Far infrared drying equipment

A technology of far-infrared drying and far-infrared radiant panels, which is used in drying solid materials, drying chambers/containers, drying gas layout, etc., can solve problems such as fire easily caused by open flames, reduce safety, and material pollution, and avoid drying efficiency. The effect of reducing and extending the moving distance and avoiding material contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

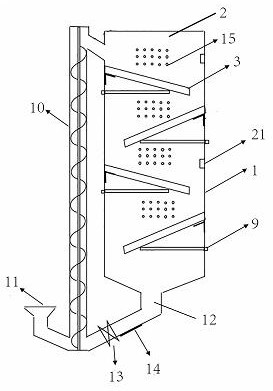

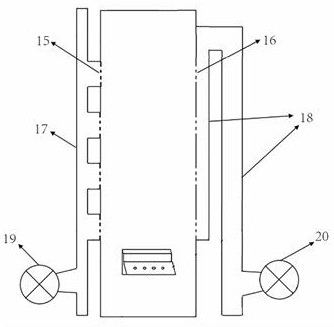

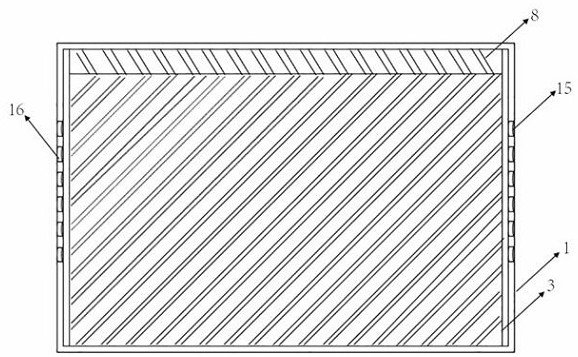

[0030] This embodiment provides a far-infrared drying device, which includes a drying box 1 , and a drying chamber 2 for drying materials is arranged in the drying box 1 . The upper part of the drying chamber 2 is provided with an entrance. On the left side wall and the right side wall in the drying chamber 2, several far-infrared radiation plates 3 are arranged alternately from top to bottom. The free ends of these far-infrared radiation plates 3 are all inclined downward, and each far-infrared radiation The free ends of the plates 3 all extend above the far-infrared radiation plates 3 located below them. The material to be dried automatically falls to the next far-infrared radiation plate 3 after sliding along the far-infrared radiation plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com