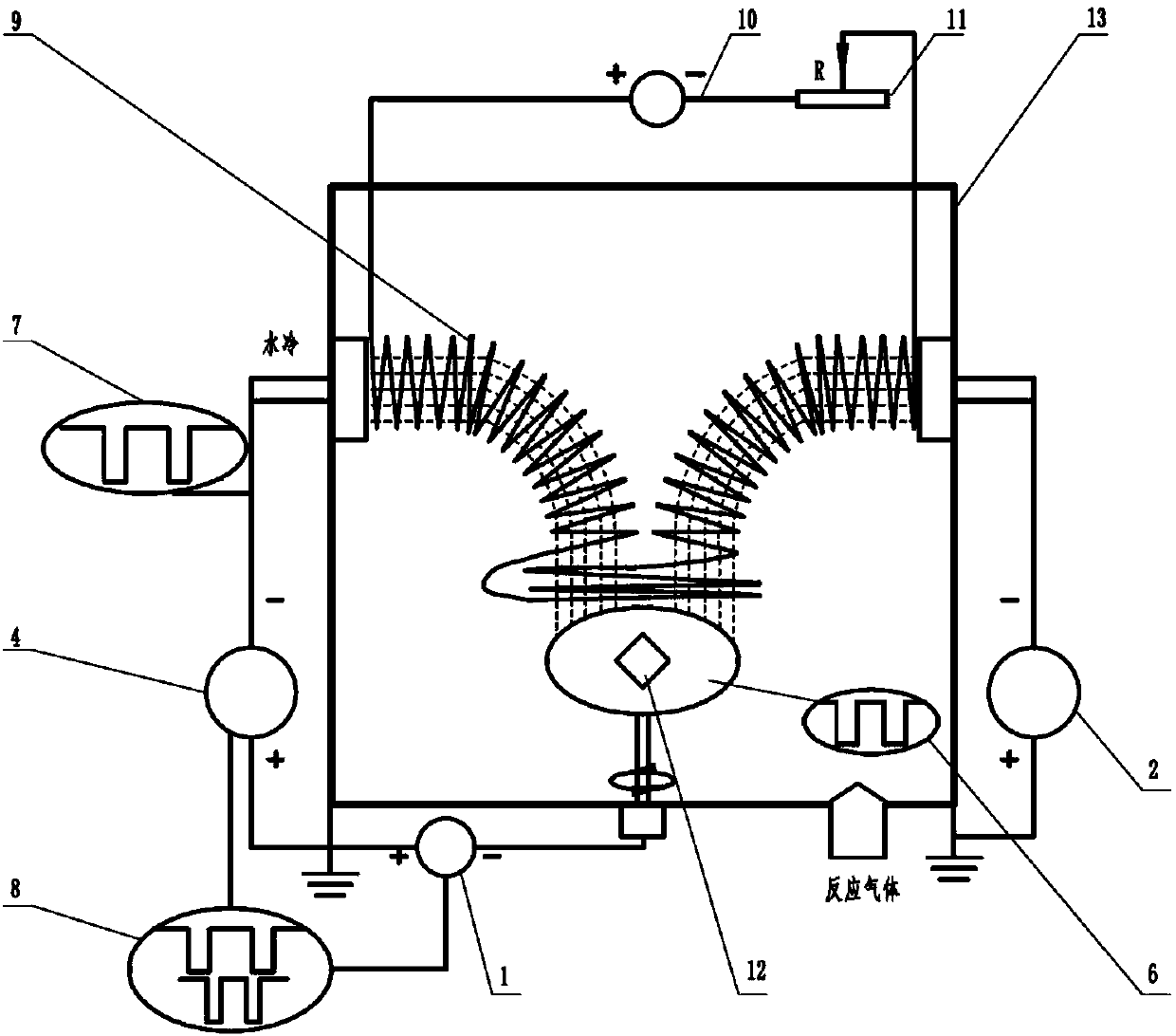

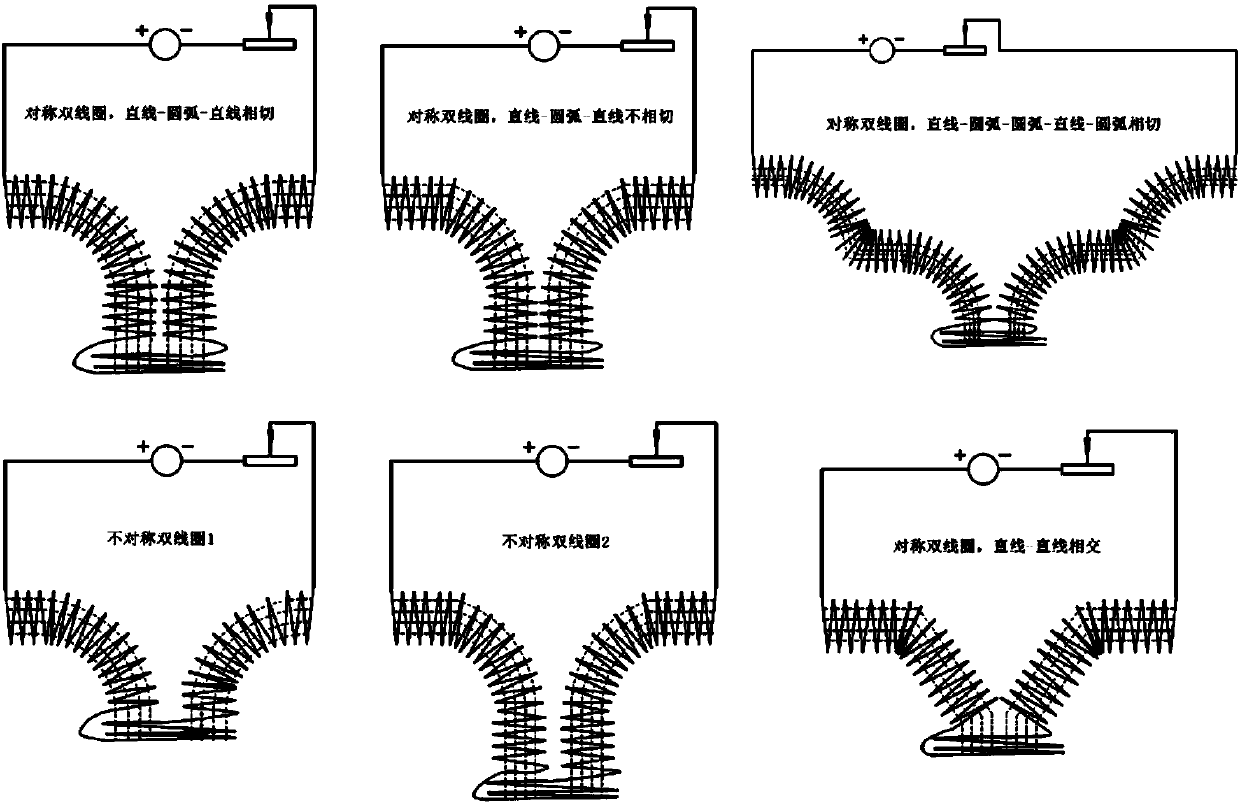

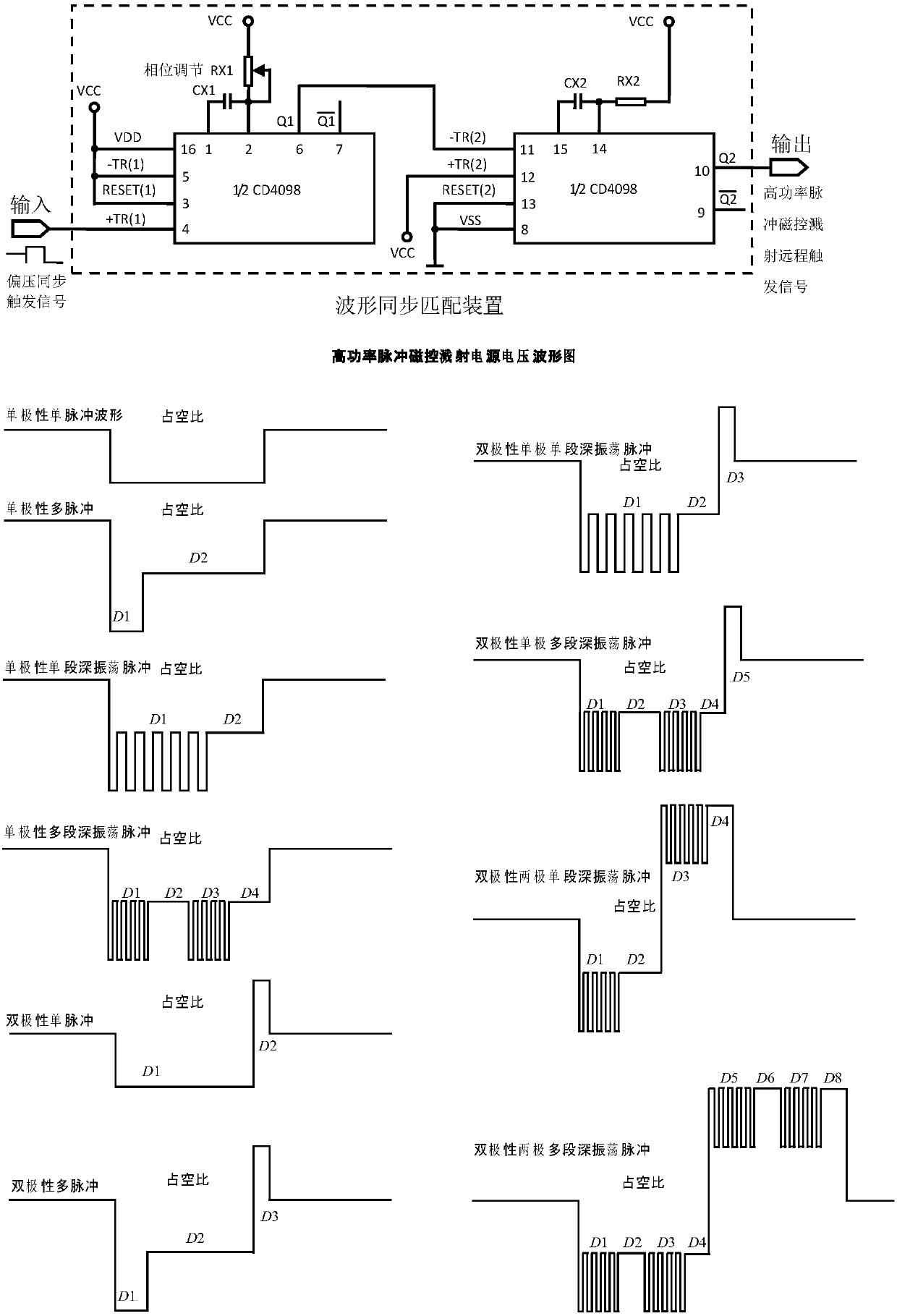

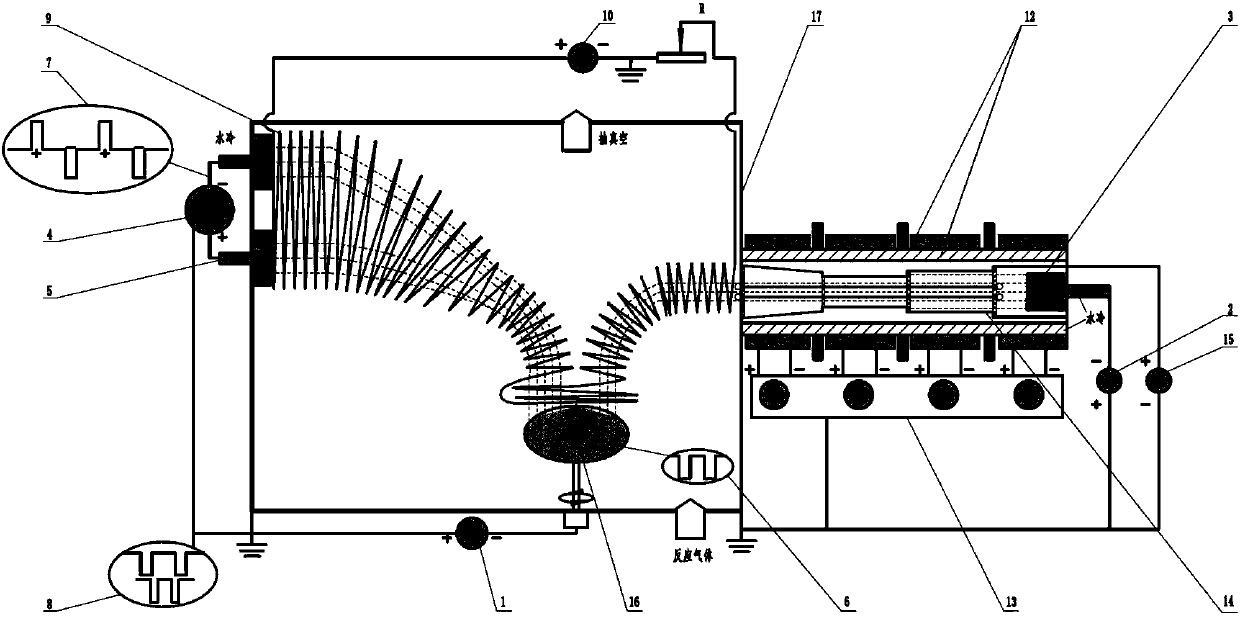

