Dust treatment device of large grain drying equipment

A technology for drying equipment and dust treatment, which can be used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., and can solve problems such as large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

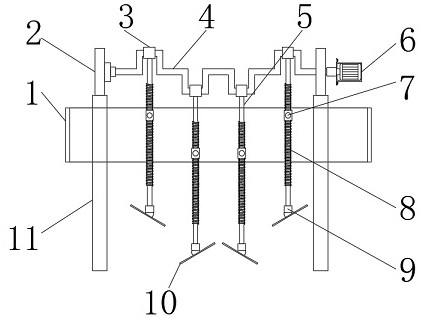

[0023] like Figure 1-2 As shown, the embodiment of the present invention provides a large-scale grain drying equipment dust processing device, including an equipment mounting frame 1 and a servo motor 6, and a driving multi-turn mounting frame 4 is arranged above the equipment mounting frame 1, which drives the multi-turn mounting frame. One end of the frame 4 is rotatably connected with the side wall of one mounting plate 2 through a bearing, and the other end of the driving multi-turn mounting frame 4 extends through the side wall of the other mounting plate 2 to the outside and is fixedly connected with the driving end of the servo motor 6, The outer surface of the driving multi-turn mounting frame 4 has a plurality of protrusions, and the outer surfaces of the plurality of protrusions of the driving multi-turn mounting frame 4 are rotatably sleeved with a connecting drum 3, and the bottoms of the plurality of connecting drums 3 are fixedly connected with The transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com