Black-coloured polyamide composition with high laser transmittance for laser welding application

A technology of polyamide composition and aliphatic polyamide, which is applied in the field of polyamide composition and can solve problems such as unsatisfactory requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

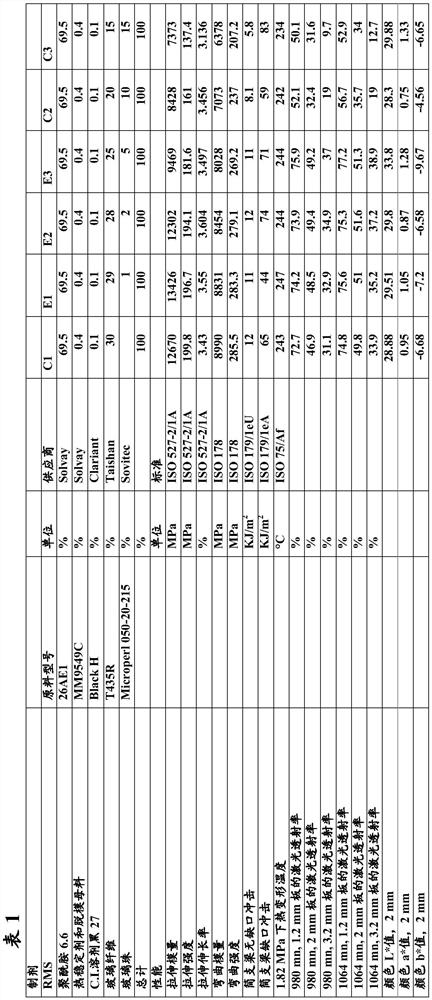

[0098] Preparation of polyamide composition:

[0099] Several polyamide compositions were prepared as examples and comparative examples.

[0100] The following components were used as starting materials:

[0101] Component (i): PA6.6 homopolymer

[0102] Component (ii): Glass fiber chopped strands with an average length of 4.5 mm and an average diameter of 10 μm (T435R purchased from Taishan)

[0103] Component (iii): Solid glass beads with an average diameter of 20 μm (Microperl 050-20-215 from Sovitec)

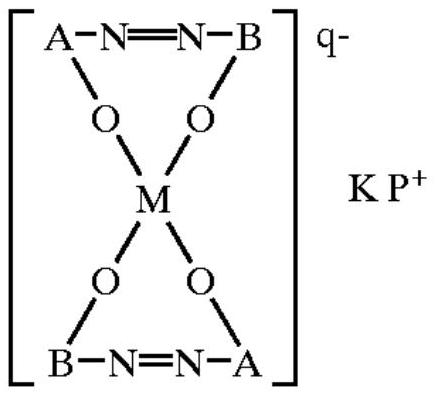

[0104] Component (iv): Monoazo complex dye solvent black 27

[0105] Component (v): Heat Stabilizer and Release Masterbatch (MM9549C from Solvay)

[0106] The composition for molding according to the invention is prepared by mixing in a twin-screw type extruder ZSK 18W at a rate of 12 kg / h and an equal screw rotation speed of 300 rev / min at a temperature ranging from 265°C to 340°C, Depending on the formulation of the various components and the amounts disclosed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com