Raw material drying device for liquor production

A drying device and raw material technology, which can be used in drying gas arrangement, static material dryer, grain drying, etc., can solve the problems of insignificant drying effect, uneven drying, and large time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

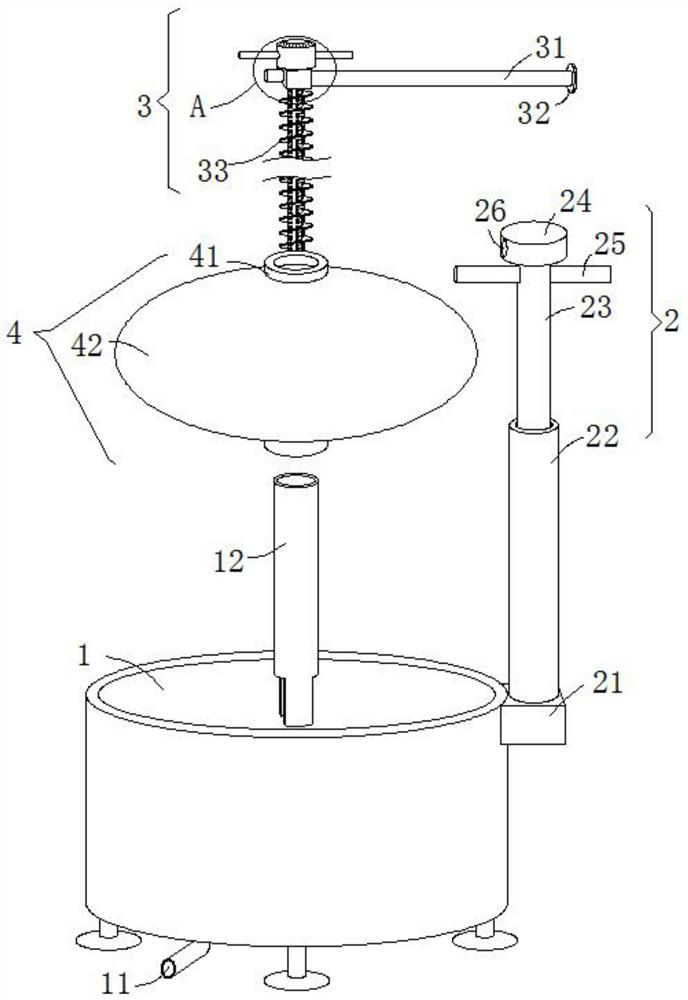

[0022] see Figure 1-3 , this embodiment provides a raw material drying device for liquor production, including a drying cylinder 1, a support adjustment mechanism 2, a transmission mechanism 3 and a secondary storage mechanism 4, the inside of the drying cylinder 1 is a hollow structure, and the inside of the drying cylinder 1 is used for To store the raw materials to be dried, the central position of the inner bottom of the drying cylinder 1 is fixed with a material guide cylinder 12. By setting the material guide cylinder 12 for conveying raw materials, the bottom end of the outer wall of the material guide cylinder 12 is provided with two mutually symmetrical , and the feed gap communicated with the inside of the material guide cylinder 12, through the feed gap to facilitate the introduction of raw materials into the inside of the material guide cylinder 12;

[0023] The support adjustment mechanism 2 is arranged on the top side of the outer wall of the drying cylinder 1, ...

Embodiment 2

[0034] see Figure 1-2 , made further improvement on the basis of embodiment 1:

