Patents

Literature

30results about How to "Avoid affecting drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

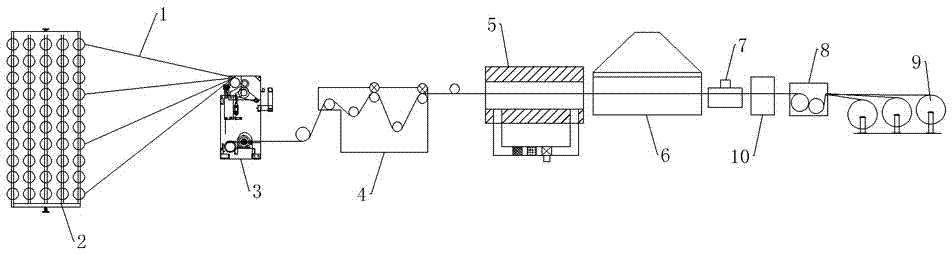

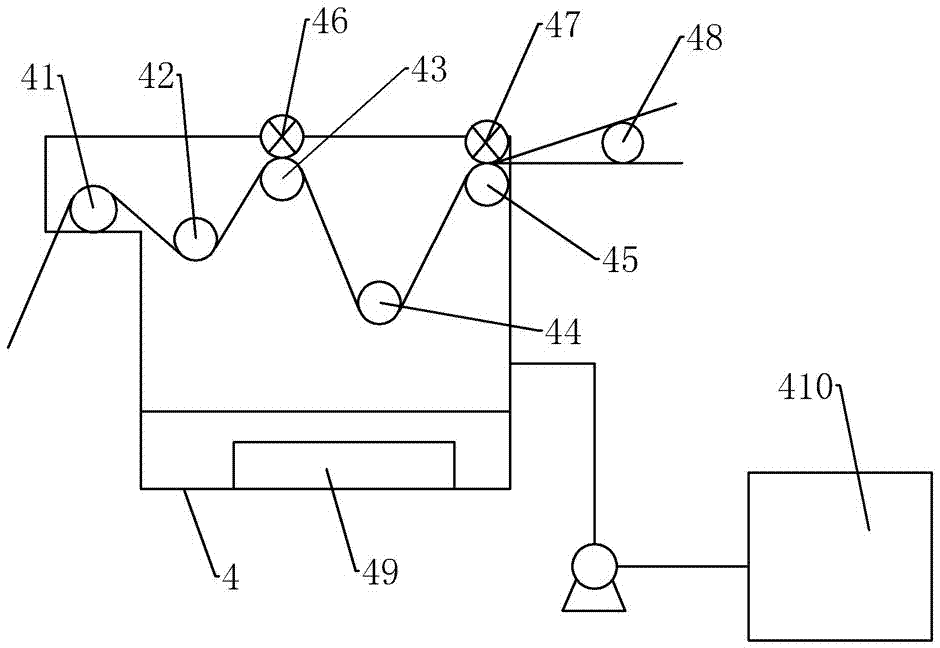

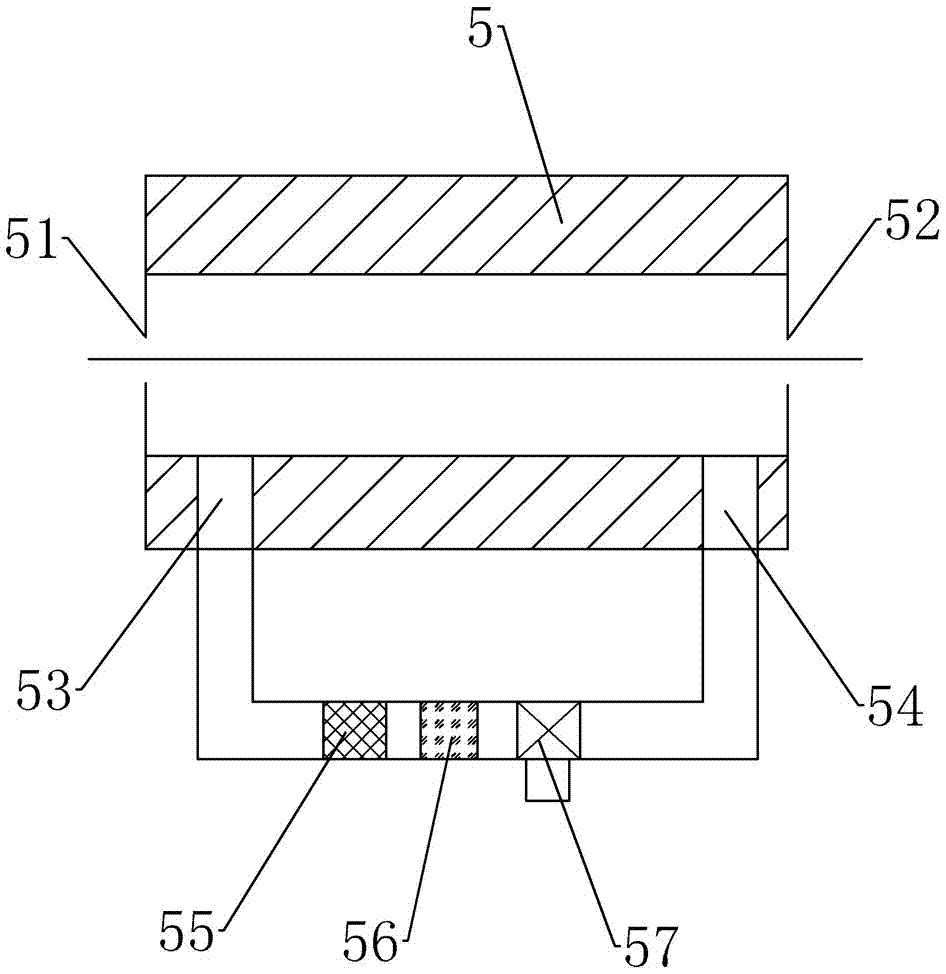

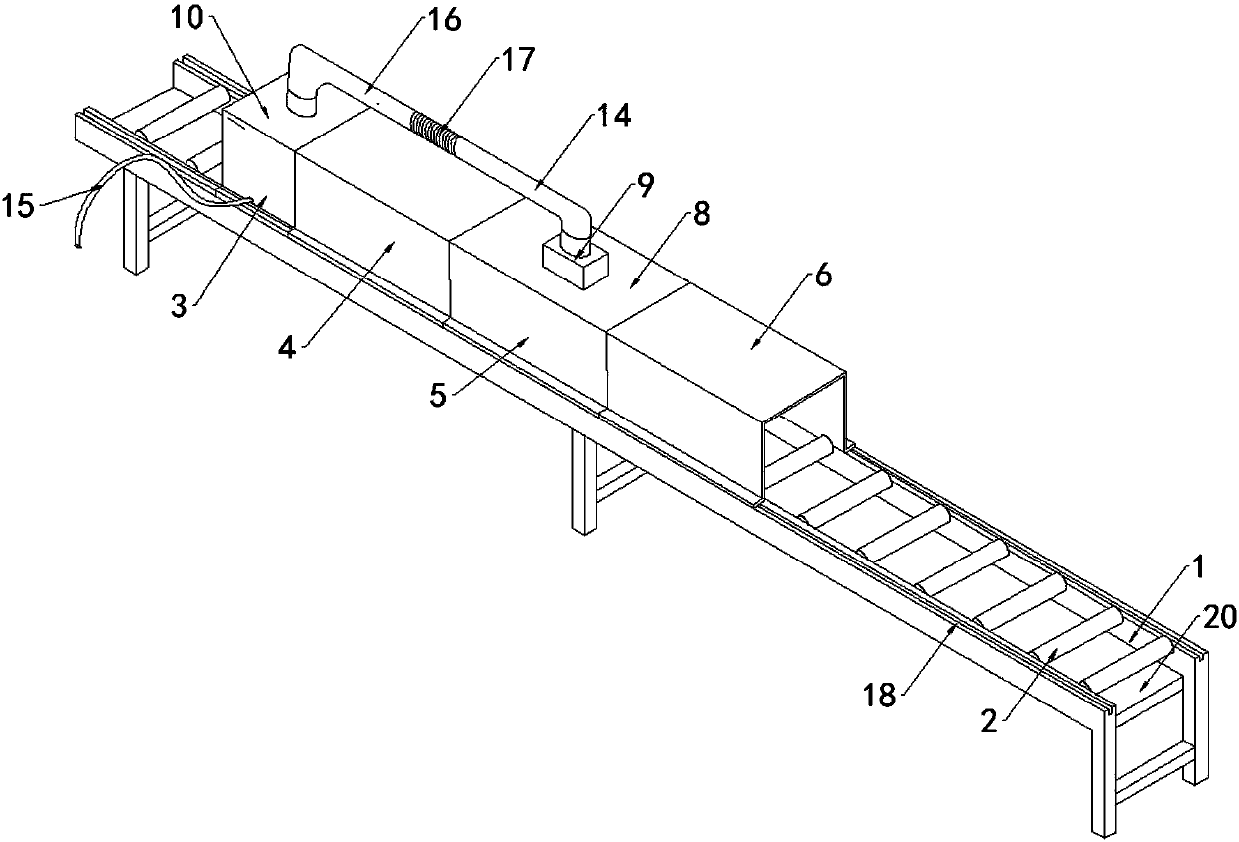

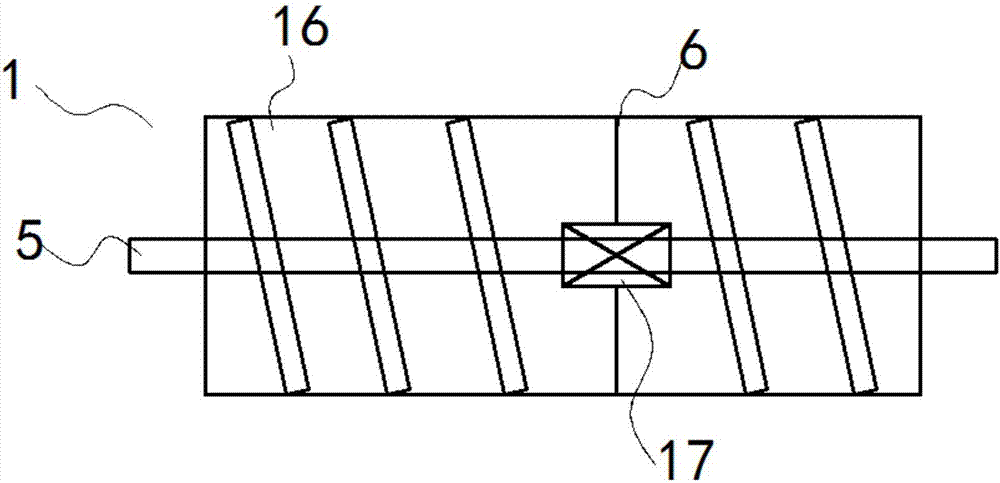

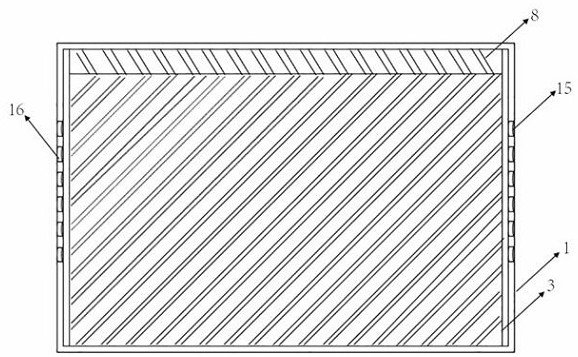

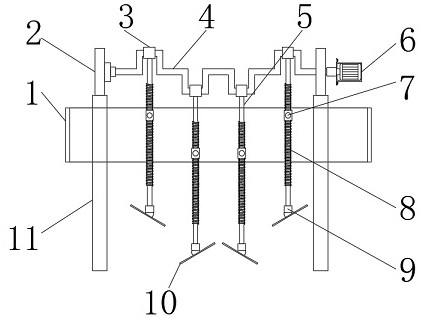

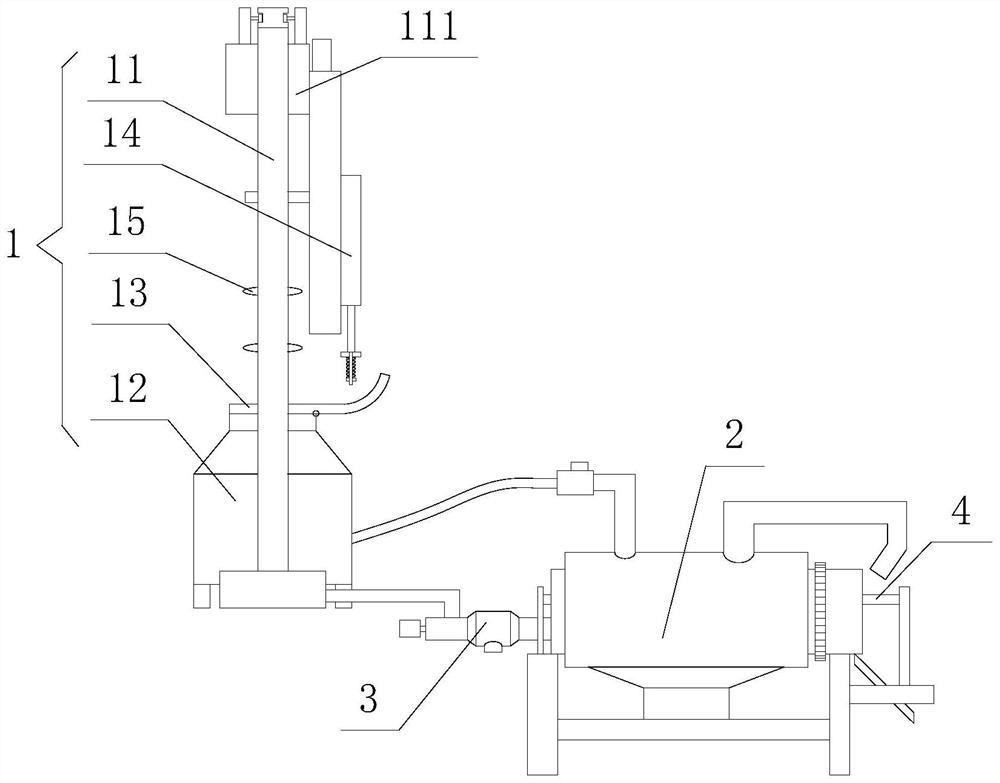

Aramid filament warping, sizing and drawing equipment

PendingCN107130381AAvoid markingsAvoid entanglementSucessive textile treatmentsCreelsBobbinStructural engineering

The invention discloses aramid filament warping, sizing and drawing equipment. The aramid filament warping, sizing and drawing equipment comprises a warping mechanism, a sizing mechanism and a re-beaming mechanism which are arranged along the advancing direction of aramid filaments sequentially, the warping mechanism comprises a bobbin creel, a destaticizing device and a tension frame, the sizing mechanism comprises a size box, a preheating oven, a drying room, a waxing device and a take-up device which are arranged along the advancing direction of the aramid filaments sequentially, a drawing roller is arranged on the inner side of a filament inlet of the size box, a first sizing roller, a second sizing roller, a third sizing roller and a fourth sizing roller are arranged in the size box along the advancing direction of the aramid filaments sequentially, a first squeezing roller is arranged at the top of the second sizing roller, and the re-beaming mechanism comprises a beam creel. The aramid filament warping, sizing and drawing equipment is applicable to processing the aramid filaments, is simple in structure, convenient to use and higher in working efficiency, and can achieve centralized control.

Owner:盐城市荣意来纺机有限公司

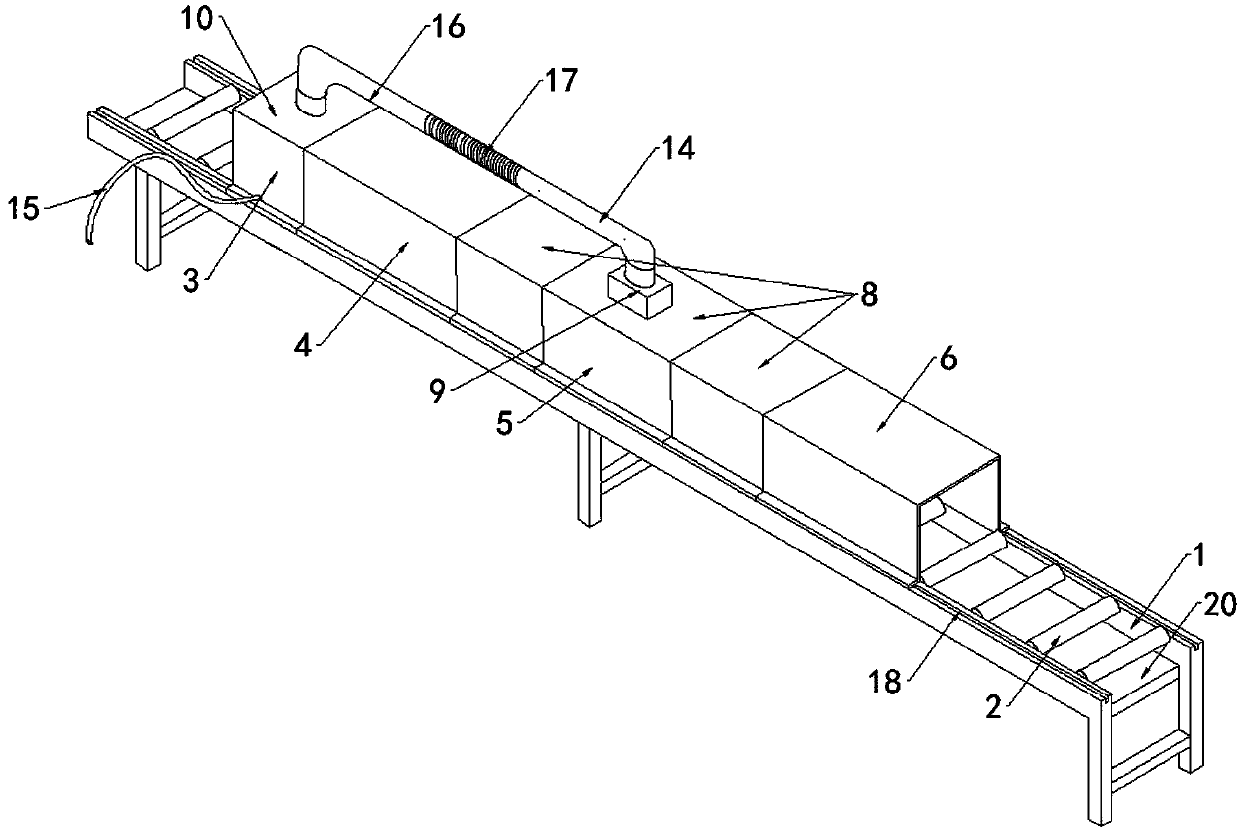

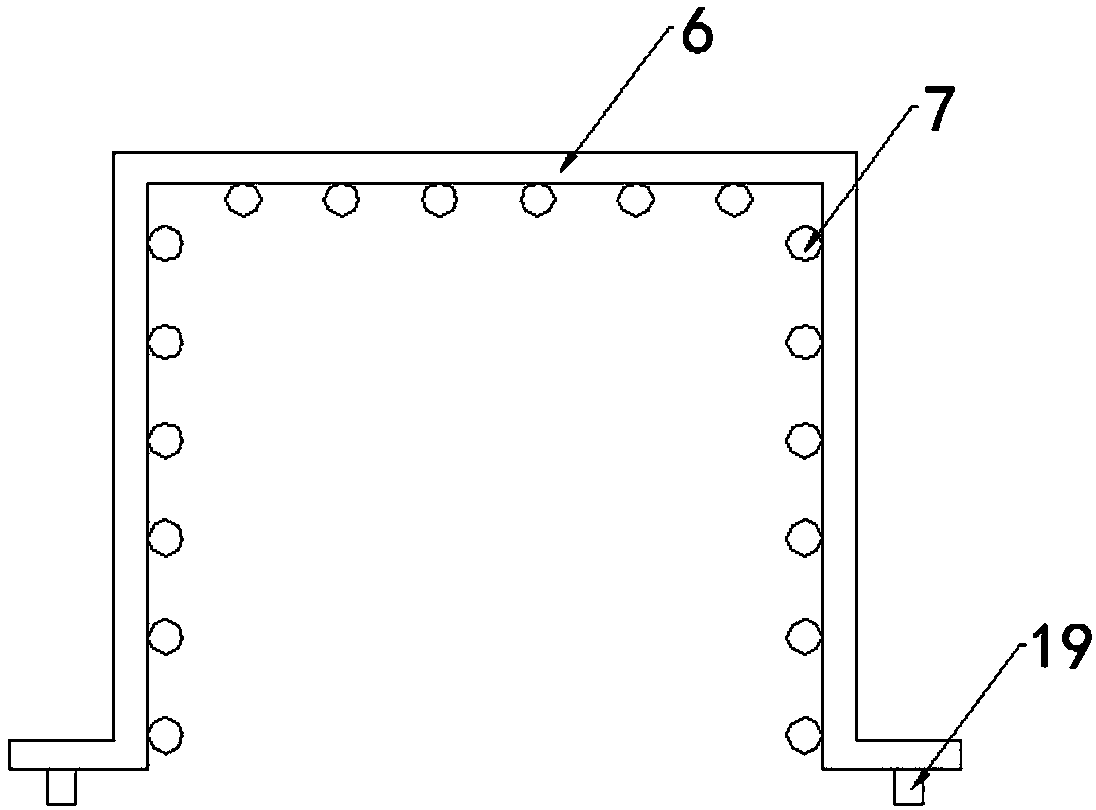

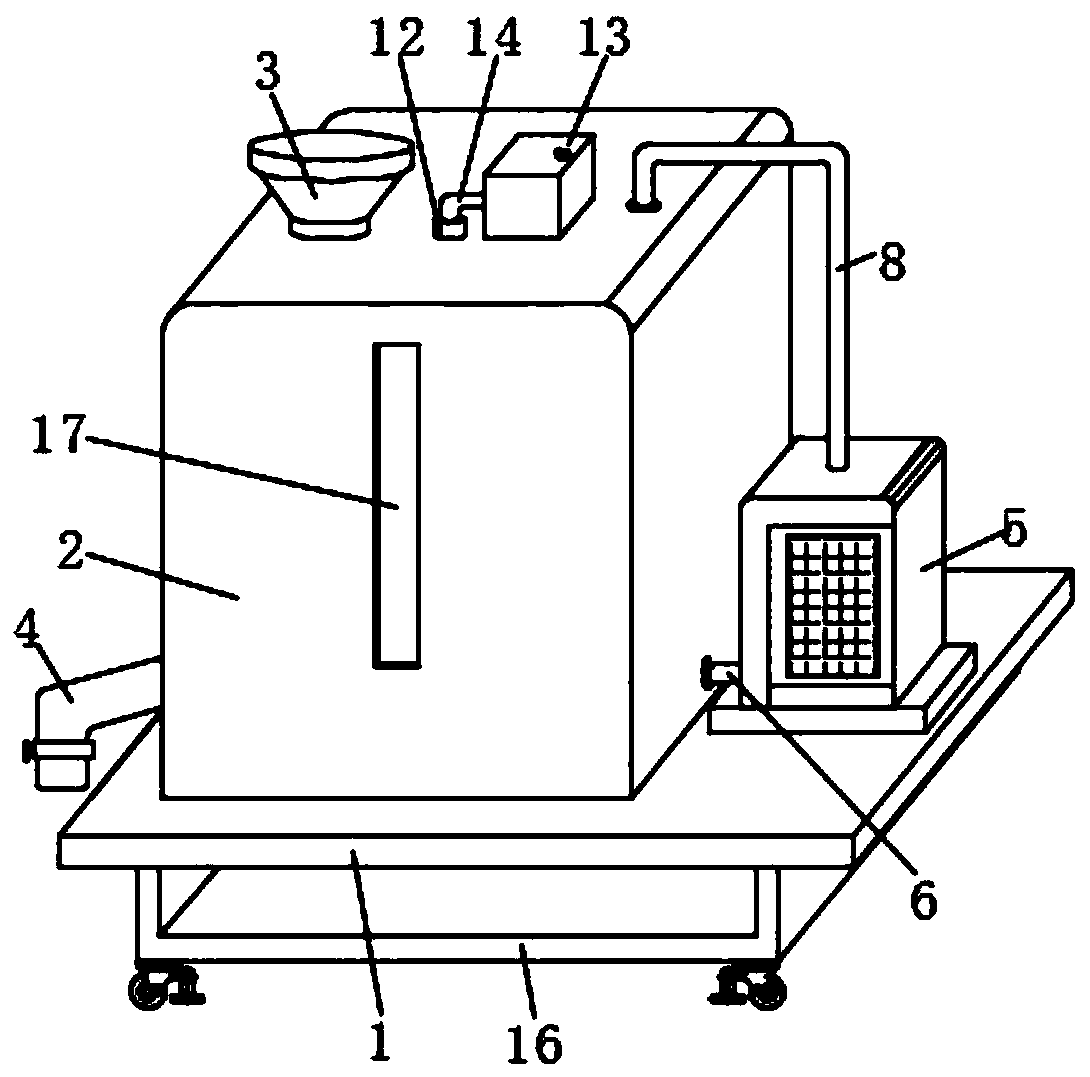

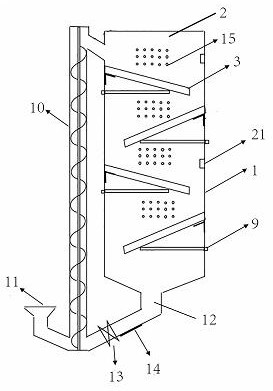

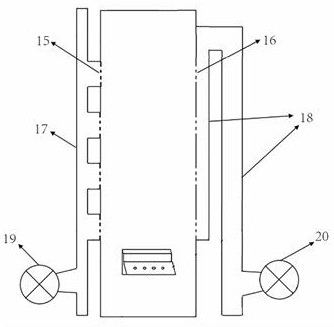

Gypsum line drying device

PendingCN107560400AEasy to drySave production spaceDrying machines with progressive movementsDrying solid materialsMicrowavePulp and paper industry

The invention relates to the technical field of gypsum line production equipment, and discloses a gypsum line drying device. The gypsum line drying device comprises a supporting frame and rollers; a pre-heating device, a primary drying device, a dehumidifying device and a secondary drying device are sequentially arranged on the supporting frame; the primary drying device is a microwave heater; a plurality of heating pipes are evenly distributed in the secondary drying device; an exhaust fan is arranged on the upper portion of the dehumidifying device; and a pipeline is arranged between the dehumidifying device and the exhaust fan. By means of the gypsum line drying device, gypsum lines can be fast dried, and therefore it is not needed to move the gypsum lines to an airing field for naturalairing, the production site is saved, the work efficiency is improved, and the production cost is saved; the microwave heater is adopted as the primary drying device, the interiors of the gypsum lines can be heated by microwave heating, heating is uniform, the secondary drying device can fast heat the gypsum lines, the drying efficiency is improved, and therefore the production time is shortened,and the production cost is reduced; and waste heat can be utilized to pre-heat the gypsum lines, and energy conservation and environmental protection are achieved.