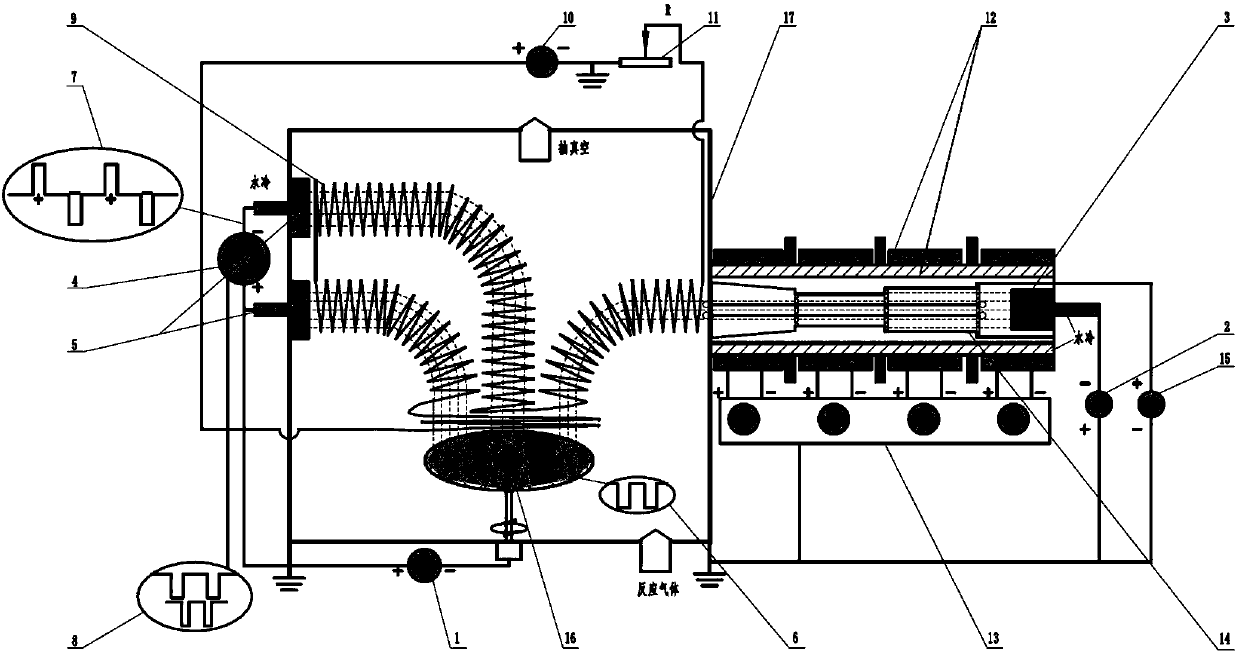

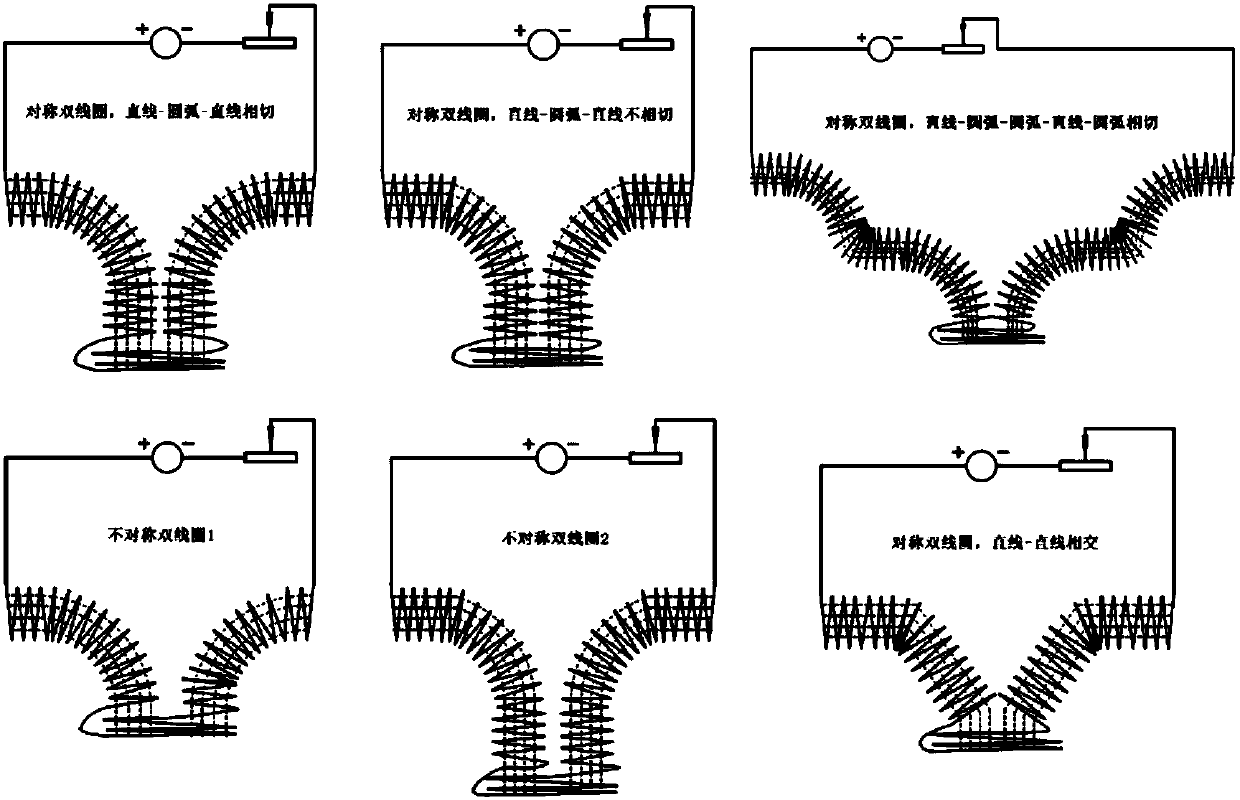

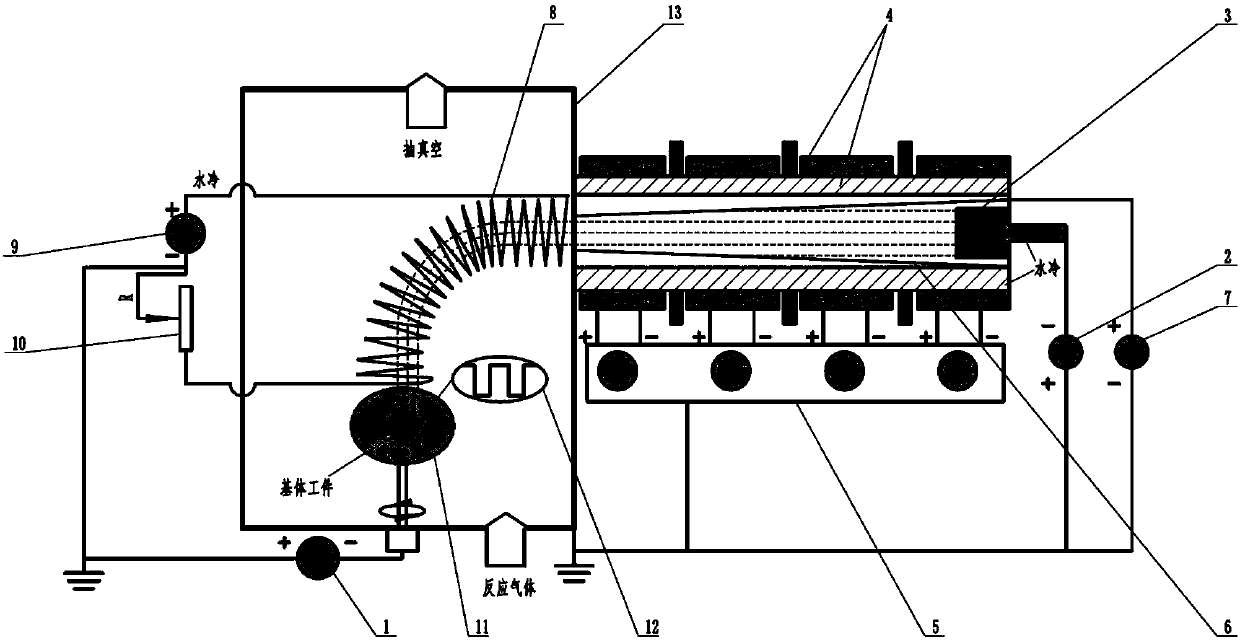

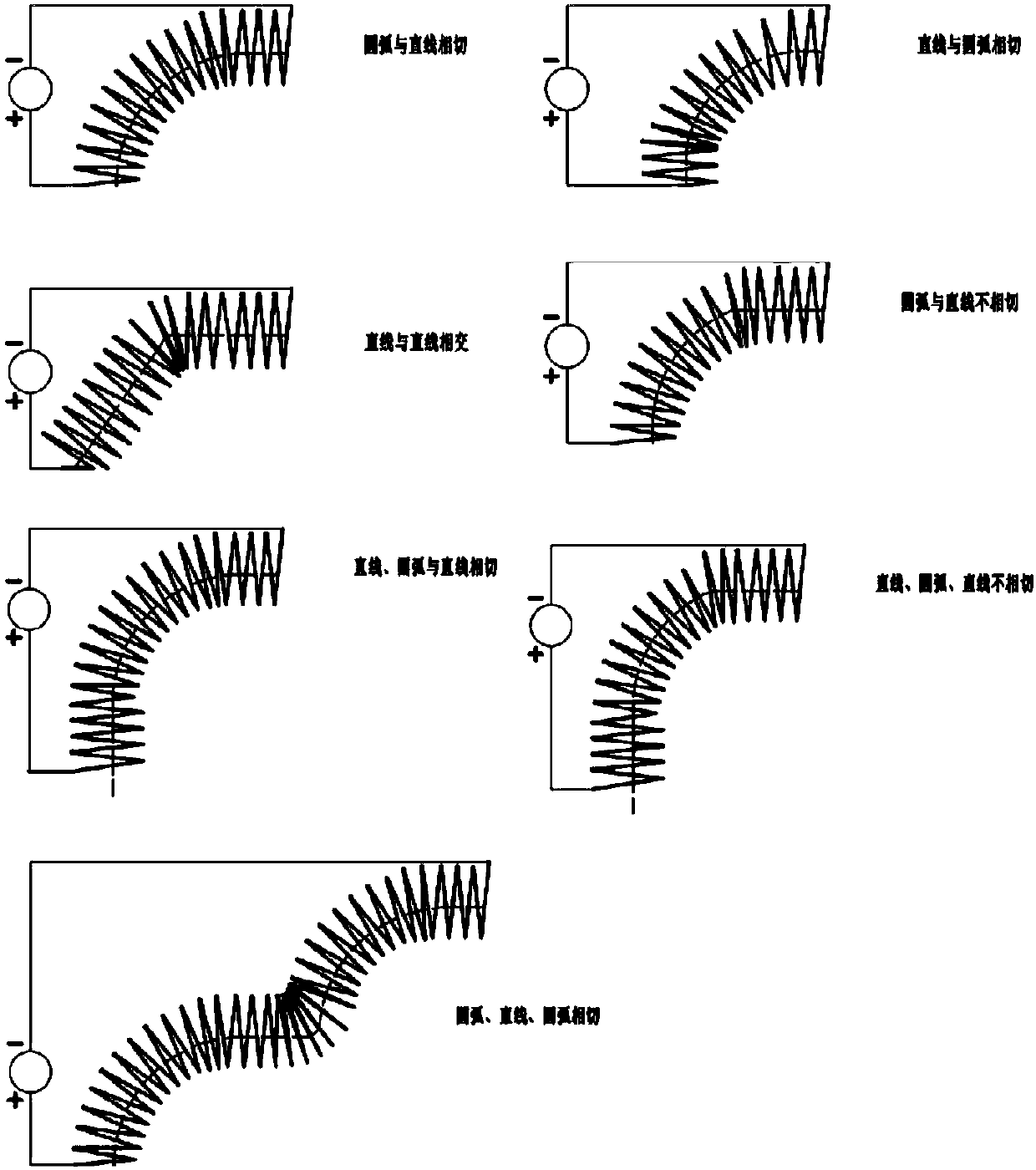

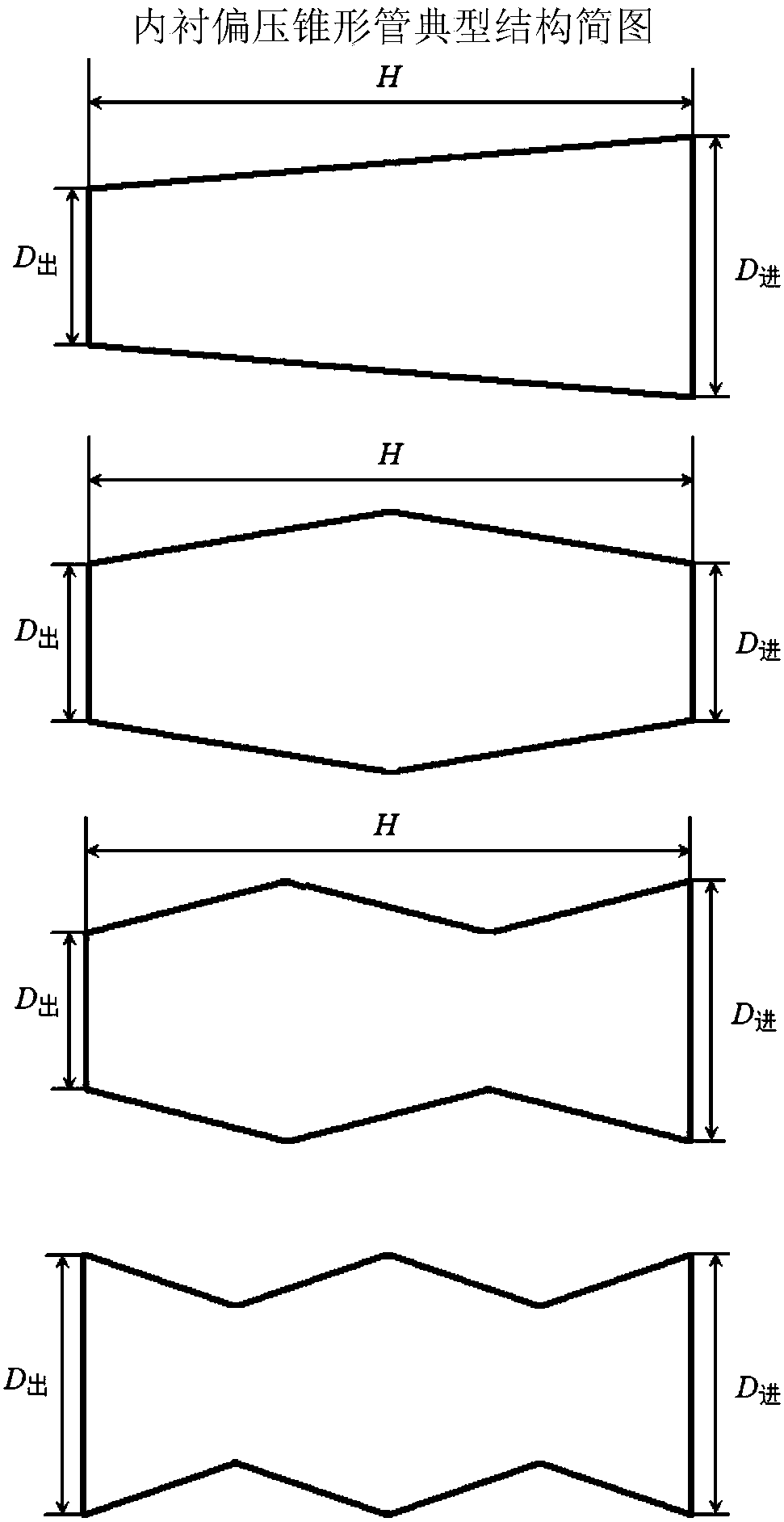

