Gypsum line drying device

A drying device and gypsum line technology, applied in drying, drying machine, heating device and other directions, can solve the problems of low production efficiency, high production cost, long production time, etc., and achieve cost saving, production site saving, and saving The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

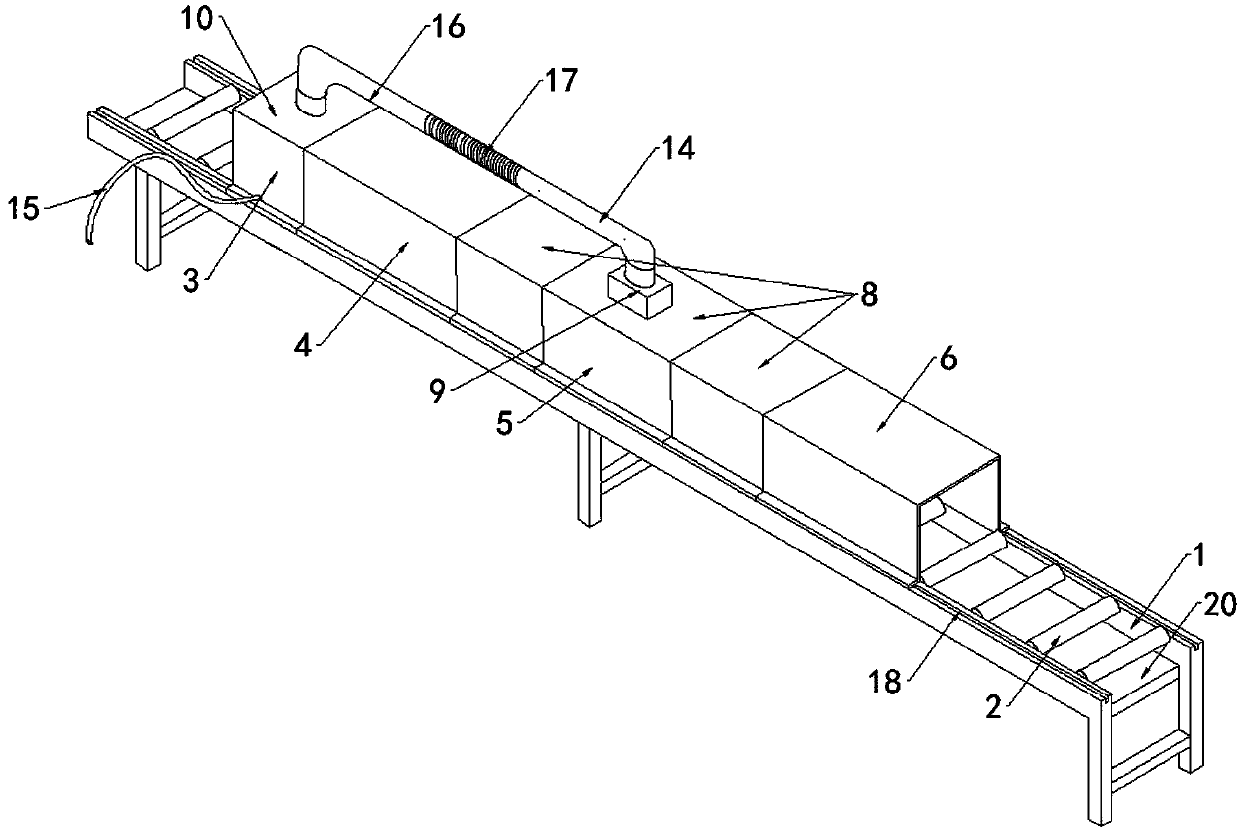

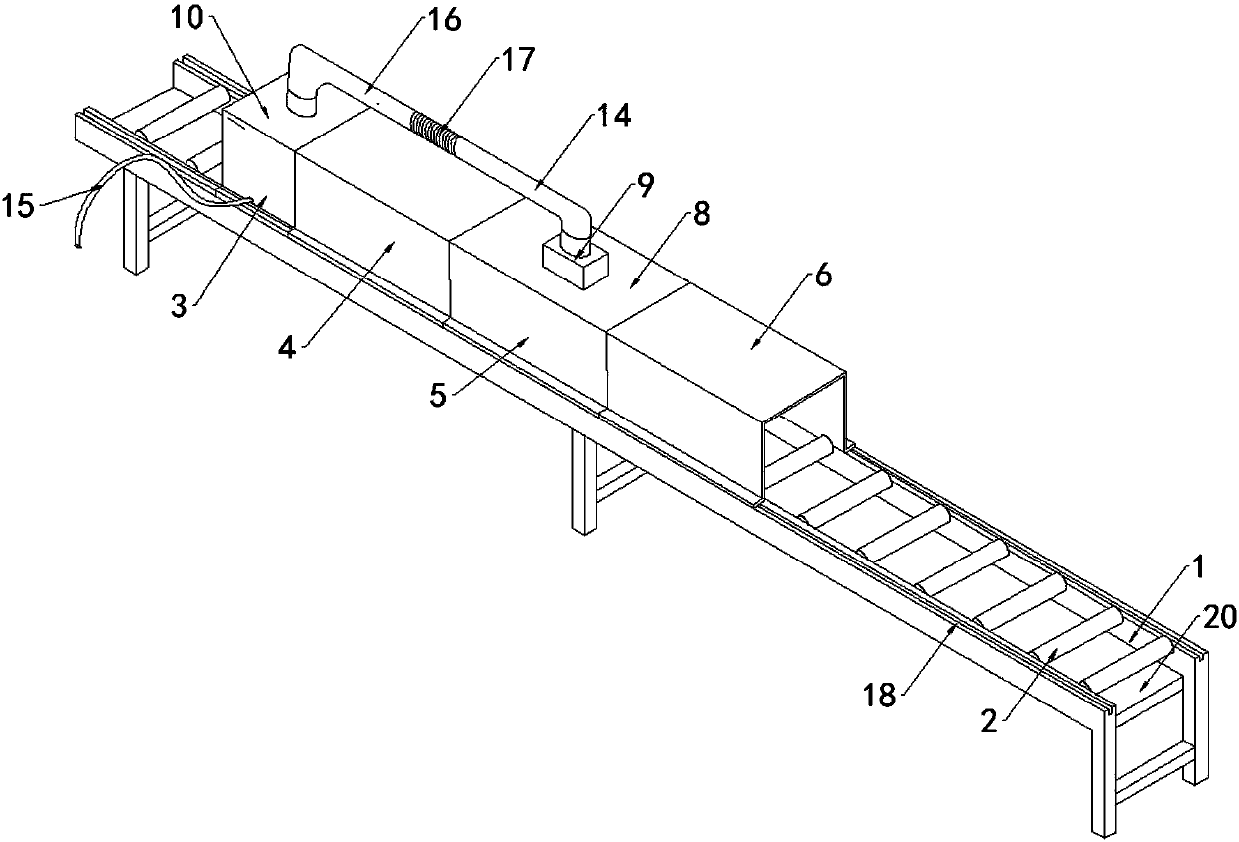

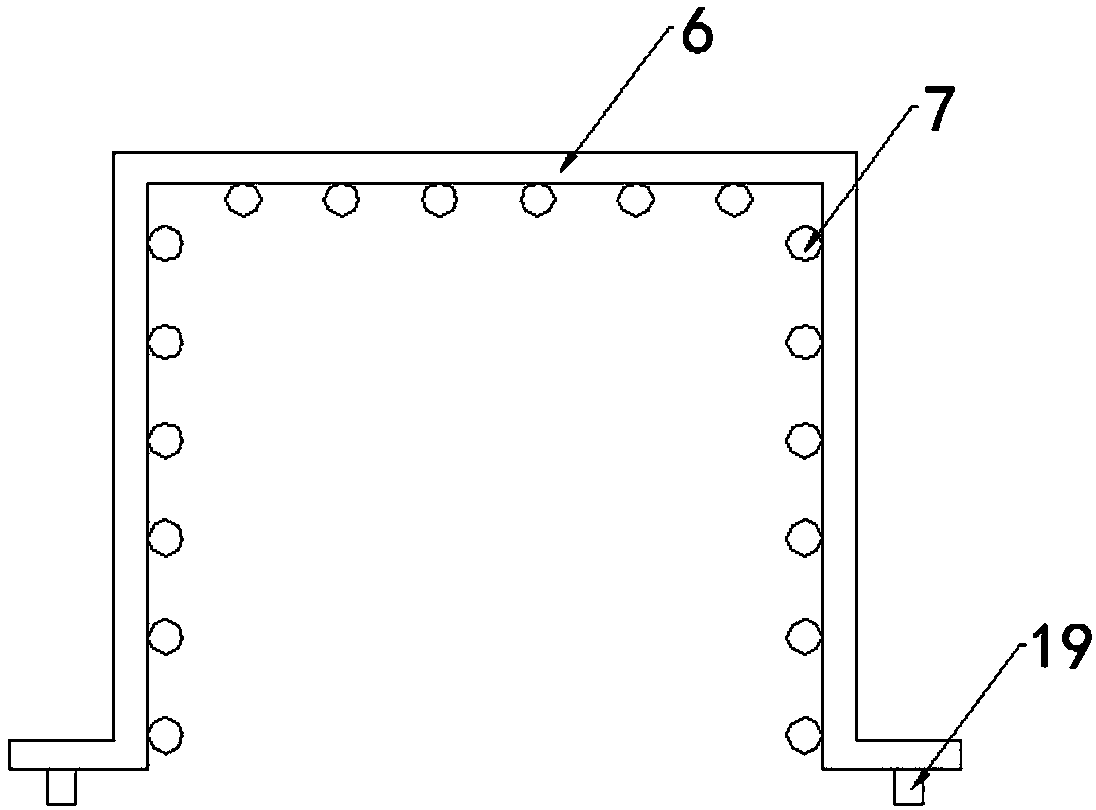

[0034] Such as figure 2 As shown, a gypsum line drying device includes a support frame 1 and a roller 2 arranged in the middle of the support frame 1. The support frame 1 is sequentially provided with a preheating device 3, a primary drying device 4, and a dehumidification device. 