Owner:峨眉山市万晟新材料科技有限公司

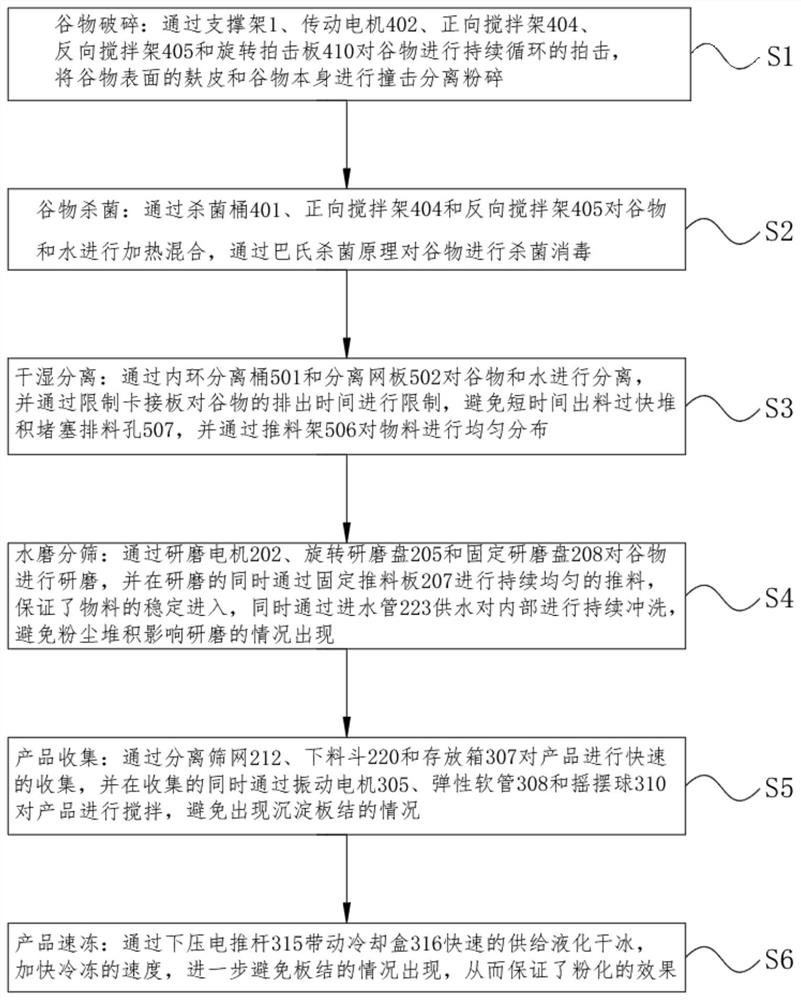

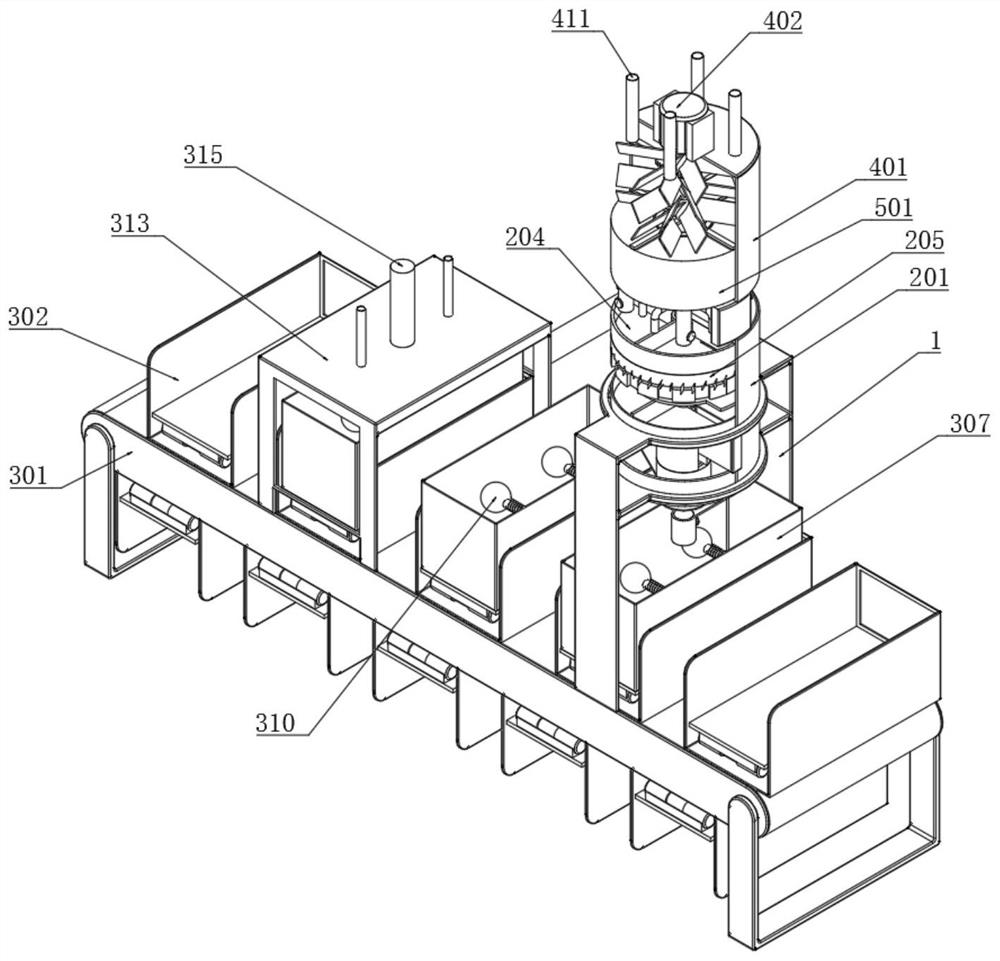

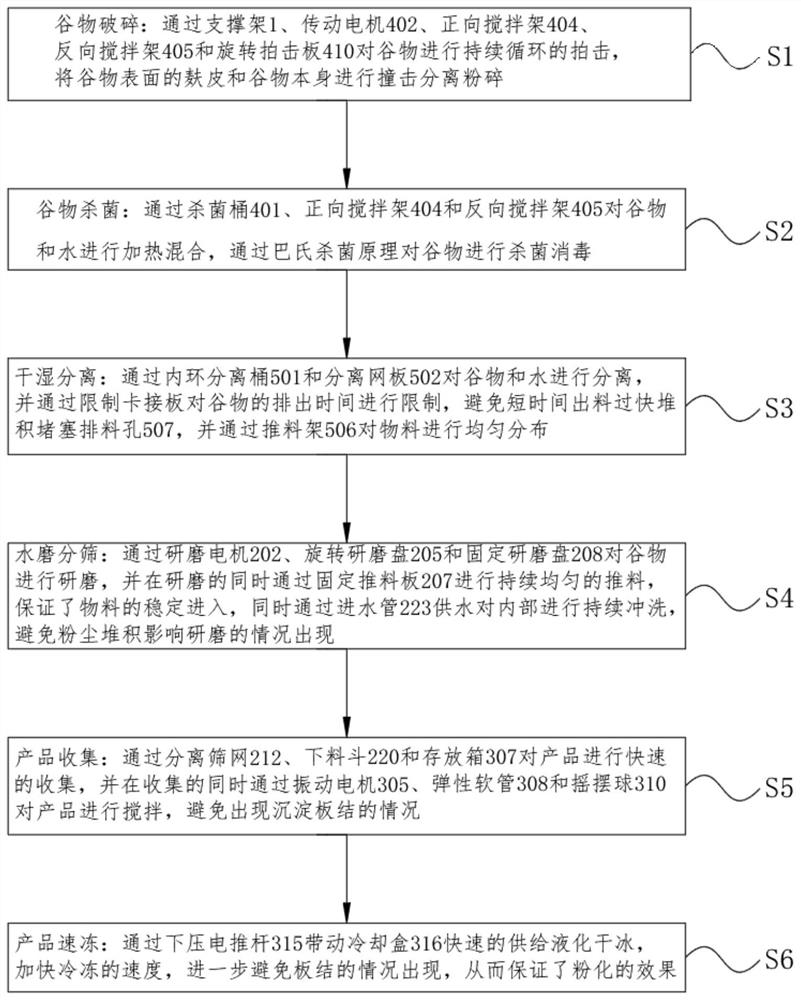

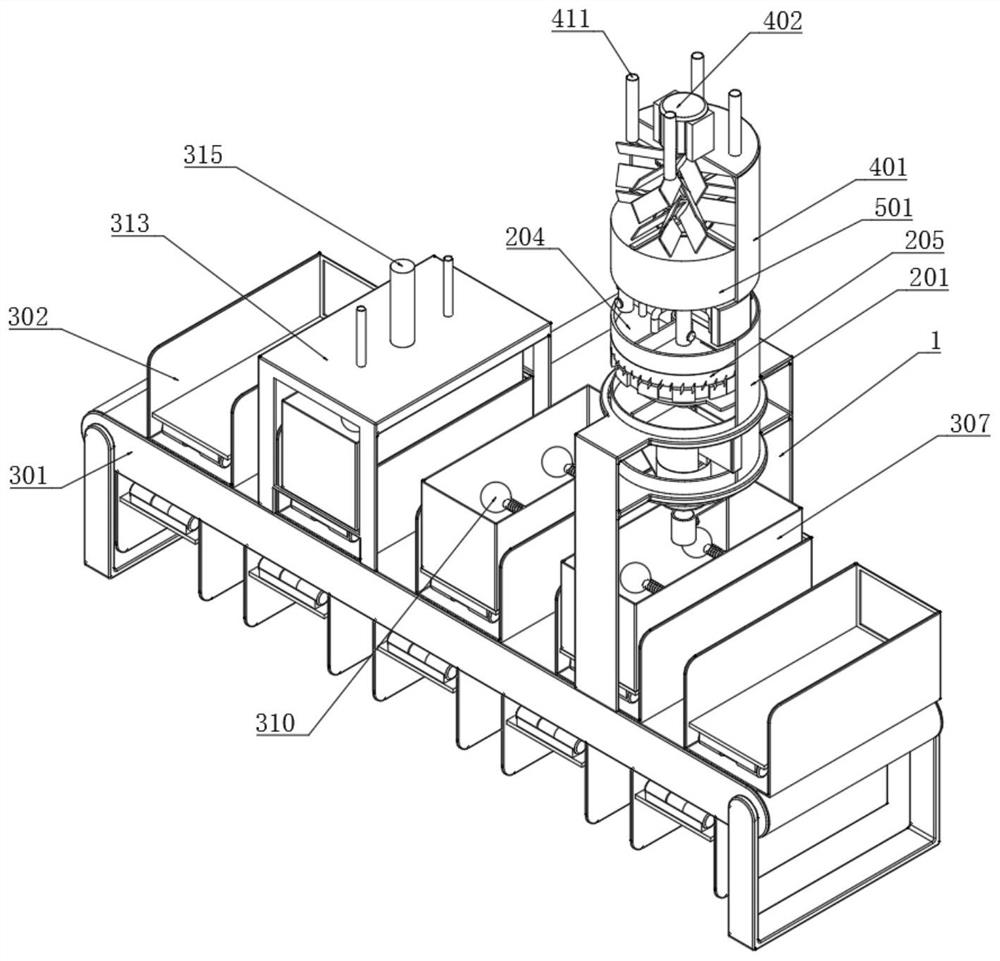

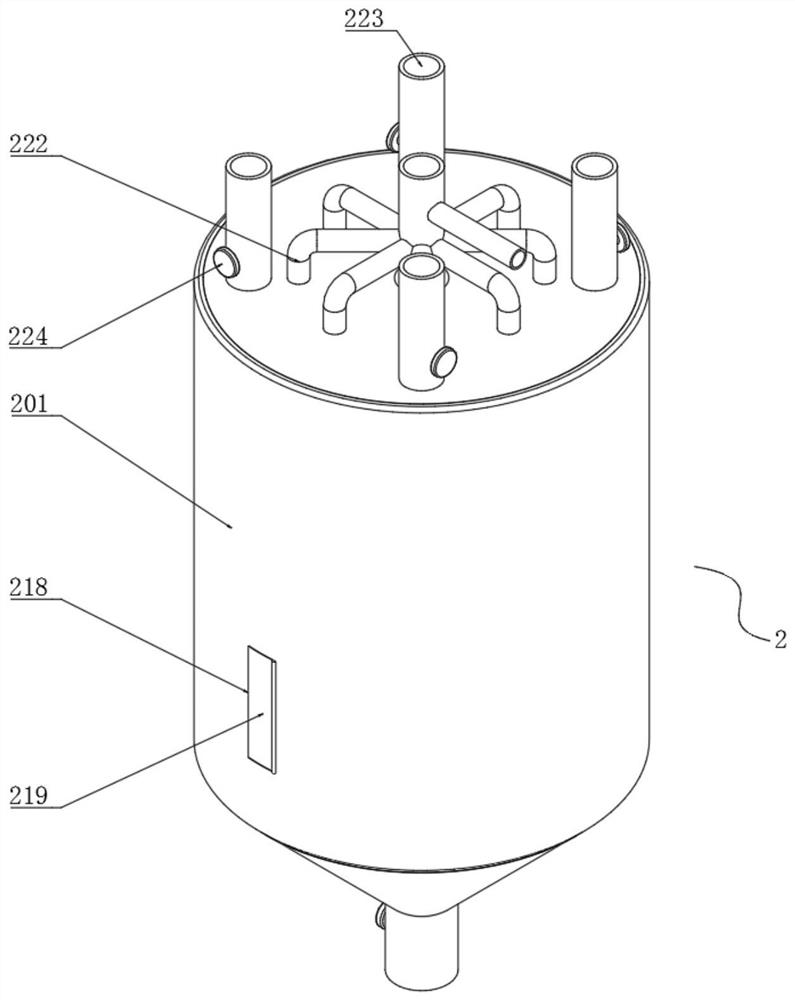

Preparation method of meal replacement powder

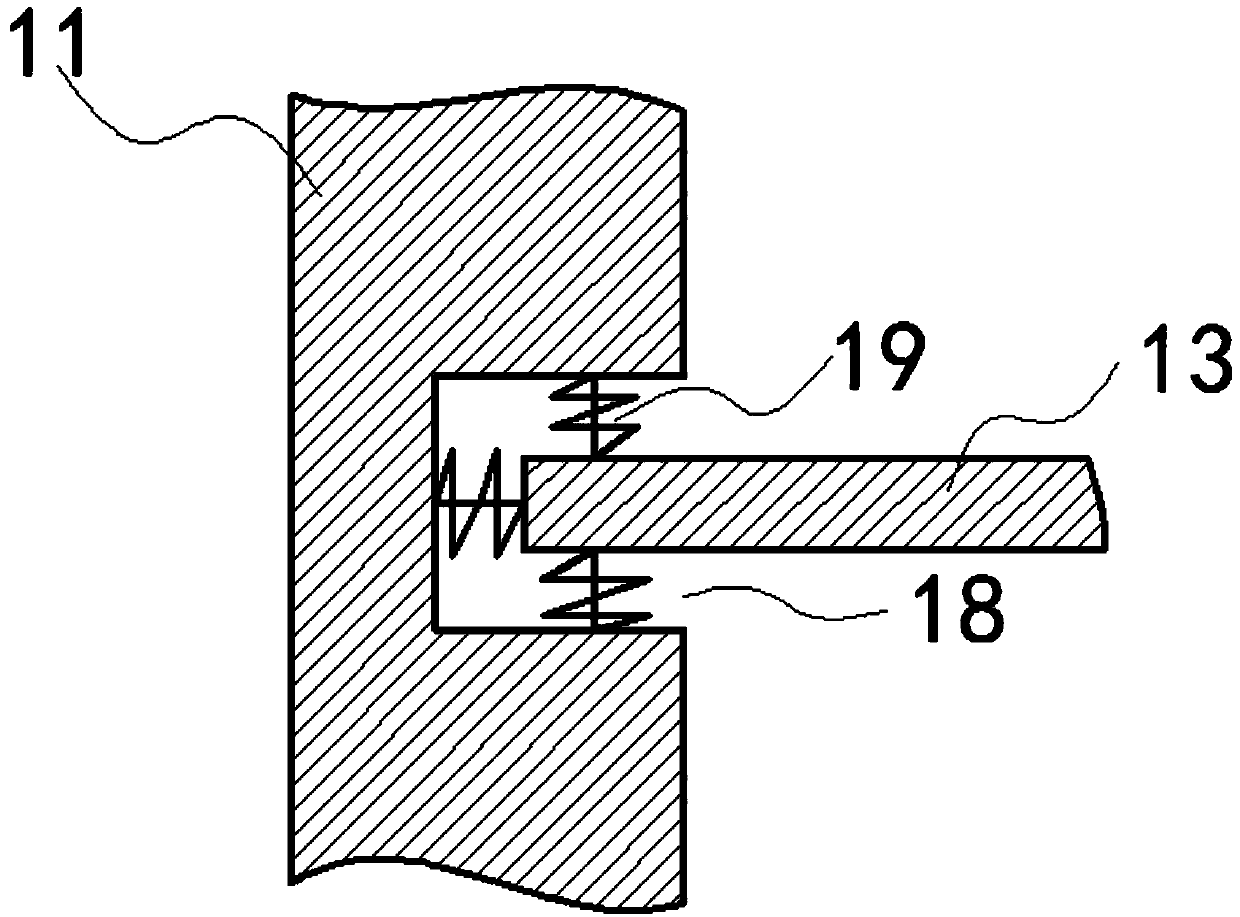

ActiveCN113198564AScientific and reasonable structureEasy to useGrain huskingGrain polishingMeal replacementProcess engineering

The invention discloses a preparation method of meal replacement powder. The preparation method comprises the steps of S1, cereal crushing; S2, cereal sterilization; S3, dry-wet separation; S4, water milling and screening; S5, product collection; S6, quick freezing of the product. The cereals are beaten and crushed, bran remaining on the surfaces of the cereals is removed, and large cereals are rapidly crushed, so that the surfaces of the cereals are clean. Meanwhile, the situation that a discharging port is blocked due to accumulation of large particles is avoided, the bacteria-free condition of subsequent production of the product is guaranteed through continuous sterilization, dry-wet separation is conducted on the sterilized product, a large amount of water is prevented from rapidly entering the grinding position, and therefore the concentration of a powder solution is guaranteed, and the situation that the drying efficiency is affected due to too low concentration is avoided. Dust raising and wet powder accumulation caused by too dry powder are avoided through water milling, normal production of the product is guaranteed, and in addition the production quality of the product is guaranteed.

Owner:东莞市霖鑫牛食品科技有限公司

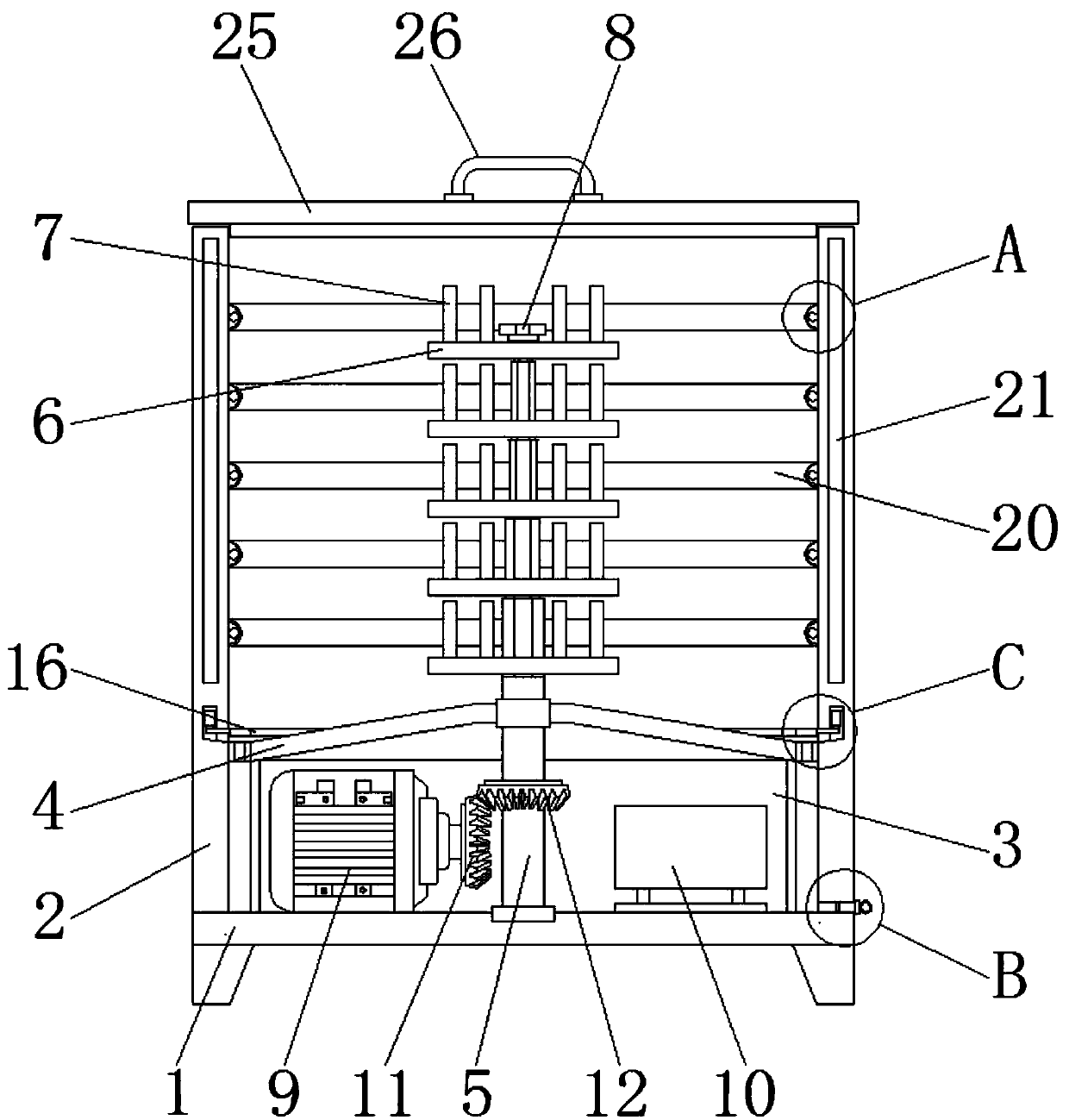

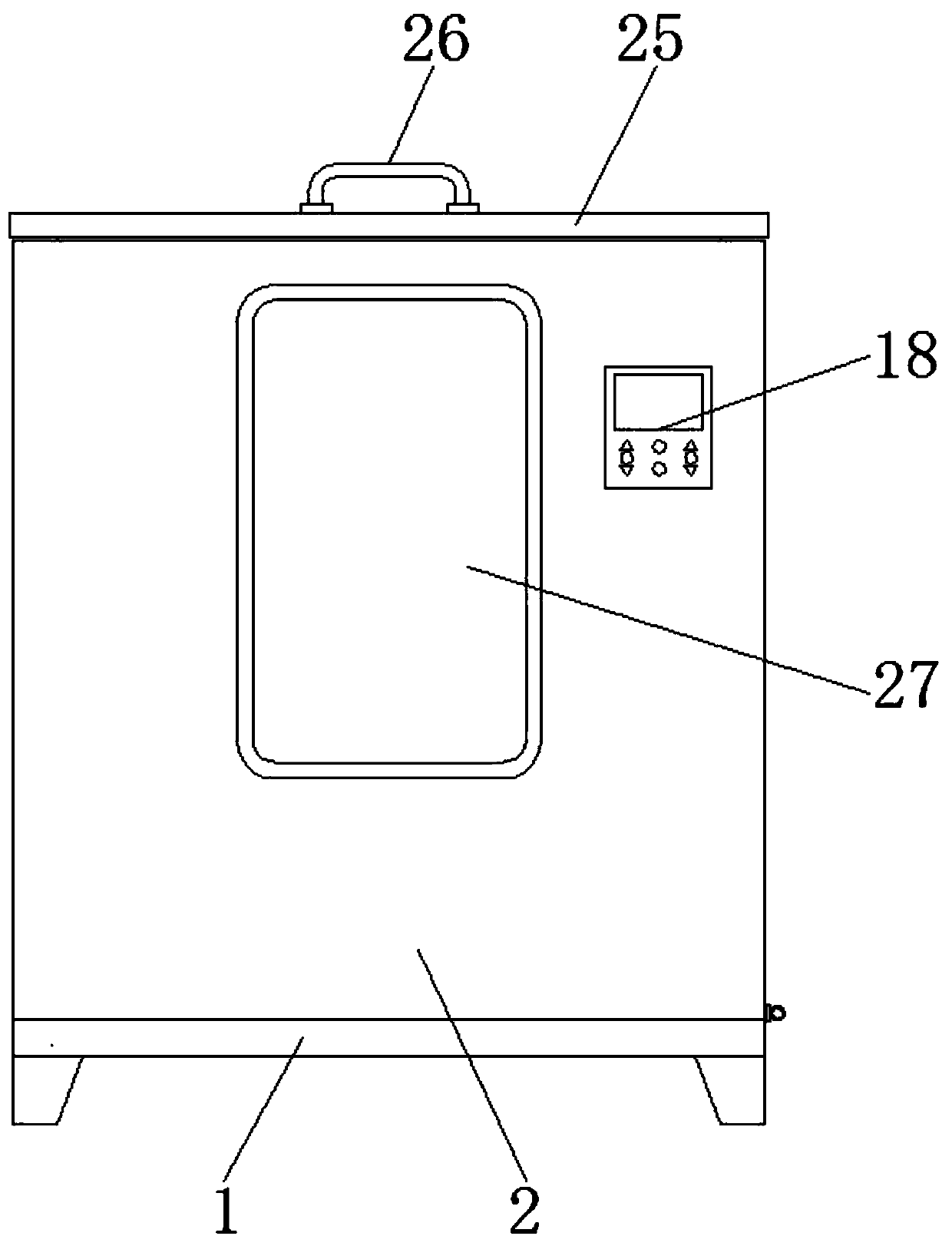

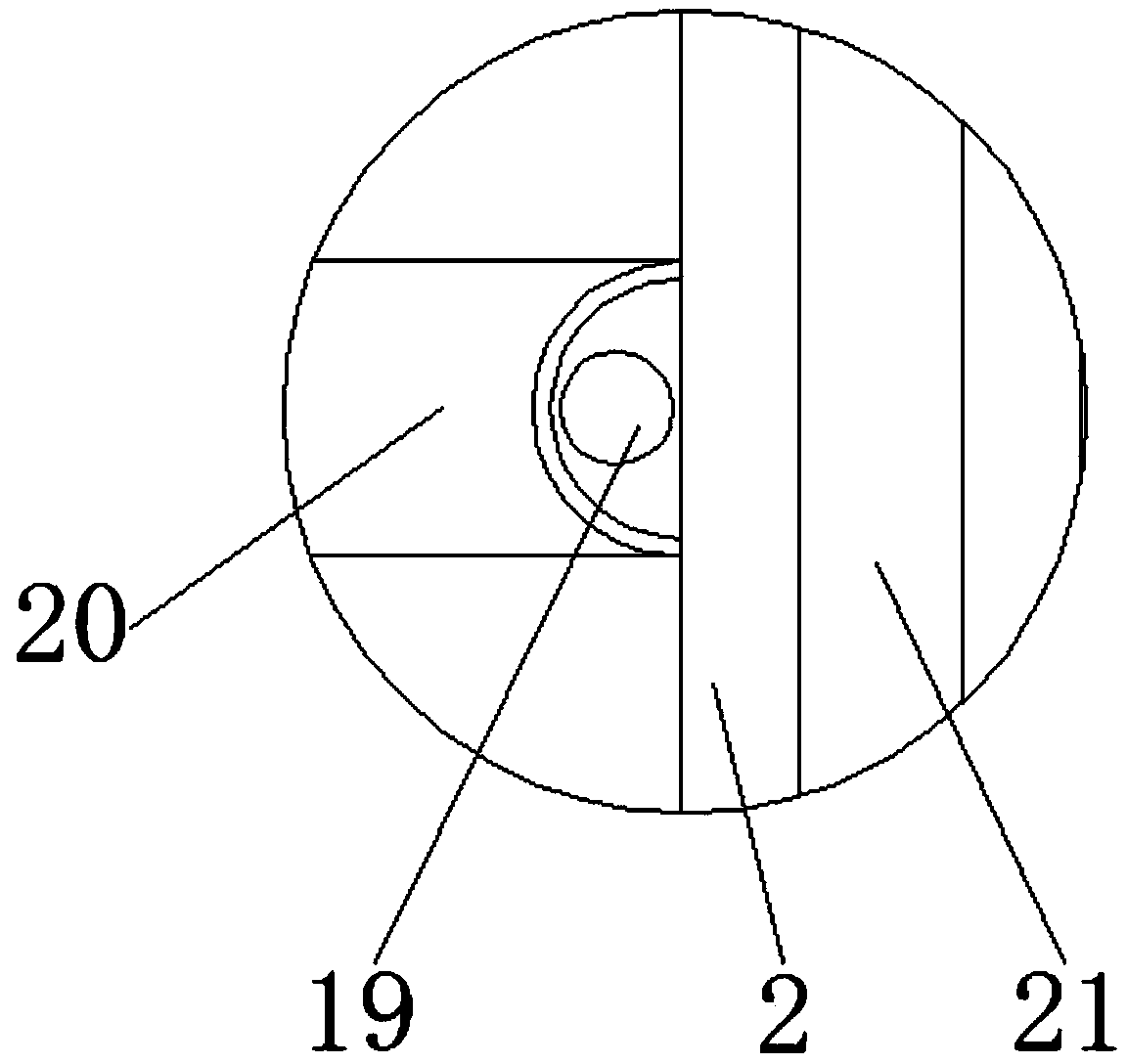

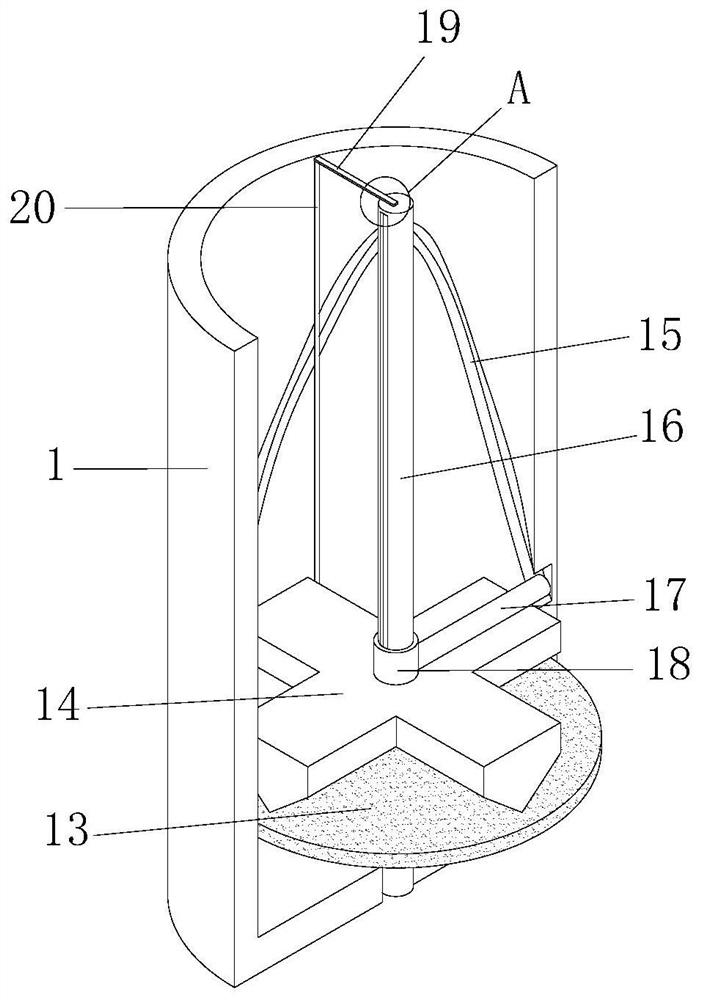

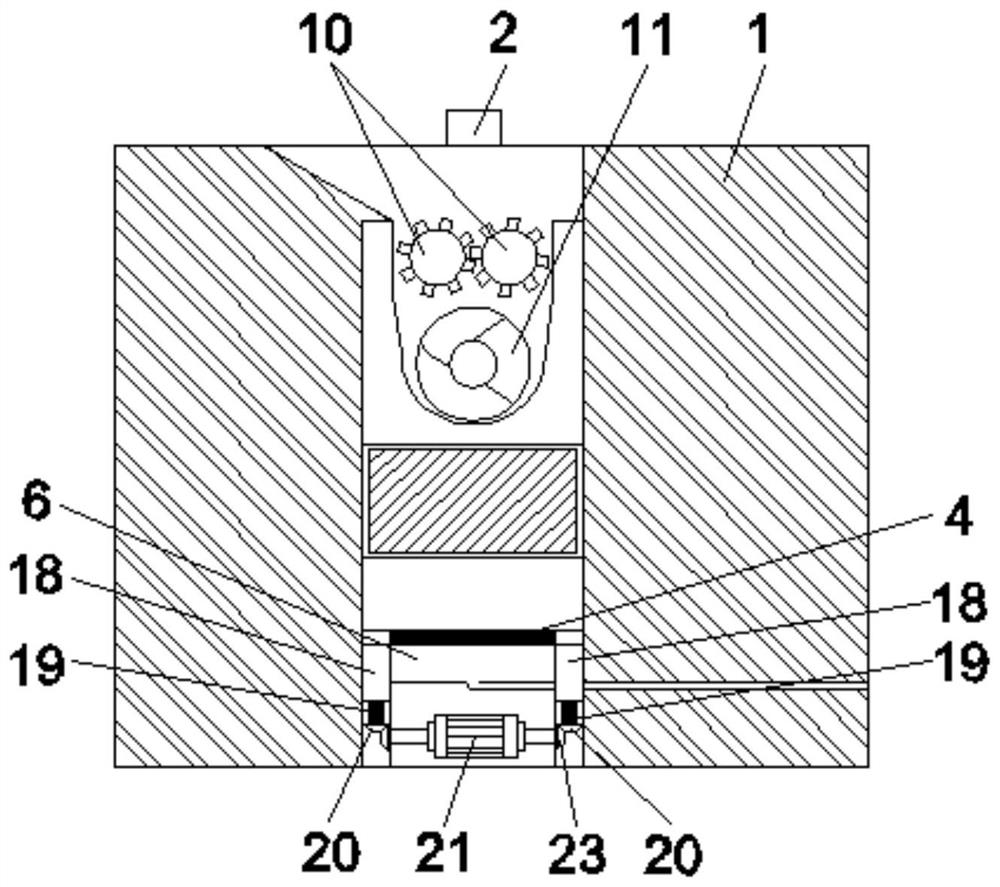

Drying unit for car flange production

InactiveCN108050788AImprove efficiencyPrevent heat lossDrying solid materials without heatDrying machines with non-progressive movementsEngineeringFlange

The invention discloses a drying unit for car flange production. The drying unit comprises a base, a box is fixedly installed at the top of the base, a waterproof barrel is fixedly installed at the top of the base and located inside the box, a separating plate is fixedly installed at the top of the waterproof barrel, a rotating shaft is rotationally connected to the center of the bottom of the base, the top end of the rotating shaft penetrates the separating plate and extends to the upper portion of the separating plate, the positions, located above the separating plate, of the surface of therotating shaft are sleeved with centrifugal pans, limiting rods are fixedly connected to the tops of the centrifugal pans, and the drying unit relates to the technical field of car part production. According to the drying unit for car flange production, the surface of the rotating shaft is in a hexagonal prism type, the centrifugal pans can be driven to rotate together, the surface of the rotatingshaft is divided into multiple orders and is gradually thinned from bottom to top, through grooves matched with the rotating shaft are formed inside the multiple centrifugal pans, the limiting rods corresponding to through holes in the surfaces of flanges and can be used for limiting the flanges, the multiple flanges can be subject to dehydration treatment, and the later-period drying efficiencyis improved.

