Textile fabric heat pump dryer

A drying machine and textile technology, applied in the direction of drying machine, drying, progressive drying machine, etc., can solve the problems of textile pulling, textile wrinkling, affecting drying effect, etc., and achieve the goal of improving product quality and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

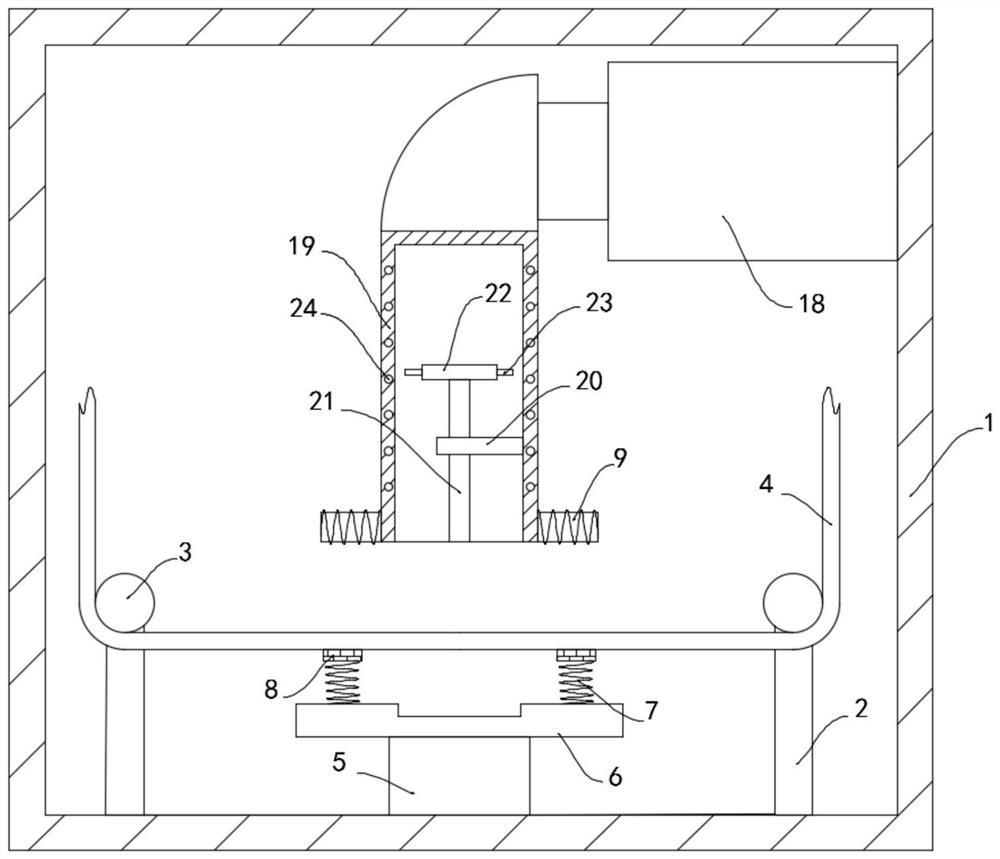

[0023] Such as figure 1 As shown, a heat pump dryer for textiles includes a drying box 1, the inner lower wall of the drying box 1 is fixedly connected with two symmetrically arranged brackets 2, and the side wall of the bracket 2 is rotatably connected with a transmission wheel 3 , the two transmission wheels 3 are jointly driven and connected with a cloth 4, the inner wall of the drying box 1 is fixedly connected with a heat pump machine 18, the side wall of the heat pump machine 18 is sealed and fixedly connected with an air outlet pipe 19, and the side wall of the air outlet pipe 19 A plurality of spiral coils 24 are embedded, and the inner side wall of the air outlet pipe 19 is fixedly connected with a support block 20, and the side wall of the support block 20 is rotatably connected with a rotating shaft 21. It should be noted that the rotating shaft 21 is connected to the supporting block 20 through a bearing. Rotationally connected, the upper end of the rotating shaft ...