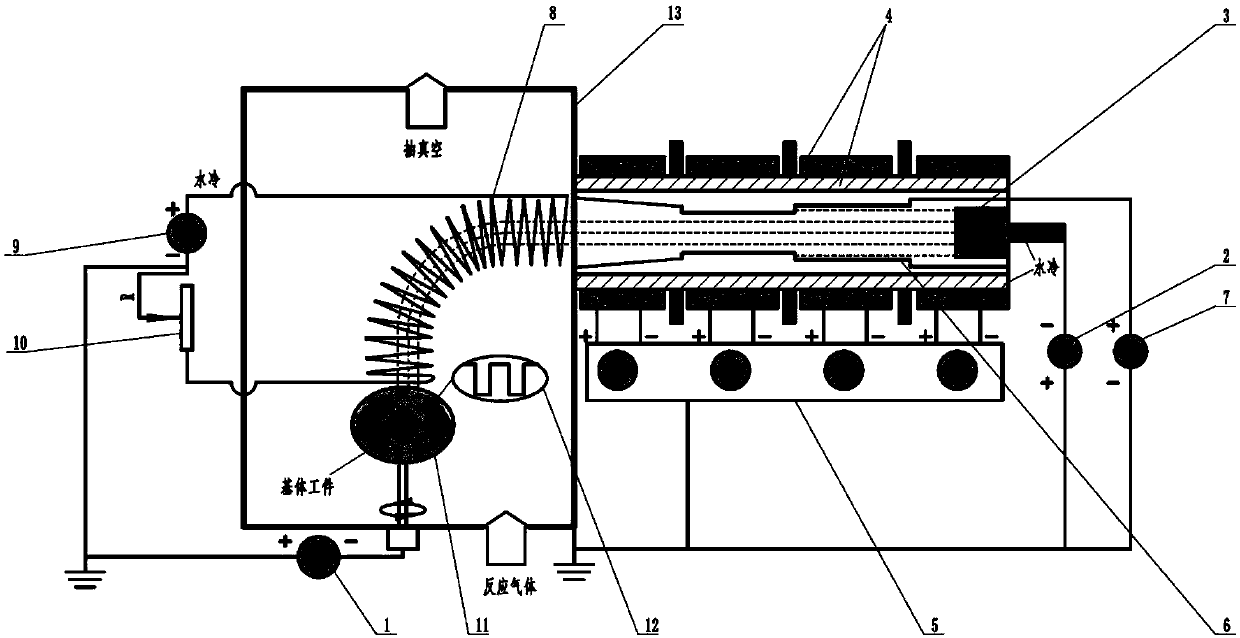

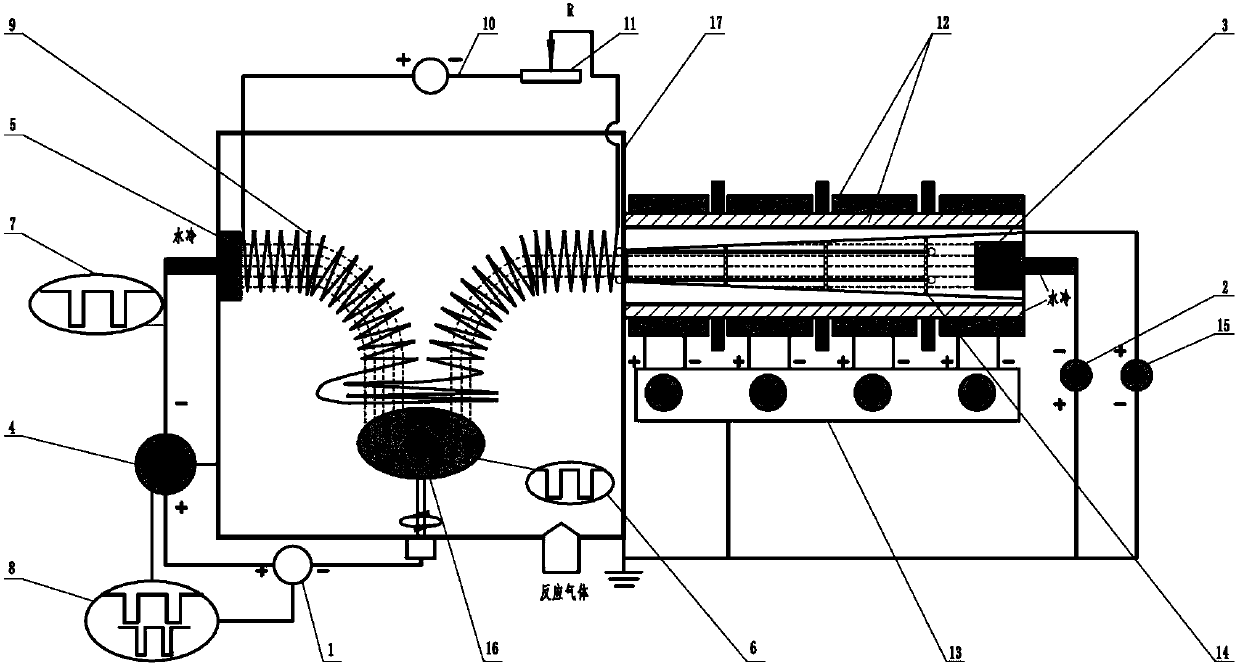

Composite filtered arc ion plating of combination magnetic field, lined tapered tube and porous baffle

