Vacuum coating method for compounding combined magnetic field and lining bias-voltage straight tube

A technology of vacuum coating and magnetic field, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of film component pollution, large particle defects, low film deposition efficiency, etc., to ensure uniformity, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

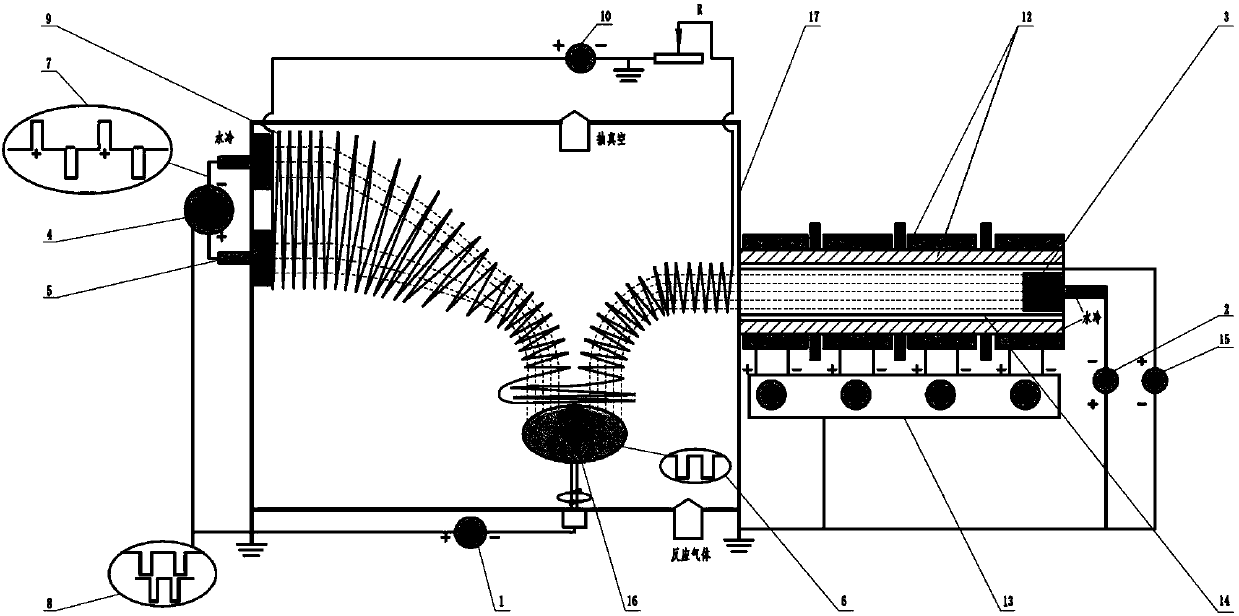

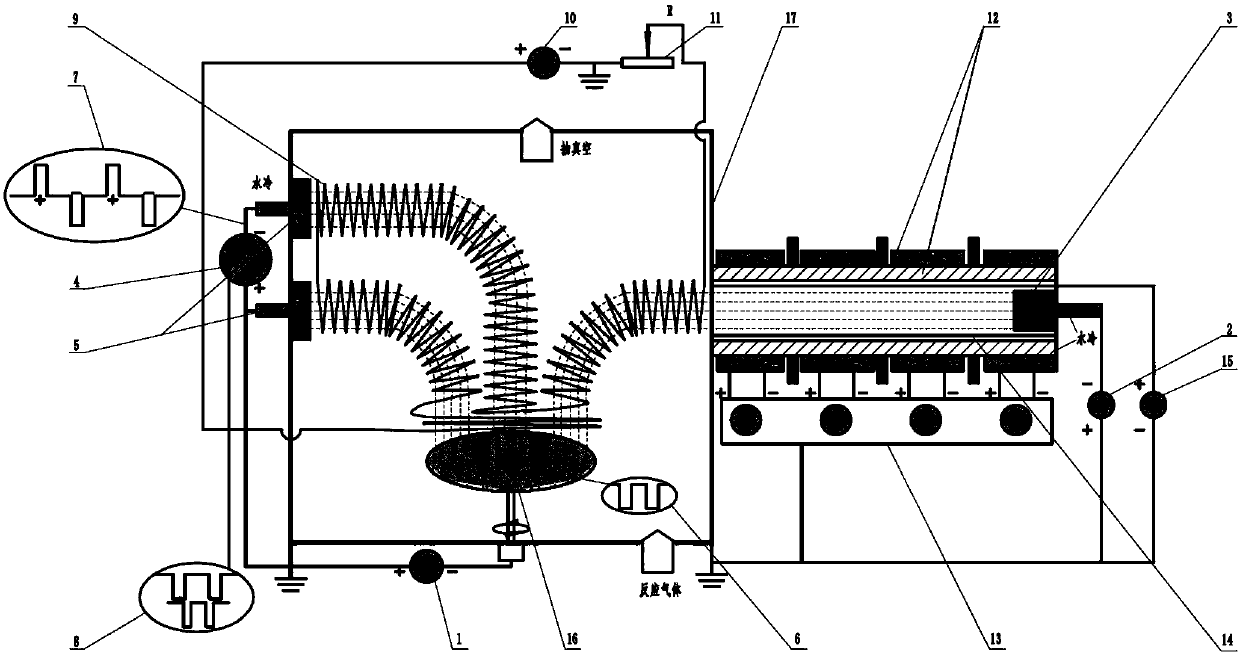

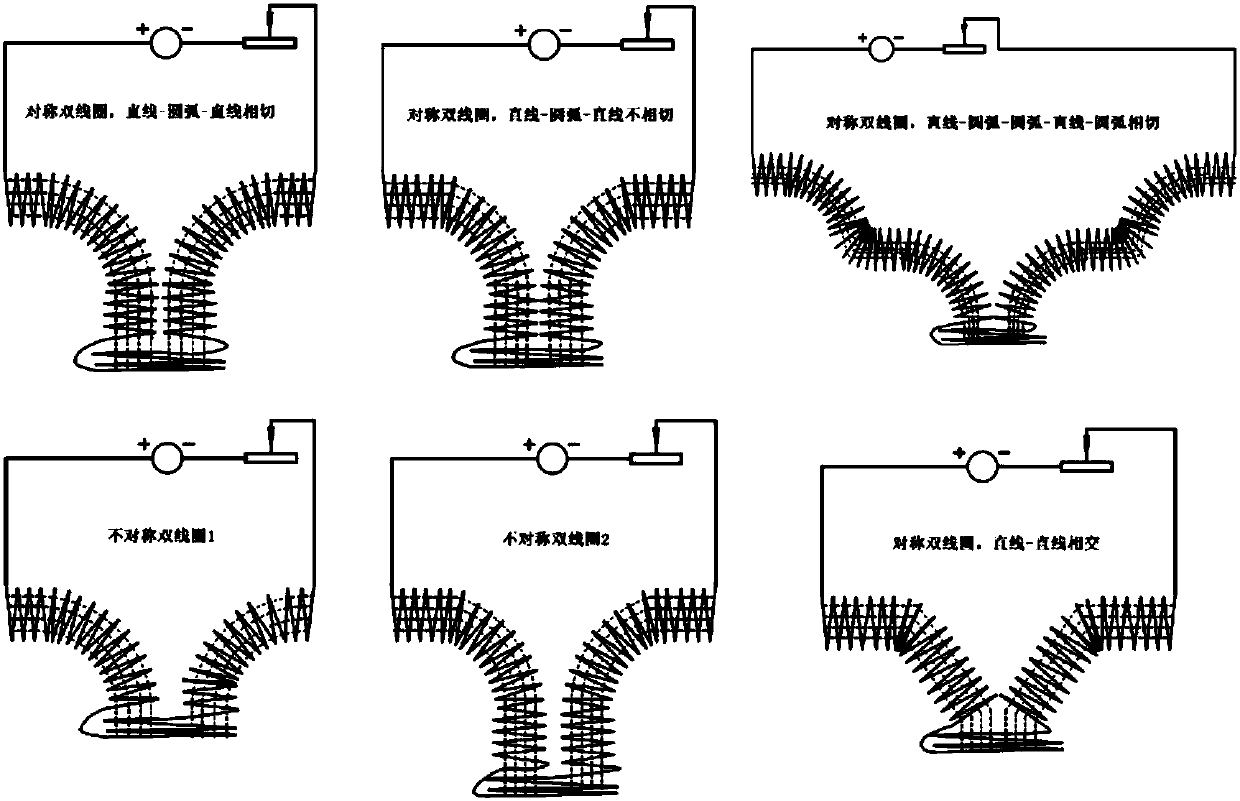

[0025] Specific implementation mode one: the following combination Figure 1-6 Describe this embodiment. In this embodiment, a device used in a vacuum coating method in which a combined magnetic field is combined with a lined bias straight tube includes a bias power supply (1), an arc power supply (2), an arc ion plating target source (3), Twin target high power pulse magnetron sputtering power supply (4), twin target high power pulse magnetron sputtering target source (5), bias power supply waveform oscilloscope (6), twin target high power pulse magnetron sputtering power supply waveform oscilloscope (7), waveform synchronous matching device (8), movable coil device (9), movable coil device power supply (10), rheostat device (11), multi-level magnetic field device (12), multi-level magnetic field device power supply (13), Lined bias straight tube device (14), lined bias power supply (15), sample stage (16) and vacuum chamber (17);

[0026] In this device:

[0027]The workpi...

specific Embodiment approach 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a combined magnetic field is connected with a vacuum coating method in which the lined bias straight tube is combined, the arc power supply (2) is turned on, and the multi-stage magnetic field power supply (5 ) adjust the multi-stage magnetic field device (12), turn on the lining bias power supply (15) to adjust the bias voltage of the lining bias straight tube device (14), turn on the movable coil device power supply (10) and adjust the movable coil device (9), Adjust the output resistance of the rheostat device (10), and the waveform synchronous matching device (8) controls the bias power supply (1) and the twin target high-power pulse magnetron sputtering power supply (4) to be turned on simultaneously, and the twin target high-power pulse magnetron sputtering power supply (4) The period of the output pulse of the radio source (4) is an integer multiple of the output pulse of the bias power ...

specific Embodiment approach 3

[0045] Embodiment 3: The difference between this embodiment and Embodiment 1 is that a combined magnetic field is connected with a vacuum coating method in which the liner bias straight tube is compounded, the arc power supply (2) is turned on, and the multi-stage magnetic field power supply (5 ) adjust the multi-stage magnetic field device (12), turn on the lining bias power supply (15) to adjust the bias voltage of the lining bias straight tube device (14), turn on the movable coil device power supply (10) and adjust the movable coil device (9), Adjust the output resistance of the rheostat device (10), and the waveform synchronous matching device (8) controls the bias power supply (1) and the twin target high-power pulse magnetron sputtering power supply (4) to be turned on simultaneously, and the twin target high-power pulse magnetron sputtering power supply (4) The phase of the high-power pulse output by the radio source (4) and the bias pulse waveform output by the bias po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com