Owner:曹诗晴

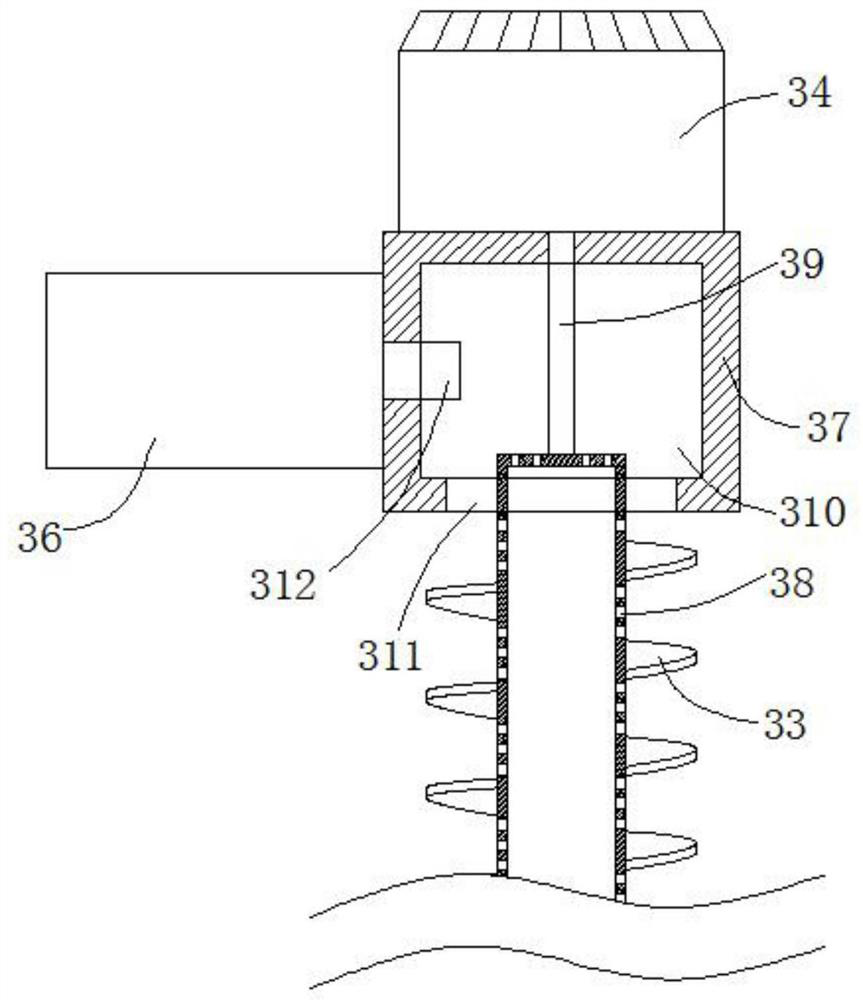

Sludge drying and reducing device and method

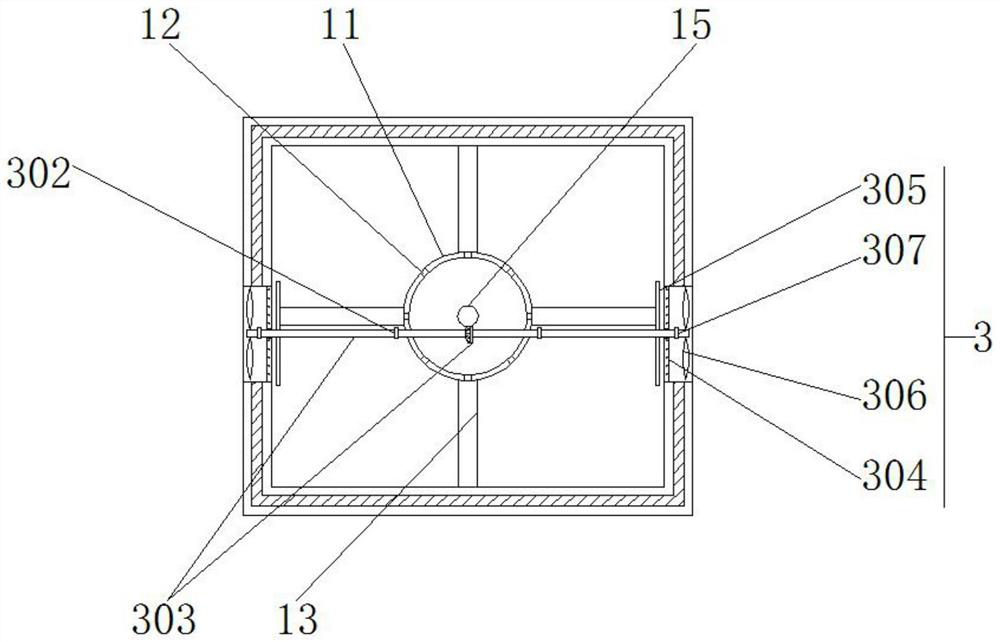

ActiveCN107459244BFast evaporationTo avoidSludge treatment by de-watering/drying/thickeningGrain treatmentsRadial planeSludge

The invention relates to a sludge drying reduction device and method. The device comprises a drying cylinder which is transversely arranged, wherein the drying cylinder comprises a feeding end and a discharging end; an air inlet is formed in the feeding end of the drying cylinder; an air outlet is formed in the discharging end; a rotating shaft penetrates through the center of an inner cavity of the drying cylinder in an axis direction; the rotating shaft is connected to a motor; a plurality of annular stirring blades are distributed outside the rotating shaft; an included angle of 30-60 degrees is formed between the stirring blades and the radial plane of the rotating shaft; all the stirring blades have the consistent direction. Wet sludge is fed from the feeding end of the drying cylinder, flue gas at the temperature of 850-950 DEG C is introduced from the air inlet of the drying cylinder, the flue gas introduction speed is controlled to be 3-12m / s, and the retention time of the flue gas in the drying cylinder does not exceed 2s. The wet sludge is heated by adopting the high-temperature flue gas, so that the sludge moisture is rapidly evaporated, and the drying efficiency of the wet sludge is improved. Meanwhile, the heat conversion rate is improved, so that the heat efficiency reaches 90%. The sludge drying reduction device has the advantages of high drying strength, low heat energy consumption and energy conservation.

Owner:南通久华环保设备科技有限公司

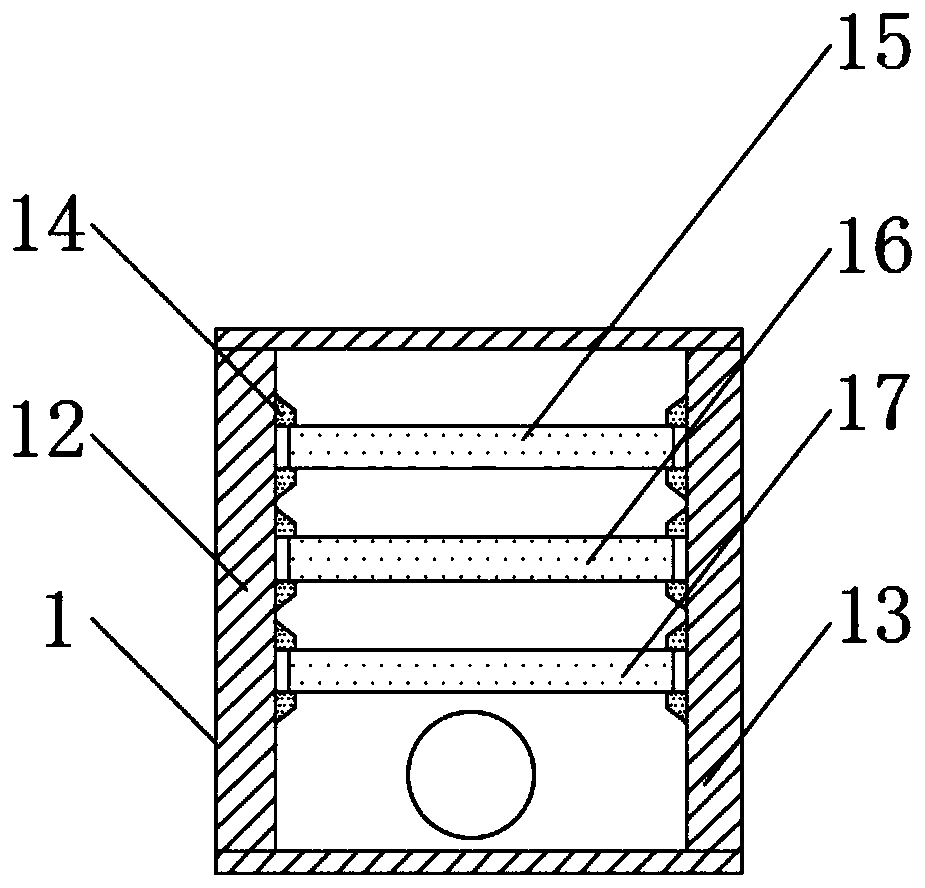

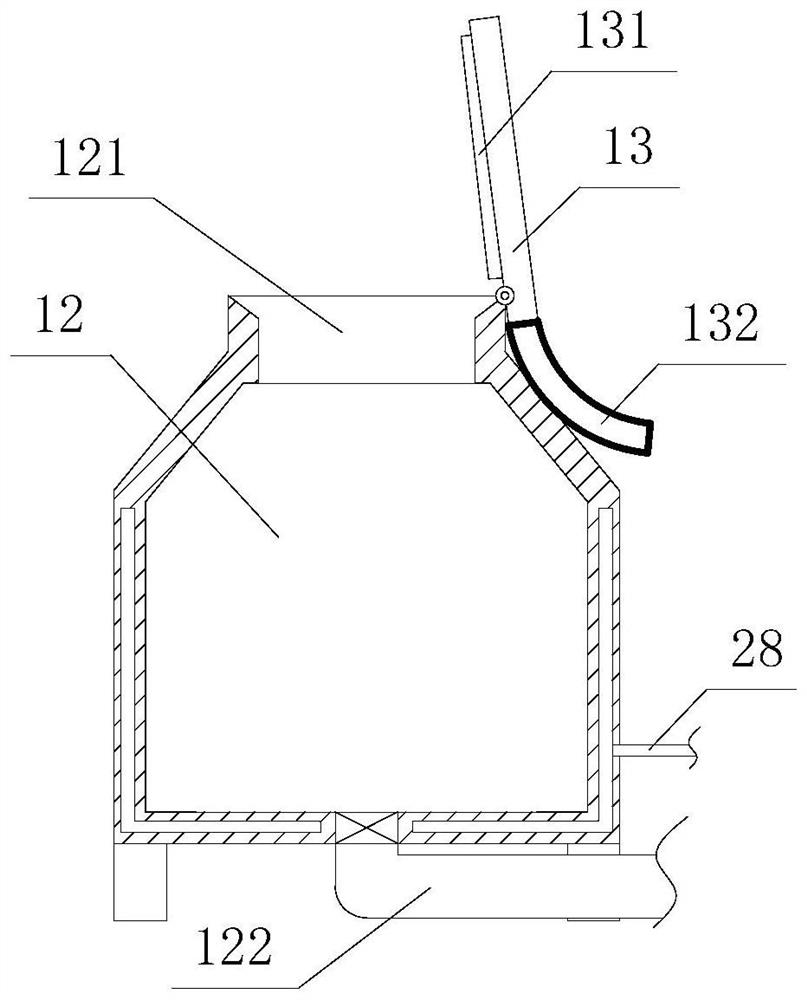

Feed drying device with spliced drying frame

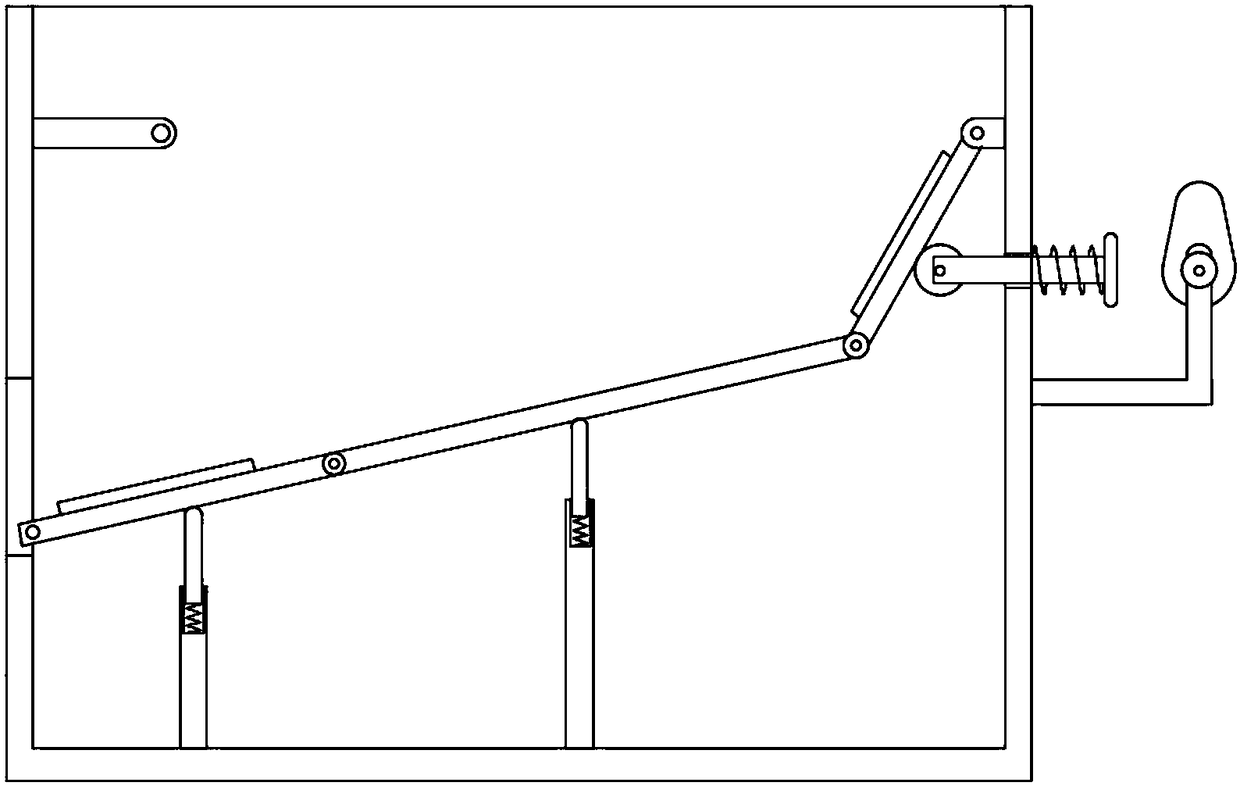

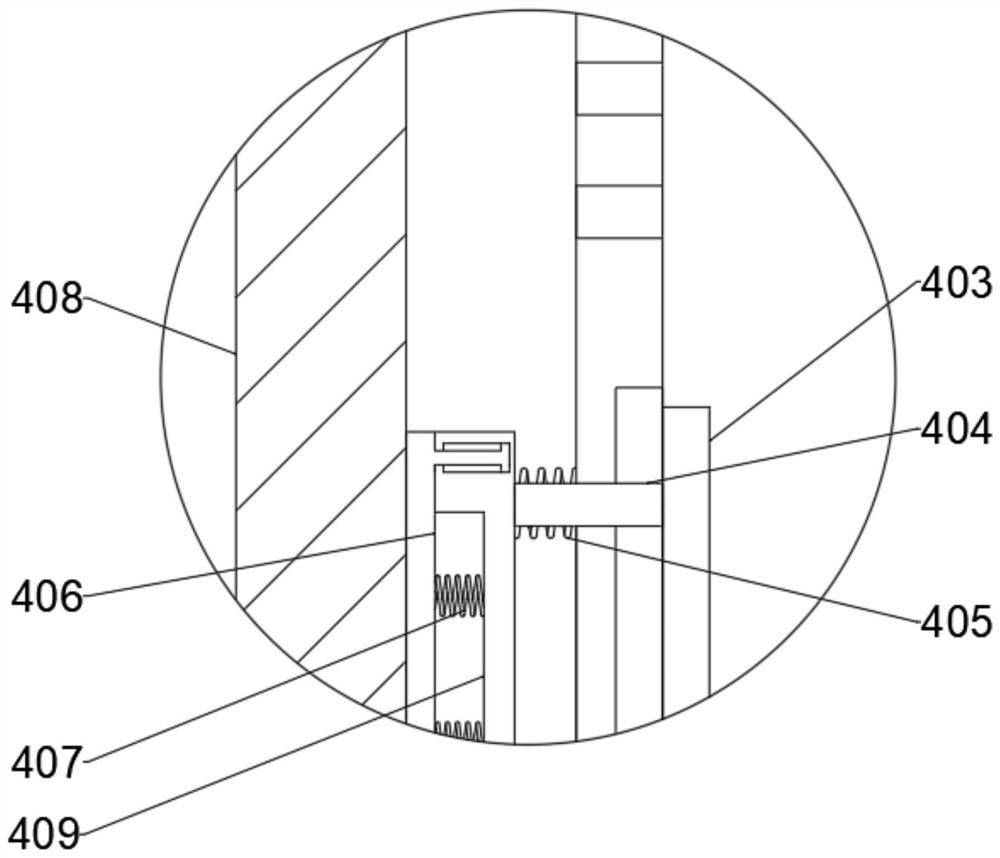

InactiveCN108168256AEffective protectionExtended service lifeDrying chambers/containersDrying machines with non-progressive movementsEngineeringCam

The invention discloses a feed drying device with a spliced drying frame. The feed drying device comprises a box and the drying frame; the box adopts top opening design; a discharge port is formed inthe lower side of the left side of the box; the drying frame is arranged in the upper position in an inner cavity of the box; the drying frame is formed by splicing a base plate, a left side plate anda right side plate; long and short support rods are fixed to the bottom surface of the inner cavity of the box; the long support rod is positioned below the base plate; the short support rod is positioned below the left side plate; an L-shaped frame is fixed to the outer wall of the right side of the box; a cam is mounted at the top of a vertical frame body of the L-shaped frame, and is providedwith a motor for driving the cam to rotate; and a moving rod is arranged in the position, opposite to the cam, of the right side plate of the box. The feed drying device is skillful in structure and simple in operation, can effectively solve the problem of influence on the drying efficiency by accumulation of feeds, and meanwhile, facilitates discharging.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

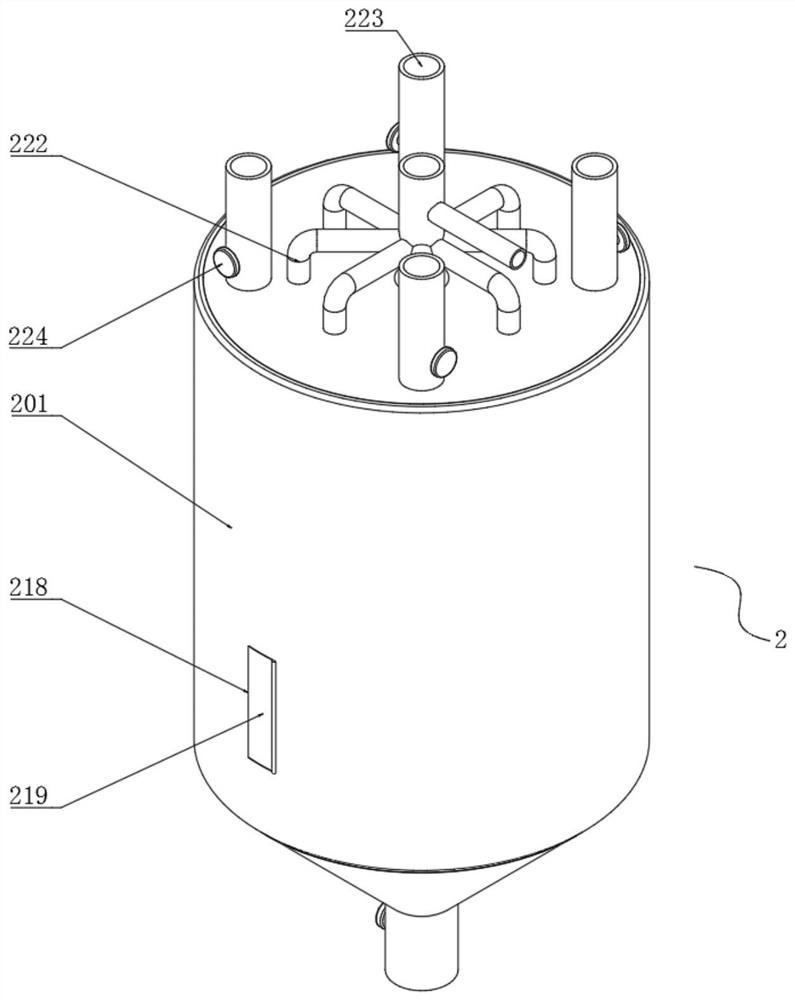

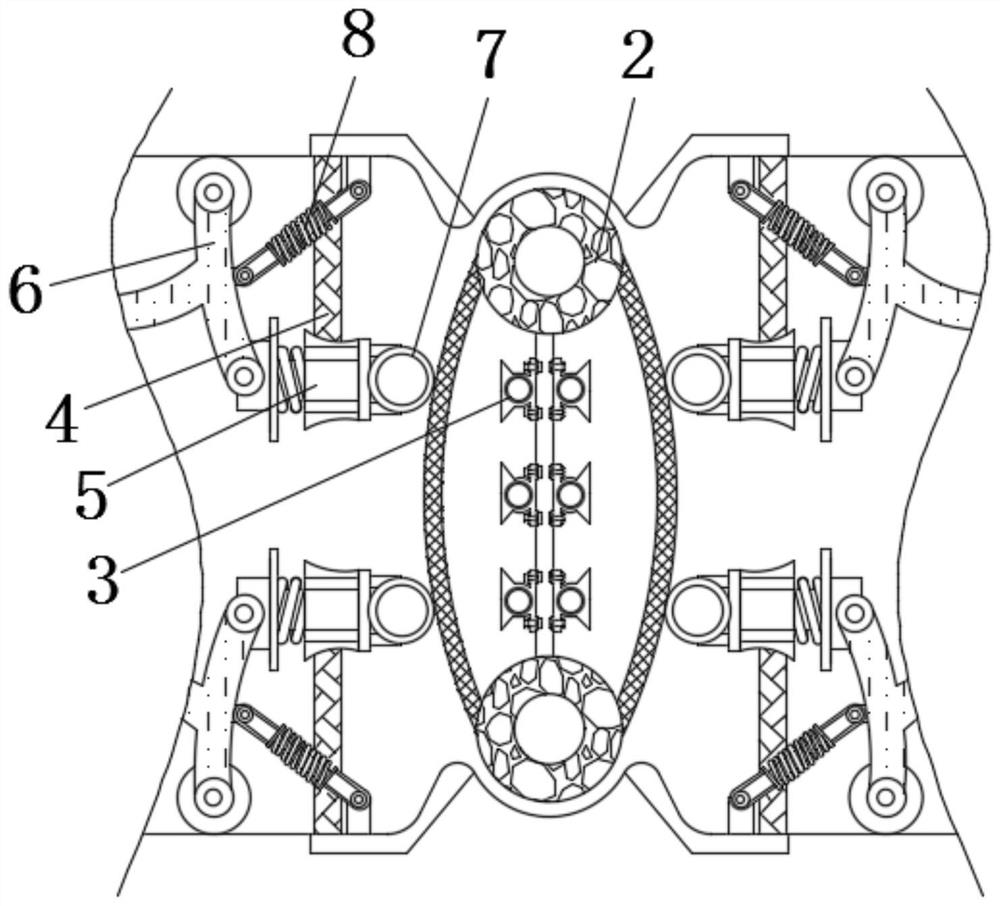

Rapid drying device for formed chemical fertilizers

ActiveCN112595057APrevent fertilizer cakingImprove drying efficiencySievingScreeningFertilizerElectric machinery

The invention relates to the technical field of chemistry, and discloses a rapid drying device for formed chemical fertilizers. The rapid drying device for the formed chemical fertilizers comprises adrying barrel, wherein the outer surface of the drying barrel is fixedly connected with a heat preservation and insulation pad; the upper end of the drying barrel is provided with a heating hole; an electric heating pipe is movably clamped in the heating hole; the upper end of the drying barrel is provided with a sealing cover; supporting legs are fixedly connected to the lower end of the drying barrel; a motor is fixedly connected to the lower surface of the drying barrel; a discharging port is formed in the outer surface of the drying barrel; and a blocking plate is arranged in the discharging port. According to the rapid drying device for the formed fertilizers, the fertilizers in the drying barrel is turned up and down, so that the fertilizers can form a material curtain, the fertilizers at the bottom can be in uniform contact with heat, the caking phenomenon caused by non-uniform heating due to fertilizer accumulation is avoided, the heating efficiency of the fertilizer is improved, the drying speed is increased, the drying time is saved, and the production efficiency is improved.