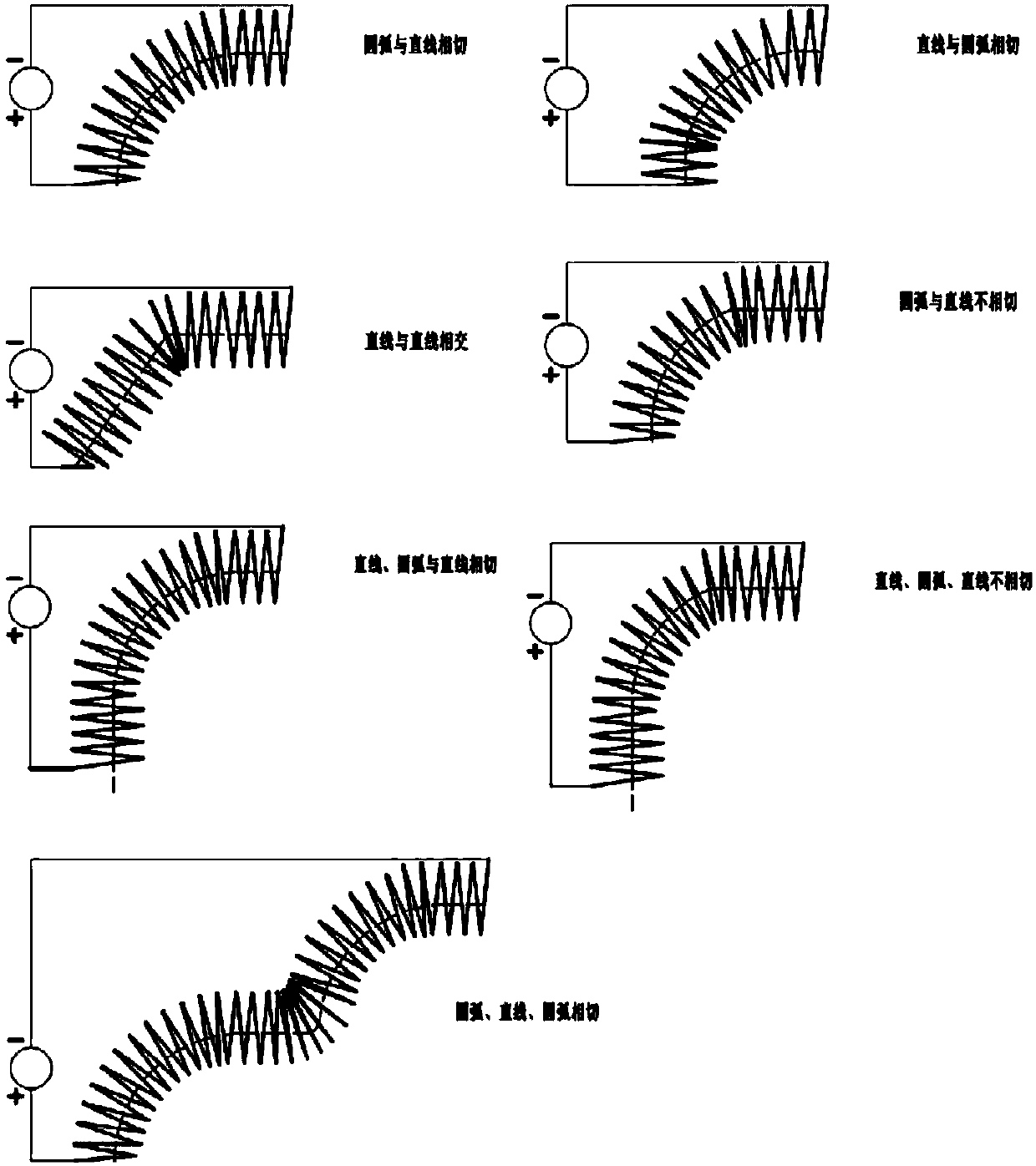

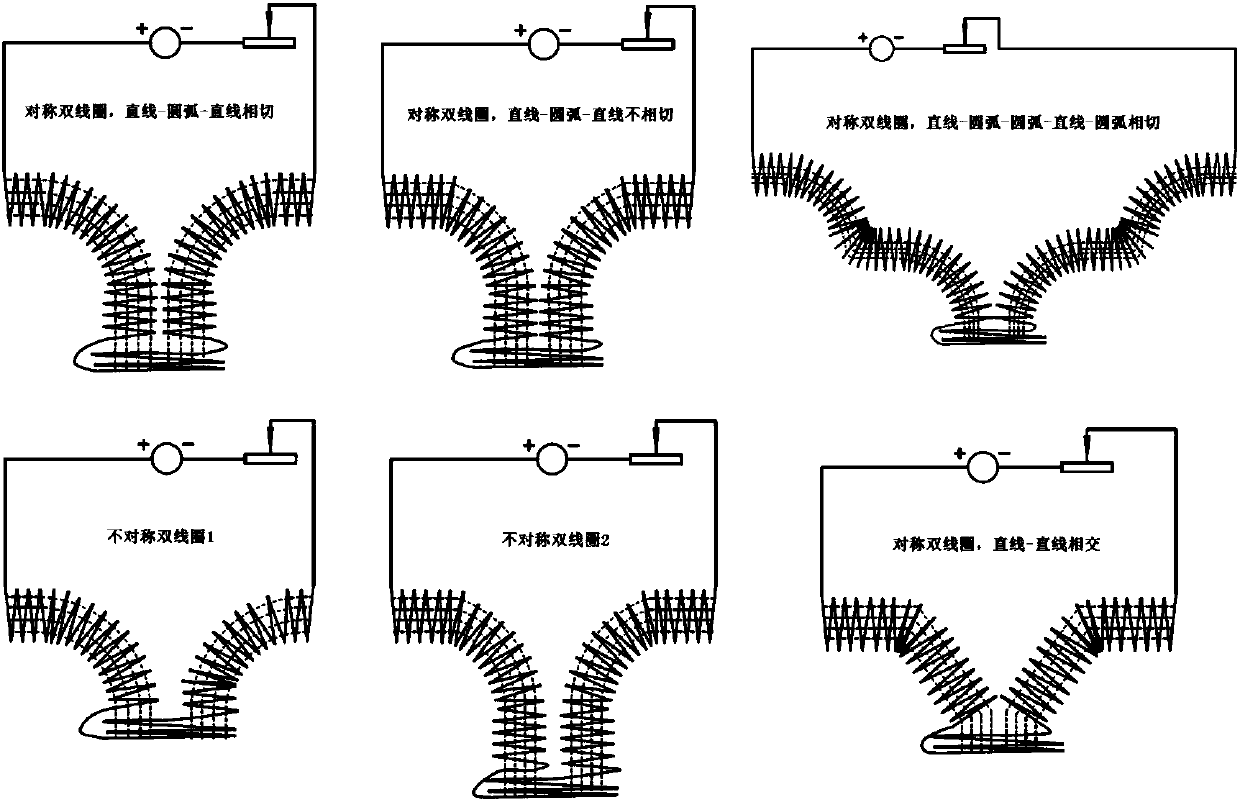

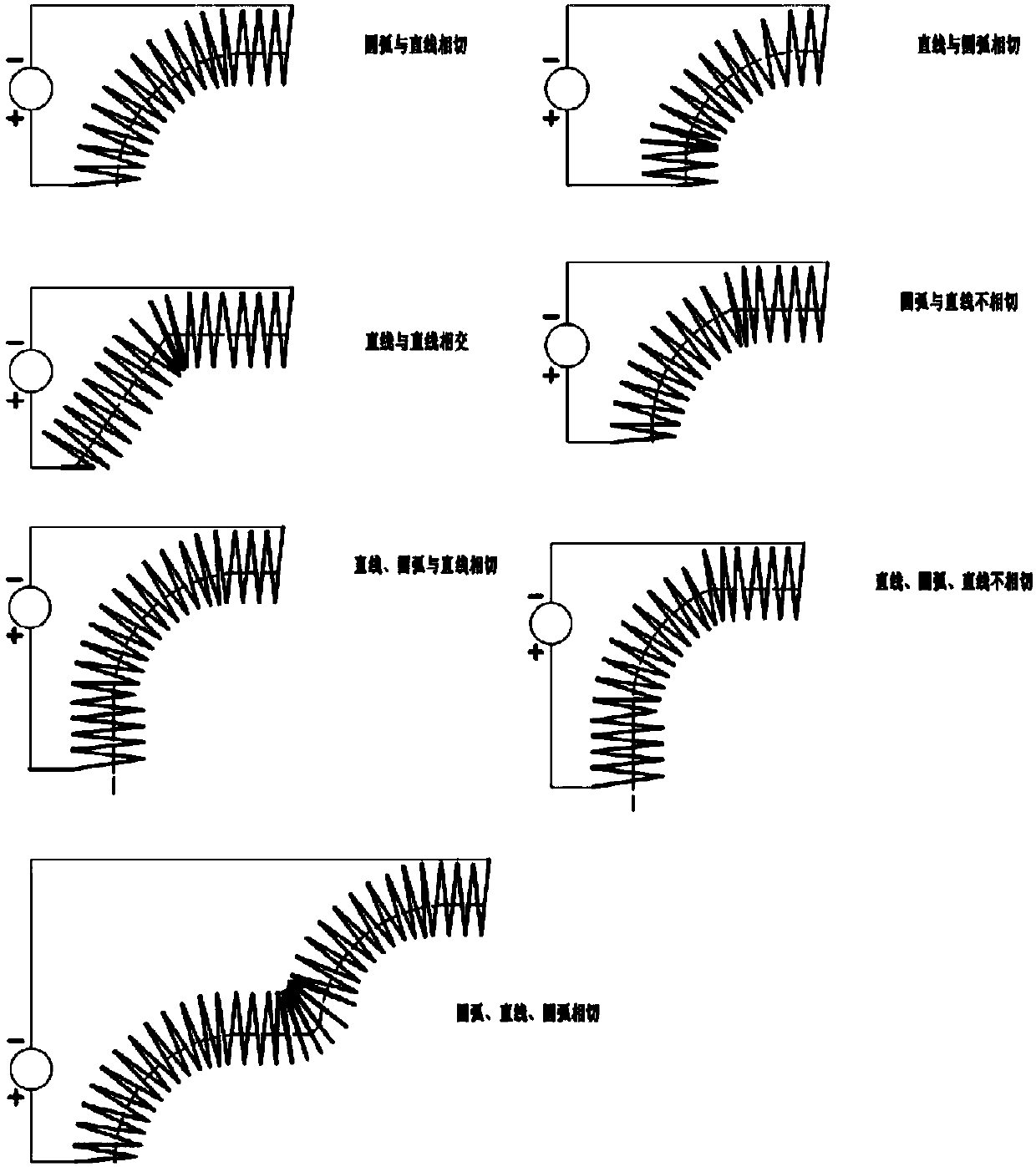

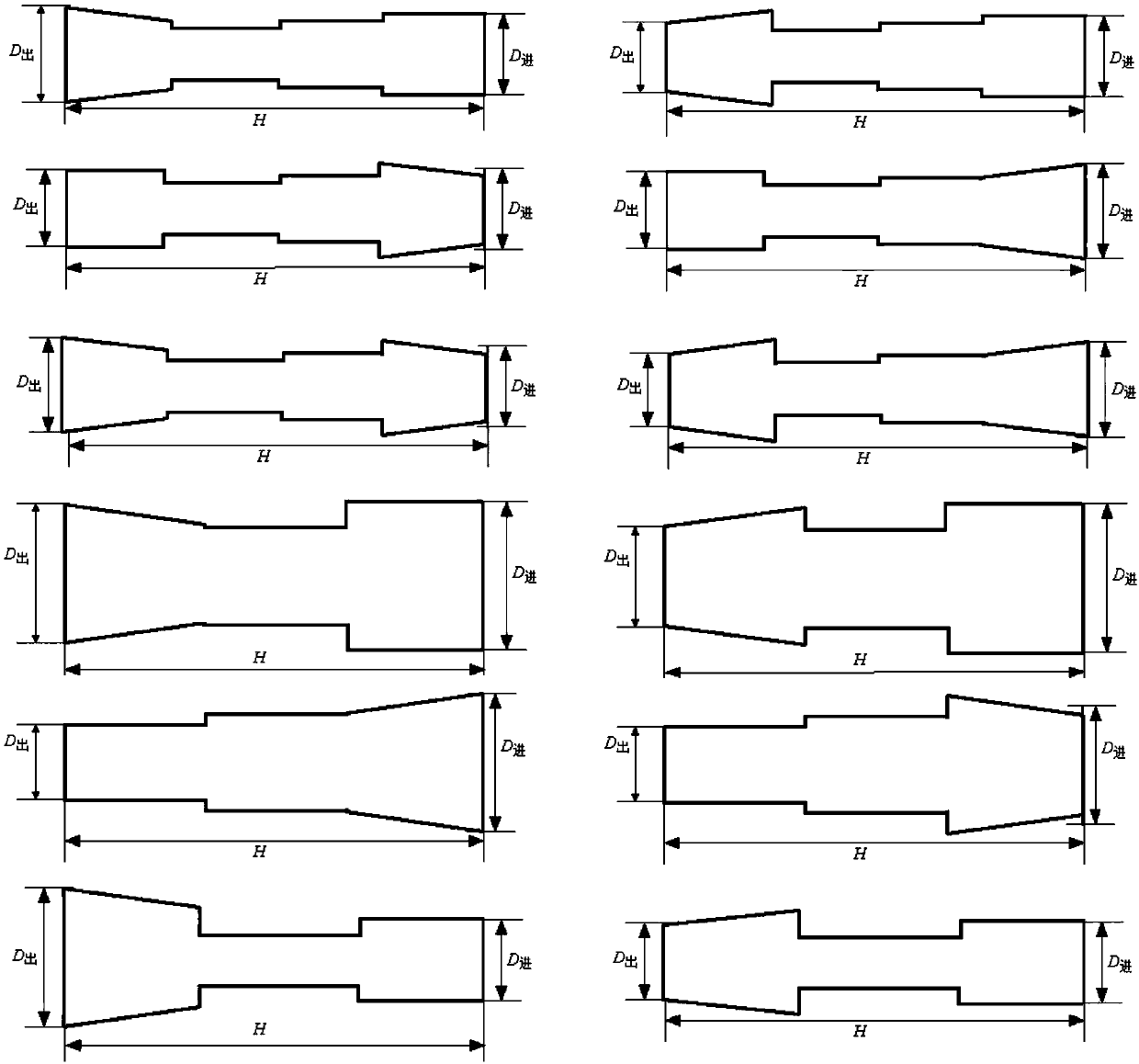

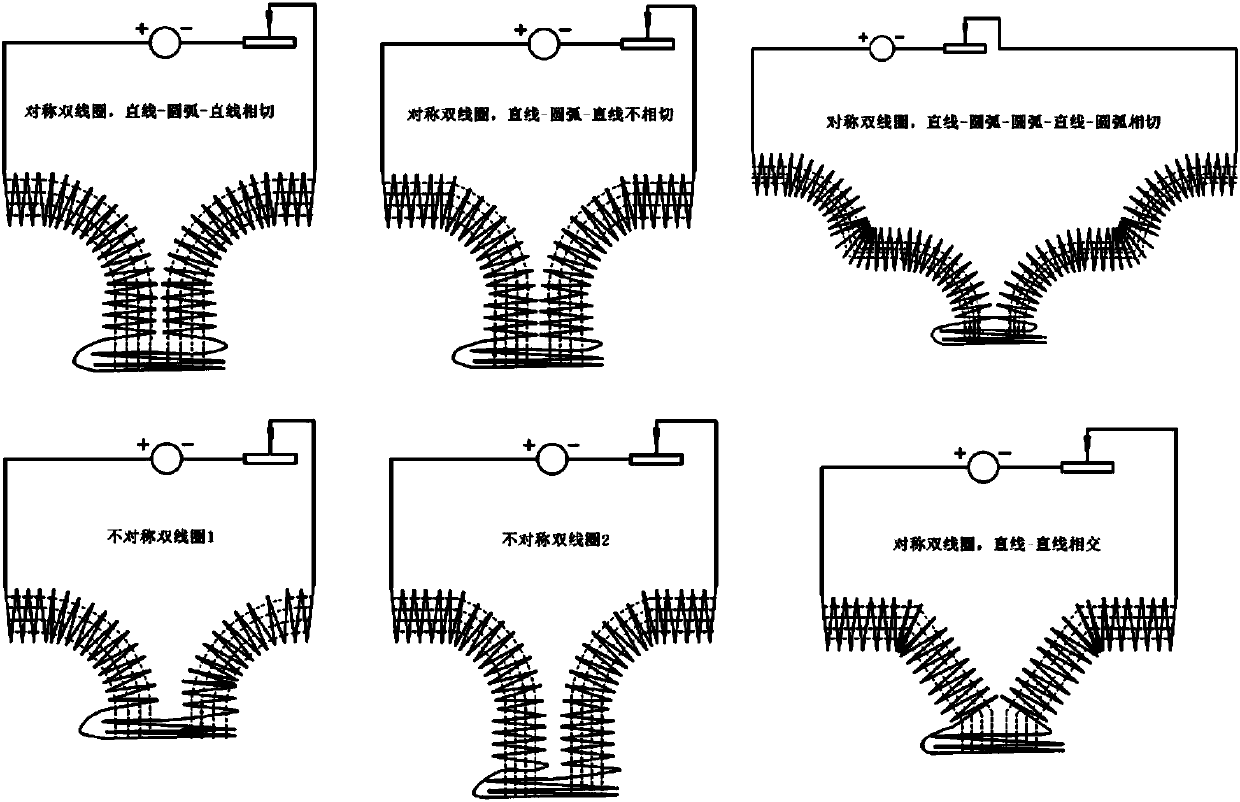

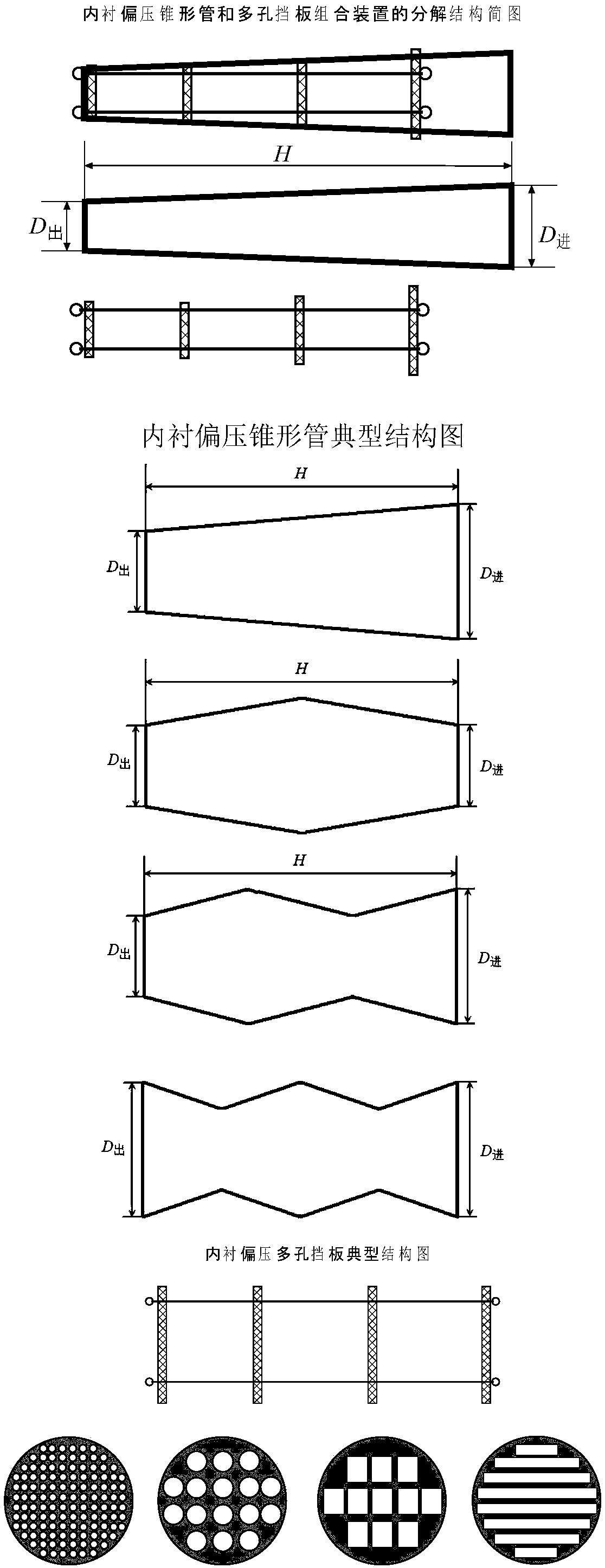

PendingCN109989020AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingPhysicsWave shape

The invention discloses a composite filtered arc ion plating of a combination magnetic field, a lined tapered tube and a porous baffle, and belongs to the technical field of material surface treatment. The problems of contamination of thin films by large particles in a multistage magnetic field filter device, and the loss of arc plasma in the transmission process are solved. A device comprises a bias voltage power supply, an arc ion plating target source and power supply, a multistage magnetic field device and power supply, a lined bias voltage tapered tube and porous baffle combination deviceand bias voltage power supply, a movable coil device and power supply, a high power pulse magnetron sputtering target source and relevant power supply, a bias voltage power supply waveform oscilloscope, a vacuum chamber, and the like; and thin film deposition is conducted, specifically, the device is connected, a system is started, working gas is injected when the vacuum degree in a vacuum chamber is less than 10<-4>Pa, a plating power supply is turned on, the bias voltage power supply regulates energy of the arc plasma, the lined bias voltage taper tube and porous baffle combination device and the multistage magnetic field device eliminate large particle defects in the arc plasma and improve the transmission efficiency of the arc plasma in the filter device, the loss in the vacuum chamber is reduced, and technological parameters are set to prepare the thin films.

