Cable butt joint device

A docking device and cable technology, which is applied in the direction of instruments, optics, light guides, etc., can solve the problems of low efficiency, unsuitable docking device for optical cable docking, and high cost, so as to achieve high docking efficiency, improve on-site docking efficiency, and high docking accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

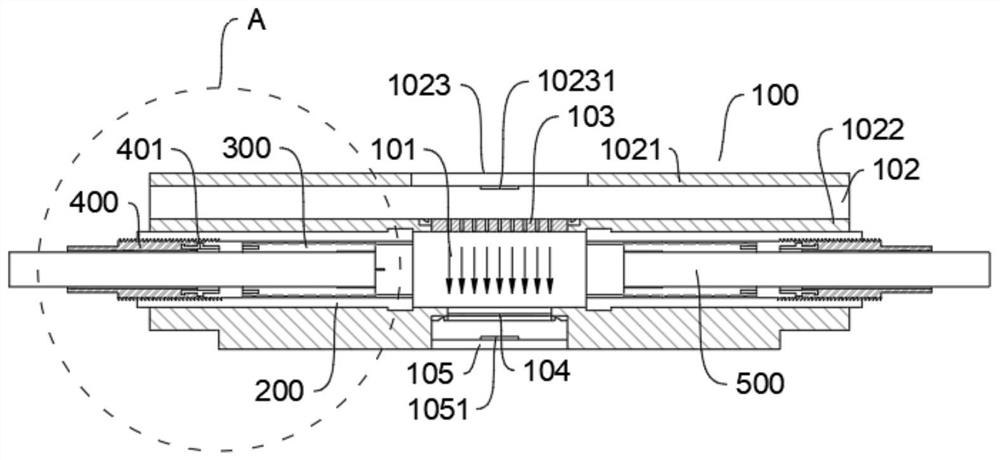

[0058] a kind of like figure 1 The cable docking device shown, this device can be applied to the docking of cables and optical cables. This embodiment only uses optical cables as an example to illustrate, but the two are substantially similar, and the protection content should not be limited due to the content of the embodiment;

[0059] The on-site cable docking device specifically includes:

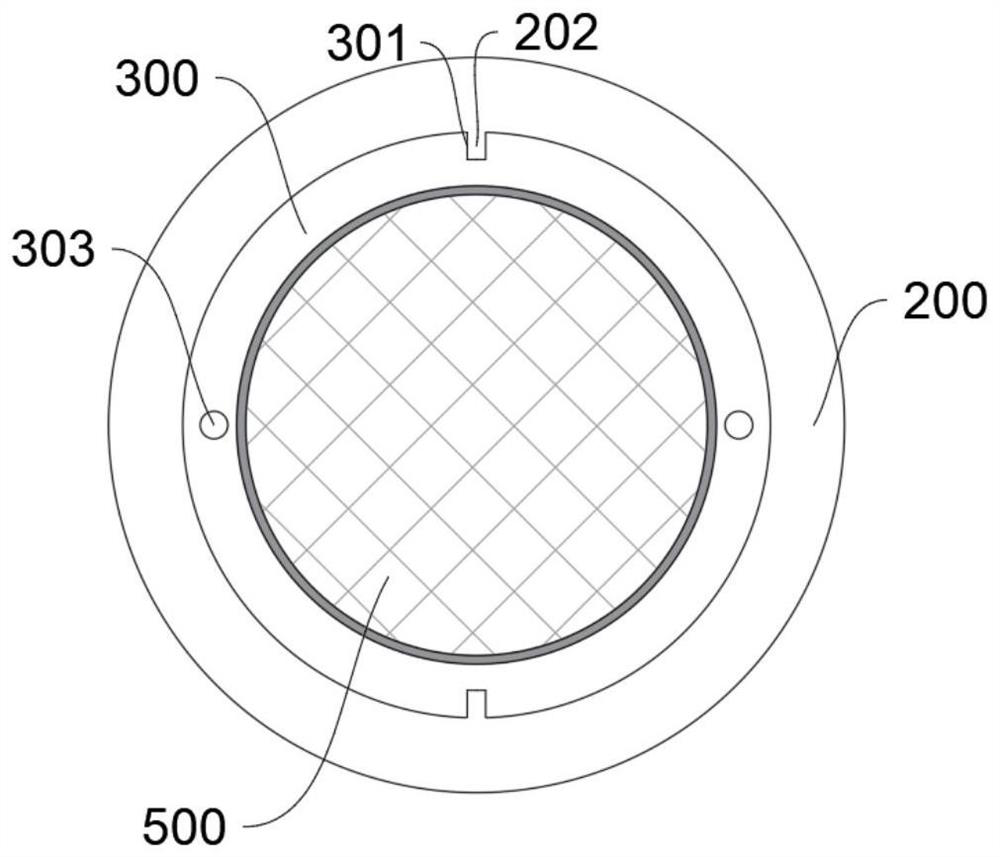

[0060] A main body 100, the main body 100 is provided with an accommodating channel 101 for accommodating, docking and fixing the optical cable 500, and a light source channel 102 parallel to the accommodating channel 101;

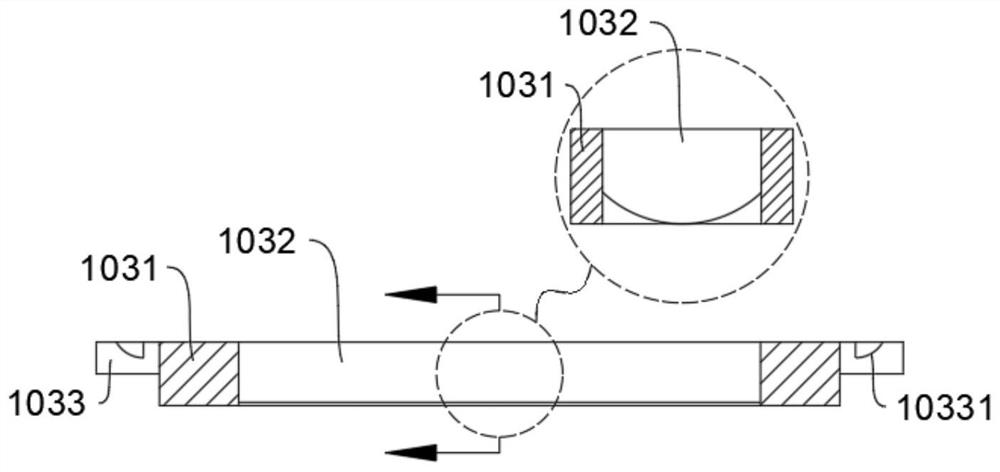

[0061] Both ends of the accommodation channel 101 are open, and the inner wall 1022 of the light source channel 102 corresponding to the middle part of the accommodation channel 101 is provided with a through groove connecting the light source channel 102 and the accommodation channel 101, and a light guide 103 is arranged in the through groove;

[0062]Two main fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com