Owner:江西瑞思博新材料有限公司

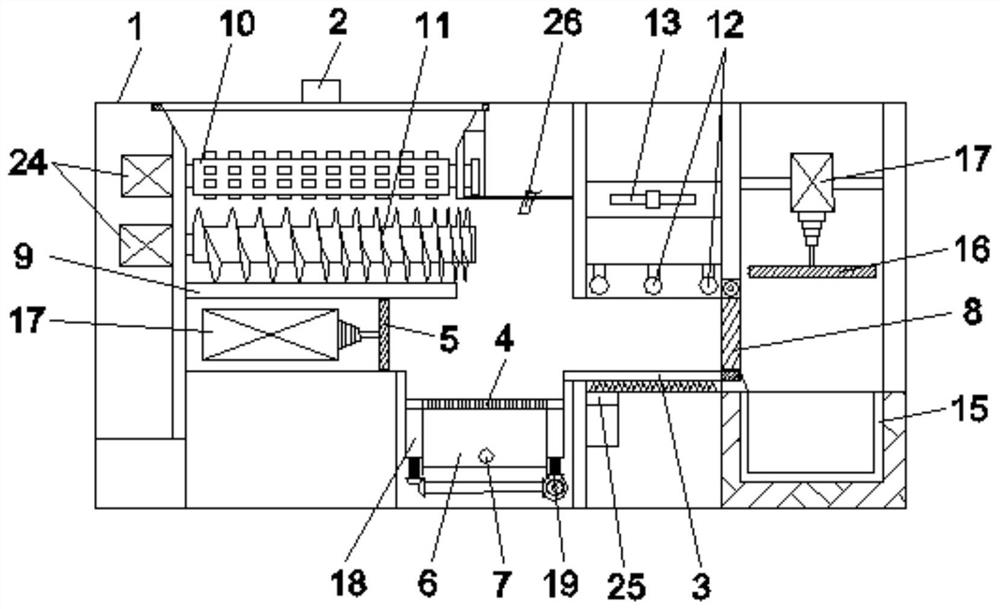

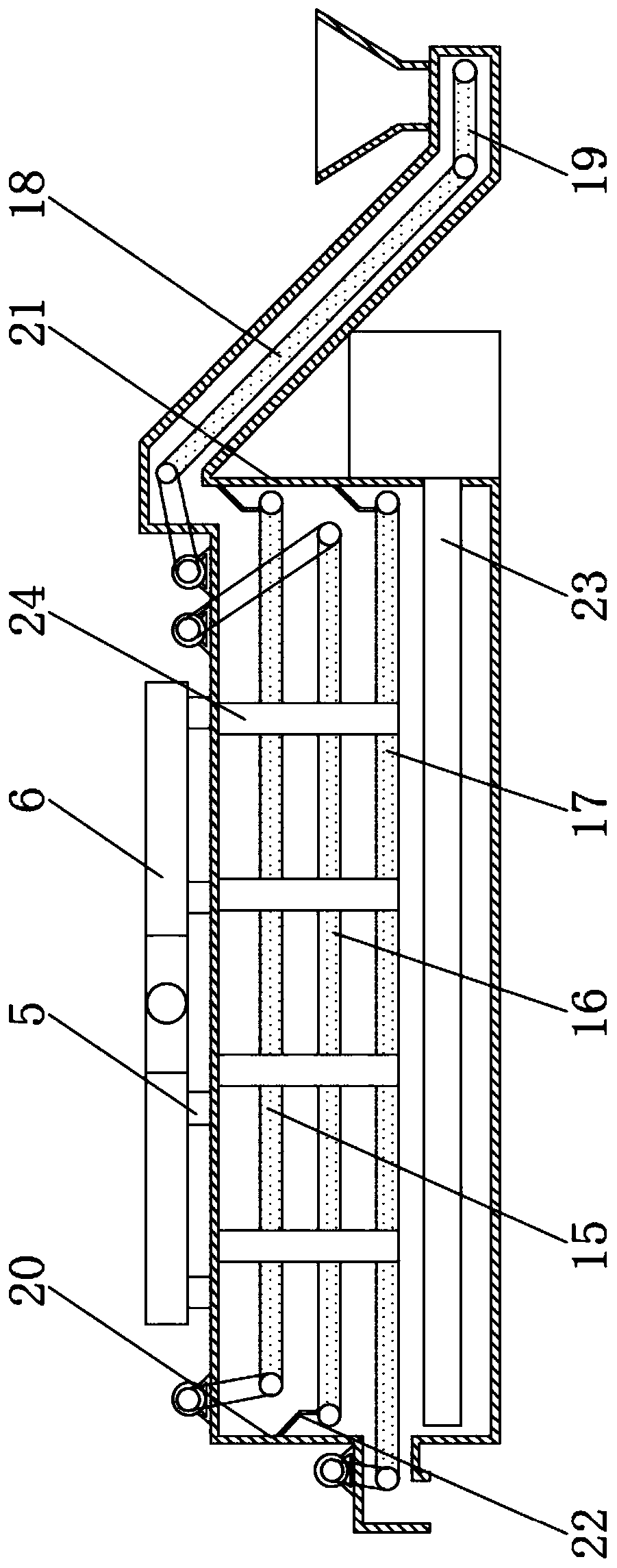

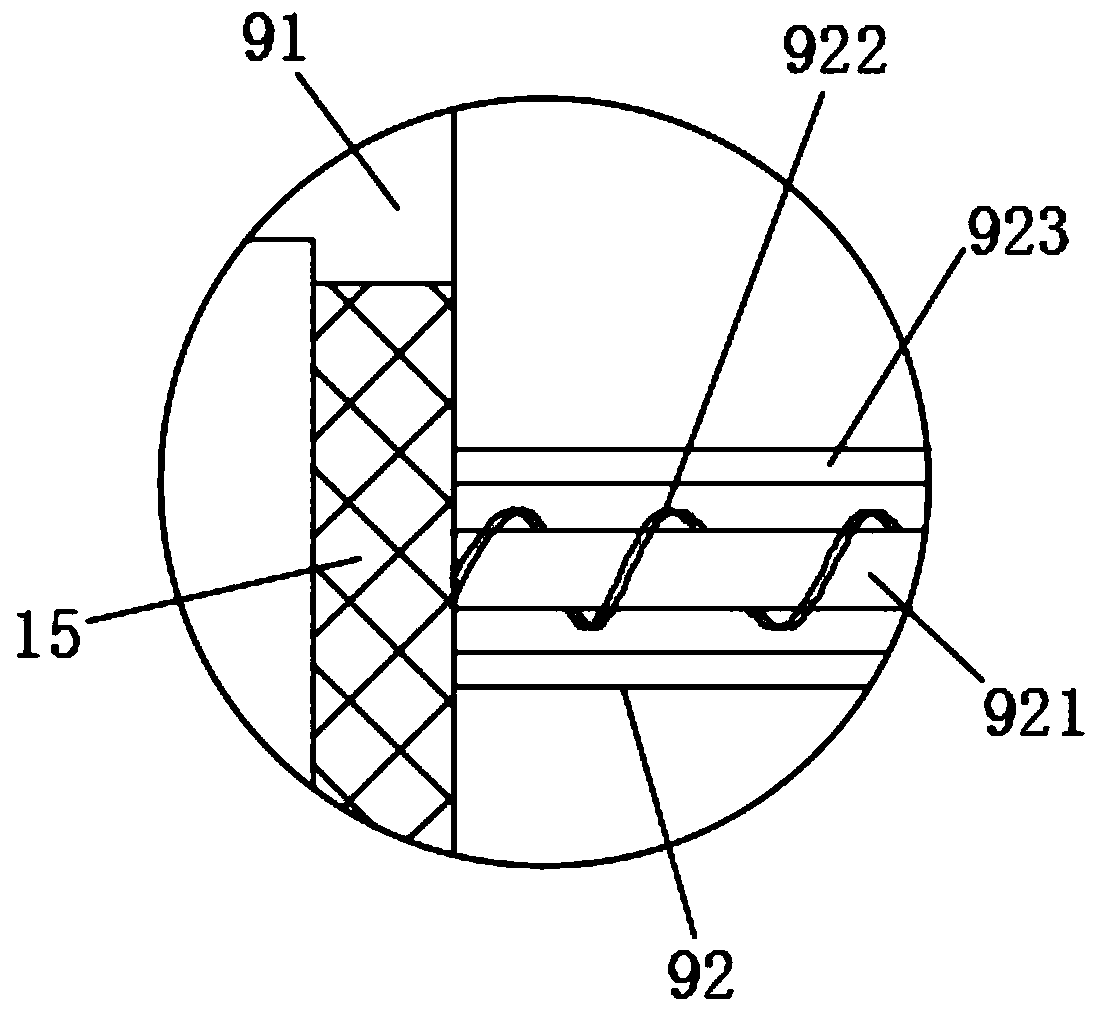

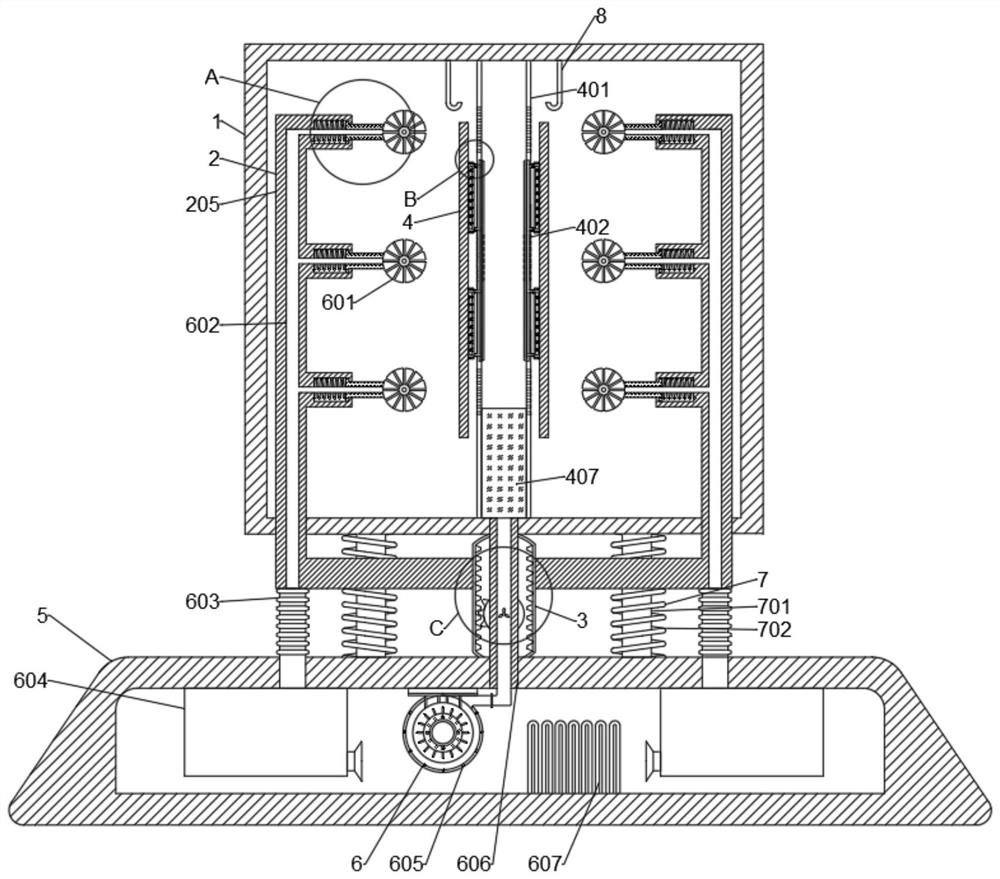

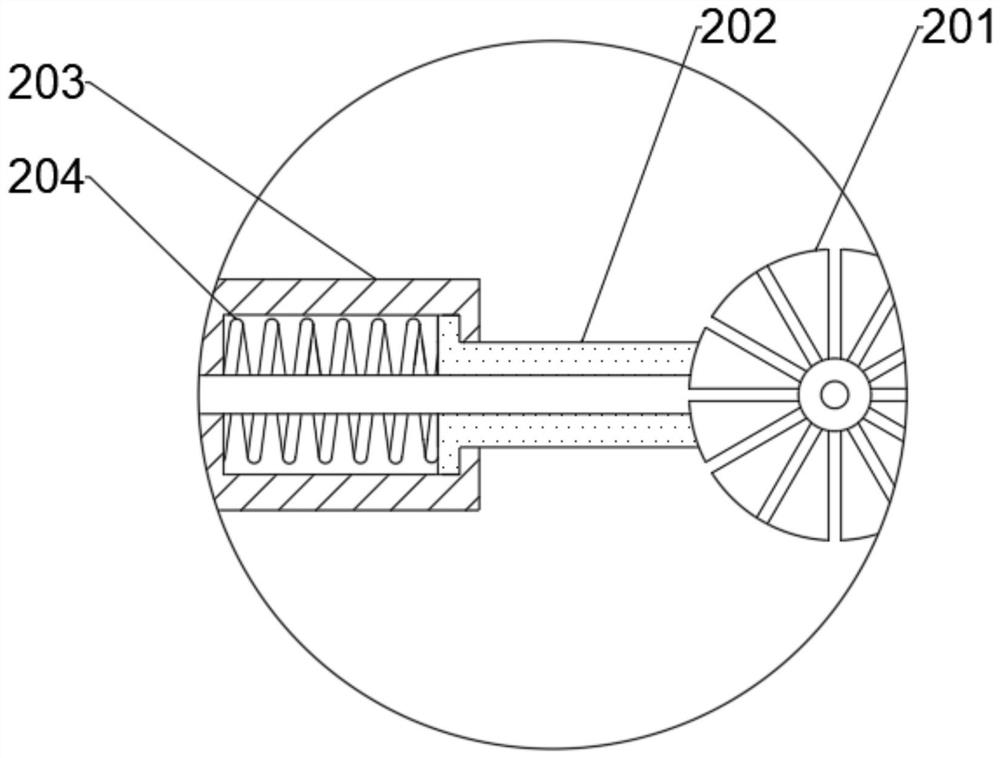

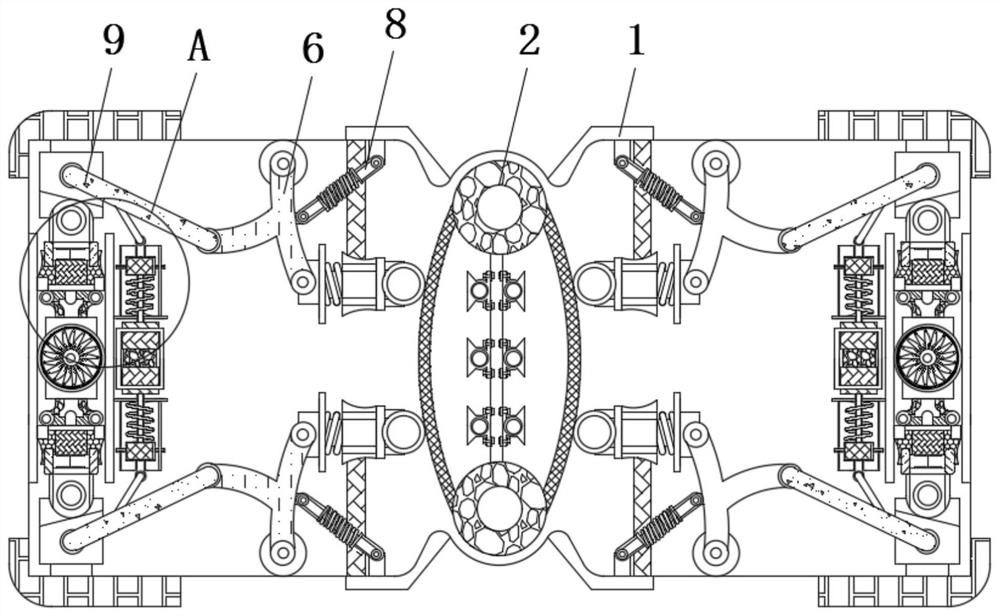

Textile fabric heat pump dryer

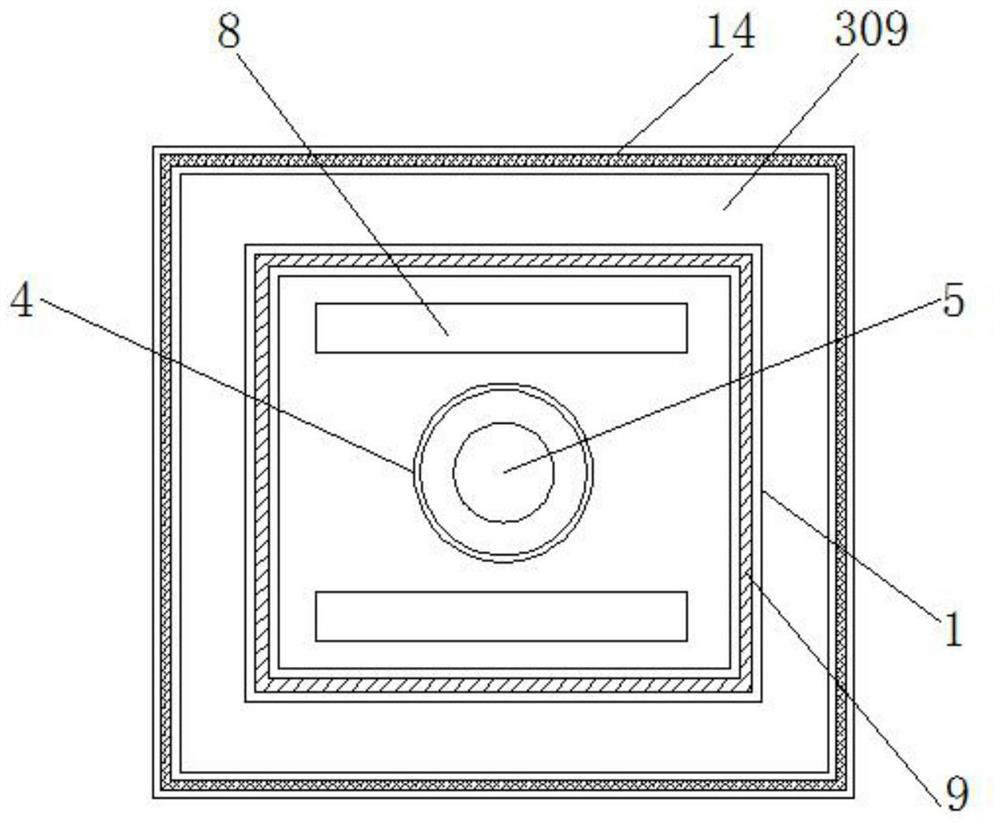

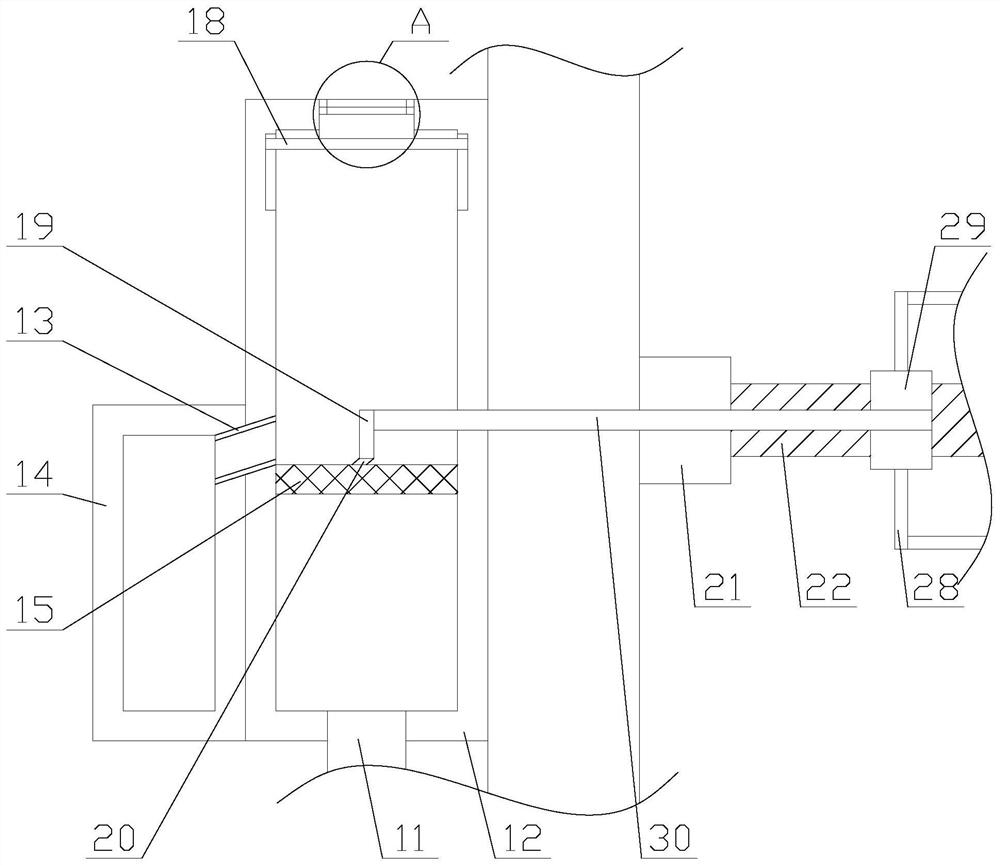

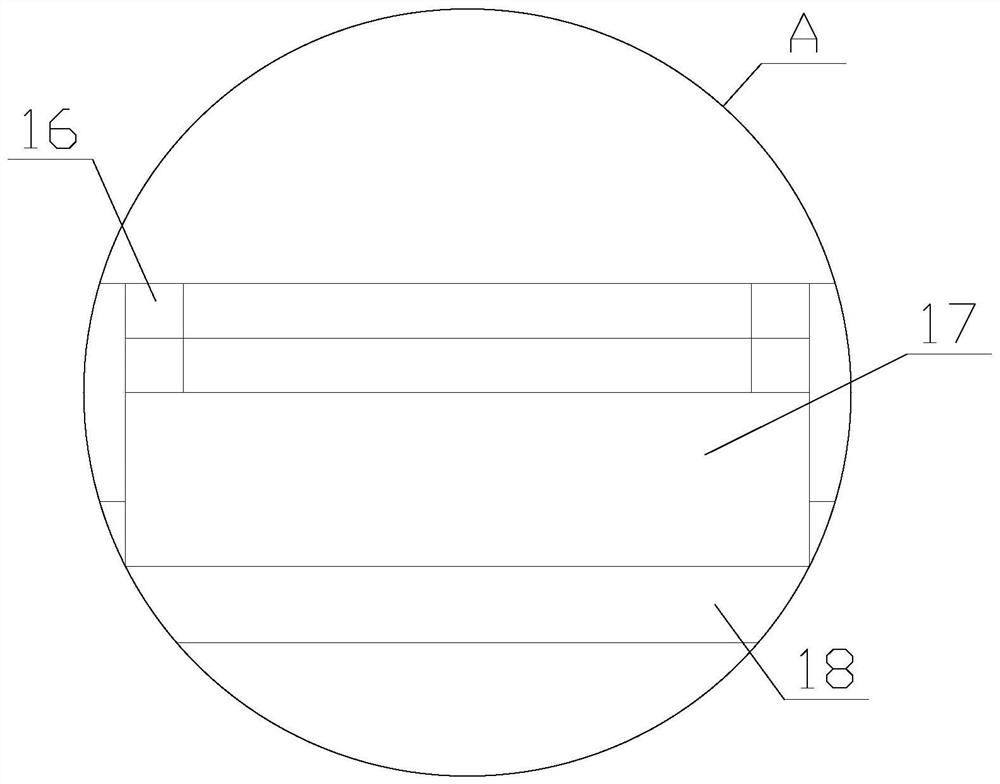

PendingCN112728908ASave energyAchieve attractionDrying gas arrangementsDrying chambers/containersEngineeringDry box

The invention belongs to the field of dryers, and particularly relates to a textile fabric heat pump dryer which comprises a drying box body. Two symmetrically-arranged supports are fixedly connected to the lower wall of the inner side of the drying box body, transmission wheels are rotatably connected to the side walls of the supports, and the two transmission wheels are jointly in transmission connection with cloth. A heat pump machine is fixedly connected to the inner side wall of the drying box body, an air outlet pipe fixedly communicates with the side wall of the heat pump machine in a sealed manner, multiple spiral coils are embedded in the side wall of the air outlet pipe, a supporting block is fixedly connected to the inner side wall of the air outlet pipe, and a rotating shaft is rotatably connected to the side wall of the supporting block. A fan is coaxially and fixedly connected to the upper end of the rotating shaft, a permanent magnet is embedded in the fan, iron cores are fixedly connected to the two sides of the air outlet pipe, and wires are wound around the iron cores. The textile fabric heat pump dryer has the advantages that by arranging the permanent magnet and the spiral coils, the situation that the cloth is blown up by wind, and consequently drying efficiency is affected is avoided, and by arranging an incomplete gear and a push plate, product quality is improved.

