Method for producing a three-dimensional glass object and glass fibres suitable for therefor

A technology of glass fiber and three-dimensional glass, which is applied in the field of glass fiber and quartz glass objects for manufacturing three-dimensional glass objects, and can solve the problems of difficulty in maintaining the nominal profile and maintaining straight-line welding, etc.

Pending Publication Date: 2021-12-24

HERAEUS QUARZGLAS

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In particular the twisting of the glass fibers about the longitudinal axis of the fibers makes it difficult to maintain the nominal contours preset by the model of the glass object and for example to maintain a rectilinear weld on the substrate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

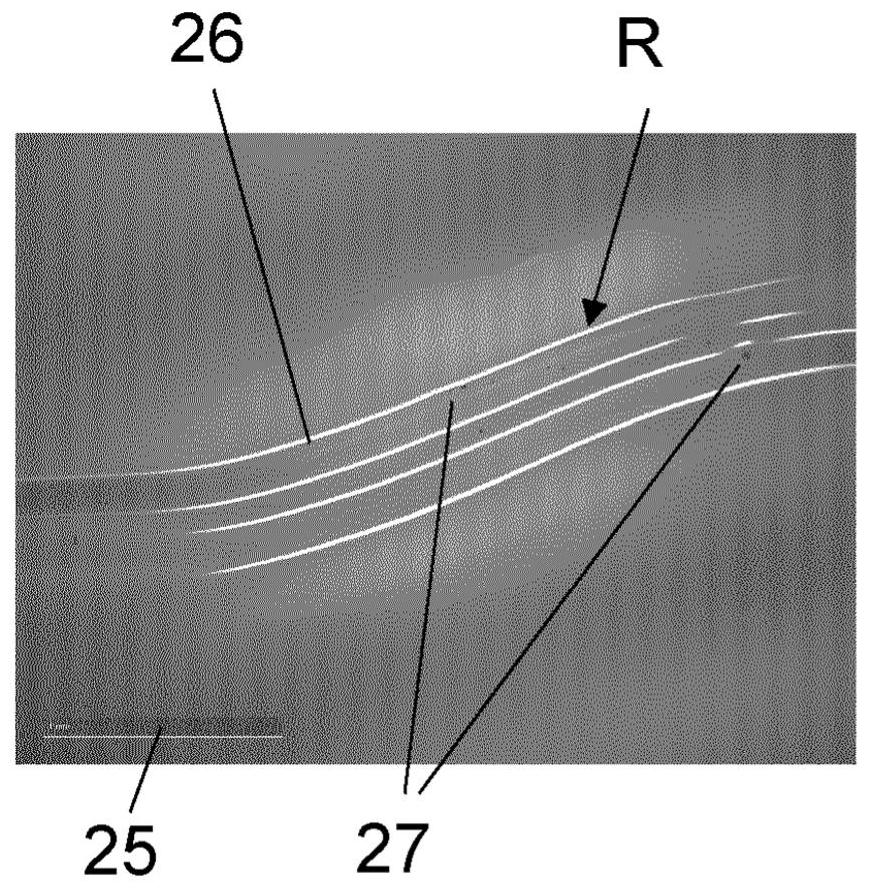

[0056] figure 2 A microscope image showing a pre-experiment of a weld overlay using a reference glass fiber,