Owner:魏永强

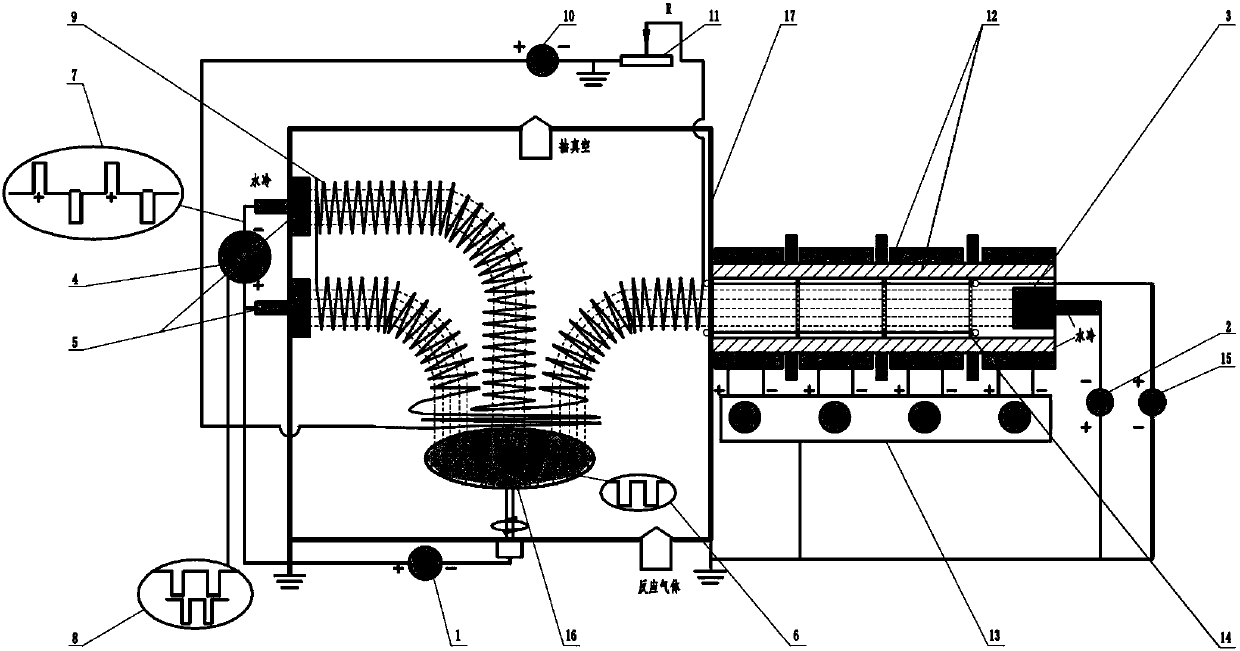

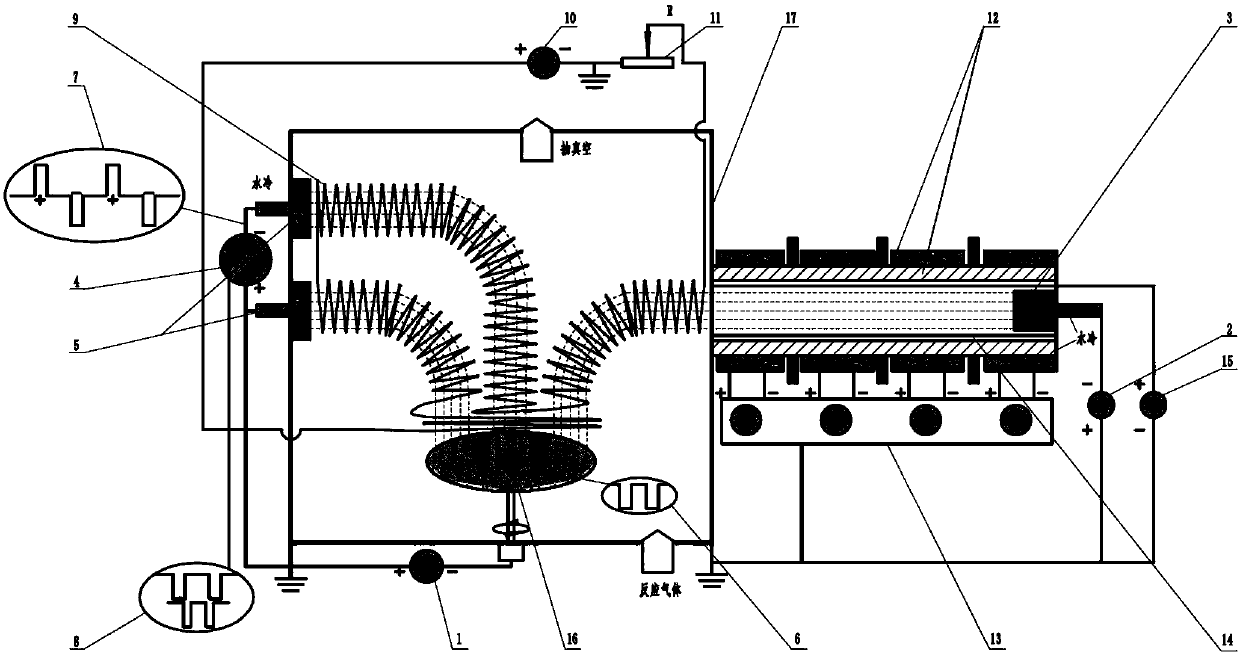

Composite vacuum deposition method of combination magnetic field, lining special-shaped tube and porous baffle

PendingCN109989011AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a composite vacuum deposition method of a combination magnetic field, a lining special-shaped tube and a porous baffle, and belongs to the technical field of material surface treatment. The problems of contamination of thin films and target material usage restrictions by large particles, loss of magnetically filtered arc plasma, and instability of high power pulsed magnetron sputtering discharge in arc ion plating are solved. A device comprises a target source of arc ion plating, a multistage magnetic field device, a lining bias voltage special-shaped tube and porous baffle combination device, a movable coil device, a high power pulsed magnetron sputtering target source and relevant power supply, a waveform matching device, a bias voltage power supply, and the like;and thin film deposition is conducted, specifically, the device is connected, a system is started, working gas is injected when the vacuum degree in a vacuum chamber is less than 10<-4>Pa, a platingpower supply is turned on, the bias voltage power supply regulates energy of the plasma, the combination magnetic field and the lining special-shaped tube and porous baffle device eliminate large particle defects and guide transmission of the composite plasma, the loss in the vacuum chamber is reduced, and preparation technological parameters are set.

Owner:魏永强

Combined magnetic field and lining bias voltage conical pipe composite vacuum deposition method

PendingCN109989015AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingPlasma energyVacuum chamber

The invention discloses a combined magnetic field and lining bias voltage conical pipe composite vacuum deposition method, belongs to the technical field of material surface treatment, and aims at solving the problems about film pollution through large particles, the target material usage limit, magnetic filter arc plasma losses, unstable high-power pulse magnetron sputtering discharge and the like in arc ion plating. The device comprises a bias voltage power source, an arc ion plating target source and power source, a multi-level magnetic field device and power source, a lining bias voltage conical pipe device and bias voltage power source, a movable coil device and power source, a waveform matching device, a high-power pulse magnetron sputtering target source and power source and other devices. Film deposition is conducted, device connection is conducted, the system is started, and when the vacuum degree in a vacuum chamber is smaller than 10<-4>Pa, inflation of work gas is conducted, a coating power source is started, and the bias voltage power source adjusts plasma energy; and the multi-level magnetic field device and the movable coil device eliminate large particle defects andguiding composite plasma transmission, losses in the vacuum chamber are reduced, and preparing technology parameters are set.

Owner:魏永强

Combined magnetic field, combined tube and perforated baffle composite vacuum film coating method

PendingCN109989016AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingLarge particleMaterials science

The invention relates to a combined magnetic field, combined tube and perforated baffle composite vacuum film coating method, and belongs to the technical field of material surface treatment. The problems ofcontamination of thin films by large particles and using limiting of target materials in arc ion plating, loss of magnetically filtered arc plasmaand unstable high power pulsed magnetron sputtering discharging. A device of the method comprises an arc ion plating target source, a multistage magnetic field, a lining bias voltage tapered tube, straight tube and perforated baffle combination device, a twin target high power pulse magnetron sputtering target source, a movable coil device and relative power supply, a grid bias power supply, a waveform matching device and the like; thin film deposition comprises the steps that devices are connected, the system is started, when the vacuum degree of the vacuum cavity is smaller than 10-4 Pa, a working gas is introduced, a film plating powersupply is opened, energy of an arc plasma is adjusted by using the grid bias power supply, through the multistage magnetic field device and the movable coil device, the large particle defect in the arc plasma is eliminated, and the transportation of the composite plasma is guided, loss in the vacuum cavity is reduced, andtechnology parameters are set.

Owner:魏永强

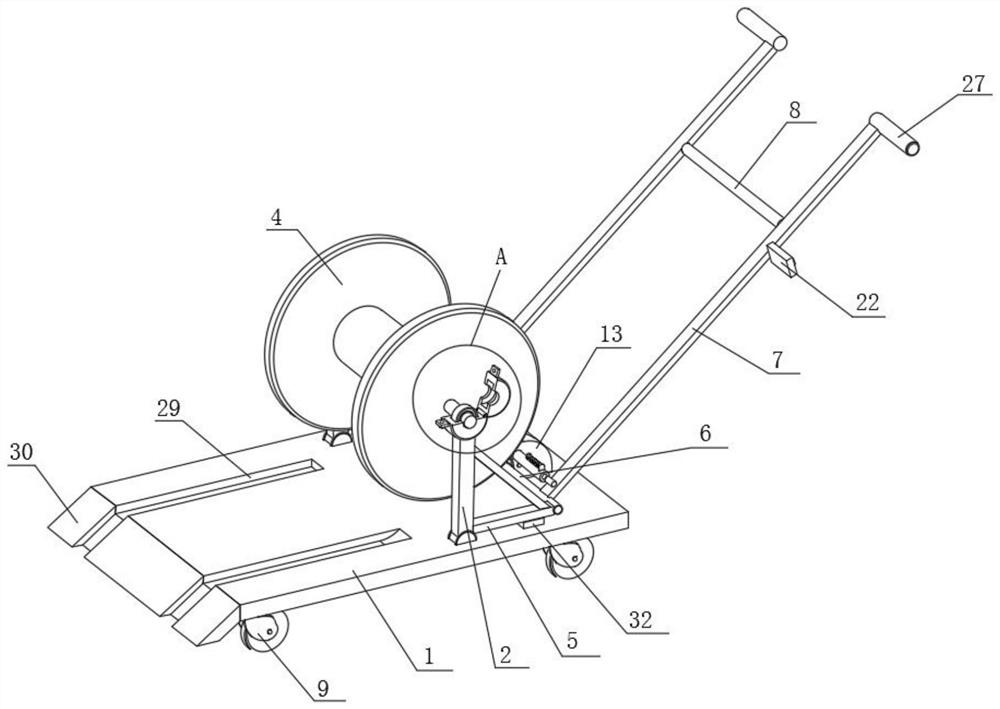

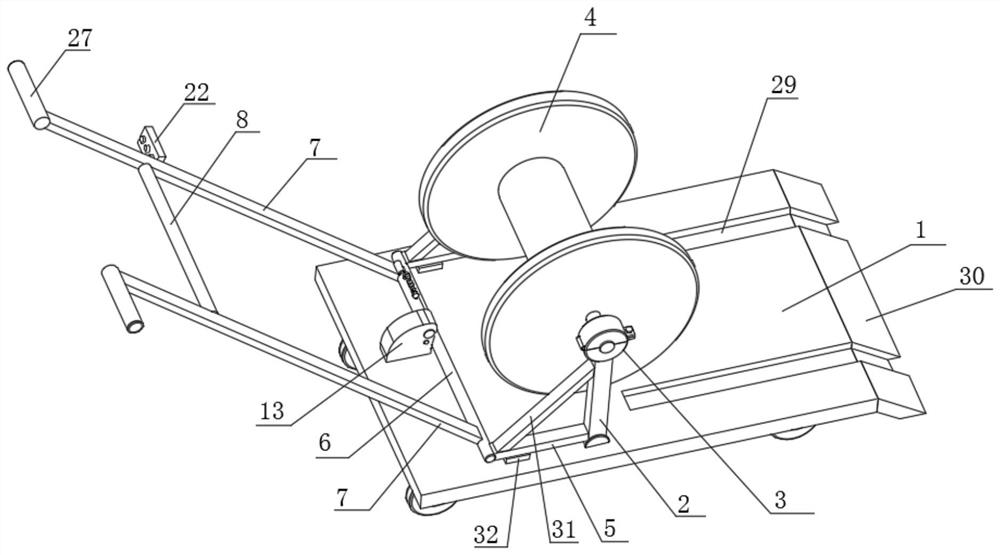

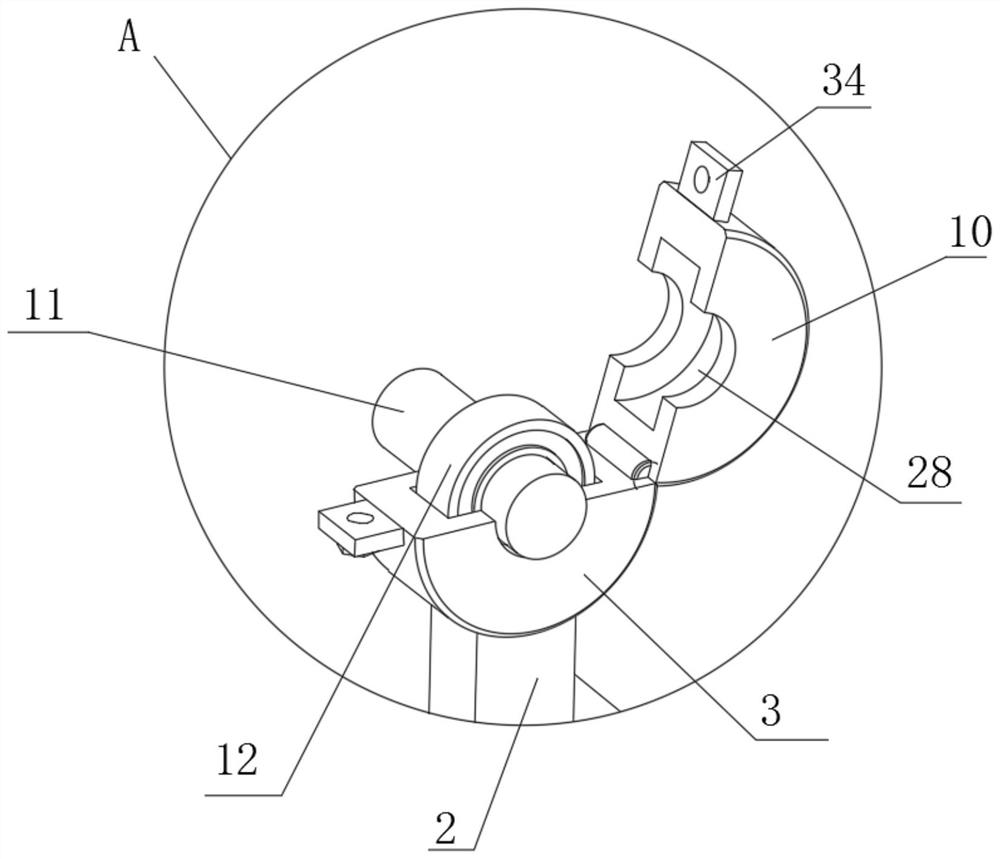

Electric power engineering wire winding vehicle facilitating loading and unloading of reel

ActiveCN114132794AEasy to installRealize pay-off operationFilament handlingEngineeringStructural engineering

The electric power engineering winding vehicle comprises a vehicle body and the reel, two parallel first supporting rods are hinged to the top of the vehicle body, and a second supporting rod is fixedly connected to the outer wall, close to the hinged position, of each first supporting rod; the ends, away from the first supporting rod, of the second supporting rods are fixedly connected with fixing rods, the two second supporting rods are fixedly connected together through the arranged fixing rods, and the end, away from the fixing rods, of the long rod is fixedly connected with a first holding rod. A first holding rod is lifted upwards, so that a first supporting rod rotates along the hinged position, a reel inclines leftwards, the reel is pushed to a vehicle body, then shaft rods on the two sides of the reel are clamped into a fixing base, an upper fixing buckle is closed, the upper fixing buckle is fixed between the fixing base and the upper fixing buckle, the reel is fixed, one end of a long rod is pressed downwards, and the reel is fixed to the vehicle body. According to the lever principle, the long rod has a long force arm, and the reel can be easily lifted up.