Owner:兰建德

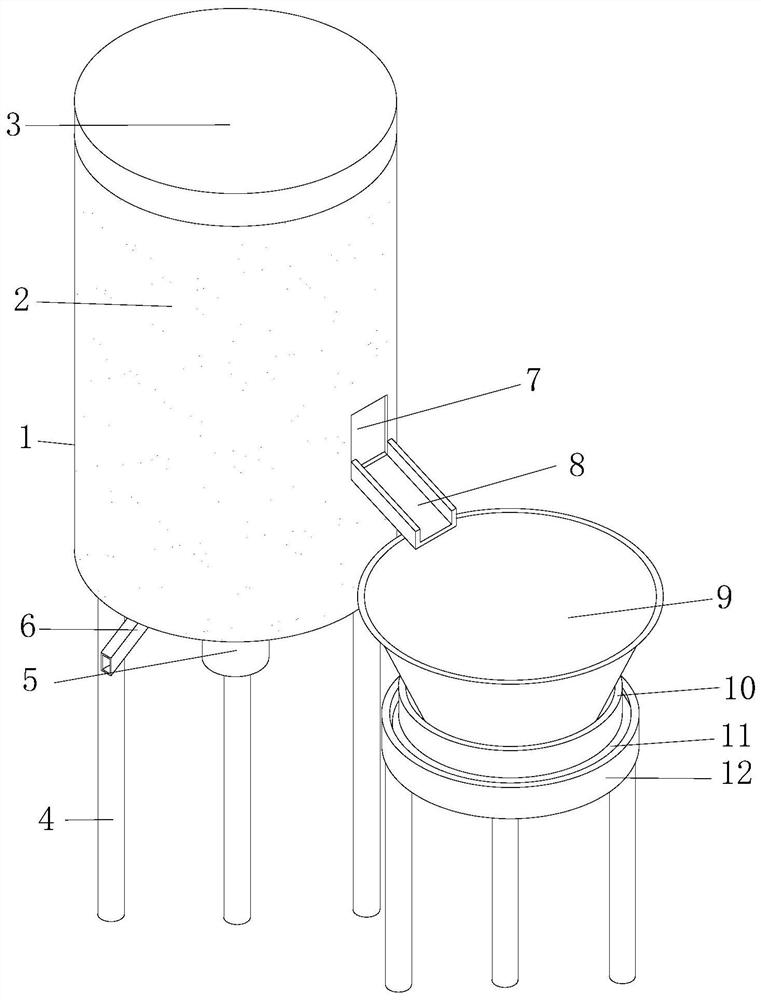

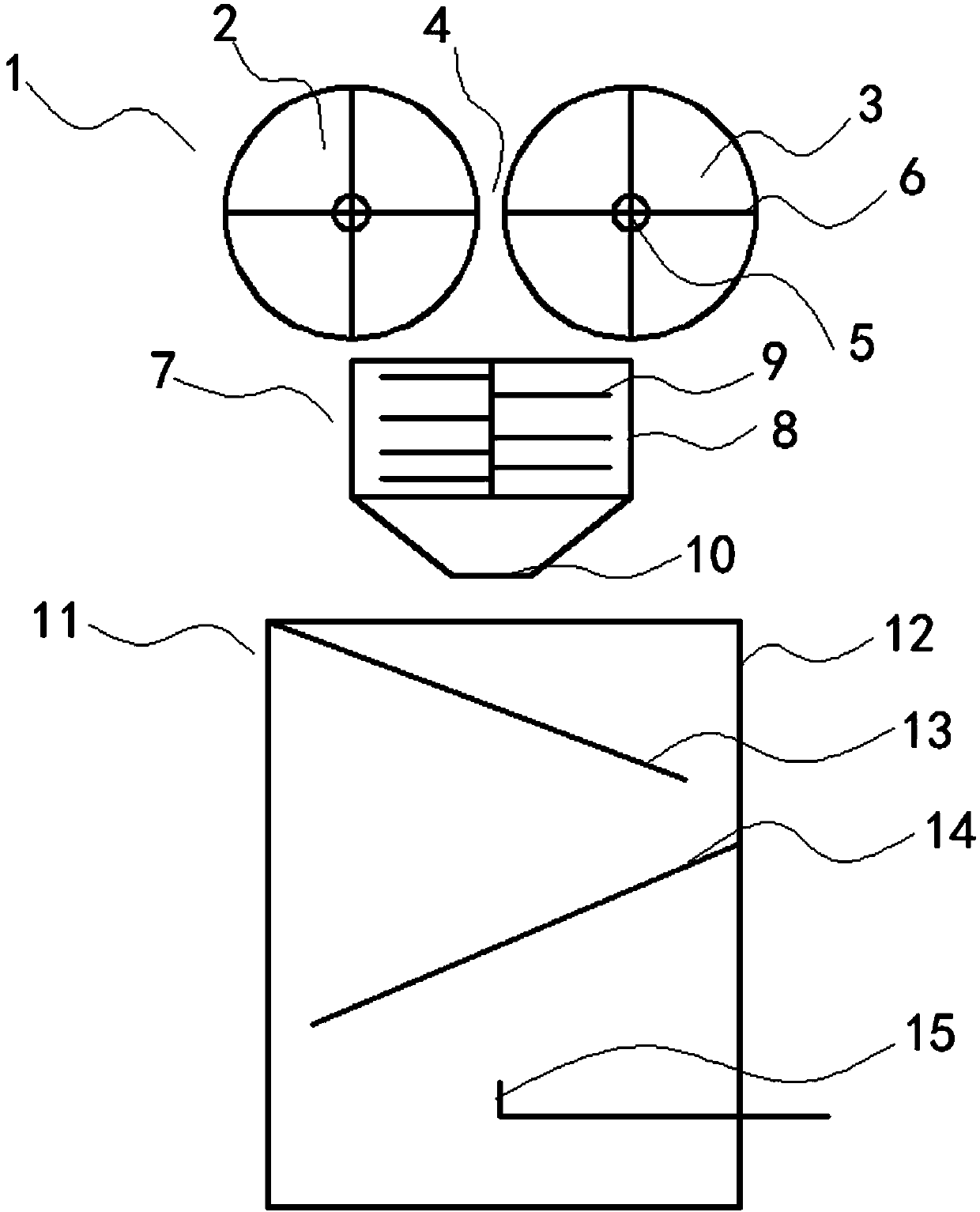

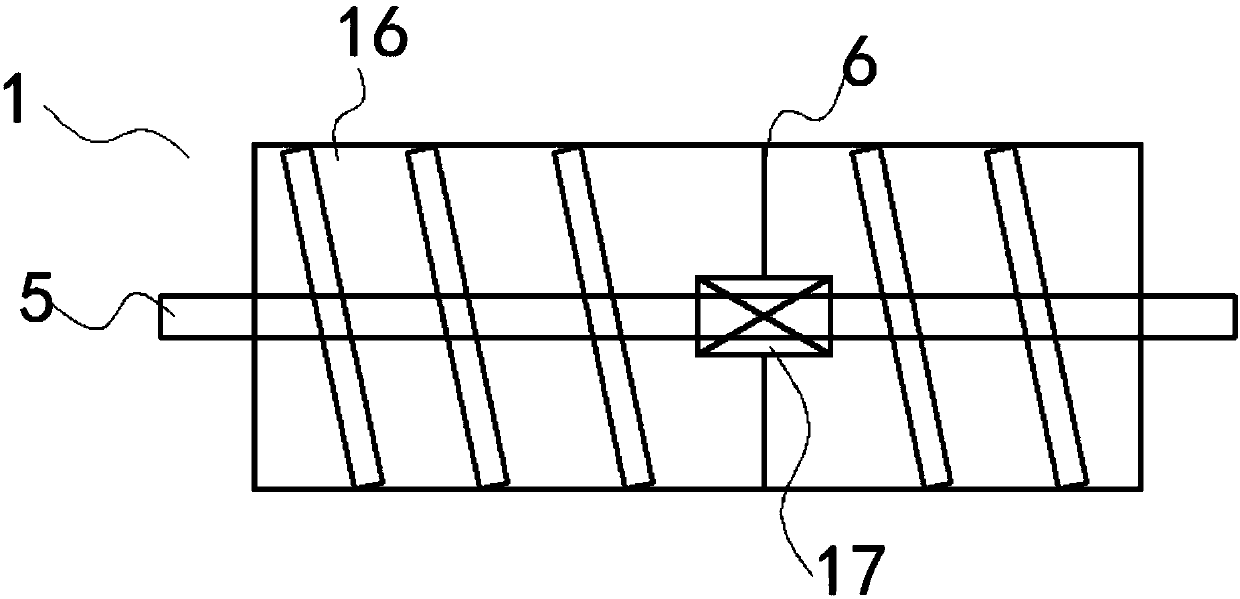

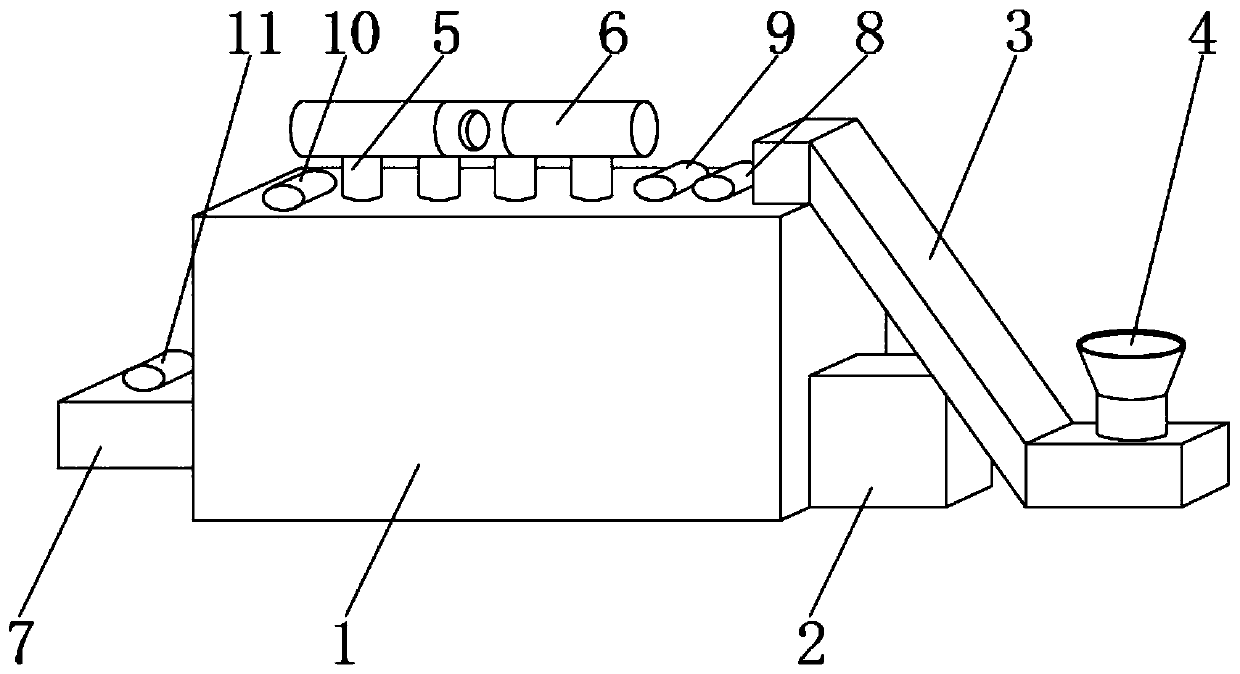

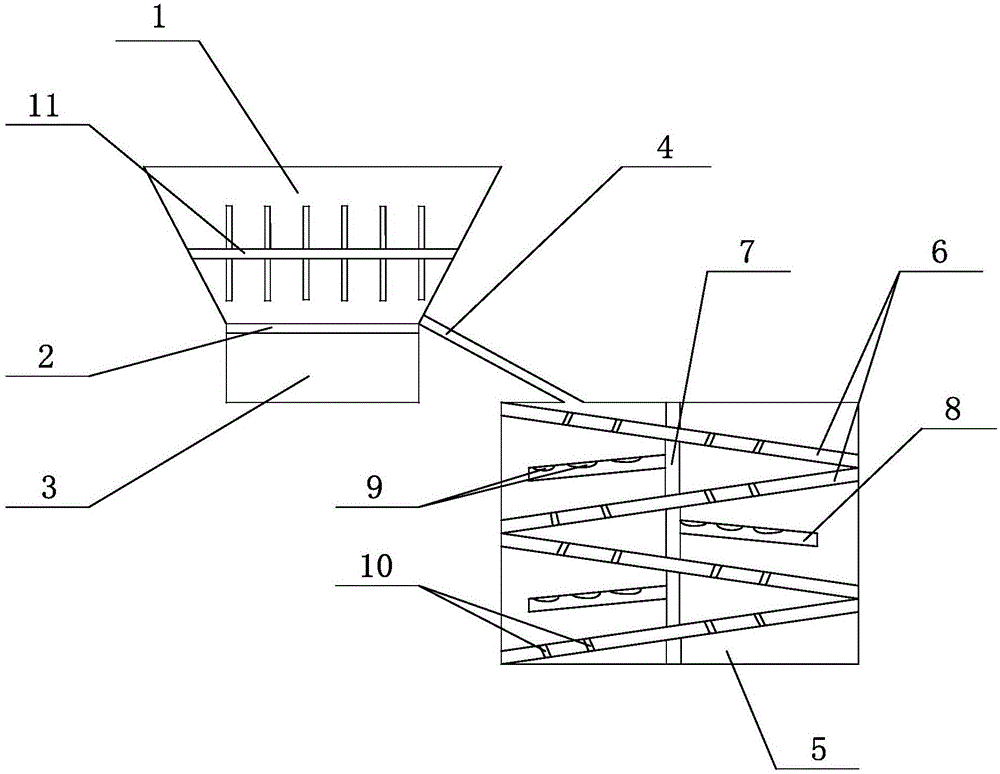

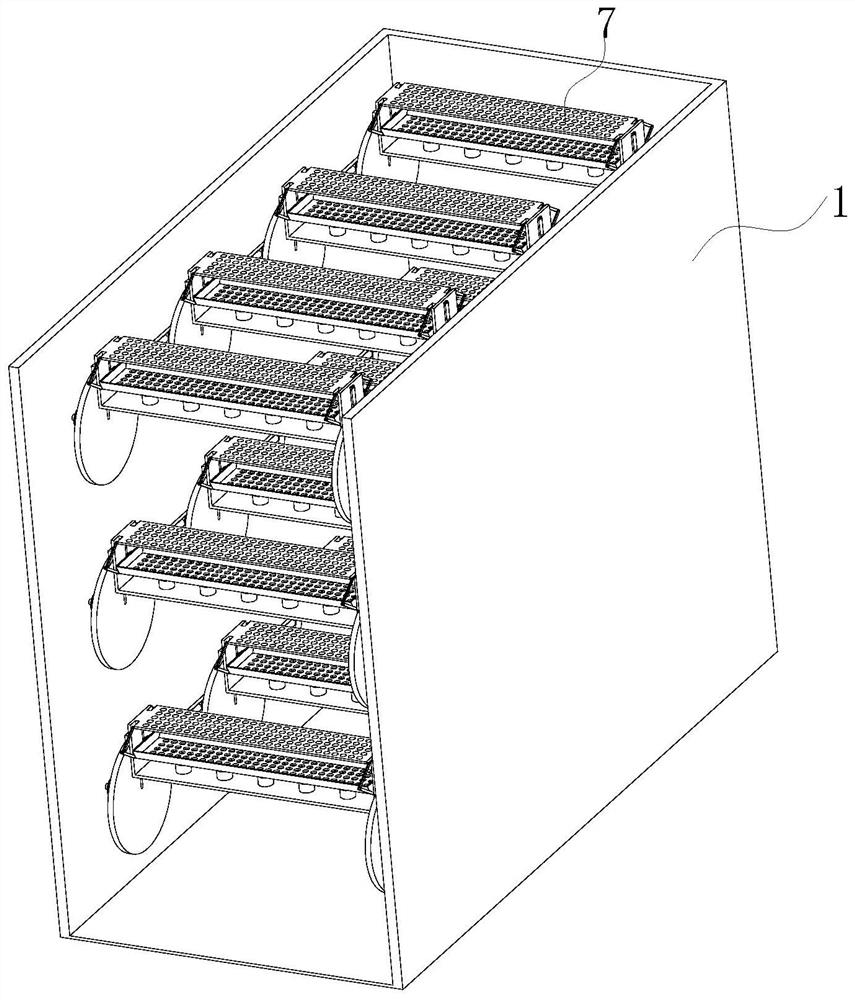

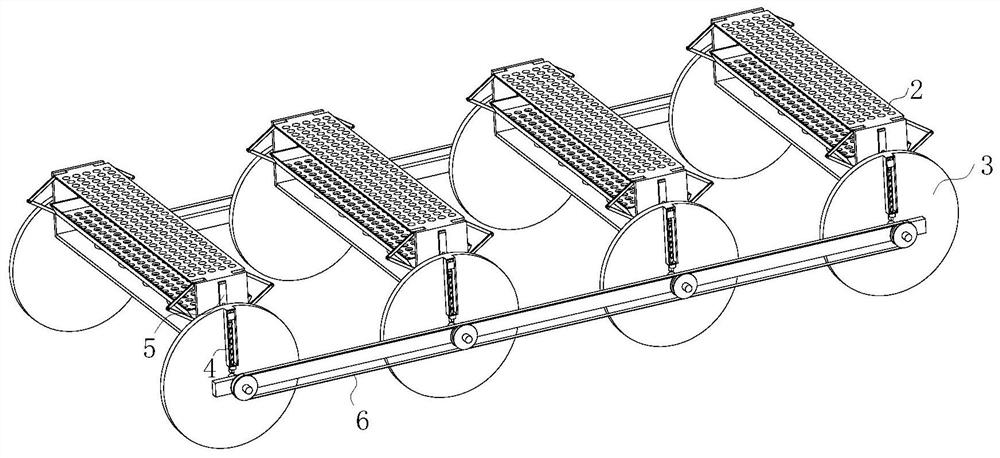

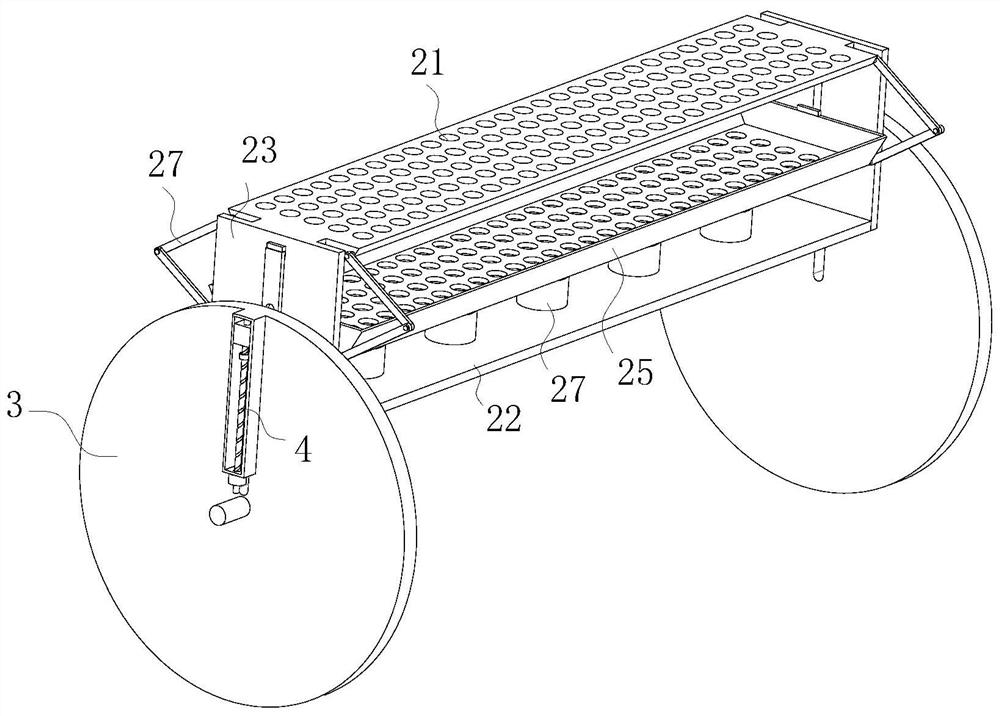

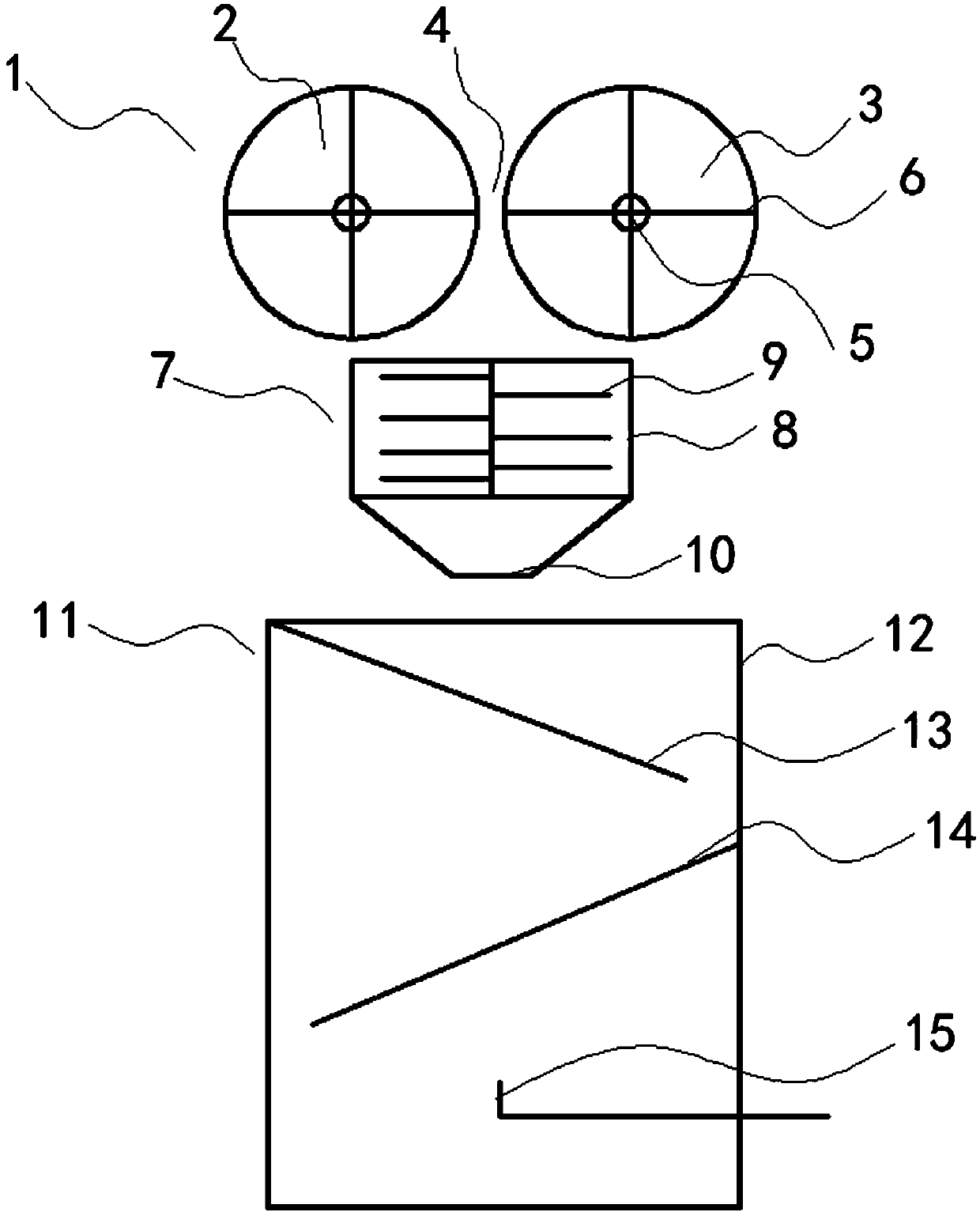

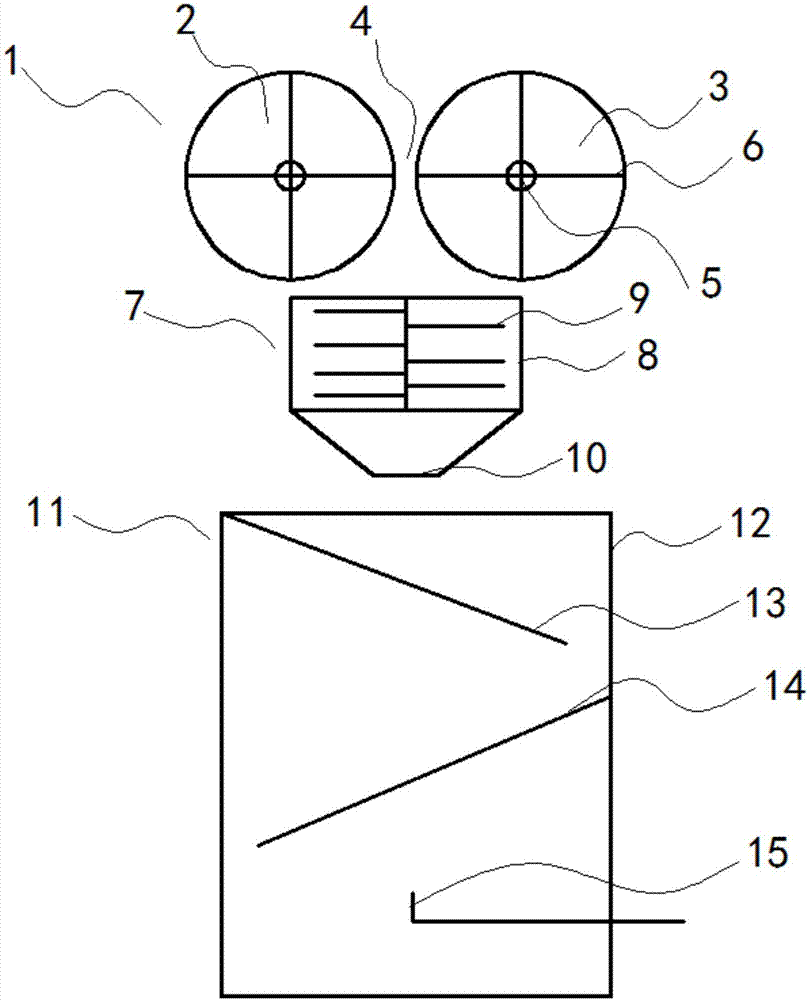

Drying device for bagasse drying

InactiveCN107726746ATake away in timeIncrease contact timeDrying solid materials without heatPreliminary solid treatment for dryingEngineeringFunnel shape

The invention discloses a drying device for bagasse drying. The drying device for bagasse drying comprises a dewatering device, a smashing device and a drying box, the dewatering device comprises a rolling unit and a sucking unit arranged in the rolling unit; the rolling unit comprises a first rolling column and a second rolling column which are equal in size; a first gap used for rolling materials is formed between the first rolling column and the second rolling column; first grooves are formed in the outer surfaces of the rolling columns, and are spirally encircled on the outer surface of abarrel; the annular grooves are in parallel at equal intervals; the smashing device is arranged below the dewatering device, and comprises a funnel-shaped material bin and a stirrer; and the drying box is arranged below the smashing device, and a gas inlet used for introducing hot gas is further formed in the lower portion of the drying box.

Owner:陈志周

Multifunctional household kitchen garbage pretreatment device

PendingCN113334827AReduce moisture contentFor subsequent collectionGrain treatmentsPressesHome useEnvironmental engineering

The invention relates to a multifunctional household kitchen garbage pretreatment device which comprises a box body, the internal space of the box body is divided into a treatment chamber and a collection chamber by a vertically and fixedly mounted partition plate, the top of the box body is provided with at least one feed port communicated with the treatment chamber, and the bottom of the box body is provided with a discharge port communicated with the collection chamber; an opening communicated with the treatment chamber and the collection chamber is formed in the partition plate, and a drying platform is horizontally and fixedly installed at the position, corresponding to the opening, of the lower part in the treatment chamber; and to-be-treated kitchen garbage fed from the feed port can fall onto the drying platform to be dried, and can enter the collection chamber from the opening to be collected. The device has the beneficial effects that the structure is compact, the operations of crushing, dewatering, drying, sterilizing, compressing and the like of the kitchen garbage can be realized, and subsequent recycling, secondary utilization, collection and transportation of the kitchen garbage are facilitated.

Owner:WUHAN UNIV OF SCI & TECH

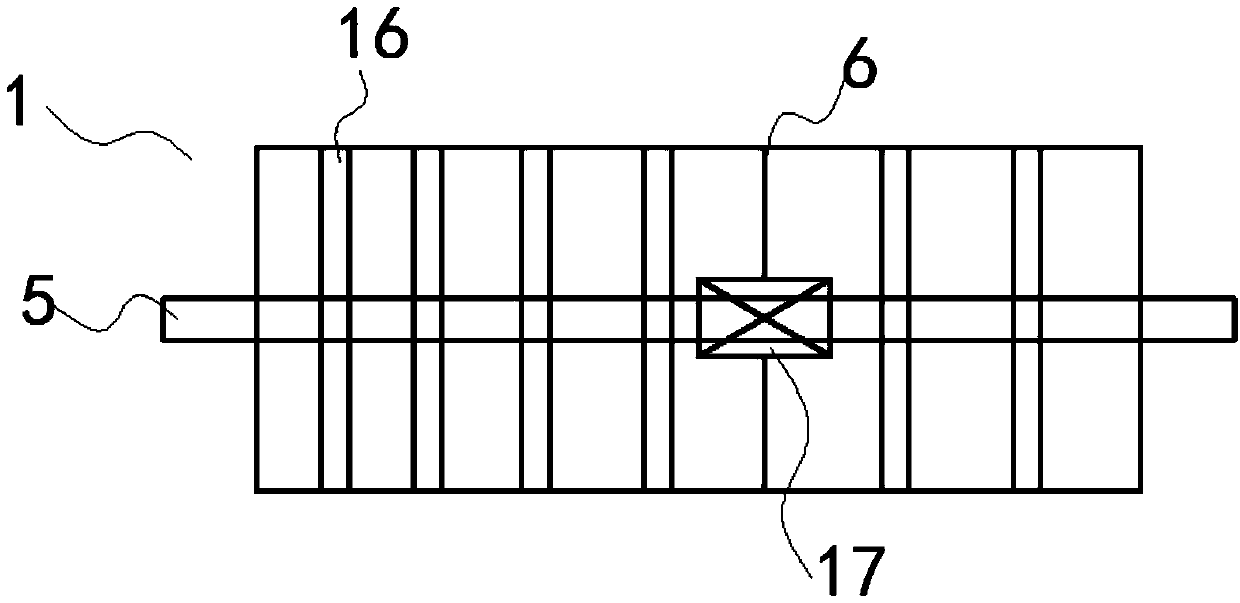

Dryer

PendingCN109780842APracticalSimple structureDrying solid materialsHeating arrangementEngineeringEvaporator

The invention discloses a dryer. The dryer comprises a dryer main body box and a drying unit; the drying unit consists of an evaporator, a compressor, a condenser and an expansion valve; the peripheryof the dryer main body box consists of a front box plate, a back box plate, a left box plate and a right box plate; and the drying unit is fixedly mounted on one side of the bottom end of the dryer main body box. The dryer is provided with a support rod, a ventilation pipe, an exhaust port and a feeding cross bar; when grain particles are conveyed on a conveying belt after entering the dryer mainbody box, the particles can be prevented from falling from cracks, and meanwhile, the drying effect is improved; hot steam generated by the drying unit can be uniformly transferred up to prevent nonuniform drying caused by narrow transfer range; and the grain particles can be preferably loaded, so that the supply insufficiency caused by slippage is prevented, the influence on the drying quantityand the drying efficiency is prevented, a certain practicability is achieved, and the better application prospect is achieved.

Owner:ANHUI PROVINCE YINGSHANG COUNTY SANJIN GRAINS ANDOILS CO LTD

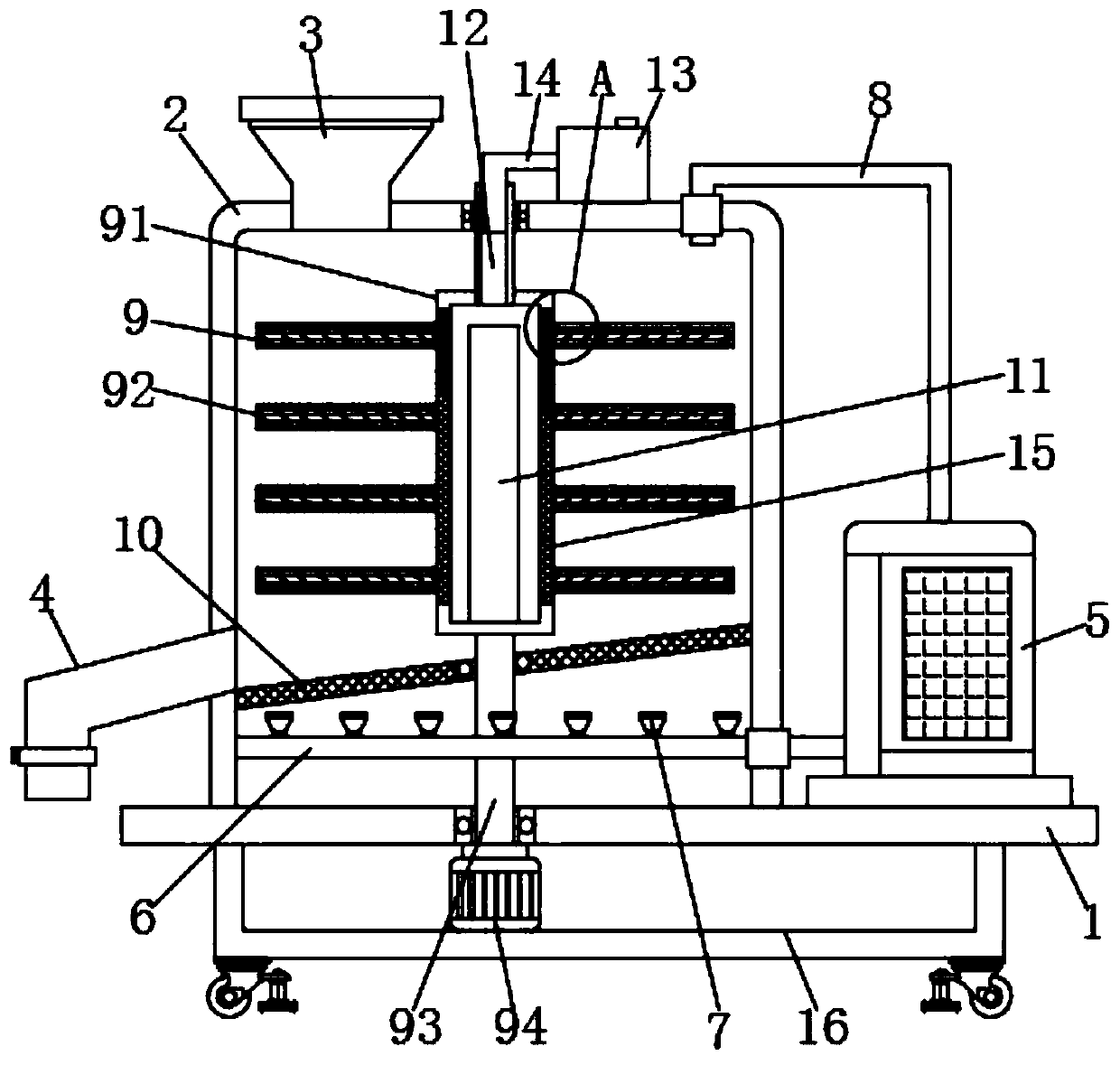

Food processing and drying treatment device

PendingCN110537572AImprove work efficiencyDry evenlyFood processingClimate change adaptationProcess engineeringHeat flow

The invention discloses a food processing and drying treatment device, and belongs to the field of food processing. The food processing and drying treatment device comprises a supporting plate, a drying box is fixedly connected to the top of the supporting plate, a feeding hopper communicates with the top of the drying box, a sealing cover is arranged at the top of the feeding hopper, and a discharge pipe communicates with the lower part of the left side of the drying box. An air energy heat pump dryer is energized, hot air is sent into the inside of the drying box through an air inlet pipe and a plurality of sprayers to heat and dry food materials, generated hot and humid air rises through an upper air return pipe, and then enters the air energy heat pump dryer, the air energy heat pump dryer dehumidifies and heats the hot and humid air, and the hot air enters the drying box again to form a heat flow cycle, the materials in the drying box are dried gradually, the working efficiency isimproved, energy conservation and environmental protection are achieved, meanwhile the food materials in the drying box can be dried and stirred under the action of a heating and stirring device, thus the materials are dried more evenly, and the drying effect is better.

Owner:XUZHOU UNIV OF TECH

Drying device for producing sodium dihydrogen phosphate

InactiveCN106839659AImprove drying efficiencyAvoid thermal decompositionDrying solid materials without heatDrying gas arrangementsWater filterPulp and paper industry

The invention discloses a drying device for producing sodium dihydrogen phosphate, which comprises a water filtering device, a water filtering plate is arranged under the water filtering device, a water filtering collecting chamber is arranged under the water filtering plate, and a discharge is arranged at the bottom of the side of the water filtering device. The tail end of the discharge pipe is connected with a drying chamber, the top of the drying chamber is provided with a plurality of ventilation pipes, and the drying chamber is provided with a spiral plate from top to bottom, and an aeration shaft is provided on the axis of the spiral plate, and on the aeration shaft A plurality of aeration rods are connected, and a plurality of aeration holes are arranged on the aeration rod; a plurality of evenly distributed through holes are arranged on the spiral plate; a refrigeration device is arranged in the drying chamber. The drying device of the present invention can improve the drying efficiency of the sodium dihydrogen phosphate, and keep it dried in a low-temperature environment, thereby avoiding thermal decomposition of the sodium dihydrogen phosphate.