5 and the secondary drying device 6, the preheating device 3, the primary drying device 4, the dehumidification device 5 and the secondary drying device 6 are all hollow inside and open at the bottom; the primary drying device 4 is microwave A heater, a plurality of heating pipes 7 are evenly distributed inside the secondary drying device 6;

[0035] The dehumidification device 5 includes a housing a8, the upper part of the housing a8 is provided with an exhaust fan 9, the preheating device 3 includes a housing b10, the housing b10 includes an outer plate 11 and an inner plate 12, and the outer plate 11 and the inner plate 12 There is a gap between them, and a closed heat exchange chamber 13 is forme...

Embodiment 2

[0037] This embodiment is further optimized based on Embodiment 1. The housing a8 in the dehumidification device 5 is set to a plurality; The pipe 17 is screwed to the two connecting pipes 16, and the length of the dehumidification device 5 can be changed by adjusting the number of shells a8 according to the moisture in the gypsum line due to weather or ingredients, so that the water vapor in the drying process All discharge; adjusting pipe 17 is threadedly connected with connecting pipe 16, and the length of pipeline 14 can be adjusted according to the length of dehumidifier 5, so that pipeline 14 can adapt to the change of dehumidifier 5 length.

Embodiment 3

[0039] This embodiment is further optimized based on Embodiment 2, and the joints of the plurality of casings a8 are provided with sealing rings, which can improve the sealing performance of the dehumidification device 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com