Owner:DANDONG ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Composite deposition method combined magnetic field arc ion plating and high-power pulse magnetron sputtering

PendingCN109989009AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a composite deposition method combined magnetic field arc ion plating and high-power pulse magnetron sputtering, and belongs to the technical field of material surface treatment. The problems such as pollution of macroparticles to thin films and the use limitation of target materials in the arc ion plating, and the losses of arc plasmas and the instability of high-power pulse magnetron sputtering discharge in the transmission process of a magnetic filter device are solved. Devices relating to the composite deposition method combined the magnetic field arc ion plating and the high-power pulse magnetron sputtering comprise a bias voltage power source, an arc ion plating target source, a power source of the arc ion plating target source, a multi-stage magnetic field device, a power source of the multi-stage magnetic field device, a movable coil device, a power source of the movable coil device, a waveform matching device, a high-power pulse magnetron sputtering target source, a power source of the high-power pulse magnetron sputtering target source, an oscilloscope and a vacuum chamber. The thin film deposition comprises the steps that the devices are connected, and a system is started; and when a vacuum degree in the vacuum chamber is less than 10<-4> Pa, a working gas is introduced, and a film plating power source is turned on. The bias voltage power source adjusts the energy of plasmas, the multi-stage magnetic field device and the movable coil device eliminate macroparticle defects and guide the transmission of composite plasmas, the losses in the vacuum chamber are reduced, and technological parameters are set.

Owner:魏永强

Compound filtering arc ion plating by combined magnetic fields and lining bias porous baffle plate

PendingCN109989003AReduce lossImprove transmission efficiencyVacuum evaporation coatingSputtering coatingVacuum chamberCondensed matter physics

The invention relates to compound filtering arc ion plating by combined magnetic fields and a lining bias porous baffle plate and belongs to the technical field of material surface treatment. The compound filtering arc ion plating by combined magnetic fields and the lining bias porous baffle plate solves the problems of pollution of macroparticles to a film in a multi-stage magnetic field device and loss in a plasma transmission process. A device comprises a bias power supply, an arc ion plating target source and a power supply, the multi-stage magnetic field device and a power supply, a lining bias porous baffle plate device and a bias power supply, a movable coil device and a power supply, a sample table, a bias power supply kymographion and a vacuum chamber. A film is prepared by the following step: depositing a film: connecting the device; starting a system; introducing working gas when the vacuum degree in a vacuum chamber is smaller than 10<-4> Pa; starting a coating power supply; adjusting the energy of arc plasma by using the bias power supply; eliminating macroparticle contamination in the arc plasma by means of the lining bias porous baffle plate device and the multi-stage magnetic field device and improving the transmission efficiency of the macroparticles in a filter device; reducing loss in the vacuum chamber; setting process parameters; and preparing the film.

Owner:魏永强

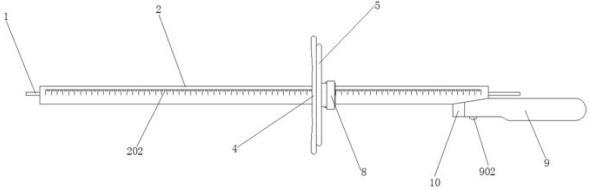

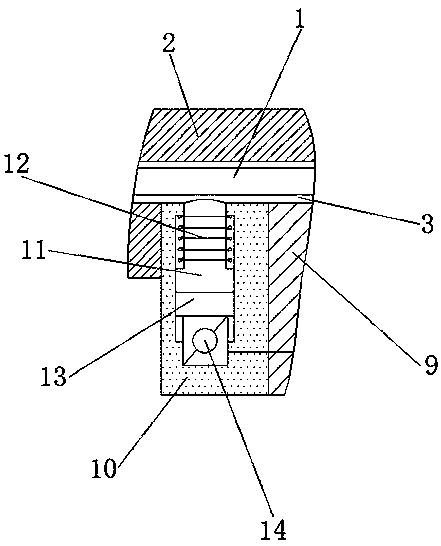

Electric coagulation suction debonder

InactiveCN101352364AReasonable structural designEasy to useSurgical instruments for heatingEngineeringHigh pressure

The invention relates to a medical instrument, in particular to an electric coagulation suction stripper which is mainly applicable to paranasal sinus of human body. The electric coagulation suction stripper comprises a handle with a hollow structure, an electronic, a suction joint with a hollow structure and an insulation pipe with high-temperature resistance and high pressure performance and a suction pipe; the handle is arranged between the suction pipe and the suction joint; the electric coagulation suction stripper is characterized in that one end of the suction pipe is provided with a stripping head which is connected with the suction pipe as a whole; the stripping head is provided with an auxiliary suction hole with the diameter of 0.9-1.1mm; furthermore, the end surface of the stripping head and the central line of the suction pipe have the angle of 35-40 DEG. The electric coagulation suction stripper has the advantages of reasonable, simple and compact structural design, realizes the electric coagulation and suction, carries out the stripping at the same time, and has convenient and reliable usage.

Owner:徐天松

Combined magnetic field and lining conical pipe and ladder pipe composite vacuum coating method

PendingCN109989042AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingVacuum chamberCondensed matter physics

The invention discloses a combined magnetic field and lining conical pipe and ladder pipe composite vacuum coating method, and belongs to the technical field of material surface treatment. The problems that during arc ion plating, due to macroparticles, a thin film is polluted, target use is limited, magnetically filtered arc plasmas are damaged, and high-power pulse magnetic control discharge isnot stable are solved. A device comprises an arc ion plating target source, a multi-stage magnetic field device, a movable coil device, a twin target high-power pulse magnetron sputtering target source, a lining bias conical pipe and ladder pipe combined device and related power source, a grid bias power supply, a waveform matching device and the like. The method comprises the steps of thin film deposition, device connecting and system starting. When the vacuum degree in a vacuum chamber is smaller than 10<-4> Pa, work gas is led in, a coating power source is started, energy of plasmas can beadjusted through the grid bias power supply, the multi-stage magnetic field device and the movable coil device remove macroparticle defects and guide transmission of composite plasmas, losses in the vacuum chamber are reduced, and process parameters are set.

Owner:魏永强

Scraper falling-film evaporator for material concentration

InactiveCN112206547AChange the direction of the magnetic fieldAchieve attractionEvaporator accessoriesButt jointRepulsion force

The invention relates to the technical field of evaporators, and discloses a scraper falling-film evaporator for material concentration, which comprises a tank body, the middle part of the inner cavity of the tank body is rotatably sleeved with a rotating rod, the outer wall of the rotating rod is fixedly connected with a connecting rod, and one end, close to the inner wall of the tank body, of the connecting rod is connected with a butt joint rod; and a scraping plate is fixedly installed at the end, away from the connecting rod, of the butt joint rod, and a magnetic induction coil corresponding to the scraping plate in position is fixedly installed on the outer wall of the tank body. A current in different directions is introduced into the electromagnet, so that the magnetic field direction of the electromagnet is changed, attraction and repulsion effects on the vertical magnet are achieved, when the damaged scraper is taken down, the electromagnet has upward repulsive force on the vertical magnet, the butt joint rod can be taken down from the connecting rod, and when a new scraper is installed, through the attraction effect of the electromagnet on the vertical magnet, the connecting stability of the connecting rod and the butt joint rod is guaranteed, the replacement mode is simple and convenient, and the replacement cost is greatly reduced.

Owner:张昆

Composite type filtered arc ion plating with composite magnetic field and lined bias voltage stepped tube

PendingCN109989017AAchieve independent adjustmentImprove utilization efficiencyVacuum evaporation coatingSputtering coatingWave shapeVacuum chamber

The invention discloses a composite type filtered arc ion plating with a composite magnetic field and a lined bias voltage stepped tube, and belongs to the technical field of material surface treatment. The problems of contamination of thin films by large particles and loss in the process of plasma transmission in a multistage magnetic field filter device are solved. A device comprises bias voltage power supply, an arc ion plating target source and power supply, a multistage magnetic field device and power supply, a lined bias voltage stepped tube device and bias voltage power supply, a movable coil device and power supply, a sample table, a bias voltage power supply waveform oscilloscope, and a vacuum chamber; and thin film deposition is conducted, specifically, the device is connected, asystem is started, working gas is injected when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, a plating power supply is turned on, energy of arc plasma is regulated by using the biasvoltage power supply, large particle defects in the arc plasma are eliminated and the transmission efficiency in the filter device is improved through the lined bias voltage stepped tube device and the multistage magnetic field device, the loss in the vacuum chamber is reduced, technological parameters are set, and thin film preparation is conducted.

Owner:魏永强

Device and method for preparing vegetation soil layer from magnetic mortar

ActiveCN113306015AAchieving Controlled AttractionControl porosity sizeDischarging apparatusCement mixing apparatusVegetationSoil science

The invention provides a device and method for preparing a vegetation soil layer through magnetic mortar. The device comprises a storage tank, wherein the magnetic mortar and soil are stored in the storage tank; a mortar storage tank is suspended and supported on the inner upper portion of the storage tank through an upper covering plate, and the upper covering plate is fixed to the top of the mortar storage tank; a plurality of uniformly distributed electromagnets are arranged in the mortar storage tank, a through hole is formed in the bottom end of the mortar storage tank, and a one-way door is arranged at the position of the through hole; and the electromagnets are connected with an electromagnet control system for controlling the on-off of the electromagnets through wires. The device mainly aims at soil factors during vegetation planting, on the premise that plants can survive to the maximum extent, the vegetation soil body with the controllable porosity and pore distribution is prepared, utilization of land resources is reduced as much as possible, and therefore the purpose of efficient utilization is achieved.

Owner:CHINA THREE GORGES UNIV

Vacuum film plating method with combined magnetic field, lined straight pipe and multihole baffle combined

PendingCN109989024AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringInstability

The invention discloses a vacuum film plating method with a combined magnetic field, a lined straight pipe and a multihole baffle combined, and belongs to the technical field of material surface treatment. The vacuum film plating method with the combined magnetic field, the lined straight pipe and the multihole baffle combined aims to solve the problems such as the pollution of macroparticles to athin film, the use limitation of a target material, the loss of magnetically-filtered arc plasma and the instability of high-power pulsed magnetron sputtering discharge in arc ion plating. Devices relating to the vacuum film plating method comprise a bias voltage power source, an arc ion plating target source, a power source of the arc ion plating target source, a multistage magnetic field device, a power source of the multistage magnetic field device, a movable coil device, a power source of the movable coil device, a waveform matching device, a high-power pulsed magnetron sputtering targetsource, a power source of the high-power pulsed magnetron sputtering target source, a combined device of the lined bias voltage straight pipe and the multihole baffle, a power source of the combined device of the lined bias voltage straight pipe and the multihole baffle and the like. Thin film deposition comprises the steps that the devices are connected; a system is started; when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, a working gas is introduced into the vacuum chamber, a film plating power source is started, the bias voltage power source adjusts the energy of the plasma, the multistage magnetic field device and the movable coil device eliminate defects of the macroparticles and guide the transmission of the composite plasma, the loss in the vacuum chamber is reduced, and technical parameters are set.