Owner:SICHUAN BESTLUCK CHEM

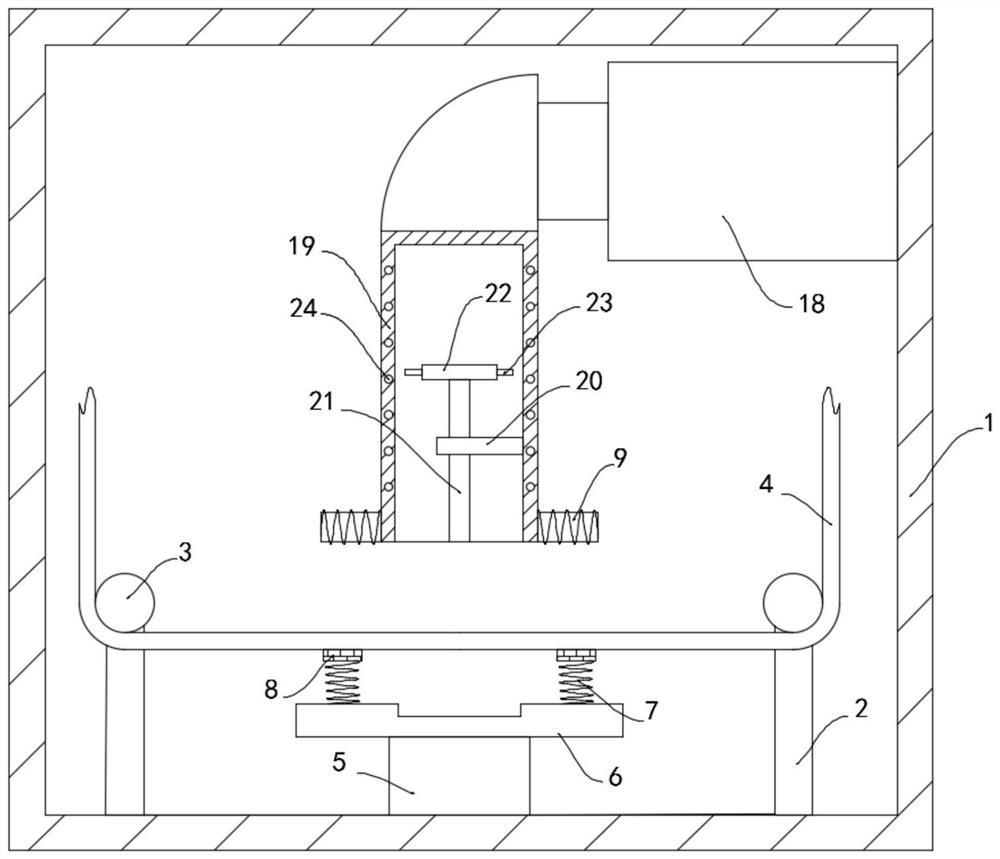

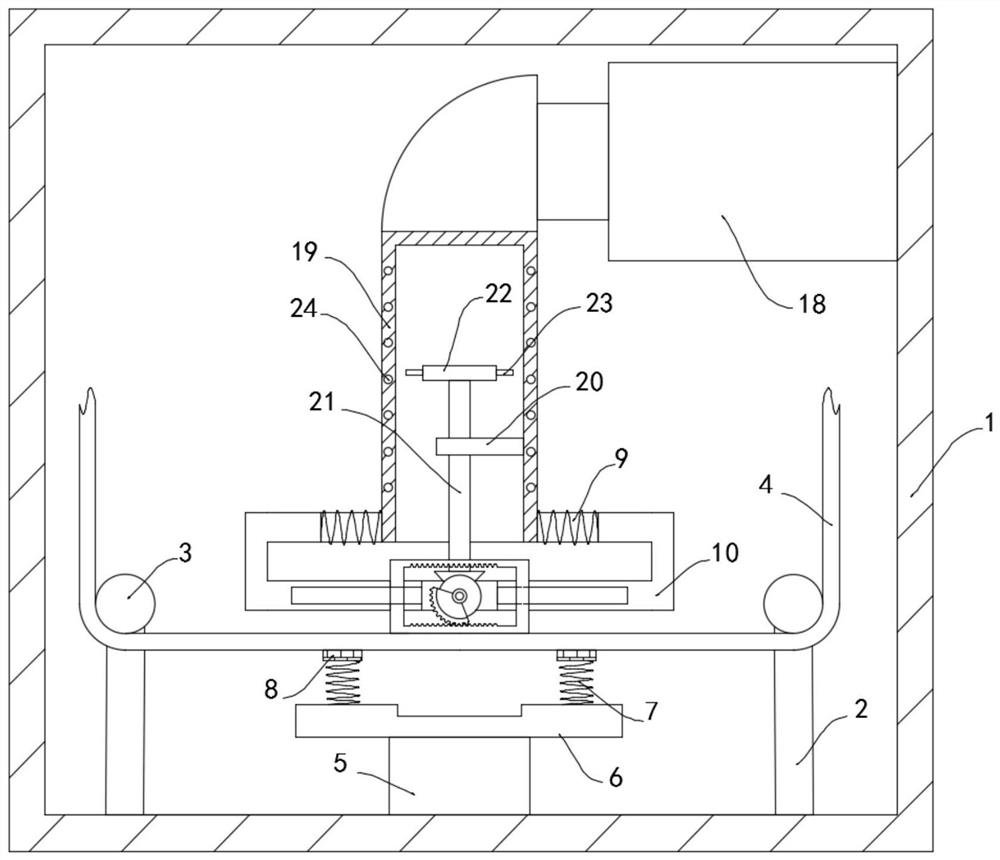

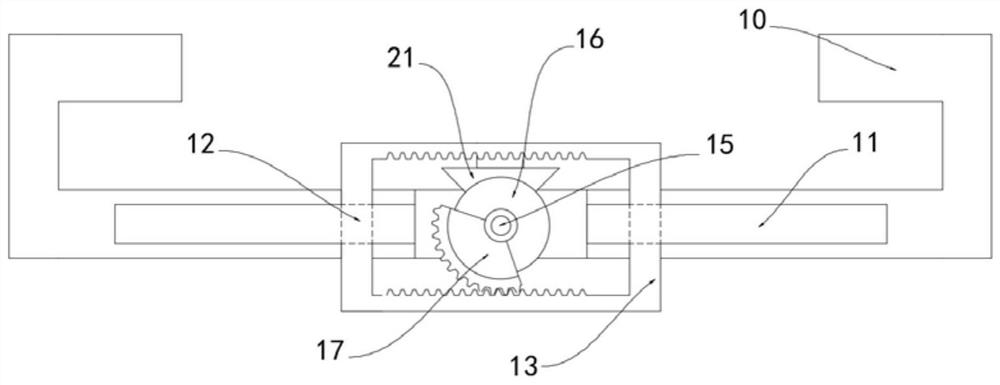

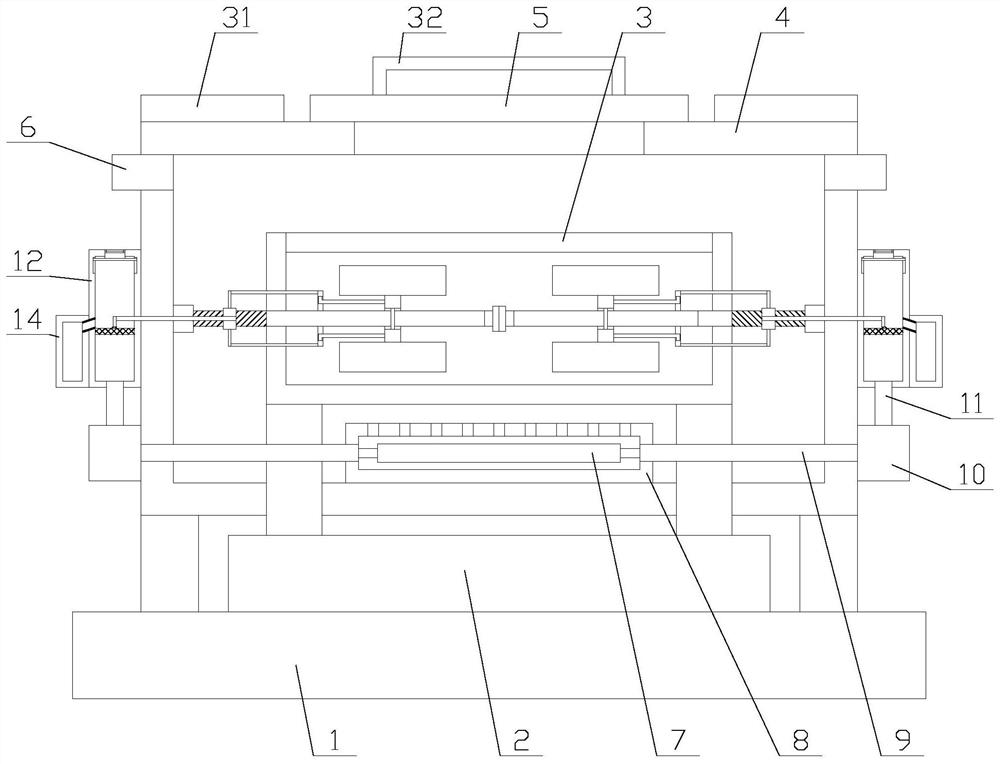

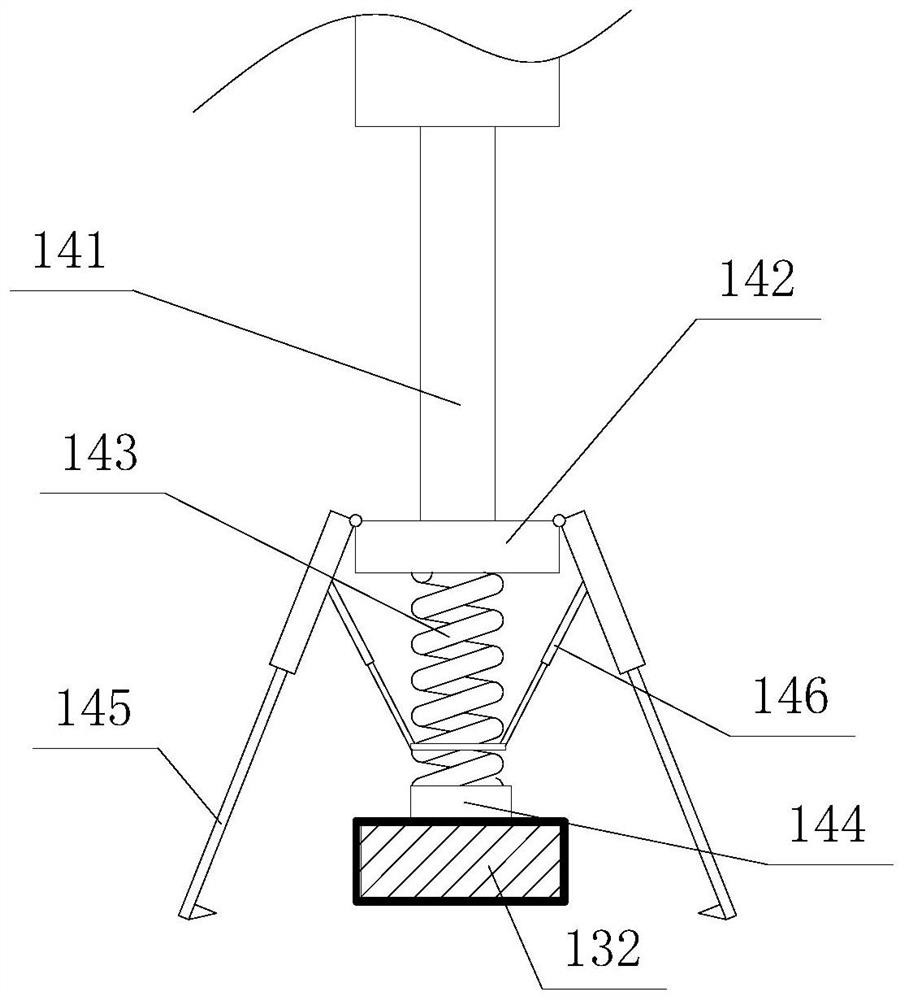

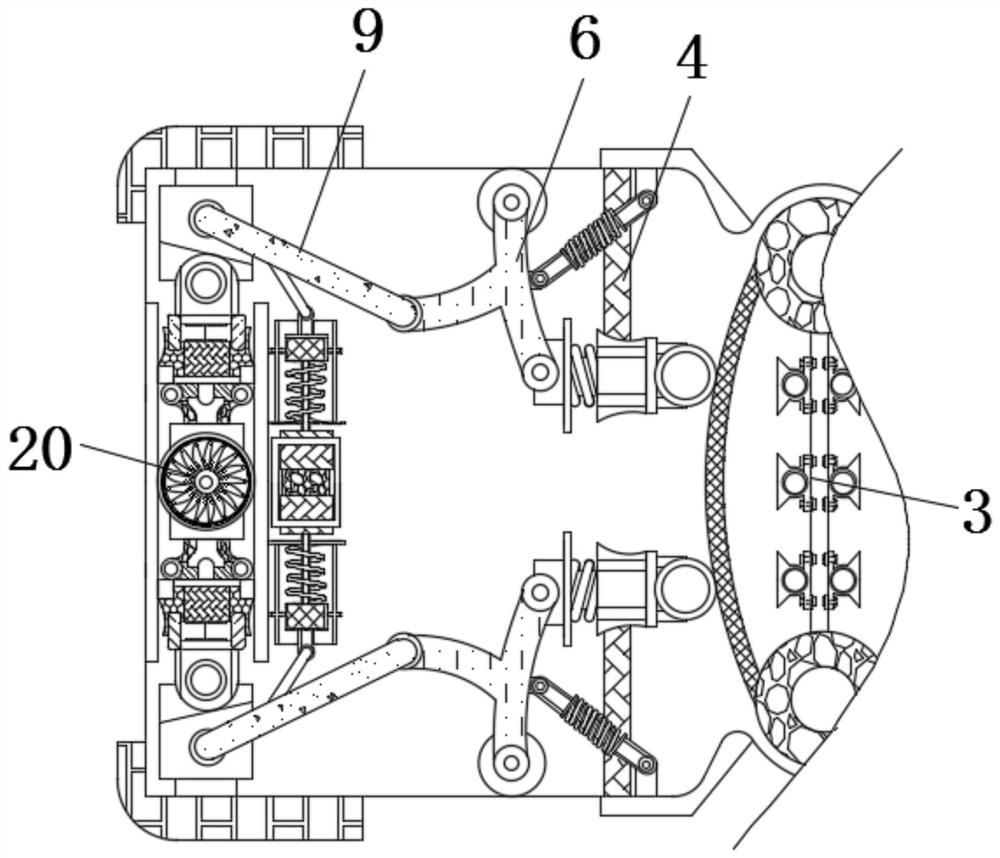

Hardware part heat treatment drying system and drying method thereof

ActiveCN113503712AReduce centrifugal forceIncrease centrifugal forceDrying solid materials without heatDrying chambers/containersGear wheelCentrifugation

The invention discloses a hardware part heat treatment drying system and a drying method thereof, which belong to the field of gear processing. The hardware part heat treatment drying system comprises a vacuum negative pressure drying box body, and a loading mechanism for loading to-be-dried parts is installed on the inner wall of the vacuum negative pressure drying box body in a sliding mode; the loading mechanism comprises a fixing unit for clamping and fixing parts and a centrifugal unit for centrifugally drying the parts, wherein the centrifugal unit comprises a centrifugal disc externally connected with a driving source, the fixing unit is slidably mounted on the centrifugal disc in the radial direction of the centrifugal disc, and an adjusting unit is further arranged on the centrifugal disc; and the adjusting unit adjusts the position of the fixing unit on the centrifugal disc according to the weight of the part on the fixing unit. The vacuum negative pressure drying box can conduct centrifugation while conducting drying, so that moisture on the surfaces of parts is spin-dried, and the drying efficiency is improved; the part can be automatically clamped during centrifugation, the position of the part on the centrifugal disc is adjusted according to the weight of the part, and the centrifugal force is controlled.

Owner:东莞市先力得热处理有限公司

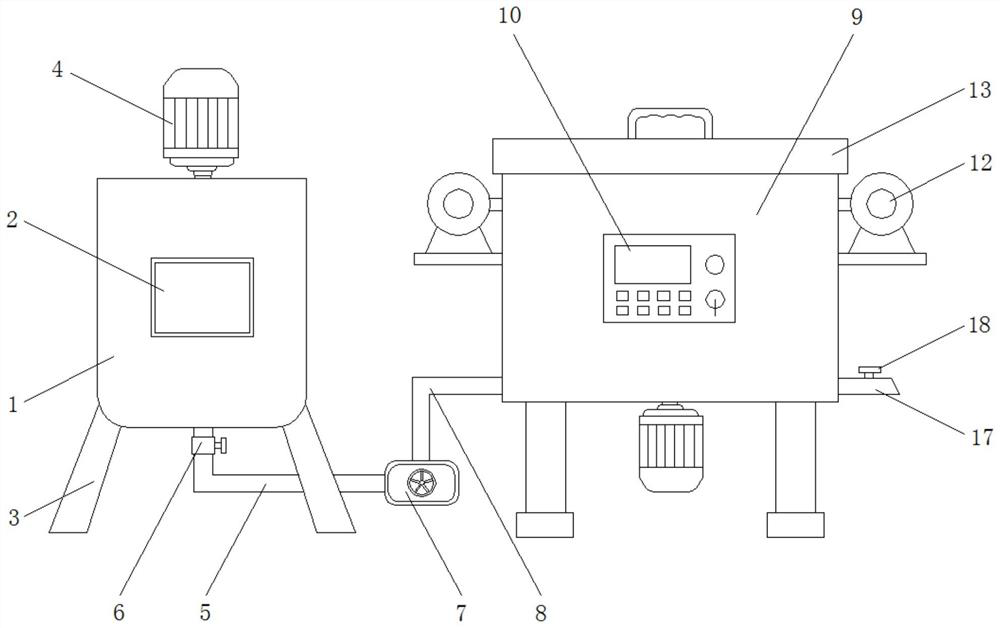

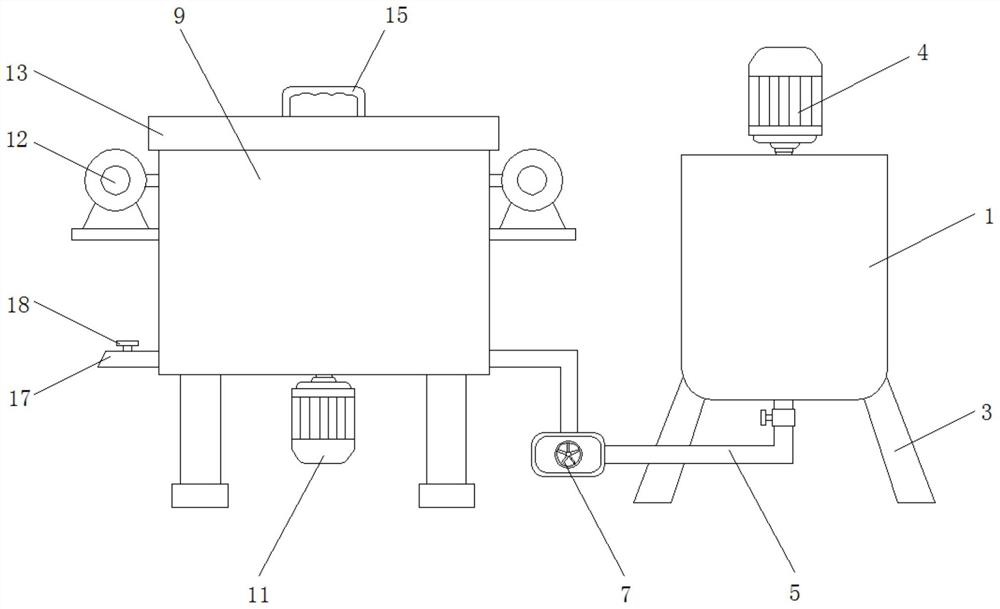

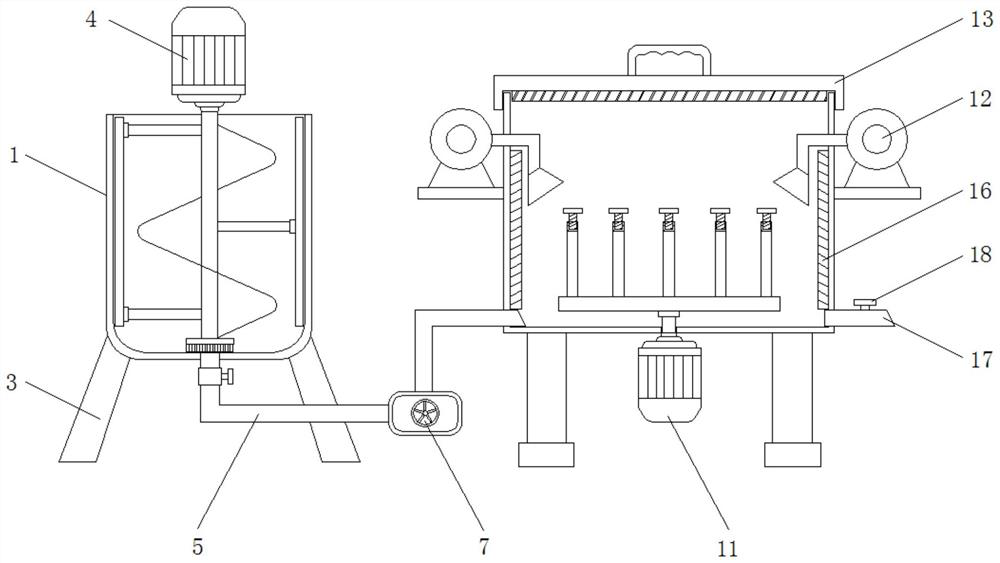

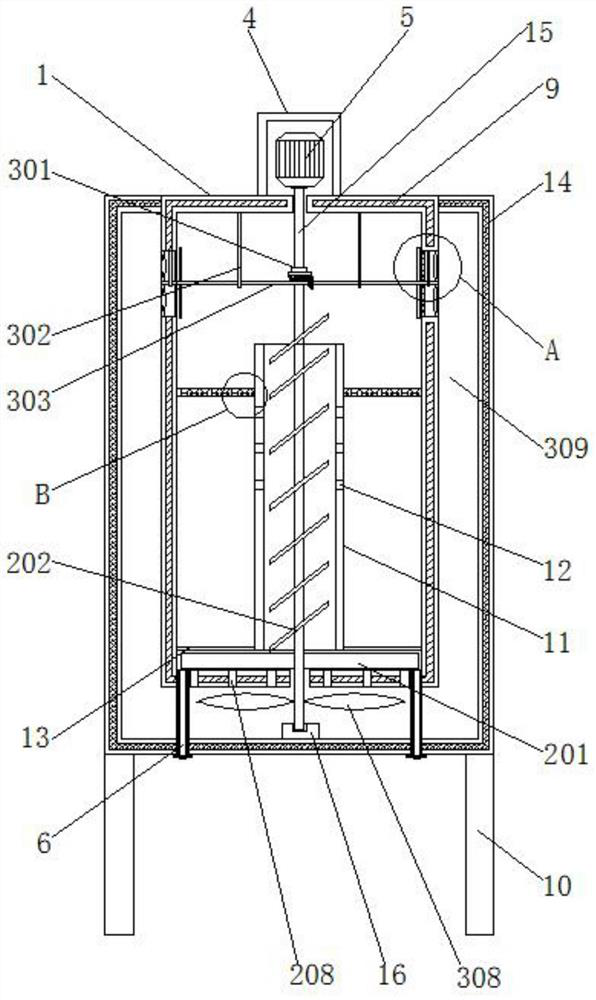

Coloring device for core spun yarn processing

InactiveCN114214800AImprove insulation effectAvoid churnTextile treatment containersDrying gas arrangementsYarnEngineering

The coloring device comprises a stirring barrel, a stirring mechanism, a conveying pump, a control panel, a drying mechanism, a heat preservation layer and a heating plate, a transparent observation window is installed on one side of the stirring barrel in an embedded mode, supporting legs are fixedly connected to the bottom of the stirring barrel, the stirring mechanism is arranged in the middle of the stirring barrel, and the conveying pump is arranged in the middle of the stirring barrel. A discharging pipe is arranged at the bottom of the stirring barrel, one end of the conveying pump is connected with the discharging pipe, the other end of the conveying pump is connected with the coloring box through a feeding pipe, the control panel is installed in the coloring box in an embedded mode, the coloring mechanism is arranged at the bottom of the coloring box, and the drying mechanisms are symmetrically arranged on the two sides of the coloring box. The heat preservation layer is arranged in the dustproof sealing cover, and the heating plate is installed in the coloring box. According to the coloring device for core spun yarn processing, the stirring mechanism and the drying mechanism are arranged, the stirring mechanism is convenient for fully and uniformly stirring pigment, subsequent coloring is convenient, and the drying mechanism is convenient for drying colored core spun yarn.

Owner:盐城鑫业纺织有限公司

Automatic overturning type processing device for drying wood flour

PendingCN114576978AGuaranteed to workGuaranteed drying workDrying gas arrangementsDrying solid materialsElectric machineryPulp and paper industry

The invention relates to the technical field of wood flour processing, and discloses an automatic overturning type wood flour drying processing device which comprises a device body, a heating layer is arranged in the device body, a driving motor is arranged above the device body, and a protective shell is arranged above the driving motor. A driving rod is arranged below the driving motor, a circulating mechanism is arranged below the driving rod, and a heat preservation layer is arranged on one side of the circulating mechanism. According to the automatic overturning type processing device for wood flour drying, the overturning mechanism is arranged in the processing device, wood flour at the bottom is driven to rotate through a cleaning block, and therefore it is guaranteed that overturning work of the wood flour is conducted, and the wood flour is driven to the position above the device body through a screw rod; the drying work of the wood flour is guaranteed in the back-and-forth descending and ascending process of the wood flour, the situation that the drying efficiency is affected due to accumulation of the wood flour is avoided, the drying effect is better improved, and subsequent wood flour use is facilitated.

Owner:桐城市亚博农业科技发展有限公司

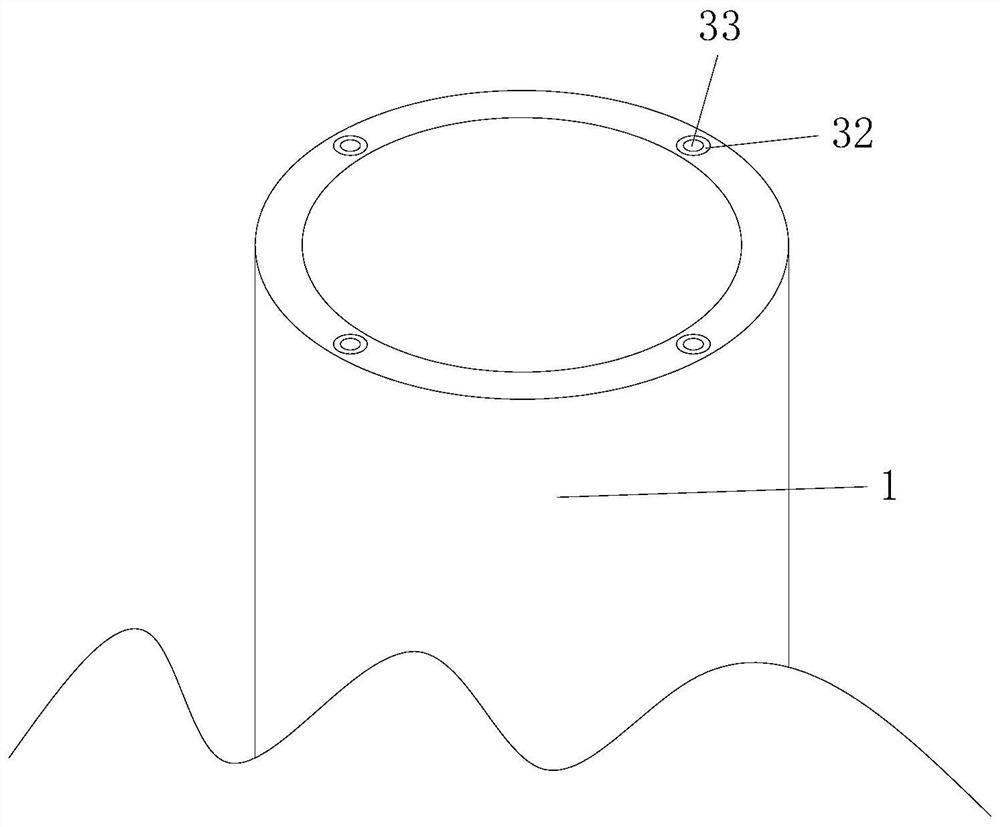

Bagasse drying equipment

InactiveCN107741121ATake away in timeIncrease contact timeDrying solid materials without heatDrying gas arrangementsFlue gasBagasse

The invention discloses bagasse drying equipment. The bagasse drying equipment comprises a dewatering device, a smashing device and a drying box; the dewatering device comprises a rolling unit and a sucking unit arranged in the rolling unit, the rolling unit comprises a first roller and a second roller which have the same size, and a first gap used for rolling materials is formed between the firstroller and the second roller; the smashing device is arranged under the dewatering device and comprises a funnel type stock bin and a smasher; and the drying box is arranged under the smashing device, and the lower portion of the drying box is provided with an air inlet used for allowing flue gas or hot air to be introduced.

Owner:陈志周

A kind of preparation method of meal replacement powder

ActiveCN113198564BScientific and reasonable structureEasy to useGrain huskingGrain polishingMeal replacementProcess engineering

Owner:东莞市霖鑫牛食品科技有限公司

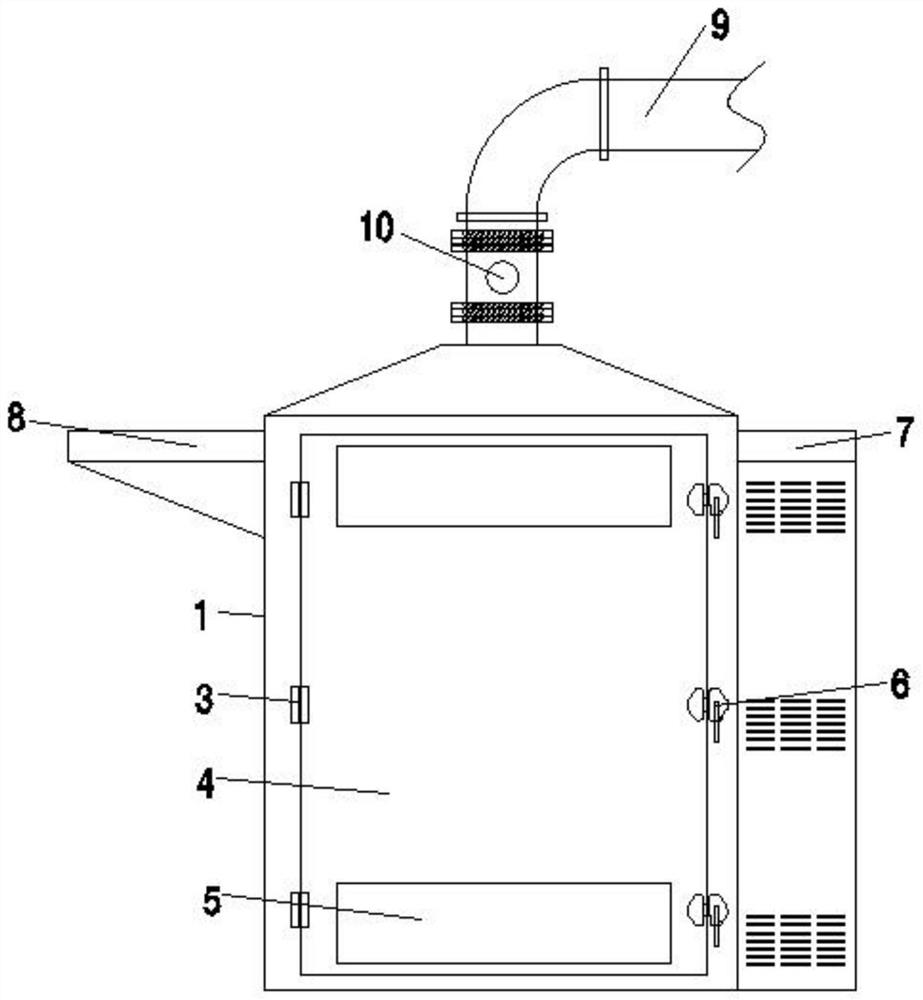

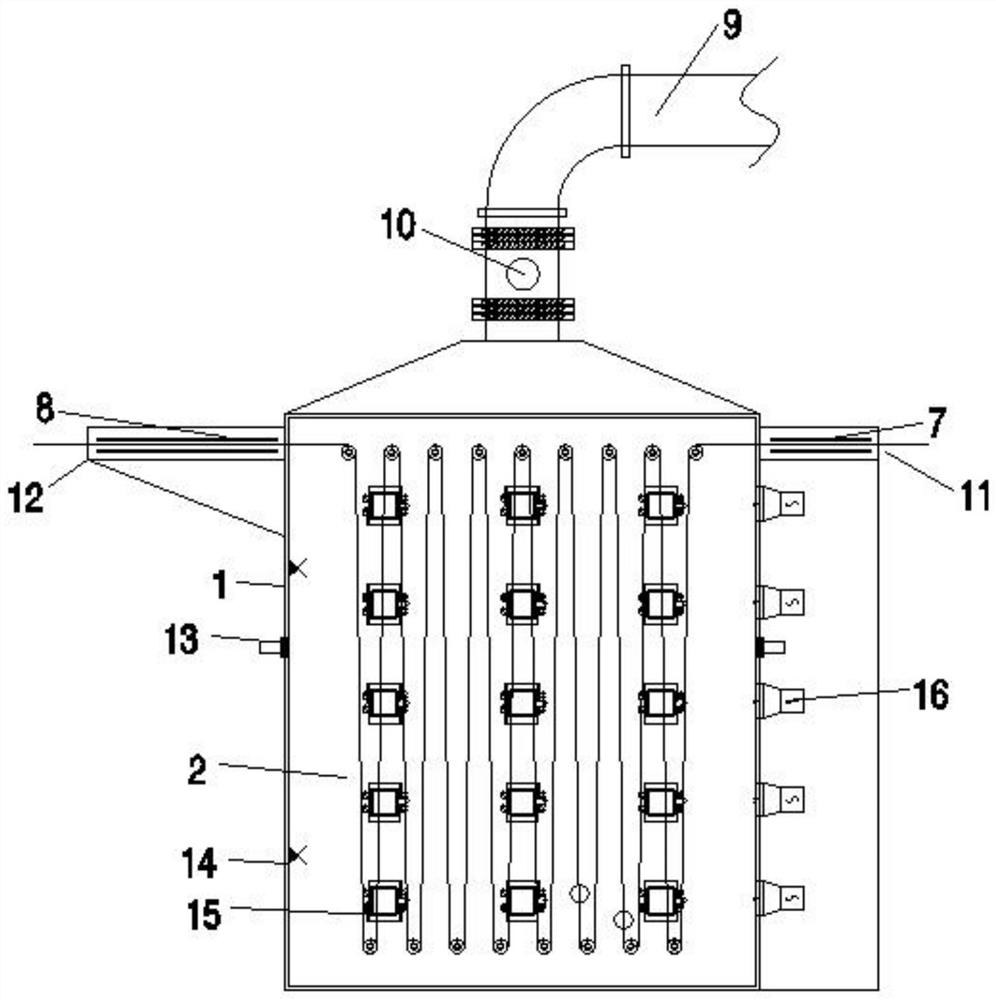

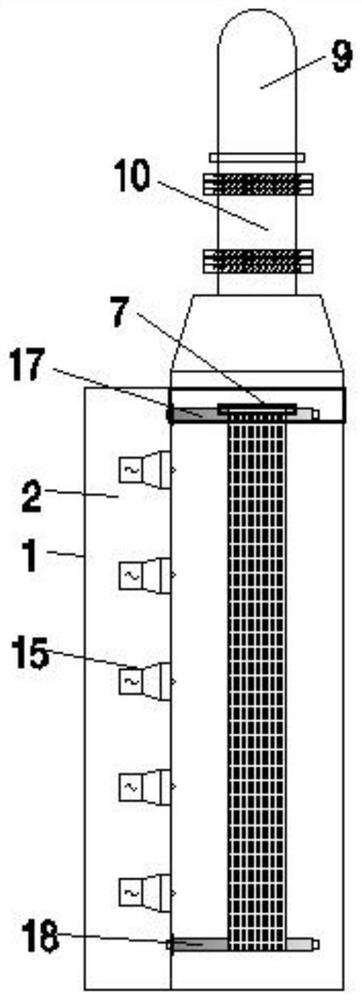

Energy-saving and environment-friendly drying device for marine product processing

