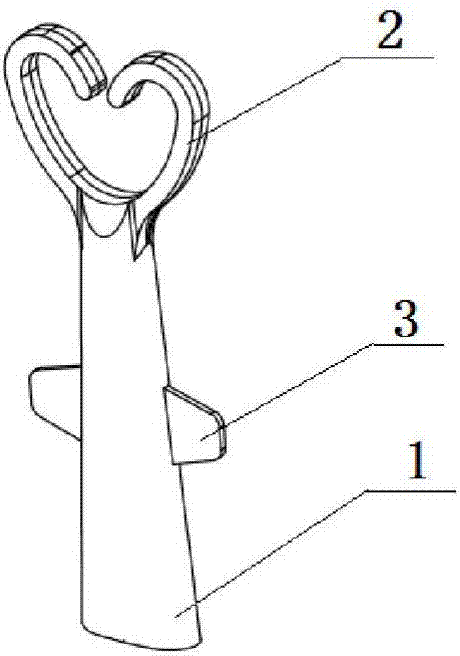

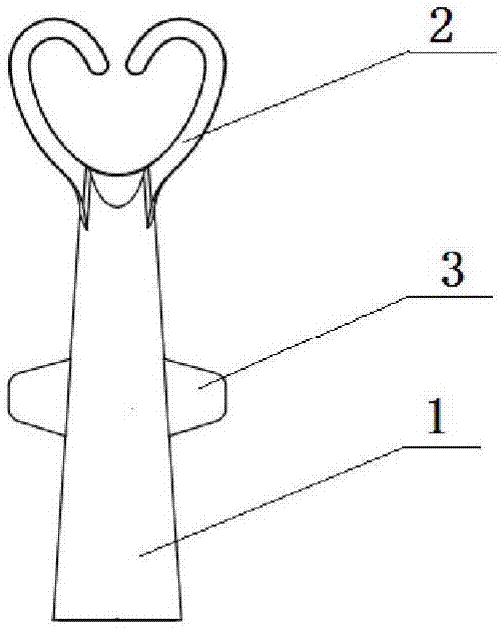

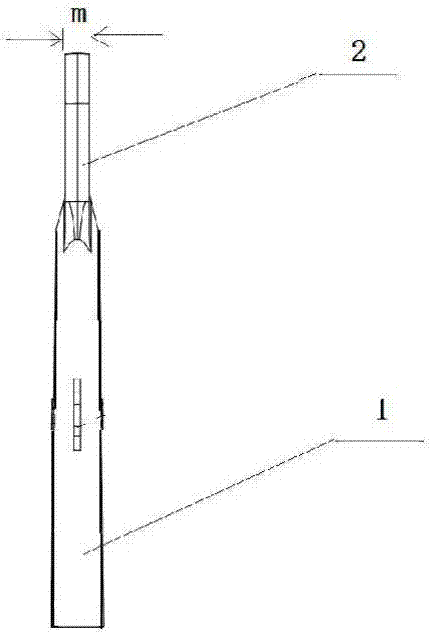

Controlled-release device for slowly releasing volatile substance and manufacturing method thereof

A volatile substance and volatile technology, applied in the agricultural field, can solve the problems of waste, unstable and short volatilization speed of lure cores, generally no more than one month, etc., to achieve the effect of avoiding waste and more flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0068] Example 1: Hexyl acetate is used as a solvent to mix and fill with the sex pheromone of the Asian corn borer. Hexyl acetate is a fast volatile solvent, and its ratio to the sex pheromone of Ostrinia officinalis is 99:1. The main body 1 of the controlled release device is made of polyethylene material. Specifically, 25 controlled-release devices with a wall thickness of 0.8 mm and polyethylene as the main material were used in the test, and each release device was filled with 1.0 ml of a mixed liquid containing 99% of the solvent hexyl acetate and 1 % sex pheromones of Ostrinia sativa. At room temperature, the release rate of 25 controlled-release devices was measured and the data was recorded to an accuracy of 0.1 mg. The entire test lasted for 190 days. During this period, the normal temperature value is between 20-30 degrees Celsius. In the course of the test, five times were divided, and two controlled-release devices were randomly selected each time to measure th...

example 2

[0074] Example 2: Mixed filling with methyl salicylate as solvent and sex pheromone of Asian corn borer

[0075] Use 25 controlled-release devices with a wall thickness of 0.8mm polyethylene material as the main body to fill the liquid mixed with methyl salicylate as a solvent and the sex pheromone of the Asian corn borer, and the methyl salicylate can volatilize quickly. The mixed liquid contains 99% of the solvent methyl salicylate and 1% of the sex pheromone of the Asian corn borer, that is, they are mixed in a ratio of 99:1, and each controlled release device is filled with 1.0ml of the mixed liquid. At room temperature, the release rate of 25 controlled-release devices was measured and the data was recorded to an accuracy of 0.1 mg. The entire test lasted for 190 days. During this period, the normal temperature value is between 20-30 degrees Celsius. In the course of the test, two controlled-release devices were randomly selected for five times each time to measure the w...

example 3

[0079] Example 3: Filling mixed with codling moth sex pheromone using α-farnesene as solvent

[0080]Using α-farnesene as a solvent, 1% codling moth sex pheromone was added at a ratio of 99:1, and the mixed liquid was filled in the controlled release device of the main body 1 made of polyethylene material. In this test, 25 controlled-release devices with a wall thickness of 0.8 mm were used. The mixed liquid contained 99% of the solvent α-farnesene and 1% of codling moth sex pheromone, and each controlled-release device was filled with 1.0 ml mixed liquid. At room temperature, the release rate of 25 controlled-release devices was measured and the data was recorded to an accuracy of 0.1 mg. The entire test lasted for 190 days. During this period, the normal temperature value is between 20-30 degrees Celsius. During the test, five times were divided, and two controlled-release devices were randomly selected each time to measure the weight of the remaining mixed solution and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com