Owner:魏永强

Vacuum coating method for compounding combined magnetic field and lining bias-voltage straight tube

PendingCN109989019AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityVacuum chamber

The invention discloses a vacuum coating method for compounding a combined magnetic field and a lining bias-voltage straight tube, belongs to the technical field of material surface treatment, and solves the problems of the pollution of the film, the target use restriction, the loss of the magnetic filtered arc plasma and the instability of high-power pulse magnetic-controlled sputtering discharging due to the macroparticles in the arc ion plating. The vacuum coating device comprises a bias-voltage power supply, an arc ion plating target source, an arc ion plating power supply, a multi-stage magnetic field device, a multi-stage magnetic field device power supply, a lining bias-voltage straight tube device, a lining bias-voltage power supply, an movable coil device, an movable coil device power supply, a waveform matching device, a twin-target high-power pulse magnetic-controlled sputtering target source, a twin-target high-power pulse magnetic-controlled sputtering power supply and thelike. The vacuum coating method comprises the steps that the film is deposited, the device is connected, the system is started, when the vacuum degree in the vacuum chamber is less than 10 <-4>Pa, the working gas is fed, the coating power supply is started, the bias-voltage power supply adjusts the energy of the plasma, the multi-stage magnetic field device and the movable coil device eliminate the macroparticles defects and guide the transmission of the compound plasma, the loss in the vacuum chamber is reduced, and the preparation process parameters are set.

Owner:魏永强

Integrated sewage treatment equipment based on rapid separation of sewage and flocculate

InactiveCN112374683AFirmly connectedLow costTreatment involving filtrationMultistage water/sewage treatmentWater flowSewage

The invention provides integrated sewage treatment equipment based on rapid separation of sewage and flocculate. The integrated sewage treatment equipment comprises a separation chamber and a first water inflow tank; the bottom end of the separation chamber is provided with a rust removal chamber; the lower surface of the rust removal chamber is fixedly connected with the top end of a lifting plate; the bottom end of the lifting plate extends into a power chamber; the bottom end of the first water inflow tank is communicated with the top end of a first longitudinal water guide pipe; the bottomend of the first longitudinal water guide pipe is communicated with the left end of a first transverse water guide pipe; the right end of the first transverse water guide pipe extends into the separation chamber; a motor bottom plate is fixed to the right surface in the separation chamber; a motor is fixed to the left side face of the motor bottom plate; a power shaft is arranged at the left power output end of the motor; and a cleaning cylinder is fixed to the left end of the power shaft. In the prior art, the rapid separation capacity for flocculate in sewage is not achieved, rust in waterflow cannot be sucked out, and assisting type lifting cannot be achieved. With the integrated sewage treatment equipment based on rapid separation of sewage and flocculate provided by the technical schemes adopted, the above technical problems can be solved.

Owner:吴斌

Movable magnetic field arc ion plating and high-power pulse magnetron sputtering composite deposition method

PendingCN109989030AMake up for unstable dischargeGuaranteed high-density continuous productionVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringInstability

The invention provides a movable magnetic field arc ion plating and high-power pulse magnetron sputtering composite deposition method, and belongs to the technical field of material surface treatment.The method aims at solving the problems of contamination of large particles in arc ion plating to thin films, the use limitations of target materials, losses of arc plasma in the transmitting processof a magnetic filtering device, the instability of high-power pulse magnetron sputtering and the like. A device comprises a bias power source, an arc ion plating target source, an arc ion plating target source power source, a movable coil device, a movable coil device power source, a waveform matching device, a high-power pulse magnetron sputtering target source, a high-power pulse magnetron sputtering target source power source, an oscilloscope and a vacuum chamber. The thin films are deposited, wherein the device is connected, a system is started, when the vacuum degree in the vacuum chamber is smaller than 10-4 Pa, working gas is introduced, a plating power source is switched on, the bias power source is used for adjusting energy of arc plasma, large particle defects are eliminated andtransmitting of the composite plasma is guided through the movable coil device, losses in the vacuum chamber are reduced, process parameters are set, and the thin films are prepared.

Owner:魏永强

Vacuum film-coating method through combined magnetic field and compounding of lining special-shaped pipe and porous baffle

PendingCN109989036AGuaranteed uniformityImprove utilization efficiencyVacuum evaporation coatingSputtering coatingInstabilityHigher Power

The invention provides a vacuum film-coating method through a combined magnetic field and compounding of a lining special-shaped pipe and a porous baffle, and belongs to the technical field of material surface treatment. The vacuum film-coating method is used for solving the problems of pollution of large particles to a film, target using limitation, loss of magnetic filtration arc plasma, instability of high-power pulse magnetron sputtering discharge and the like in arc ion plating. A device adopted by the vacuum film-coating method comprises an arc ion plating target source, a multi-stage magnetic field device, a lining bias-voltage special-shaped pipe and multi-porous baffle combination device, a movable coil device, a twin target high-power pulse magnetron sputtering target source andrelated power supply, a waveform matching device, a grid bias power supply and the like. Film deposition is conducted, specifically, the device is connected, a system is started, when the vacuum degree in a vacuum chamber is less than 10<-4> Pa, working gas is introduced, a film-coating power supply is started, energy of the plasma is adjusted through the grid bias power supply, the combined magnetic field, the lining special-shaped pipe and a porous baffle device eliminate the defects of the large particles and guide transmission of the compound plasma, loss of the plasma in the vacuum chamber is reduced, and preparation process parameters are set.

Owner:魏永强

Composite magnetic field and lining bias voltage tapered tube composite type filtered arc ion plating

PendingCN109989007AImprove transmission efficiencyAdjusting the Series Resistor ValueVacuum evaporation coatingSputtering coatingLarge particleGrid bias

The invention relates to composite magnetic field and lining bias voltage tapered tube composite type filtered arc ion plating, and belongs to the technical field of material surface treatment. According to composite magnetic field and lining bias voltage tapered tube composite type filtered arc ion plating, the problems ofcontamination of thin films by large particles in a multistage magnetic field filtering device, and loss in the process of plasma transferring are solved. According to composite magnetic field and lining bias voltage tapered tube composite type filtered arc ion plating, a device comprises a grid bias power supply, an arc ion plating target source and power supply, a multistage magnetic field device and power supply, a lining bias voltage tapered tube device and grid biaspower supply, a movable coil device and power supply, a sample table, a grid bias power supply kymographion and a vacuum cavity; thin film deposition comprises the steps that devices are connected, the system is started, when the vacuum degree of the vacuum cavity is smaller than 10-4 Pa, a working gas is introduced, a film plating power supply is opened, energy of an arc plasma is adjusted by using the grid bias power supply, through the lining bias voltage tapered tube device and the multistage magnetic field device, the large particle defect in the arc plasma is eliminated, and the transportation efficiency of the filtering device is improved, loss in the vacuum cavity is reduced, technology parameters are set, and film preparation is conducted.

Owner:魏永强

Arc ion plating for composite filtering of combined magnetic field and lined bias conical pipe and stepped pipe

PendingCN109989029AImprove transmission efficiencyAdjusting the Series Resistor ValueVacuum evaporation coatingSputtering coatingConical tubeVacuum chamber

The invention provides arc ion plating for composite filtering of a combined magnetic field and a lined bias conical pipe and a stepped pipe, and belongs to the technical field of material surface treatment. The arc ion plating aims at solving the problems of contamination of large particles in a multi-stage magnetic field filtering device to thin films and losses generated in the plasma transmitting process. The arc ion plating involves a bias power supply, an arc ion plating target source, an arc ion plating target source power supply, a multi-stage magnetic field device, a multi-stage magnetic field device power supply, a lined bias conical pipe and stepped pipe combination device, a lined bias conical pipe and stepped pipe combination device power supply, a movable coil device, a movable coil device power supply, a bias power supply kymographion and the like. Thin film deposition is carried out, wherein the device is connected, a system is started, when the vacuum degree in a vacuum chamber is smaller than 10-4 Pa, working gas is introduced, a plating power supply is started, the energy of arc plasma is adjusted through the bias power supply, by means of the lined bias conicalpipe and stepped pipe combination device and the multi-stage magnetic field device, large particle defects in the arc plasma are eliminated, the transmission efficiency of the filtering device is improved, losses in the vacuum chamber are reduced, process parameters are set, and thin films are prepared.

Owner:魏永强

Selenium-rich edible fungus planting deinsectization device

InactiveCN111972378AAchieve attractionSimple structureCultivating equipmentsMushroom cultivationLiquid storage tankPower grid

The invention discloses a selenium-rich edible fungus planting deinsectization device. The selenium-rich edible fungus planting deinsectization device comprises a main body and a deinsectization assembly, wherein the main body comprises an upper plate, a lower plate and a support; the upper plate is arranged in a disc shape; the support is fixedly connected to the side edge of the upper plate; thetail end of the support is fixedly connected with an installation ring; a clamping assembly is arranged between the installation ring and the lower plate; the deinsectization assembly is arranged between the upper plate and the lower plate and comprises a power grid, a lamp body and an adsorption assembly; the lamp body is fixedly connected to the upper plate; the power grid is fixedly connectedto the lower plate, and a certain voltage is distributed on the power grid; and the adsorption assembly is arranged on the lower plate. The device is simple and reasonable in structure, and downward rotational flow is generated in the rotating process of a rotating fan, so that mosquitoes around the power grid are further attracted; and meanwhile, under the action of a heating rod, different agents in a liquid storage tank are volatilized, mosquitoes in a larger range are attracted, caught and killed, and the using effect of the device is greatly improved; and bright application prospects arerealized.

Owner:中农航天(北京)生物技术有限公司

Electronic self-entrapment fly catching device

InactiveCN107027728AAchieve attractionRealize sticky captureInsect catchers and killersAgainst vector-borne diseasesEngineeringEntrapment

The invention provides an electronic self-entrapment fly catching device. A fly entrapment device is fixed to a mounting plate and connected with a control box arranged on the mounting plate through wires. A fly catching plate sticks to the exterior of the fly entrapment device, and attraction and stick catching of mosquitoes and flies are achieved through control over switching on / off of fly entrapment lamps in the fly entrapment device by a switch arranged on the control box. According to the electronic self-entrapment fly catching device, the fly catching plate sticks to the exterior of the fly entrapment device with the fly entrapment lamps, so that attraction and stick catching of mosquitoes and flies are achieved; the situation that people carelessly step on or stick to a fly catching layer is avoided, meanwhile, the stick catching efficiency of mosquitoes and flies is greatly improved, the use effect of the fly catching plate at night is good, and the device provides healthy, safe and reliable living and diet environments for people in the summer.

Owner:郑俊岩

Combination magnetic field and lining tapered tube-porous baffle compounded vacuum deposition method

PendingCN109989035AAchieve independent adjustmentGuaranteed uniformityVacuum evaporation coatingSputtering coatingInstabilityMagnetic filtration

The invention discloses a combination magnetic field and lining tapered tube-porous baffle compounded vacuum deposition method, and belongs to the technical field of material surface treatment. In order to solve the problems of pollution to thin films by macroparticles in arc ion plating, target material using restrictions, magnetic filtration arc plasma losses, high-power pulse magnetron sputtering discharge instability and the like, the device disclosed in the invention comprises a grid bias power source, an arc ion plating target source and power source, a multistage magnetic field device and power source, a lining bias tapered tube and porous baffle combination device and power source, a movable coil device and power source, a waveform matching device, a high-power pulse magnetron sputtering target source and power source and other devices. Thin film deposition is conducted, the devices are connected and the system is started. When the vacuum degree of the inside of a vacuum chamber is smaller than 10<-4>Pa, working gas is connected in, a film coating power source is started, the grid bias power source can adjust the energy of plasma, the combination device can remove macroparticle defects and guide composite plasma conveyance, losses in the vacuum chamber are reduced and technological parameters are set.

Owner:魏永强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com