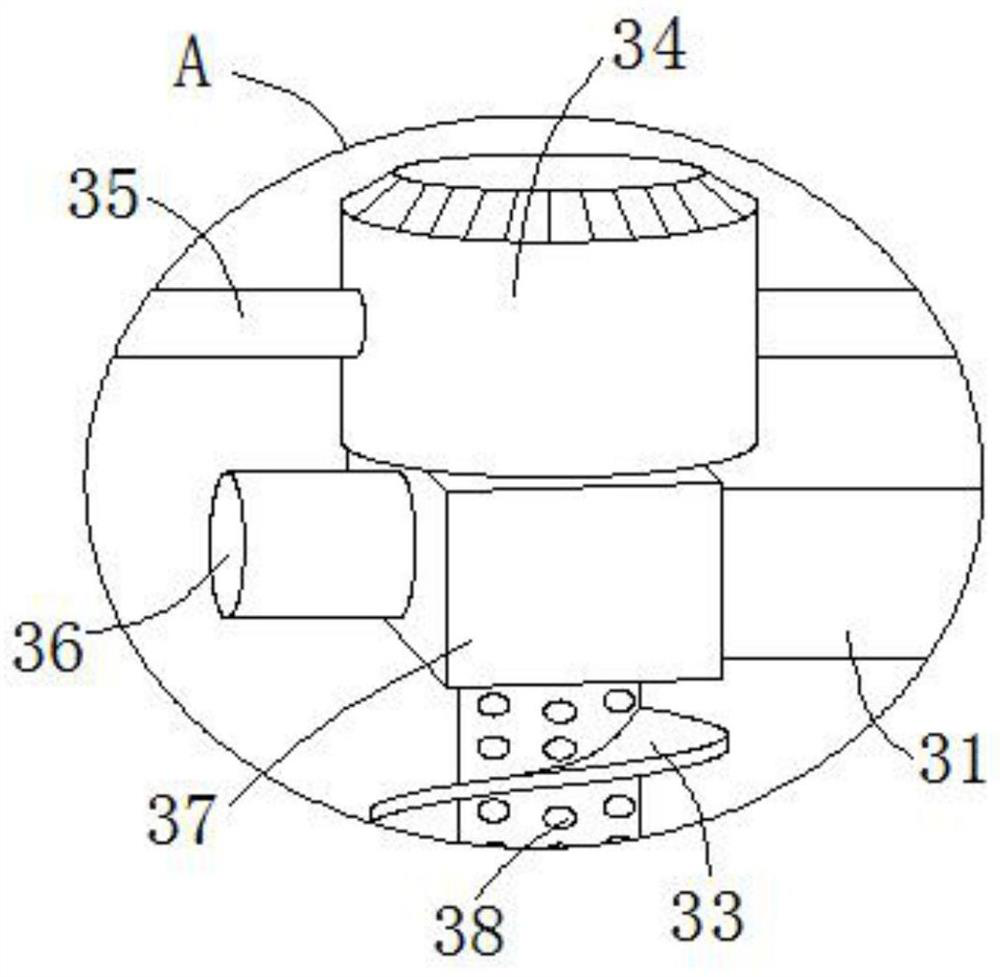

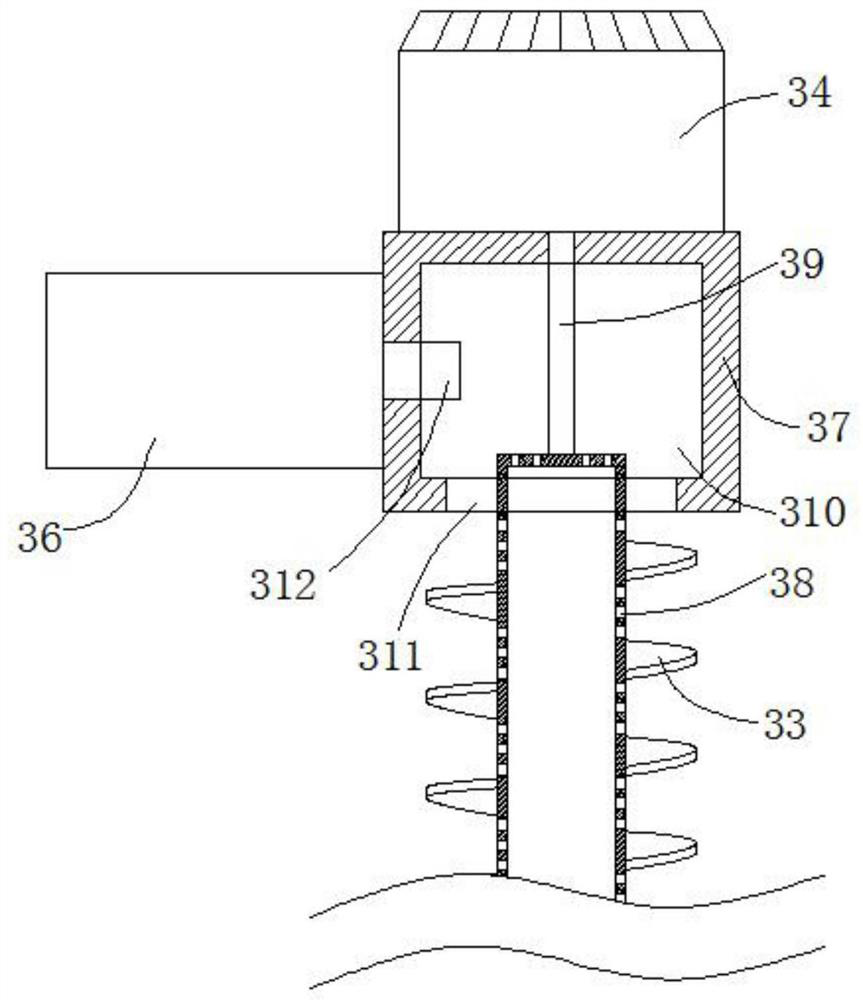

[0035] In order to solve the problem of how to reduce the vibration of the servo motor 34, the radial side wall of the servo motor 34 is symmetrically provided with two second handles 35, and by holding the second handle 35, it is convenient to assist and stabilize the stability of the servo motor 34 during work. Avoid shaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com