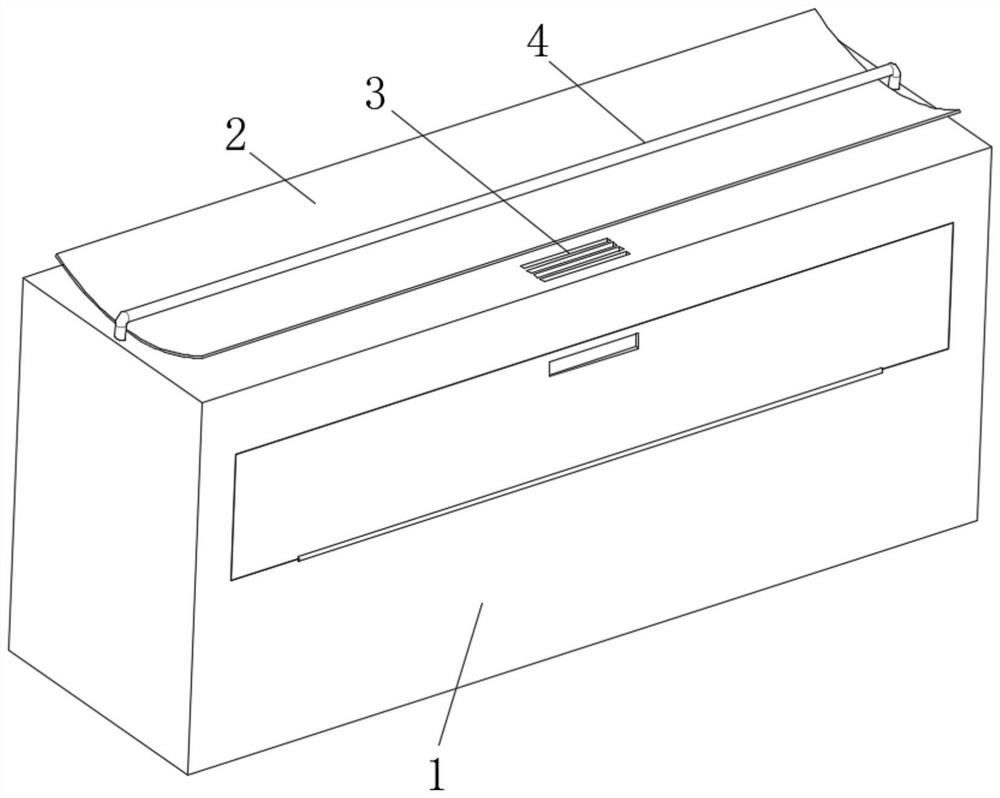

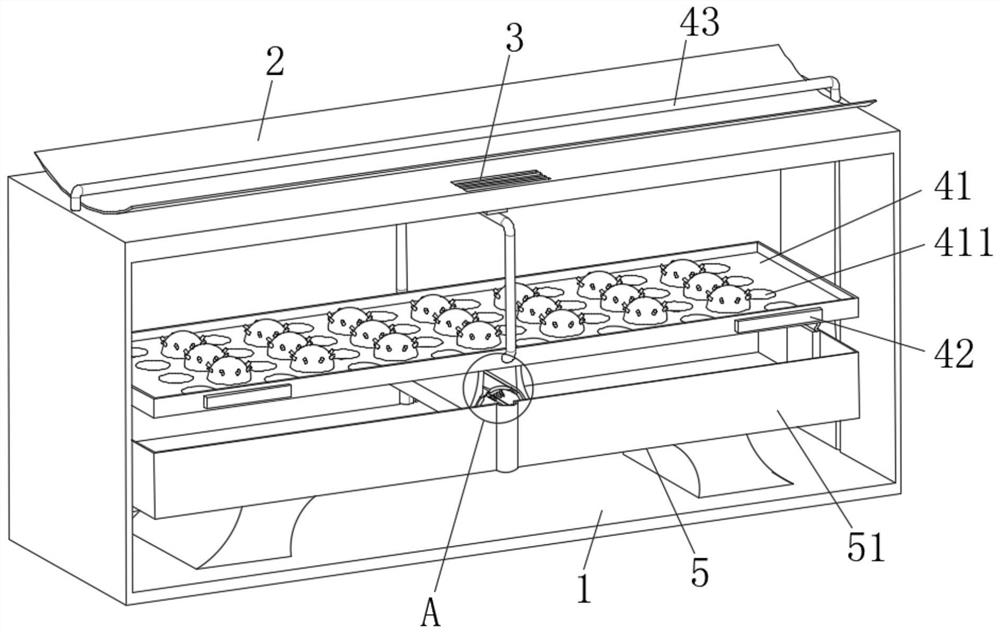

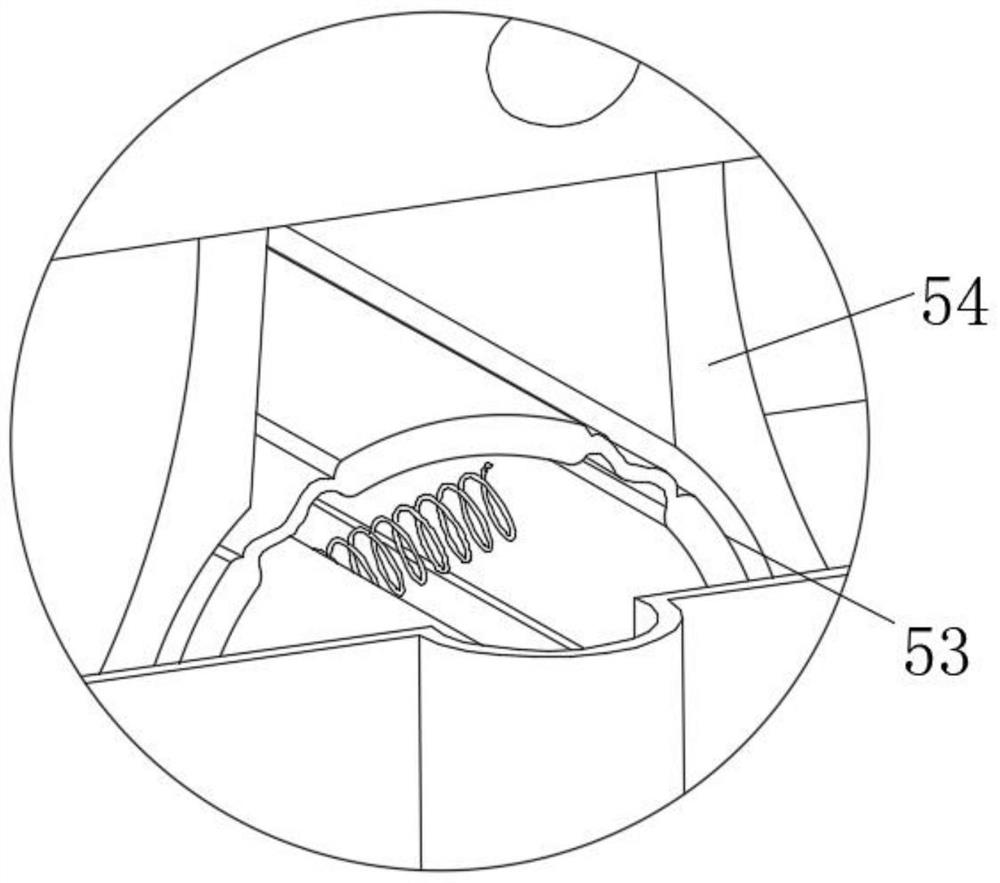

InactiveCN113983791AAvoid affecting drying efficiencyIncrease frictionFood processingDrying chambers/containersProcess engineeringMechanical engineering

The invention discloses an energy-saving and environment-friendly drying device for marine product processing, and relates to the technical field of advanced environment-friendly industries. The energy-saving and environment-friendly drying device for marine product processing comprises a box body, a heat collection plate is fixedly installed at the top of the box body, an air outlet is formed in the center of the top of the box body, a drying mechanism is arranged at the upper end of the box body, a movable mechanism is arranged at the lower end of the box body, the drying mechanism comprises a drying plate, a balance block, a heat conduction pipe and a contact piece, the drying plate is movably installed in the inner side of the upper end of the box body, balance blocks are movably clamped in grooves in the left end and the right end of the front face of the drying plate, and the lower end of the heat conduction pipe penetrates through the center of the front face of the drying plate. According to the energy-saving and environment-friendly drying device for marine product processing, the drying mechanism and the moving mechanism are arranged, seawater separated out of marine products is shaken off to the lower end of the drying plate and collected through the water collecting tank, and the situation that the seawater is scattered on the drying plate, and the drying efficiency of the device is affected is avoided.

Owner:李康伟

Flue gas drying equipment used for bagasse

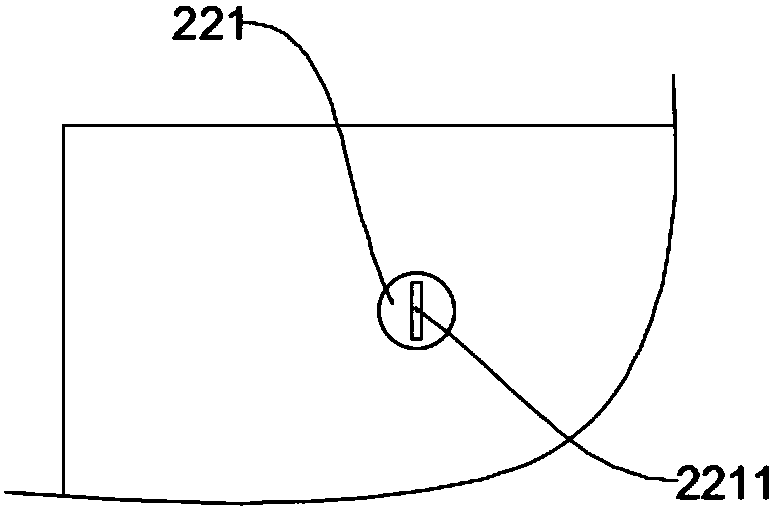

InactiveCN107576185AAvoid affecting drying efficiencyPrevent rewetDrying solid materials without heatDrying gas arrangementsFlue gasEngineering

The invention discloses flue gas drying equipment used for bagasse. The equipment comprises a dehydration device, a material scraping device, a crushing device and a drying cabinet, wherein the dehydration device comprises a rolling unit and a suction unit arranged in the rolling unit, the rolling unit comprises a first pin roller and a second pin roller which are the same in size, a first gap allowing materials to be rolled therein exists between the first pin roller and the second pin roller, a first groove is formed in the outer surface of each pin roller and spirally surrounds the outer surface of a barrel of each pin roller, the distances between the adjacent rings of each groove are the same, and the adjacent rings of each groove are parallel; the material scraping device comprises atensioning mechanism and a material scraping line, the material scraping line is arranged on the tensioning mechanism and tensioned, the material scraping device is arranged below the first pin roller and the second pin roller, and the material scraping line is tightly attached to the lower surfaces of the first pin roller and the second pin roller; the crushing device is arranged below the dehydration device and comprises a funnel-shaped stock bin and a crusher; and the drying cabinet is arranged below the crushing device, and an air inlet used for leading flue gas or hot air in is further formed in the lower portion of the drying cabinet.

Owner:陈志周

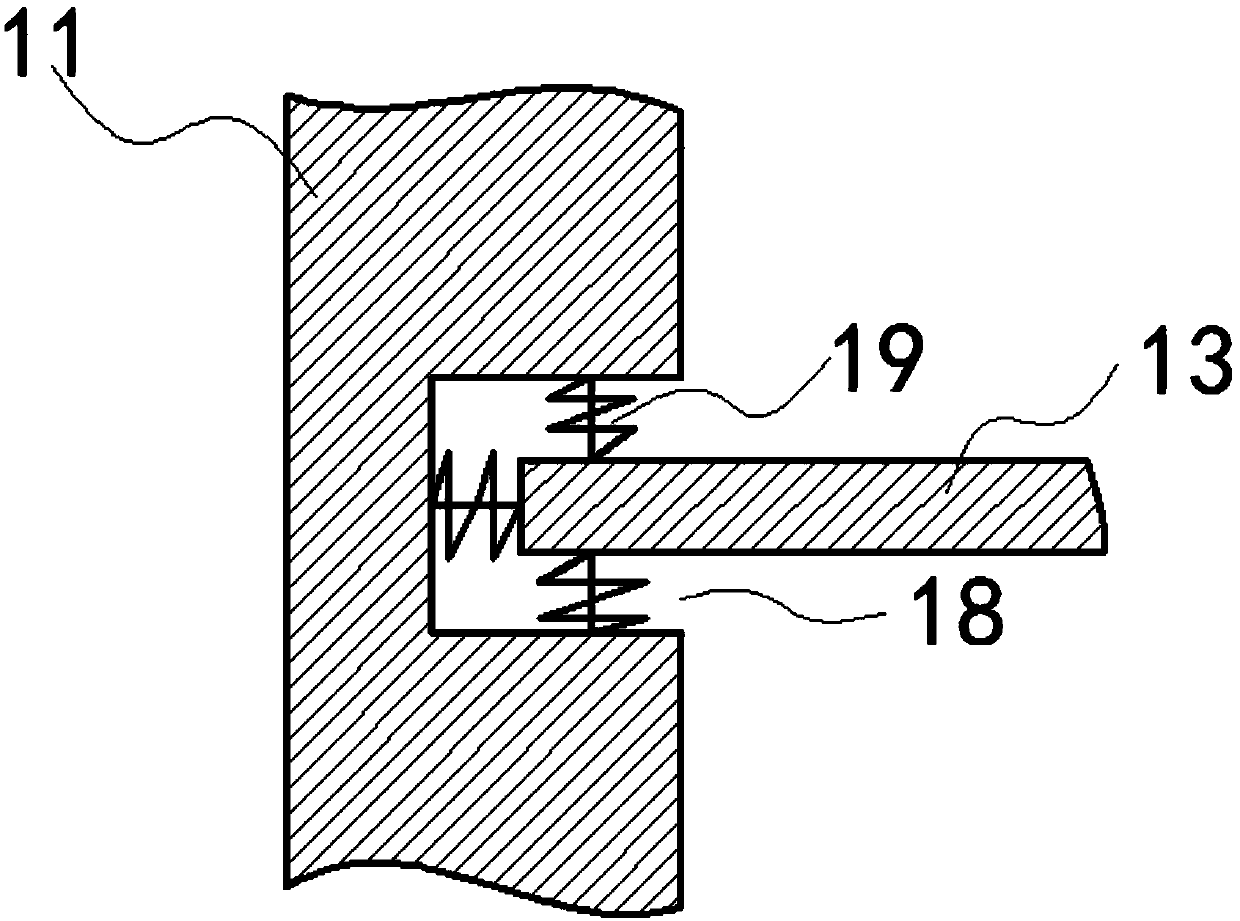

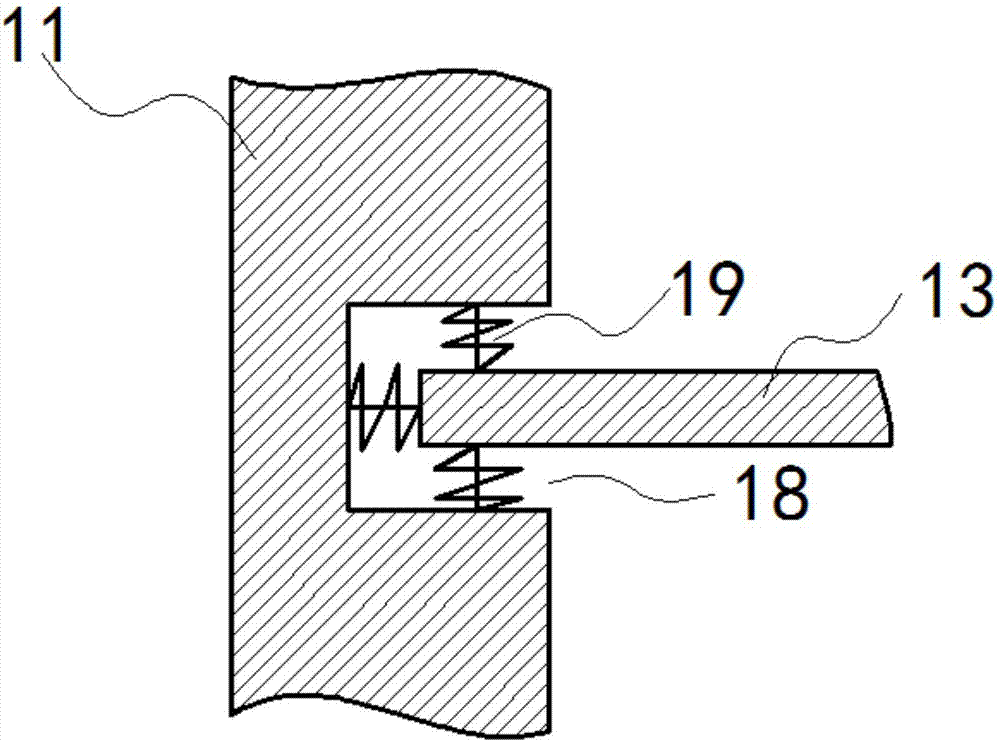

Drying device for garment processing

InactiveCN112284050AAvoid Stretch SituationsAvoid affecting drying efficiencyDrying solid materials without heatDrying gas arrangementsStructural engineeringMechanical engineering

The invention discloses a drying device for garment processing. The drying device comprises a drying chamber, wherein a supporting mechanism is arranged in the drying chamber, and the supporting mechanism comprises a hollow pipe which is arranged in the center of the drying chamber and fixedly connected with the drying chamber and a push block which is arranged in the hollow pipe and slidably connected with the hollow pipe; a plurality of air outlets are further formed in the hollow pipe, push plates are arranged at the two sides of an inner cavity of the hollow pipe, a plurality of connectingrods are fixedly connected to the outer sides of the push plates, the connecting rods penetrate through the hollow pipe and are connected with the hollow pipe in a sliding manner, and supporting plates are arranged at the outer sides of the connecting rods; and a buffering mechanism is arranged between the supporting plates and the connecting rods and comprises an outer buffering plate and an inner buffering plate which are fixedly connected to the supporting plates and the connecting rods correspondingly. Compared with a traditional drying device, a hot air drying and dehumidifying integrated circulating system is arranged in the device, so that the problem that the drying efficiency is low due to unsmooth air flowing can be solved.

Owner:熊东梅

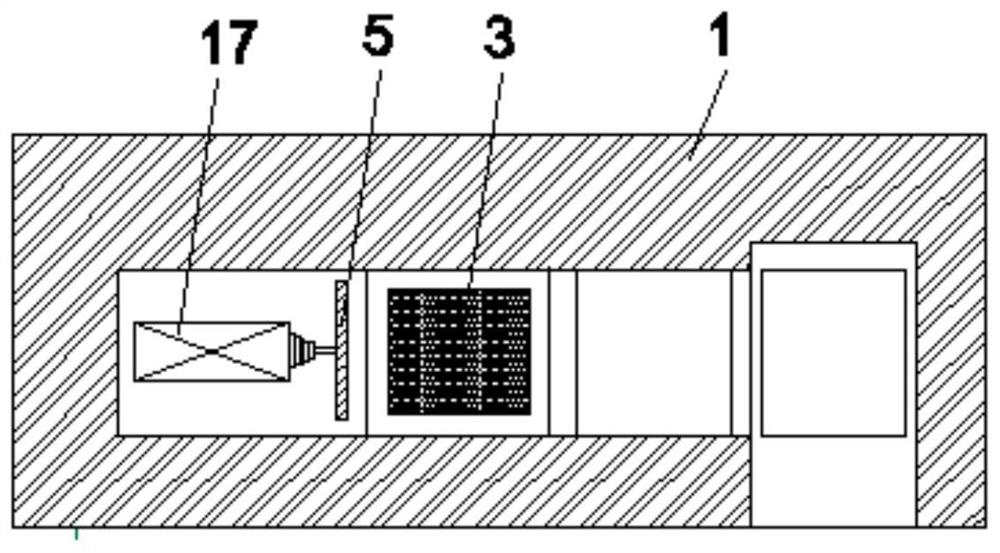

On-line drying device for heat-not-burn sheet tobacco paper

InactiveCN113303490AAvoid enteringAffect qualityTobacco preparationInfrared thermometryProcess engineering

The invention relates to the technical field of automatic drying of cigarette equipment, in particular to a heat-not-burn sheet tobacco paper on-line drying device which comprises an on-line drying device body and a drying device PLC. One end of the on-line drying device body is provided with a feeding port microwave suppressor. A discharging port microwave suppressor is arranged at the other end of the on-line drying device body, a negative pressure dehumidification pipeline is fixedly installed at the top of the on-line drying device body, an infrared thermometer is arranged below the discharging port microwave suppressor, and a back plate adjustable microwave source is arranged in the microwave inner cavity. A side plate adjustable microwave source is arranged on the side, away from the infrared thermometer, of the on-line drying device body, and a carrier roller assembly is fixedly installed in the microwave inner cavity through a mounted bearing. The water content of the tobacco paper is detected on line through a detection probe and fed back to the drying device to be automatically dried on line, redundant water is removed, and the correct control over the water content of the tobacco paper is achieved.

Owner:上海恒博自动化设备有限公司

Airing equipment for preventing deformation of knitted woolen sweater and deformation prevention method

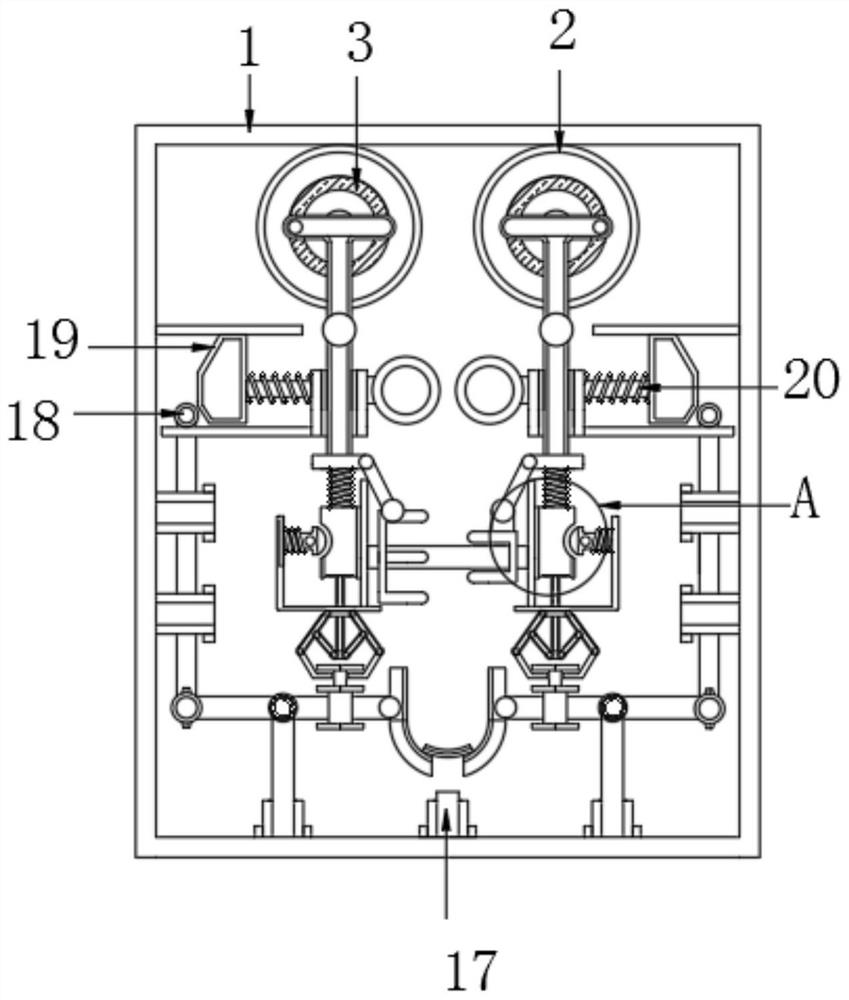

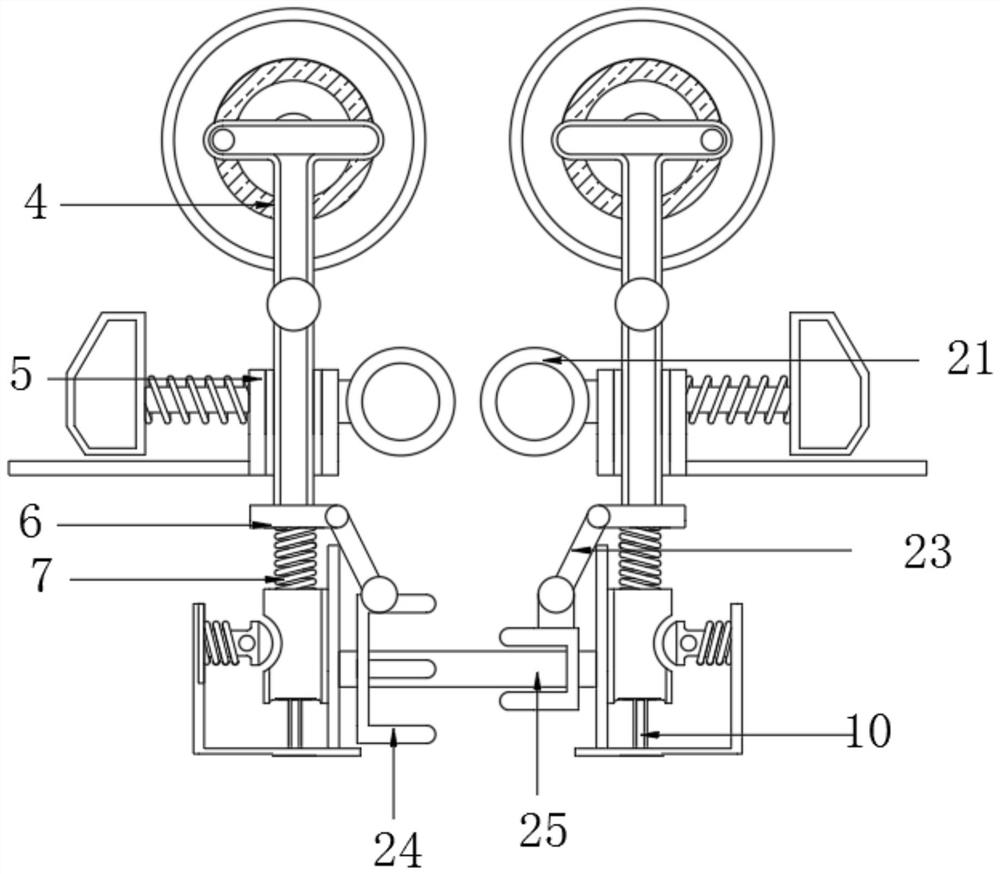

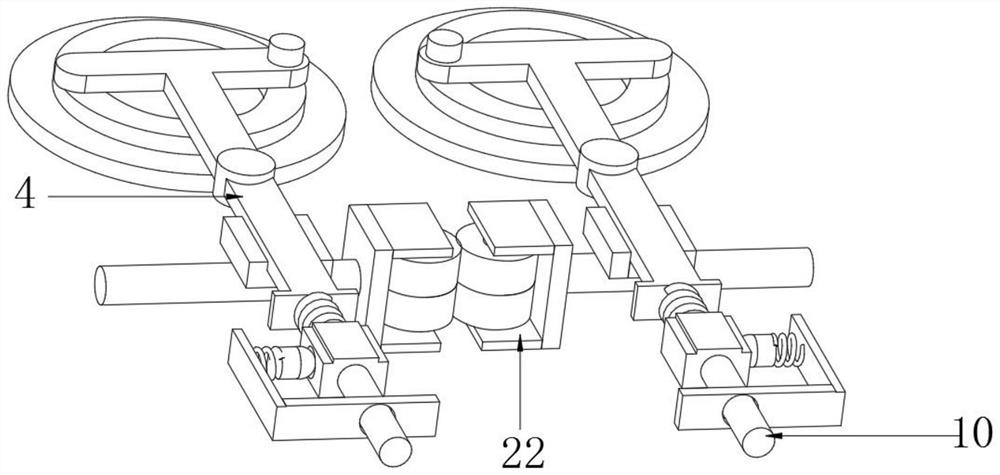

InactiveCN113832671AAvoid affecting drying efficiencyAvoid getting stuckWringing machinesTextiles and paperWater storage tankStructural engineering

The invention relates to the technical field of knitwear protection, and provides airing equipment for preventing deformation of a knitted woolen sweater. The airing equipment comprises a machine shell, wherein a fixed pressing wheel is movably connected into the machine shell; a differential wheel is movably connected to the front side of the fixed pressing wheel; a linkage rod is movably connected to the front side of the differential wheel; a concave rail is slidably connected to the back side of the linkage rod; the bottom of the concave rail is fixedly connected with a pressing plate; and the bottom of the pressing plate is fixedly connected with a delay spring. According to the airing equipment for preventing deformation of the knitted woolen sweater and a deformation prevention method, the rotation amplitude of a lever is small, the lever jacks up a rolling ball, the rolling ball extrudes an extrusion block, the extrusion block compresses a spring rod and pushes a moving frame, and a dynamic pressing wheel in the moving frame extrudes the woolen sweater again; and when a water storage tank moves to the top of a top block due to the gravity of water, water in the water storage tank is discharged to prepare for next airing and dewatering, and secondary dewatering is performed by judging the dewatering amount, so that the airing efficiency is prevented from being influenced.

Owner:王娟

Moisture measuring instrument with high reliability

InactiveCN112557242ARealize the stirring functionReduce cloggingWeighing by removing componentDispersed particle filtrationMeasuring instrumentHeater Rod

The invention relates to a moisture measuring instrument with high reliability which comprises a main body, a sealing plate, a storage box, a bottom plate, a weighing device, two supporting blocks andfour fixing blocks, and further comprises an impurity removal mechanism and two stirring mechanisms, wherein the impurity removal mechanism comprises a fixing box, a heating rod, two exhaust pipes and two impurity removal assemblies. The stirring mechanism includes a motor, a screw rod, a rotating shaft, a first bearing, a second bearing, a sliding block, a stirring assembly, a connecting rod andtwo supporting rods. Through the impurity removing mechanism, the function of removing impurities from air entering the main body is achieved, the situation that dust adheres to materials, and consequently the weight of the materials is increased is avoided, thereby avoiding affecting the detection accuracy, the stirring mechanism realizes the function of stirring the materials inside the storagebox, the situation that the materials are accumulated together and cannot be fully dried is avoided, and therefore the influence on the drying efficiency is avoided.

Owner:武桂英

Far infrared drying equipment

PendingCN111928631AImprove drying efficiencyAvoid drying efficiency reductionDrying solid materials with heatDrying gas arrangementsChemistryEngineering

The invention discloses far infrared drying equipment and relates to the technical field of drying equipment. The far infrared drying equipment comprises a drying box body, wherein a drying chamber isarranged in the drying box body, a plurality of far infrared radiant panels are alternately arranged on two opposite inner side walls of the drying chamber in a staggered manner in a vertical direction. The free ends of the far infrared radiant panels incline downward. Each far infrared radiant panel successively comprises a supporting layer, a reflective layer, an infrared radiant layer and a wear-resistant layer from bottom to top. The far infrared radiant panel successively comprises the supporting layer, the reflective layer, the infrared radiant layer and the wear-resistant layer from bottom to top, wherein the supporting layer can support the dead weight of the far infrared radiant panel and the impact force of a material, and the reflective layer can reflect far infrared rays emitted by an infrared radiant layer to the upper surface of the far infrared radiant panel, so that the drying efficiency is improved. The wear-resistant layer can protect the infrared radiant layer, so that reduction of drying efficiency and material pollution due to wear of the infrared radiant layer after long-time use is avoided.

Owner:NANJING YUANCHANG ADVANCED MATERIAL CO LTD

Dust treatment device of large grain drying equipment

PendingCN114798435AAvoid affecting drying efficiencyMaterial fullGas current separationGrain storageEngineering

The invention provides a dust treatment device of large grain drying equipment, and belongs to the technical field of grain storage equipment. The dust treatment device of the large grain drying equipment comprises an equipment mounting frame body and a servo motor, a driving multi-throw mounting frame is arranged above the equipment mounting frame body, and one end of the driving multi-throw mounting frame is rotationally connected with the side wall of a mounting plate through a bearing. According to the device, it can be guaranteed that the device is evenly filled with materials, the situation that the drying efficiency of the device is affected by excessive accumulation of the materials in the local area of the drying device is avoided, in the continuous vibration process of the materials, dust and grain are separated through inertia, the separated dust is stripped from the interior of the drying device, and the effect of drying and purifying at the same time is achieved.