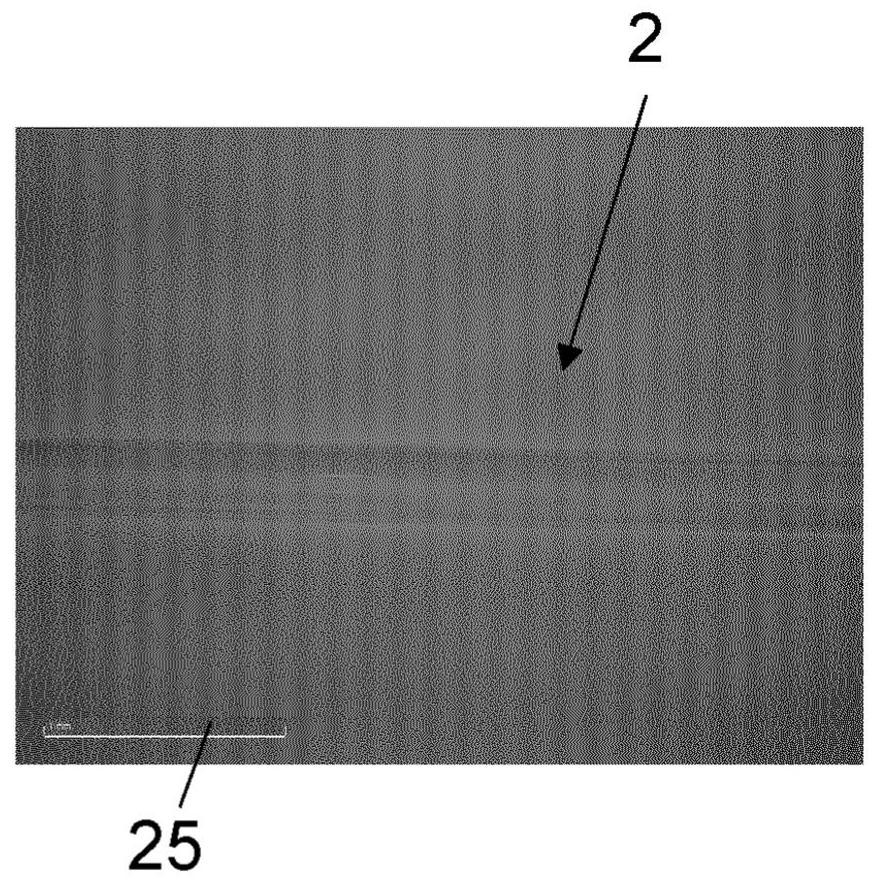

[0057] image 3 A microscope image showing a weld overlay pilot experiment using glass fibers of the present invention, and

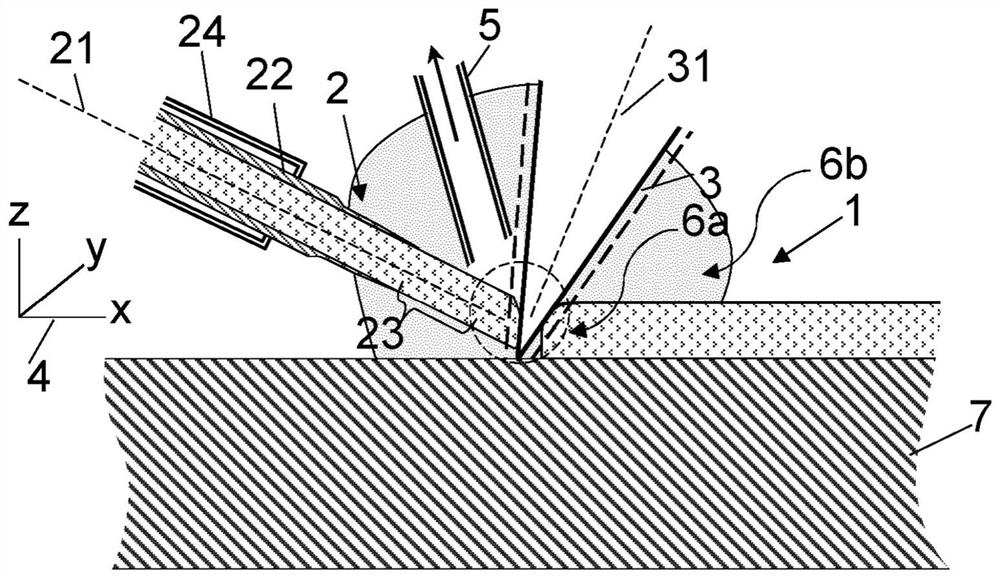

[0058] Figure 4 Another embodiment of the experimental structure for carrying out the build-up welding experiment using the glass filament of this invention is shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

Known method for producing a three-dimensional glass object comprises the steps of shaping a glass fibre, wherein the glass fibre provided with a protective sheath is continuously fed to a heating source, the protective sheath is removed under the influence of heat and the glass fibre is softened. According to the invention, in order to facilitate the production of filigree or optically distortion-free and transparent glass objects as much as possible and in particular to enable the adjustment of optical and mechanical properties with high spatial resolution, the glass fibre has a protective sheath with a layer thickness in the region of between 10 nm to 10 um.

Description

technical field [0001] The invention relates to a method for producing three-dimensional glass objects, in particular quartz glass objects, the method comprising forming glass fibers, wherein the glass fibers equipped with a protective sheath are continuously fed to a heat source, under the action of which the said The protective cover is removed and the fiberglass is softened. [0002] Furthermore, the invention relates to a glass fiber for producing a three-dimensional glass object, wherein the glass fiber is provided with a protective sheath. [0003] Intricate glass components are manufactured industrially by glass pressing techniques or fusion molding processes. These processes are time-consuming and require high processing temperatures as well as special tools and molds, which can lead to defects and damage inside and on the glass structure. [0004] Especially for the manufacture of models and prototypes or in the case of small objects and low numbers of parts, additi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B37/15C03C25/24C03C25/25C03C25/32C03B37/12C03B23/00C03B20/00

CPCC03B37/15C03B37/12C03B20/00C03B23/00C03B23/006C03C25/24C03C25/32C03C25/25C03C25/002C03C25/40C03C25/30C03C25/321B29C64/118B33Y10/00B33Y70/00B33Y80/00B29C64/268C03B19/02B32B17/02C03B29/04C03B2201/02

Inventor M·S·赫纳A·霍夫曼

Owner HERAEUS QUARZGLAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com