Embodiment 2

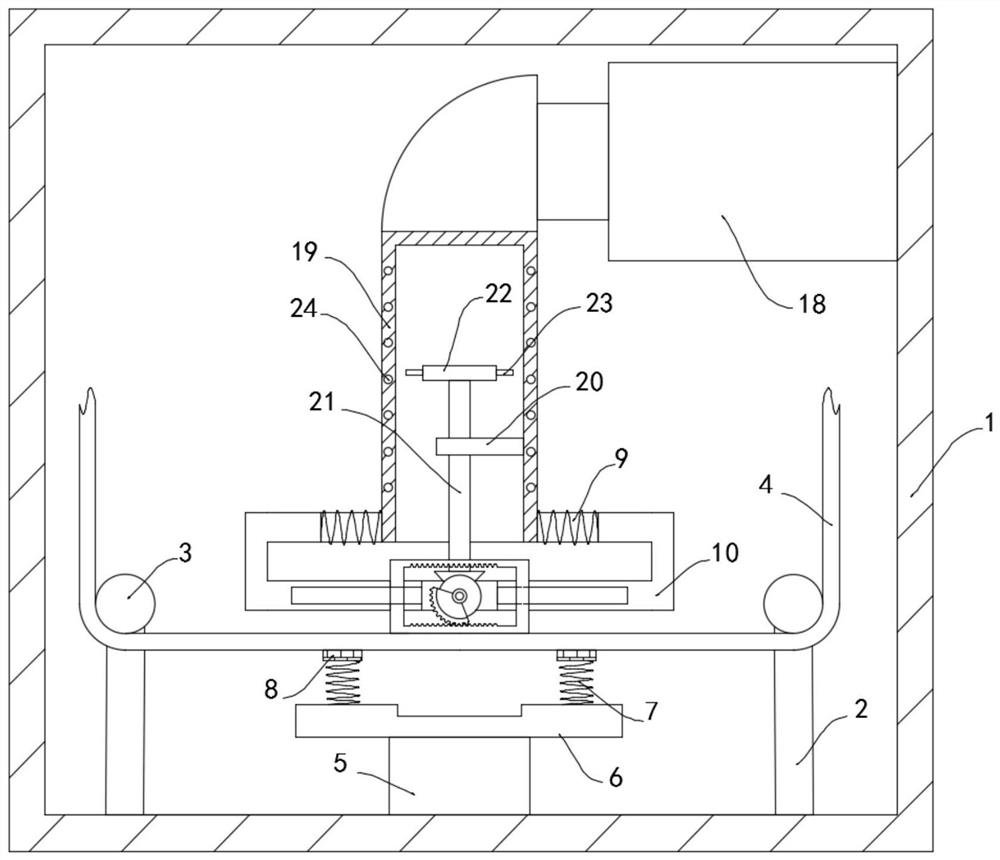

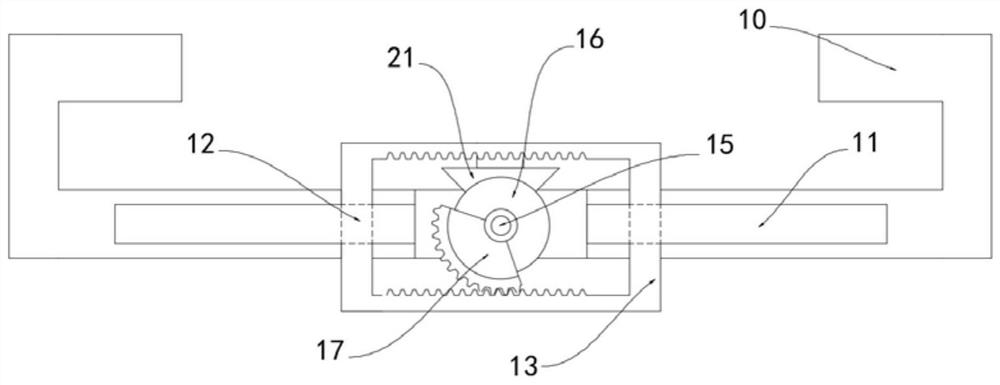

[0027] Such as Figure 2-3 As shown, the difference between this embodiment and Embodiment 1 is that: the lower end of the rotating shaft 21 is fixedly connected with the first bevel gear 14, and the two iron cores 9 are fixedly connected with the slide rail 10, and the slide rail 10 is provided with a sliding Groove 11, it is worth noting that the sliding groove 11 is coated with a smooth paint, the smooth paint is natural wood paint, two sliders 12 are slidably connected in the sliding groove 11, and the two sliders 12 are jointly fixedly connected with a push plate 13 , the push plate 13 is provided with a through hole and the inner surface is provided with a rack, the side wall of the slide rail 10 is rotatably connected with a transmission shaft 15, and the transmission shaft 15 is coaxially fixedly sleeved with a second bevel gear 16 and an incomplete gear in turn. 17. By setting the rotating shaft 21 and the second bevel gear 16, the wind energy is converted into kineti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com