Wafer automatic bearing system and method for conveying wafer by adopting wafer automatic bearing system

A carrier system and wafer carrier technology, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., which can solve the problems of unreproducible wafer deposition repeatability, inaccurate determination of wafer position, and wafer film deposition quality. It can improve the position accuracy and transfer crystallinity, reduce the movement steps, and improve the product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present application will be described in detail below in conjunction with the accompanying drawings. Aspects of the present application may be understood more readily by reading the following description of specific embodiments with reference to the accompanying drawings. It should be noted that these embodiments are only exemplary, which are only used to explain and illustrate the technical solutions of the present application, rather than limiting the present application. Those skilled in the art can make various modifications and transformations on the basis of these embodiments, and all technical solutions obtained through equivalent transformations belong to the protection scope of the present application. The names of various components used in this manual are for the purpose of illustration only and do not have a limiting effect. Different manufacturers may use different names to refer to components with the same function.

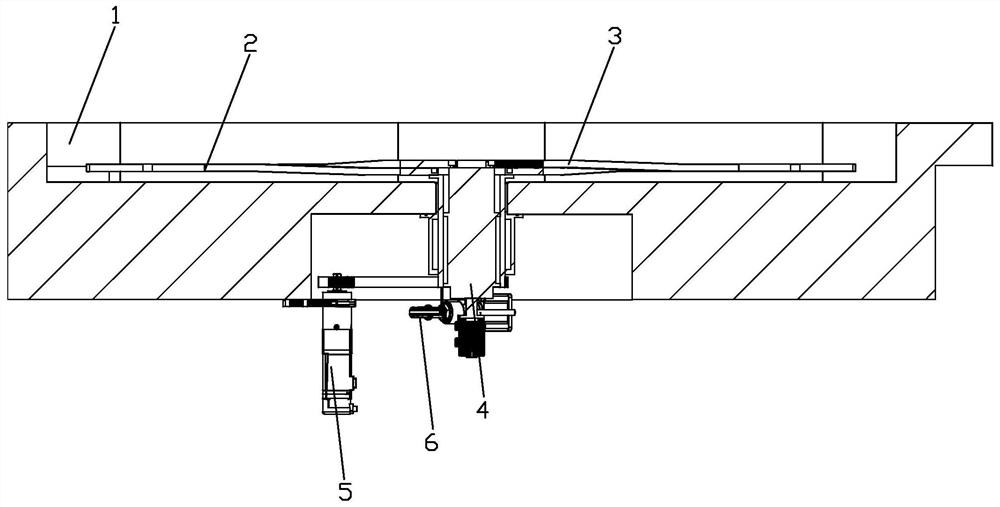

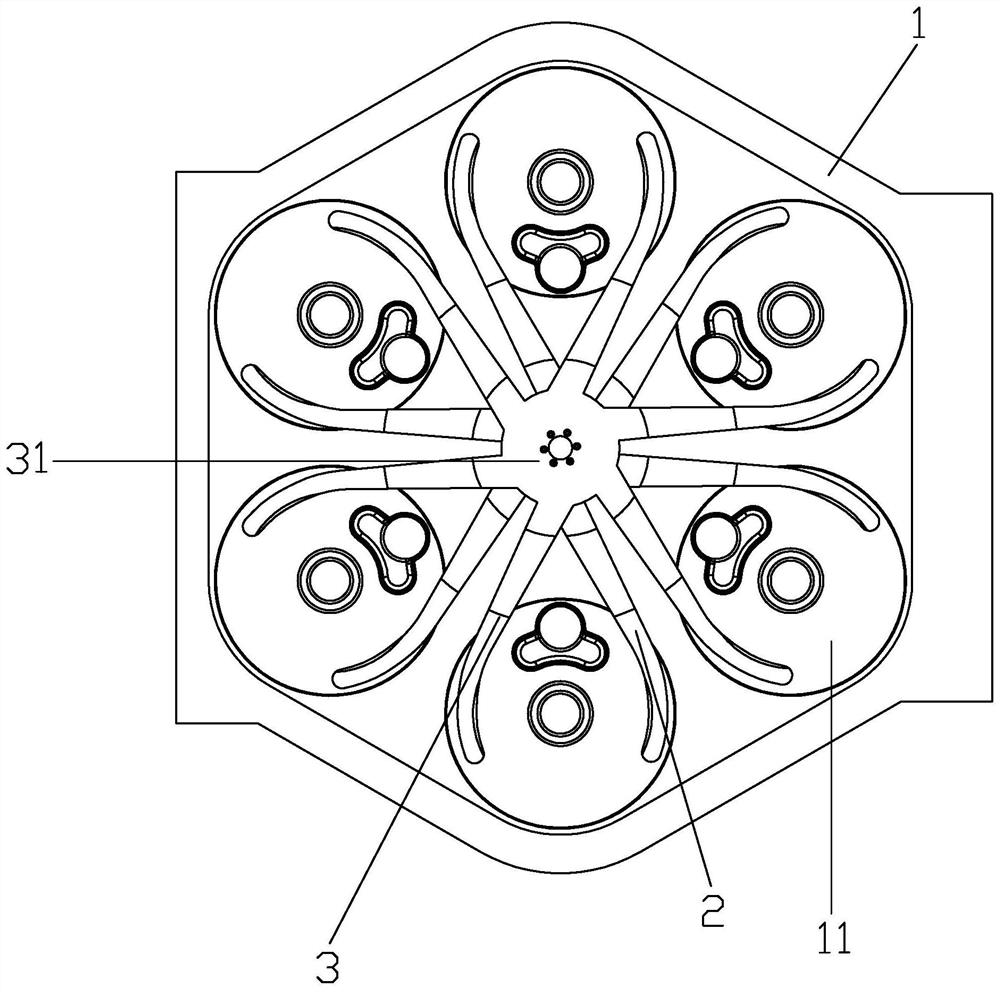

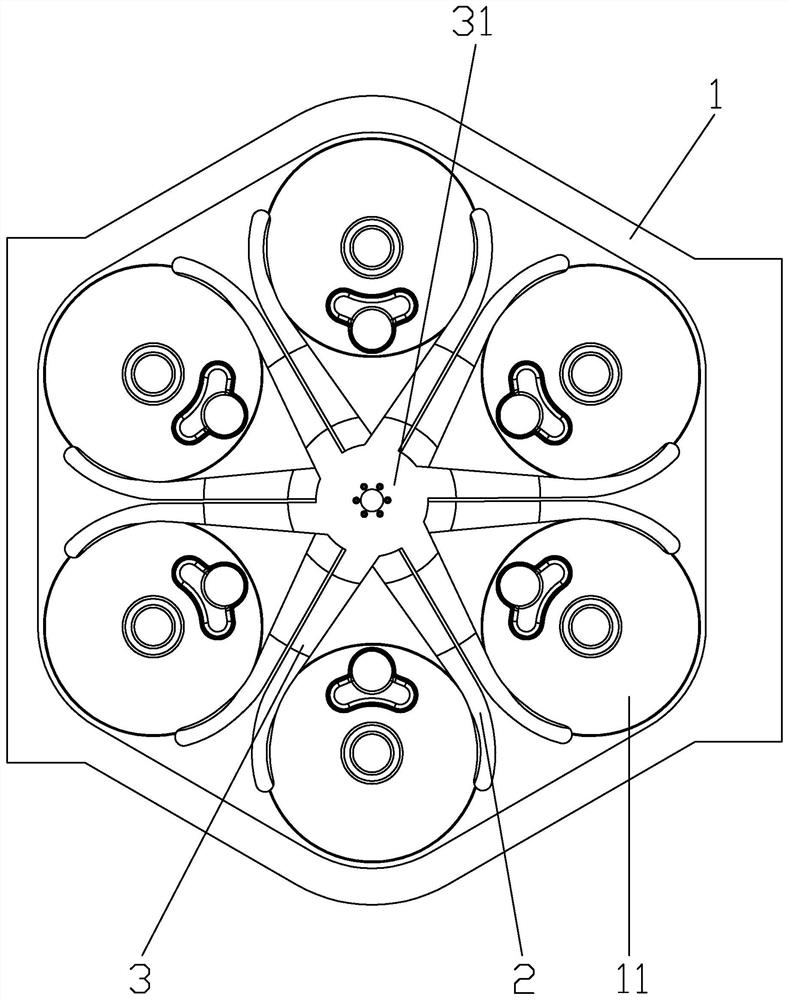

[0050] see figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com