Third-generation compound semiconductor production area personnel supervision method and related equipment.

A technology for producing personnel and semiconductors, applied in the direction of induction record carrier, electromagnetic radiation induction, instruments, etc., can solve problems such as inaccurate determination, achieve the effects of reducing personnel injuries, improving safety supervision, and reducing the scope of rescue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

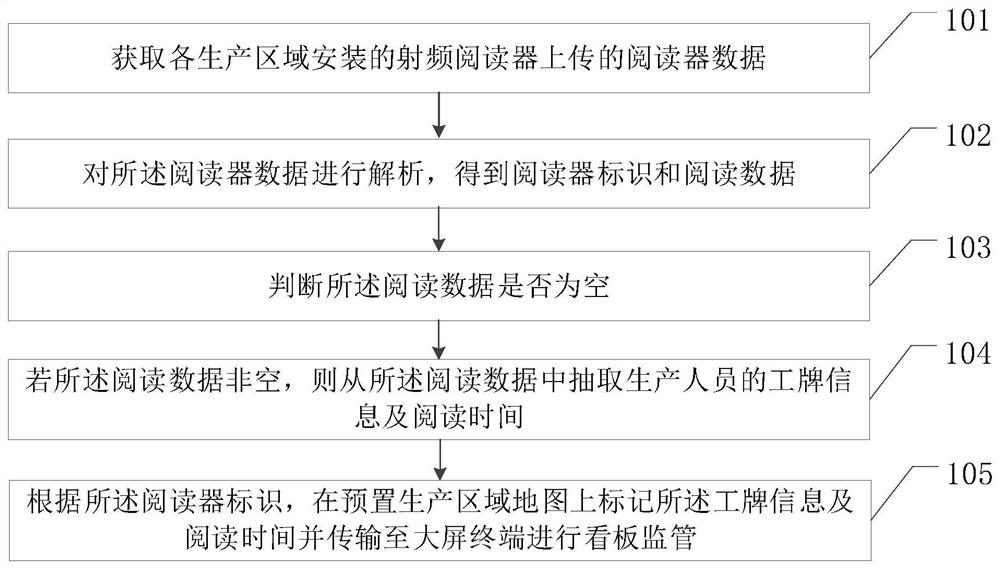

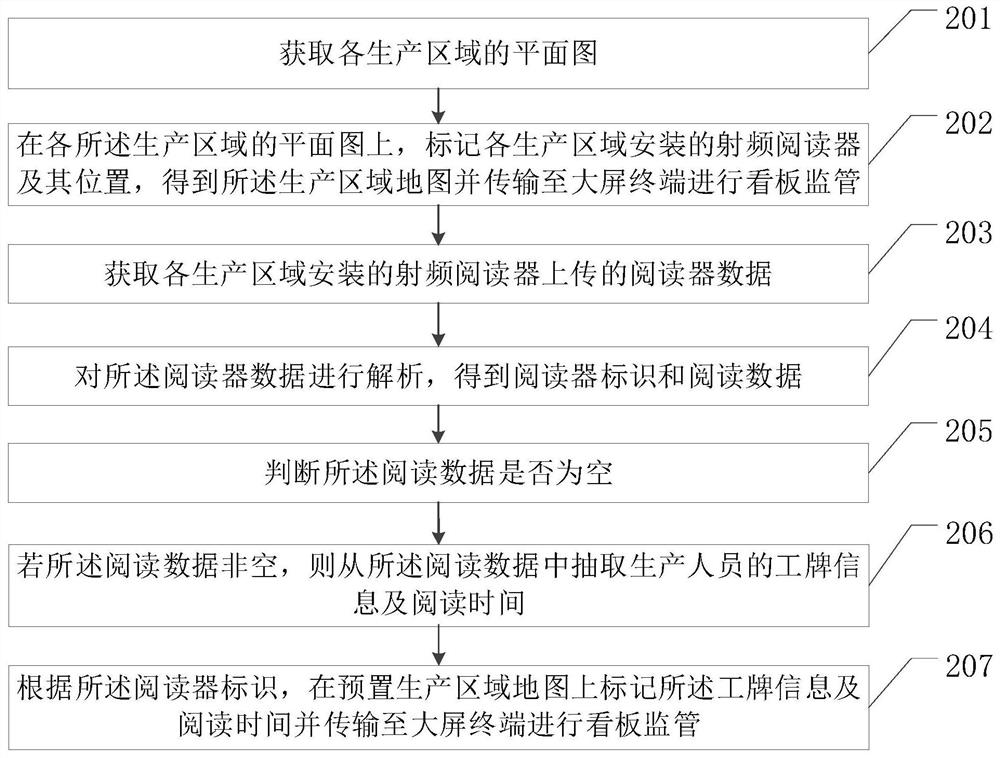

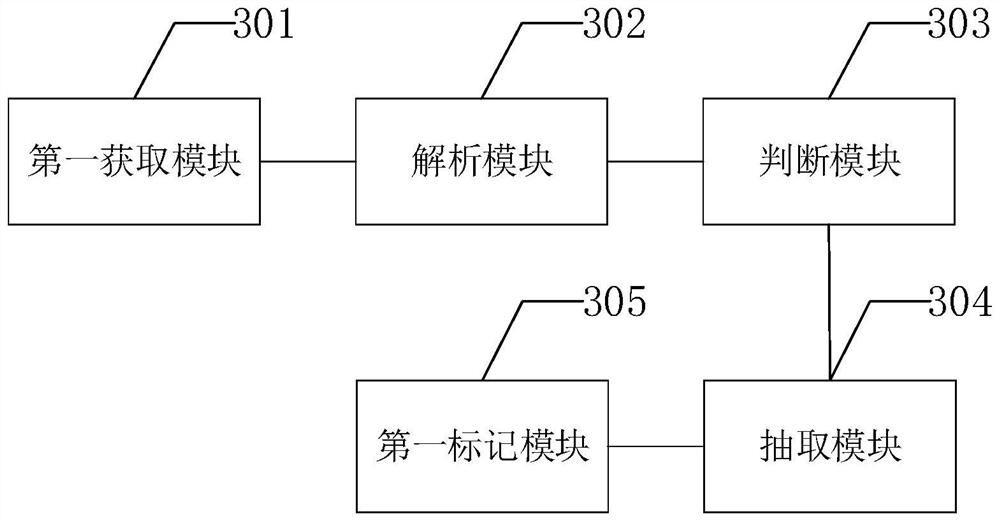

[0062] The embodiment of the present invention provides a third-generation compound semiconductor production area personnel supervision method and related equipment. The equipment accurately determines whether there are still trapped people in each production workshop and the technical problem of personnel supervision in the production area where the trapped people are located.

[0063] The terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention and the above drawings are used to distinguish similar objects, and not necessarily Used to describe a specific sequence or sequence. It is to be understood that the terms so used are interchangeable under appropriate circumstances such that the embodiments described herein can be practiced in sequences other than those illustrated or described herein. Furthermore, the term "comprising" or "having" and any variations thereof, are intended to cover a non-exclusive inclusion, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com