Owner:当涂县官圩人家供销合作社有限公司

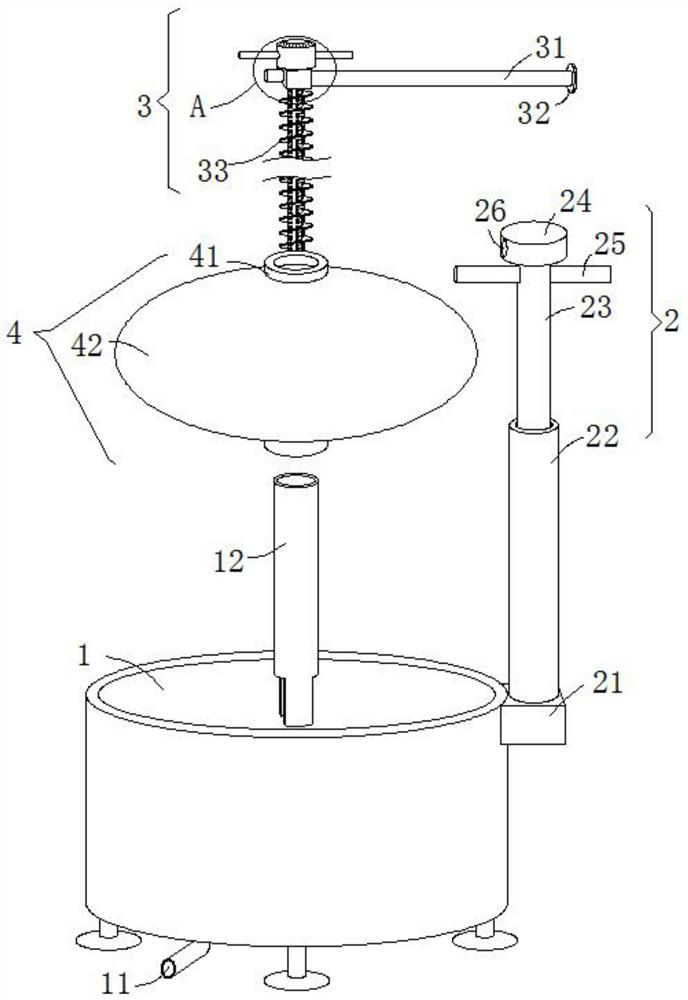

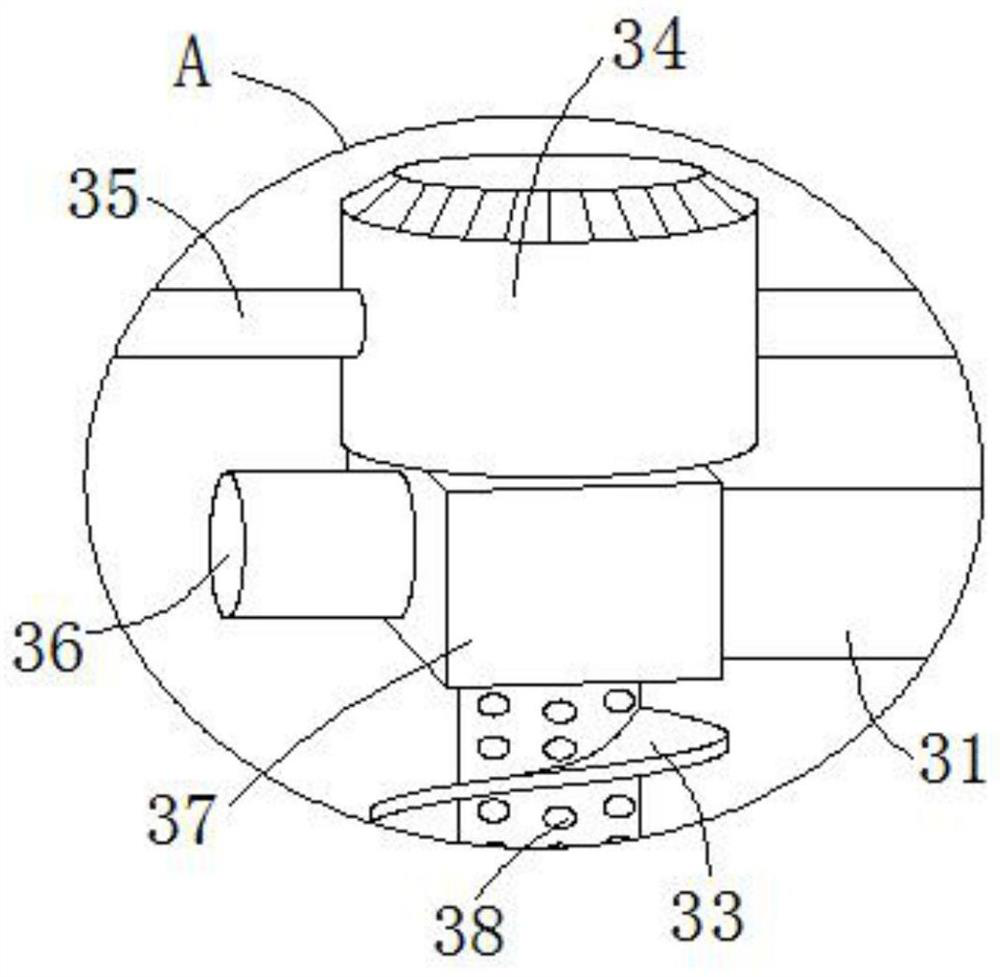

Apple pomace feed processing equipment for pregnant sows

PendingCN114752473AImprove palatabilityEasy to storeBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFodder

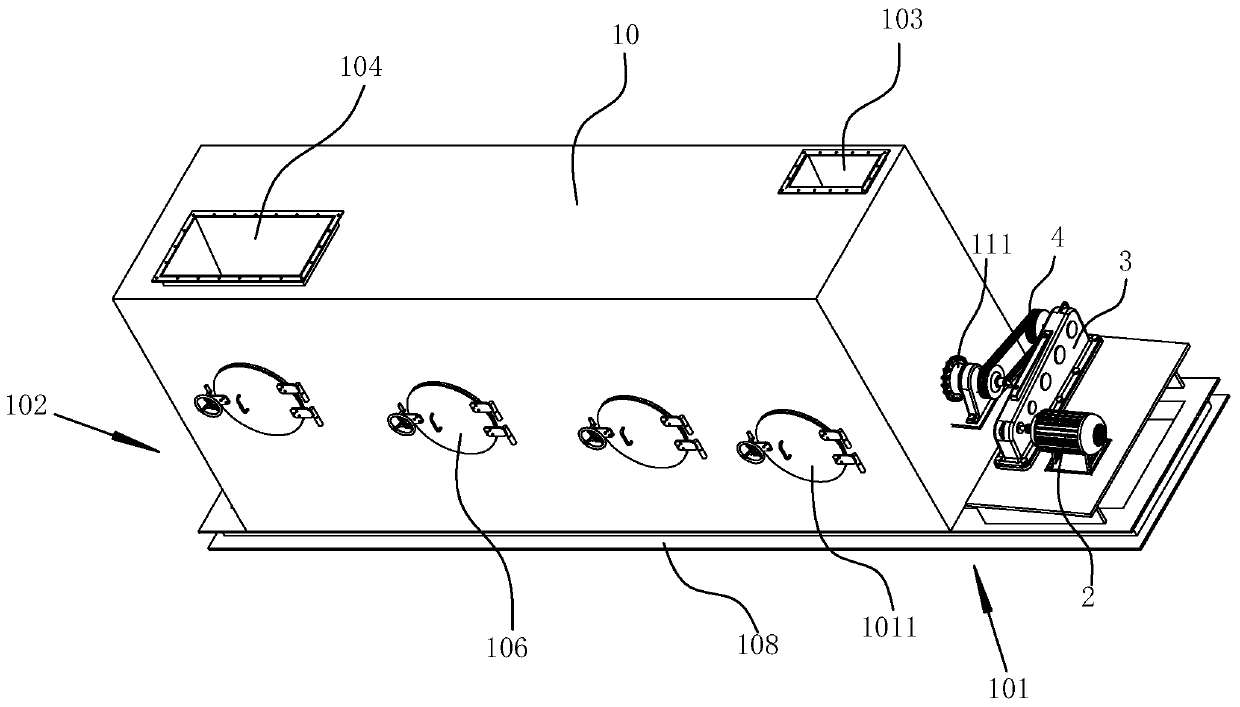

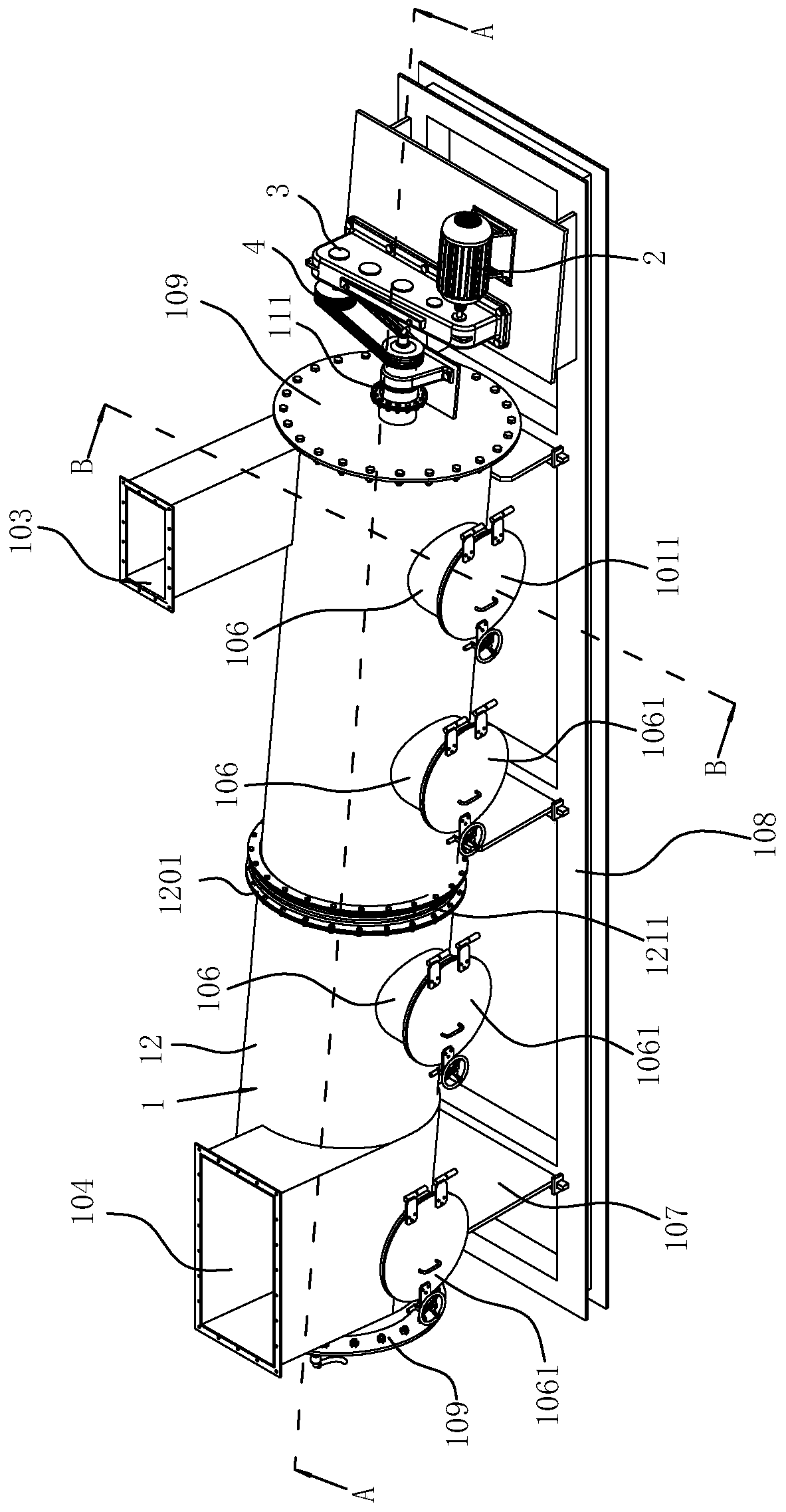

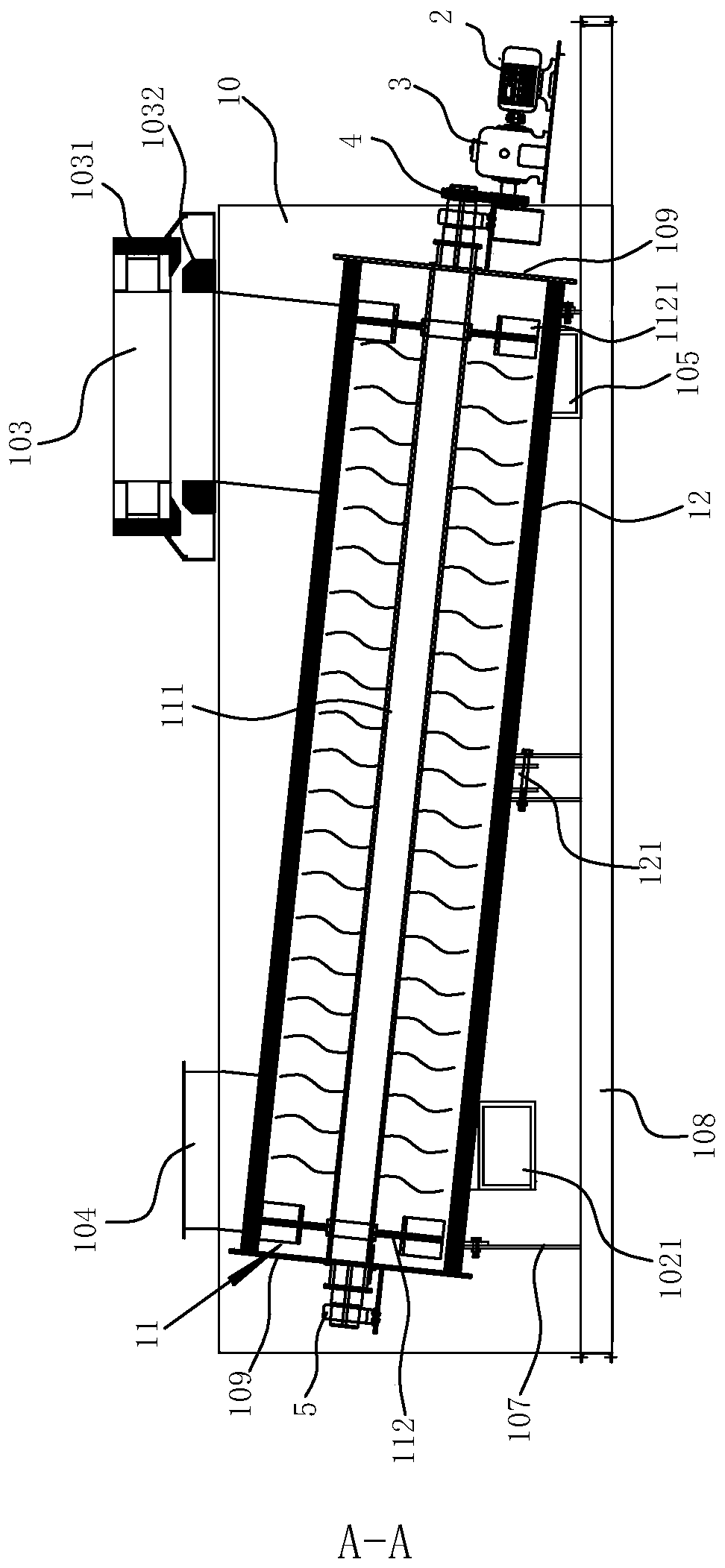

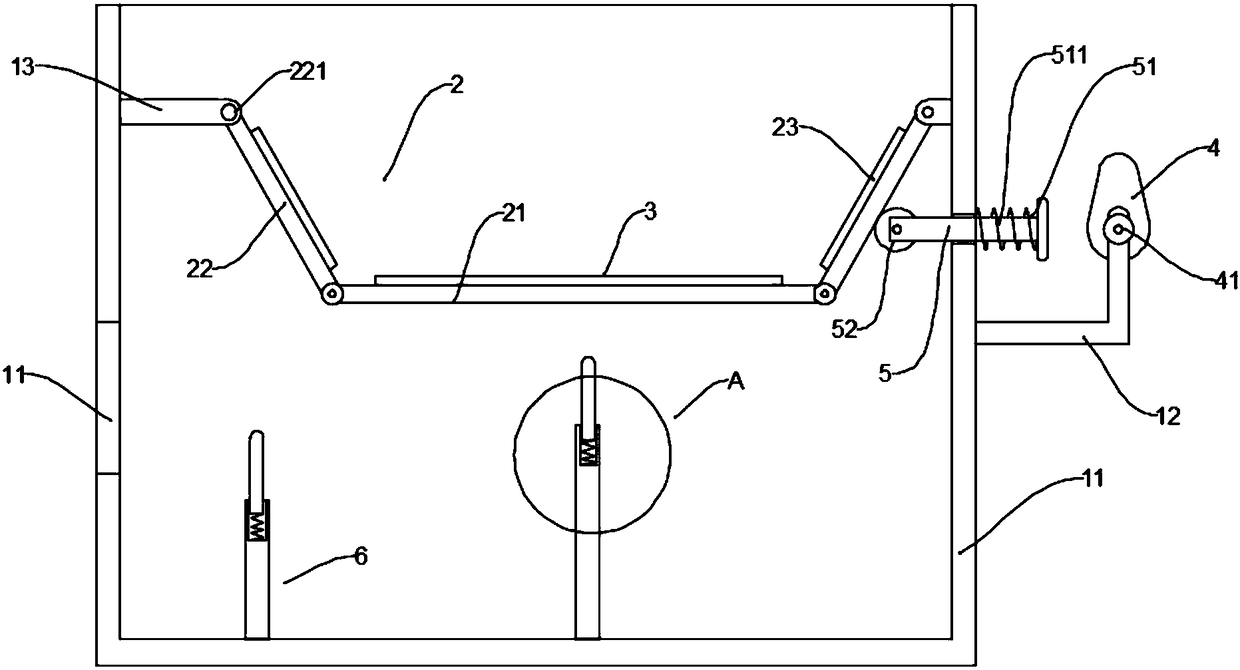

The invention discloses apple pomace feed processing equipment for pregnant sows, the apple pomace feed processing equipment comprises a fermentation device and a drying device, the fermentation device comprises a sliding frame, a plurality of fermentation tanks, a sealing cover plate, an uncovering device and a stirring device, the plurality of fermentation tanks are sequentially arranged along the length direction of the sliding frame, and the openable sealing cover plate is hinged to the top of each fermentation tank; a sealing ring matched with the tank opening is arranged on one side of the sealing cover plate, an uncovering boss is installed on the other side of the sealing cover plate, a slidable hanging bracket is hung on the sliding frame, an uncovering device aligned with the uncovering boss and a stirring device aligned with the tank opening are installed on the hanging bracket, a discharging pipe is arranged at the bottom of the fermentation tank, and the discharging end of the discharging pipe is connected with a drying device. By arranging the fermentation device, apple pomace can be fermented, the palatability of the apple pomace as pregnant sow feed can be improved, meanwhile, the fermented apple pomace feed can be continuously and automatically dried in cooperation with the drying device, and storage and transportation of the apple pomace are facilitated.

Owner:SICHUAN WANGDA FEED

Raw material drying device for liquor production

InactiveCN112556340AAvoid affecting drying efficiencyDrying gas arrangementsDrying chambers/containersProcess engineeringIndustrial engineering

The invention discloses a raw material drying device for liquor production, and relates to the technical field of liquor production. The raw material drying device comprises a drying cylinder, a supporting and adjusting mechanism, a conveying mechanism and a secondary storage mechanism; the interior of the drying cylinder is of a hollow structure; a guide cylinder is fixedly arranged in the centerof the bottom end of the interior of the drying cylinder; two symmetric feeding gaps communicating with the interior of the guide cylinder are formed in the bottom end of the outer wall of the guidecylinder; the supporting and adjusting mechanism is arranged on one side of the top end of the outer wall of the drying cylinder; the conveying mechanism is arranged on one side of the top end of thesupporting and adjusting mechanism; the secondary storage mechanism is arranged at the bottom end of the conveying mechanism; and the secondary storage mechanism is installed at the upper end of the guide cylinder. According to the raw material drying device for liquor production, a traditional single-time large-batch drying treatment mode is changed, dried raw materials are collected, reverse drying treatment operation can be conducted again after single-time drying treatment is completed, and the situation that the drying efficiency is affected due to the fact that the dried raw materials and undried raw materials are mixed together is avoided.

Owner:邱增海

Environment-friendly clothes drying auxiliary device with automatic steam output adjusting function

InactiveCN113074523AReduce outputControl outputDrying solid materials without heatDrying gas arrangementsEngineeringMechanical engineering

The invention relates to the technical field of clothes drying auxiliary equipment, in particular to an environment-friendly garment drying auxiliary device with an automatic steam output adjusting function, which comprises a steam treatment frame, wherein clothes shafts are rotatably connected in the steam treatment frame, and a steam nozzle is fixedly connected between the two clothes shafts in the steam treatment frame; a vertical limiting plate is fixedly connected to the position, located on the left sides of the clothes shafts, in the steam treatment frame, a positioning sliding plate is slidably connected to the interior of the lower end of the vertical limiting plate, and an auxiliary wheel is rotatably connected to the right end of the positioning sliding plate. A speed limiting plate is in contact with the outer surface of the rotating shaft of a steam fan, so that the speed limiting plate limits the speed of the steam fan, and thus, the steam output of the steam nozzle is reduced, the clothes are prevented from being scalded by a large amount of continuous steam, the quality of the clothes can be well guaranteed; and meanwhile, the steam output of the steam nozzle can be well controlled according to the water content of the clothes.

Owner:厦门菲潘贸易有限公司

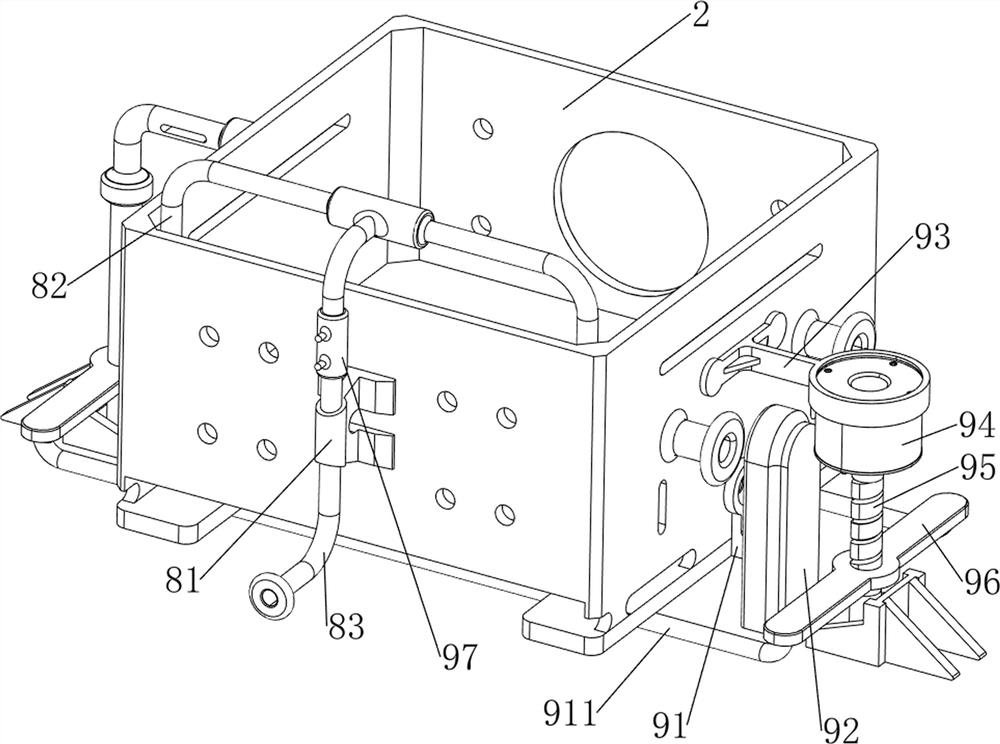

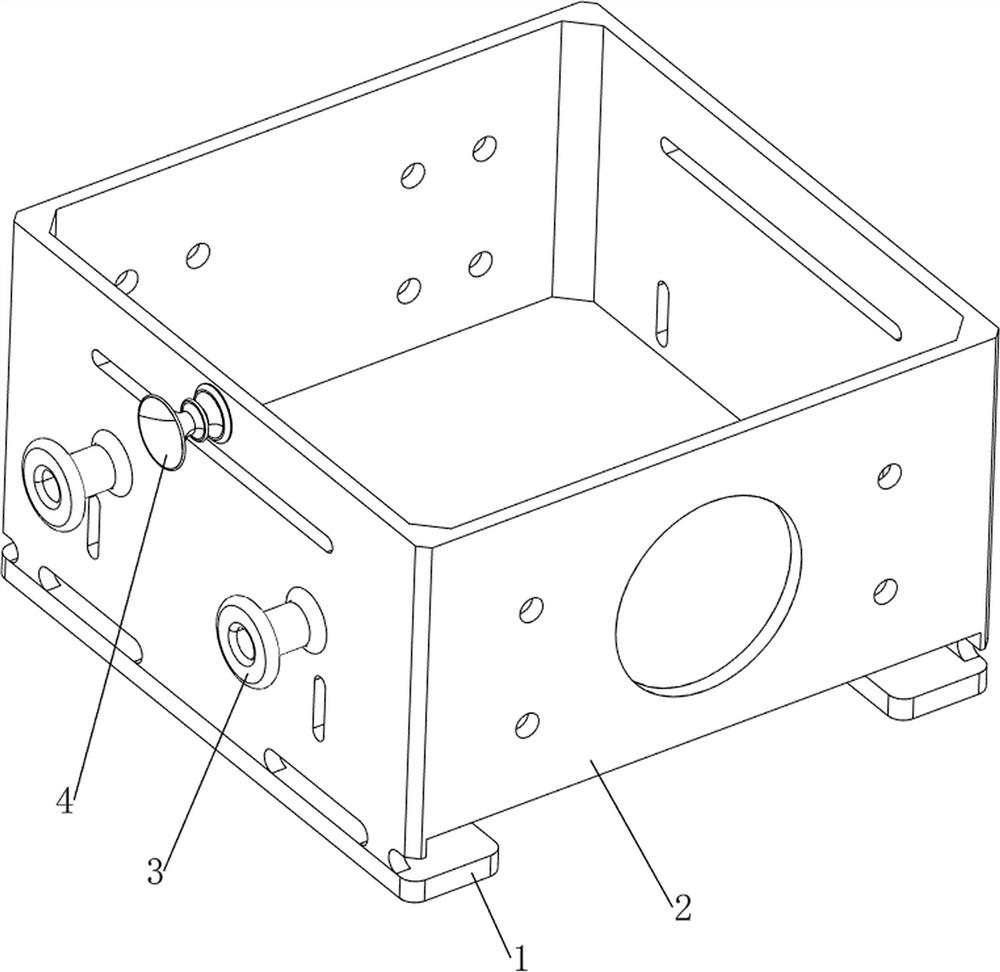

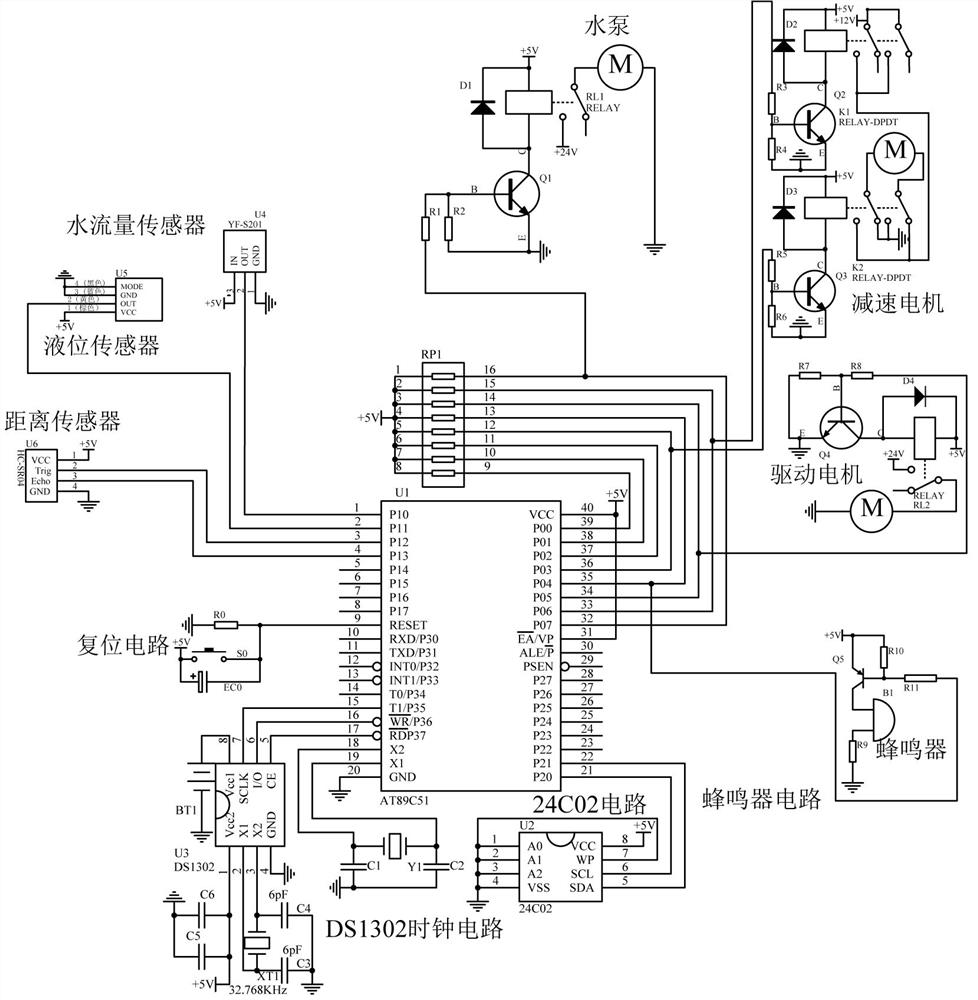

New energy ship battery drying box

PendingCN114388959ATo protect the batteryAvoid damageBattery isolationDrying gas arrangementsMarine engineeringNew energy

The invention relates to a battery drying box, in particular to a new energy ship battery drying box. The invention provides the new energy ship battery drying box capable of effectively preventing a battery from being affected with damp. A new energy ship battery drying box comprises bottom plates and an outer frame body, the two bottom plates are arranged at the bottom of the outer frame body, and the two bottom plates are arranged in a bilateral symmetry mode; the two wiring pipes are arranged on the left side of the outer frame body, and the two wiring pipes are symmetrically arranged front and back; the buzzer used for reminding people to clean water permeating into the outer frame body in time is arranged on the upper middle portion of the left side of the outer frame body; the liquid level sensor is arranged at the middle lower part of the left wall in the outer frame body; the damping mechanism for damping the battery is arranged on the inner side of the outer frame body; and the water pumping mechanism for pumping water in the outer frame body is arranged on the rear side of the outer frame body. And when the ship vibrates, the damping springs conduct damping on the inner frame body, then damping is conducted on the battery, and therefore the effect of protecting the battery is achieved.

Owner:邹长州

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com