Multi-axis rotation test box

A technology of rotating test and rotating arm, applied in the field of test box, can solve the problem that the workpiece cannot be rained from multiple angles, cannot simulate the natural state of rain spraying, and the simulation state is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout.

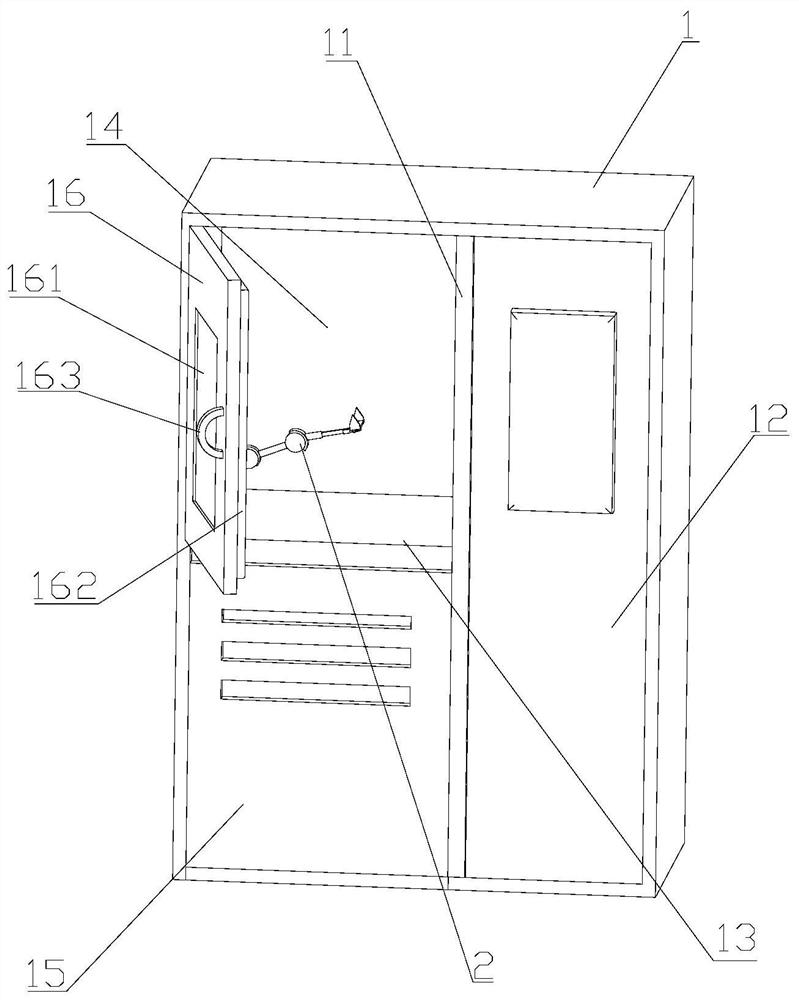

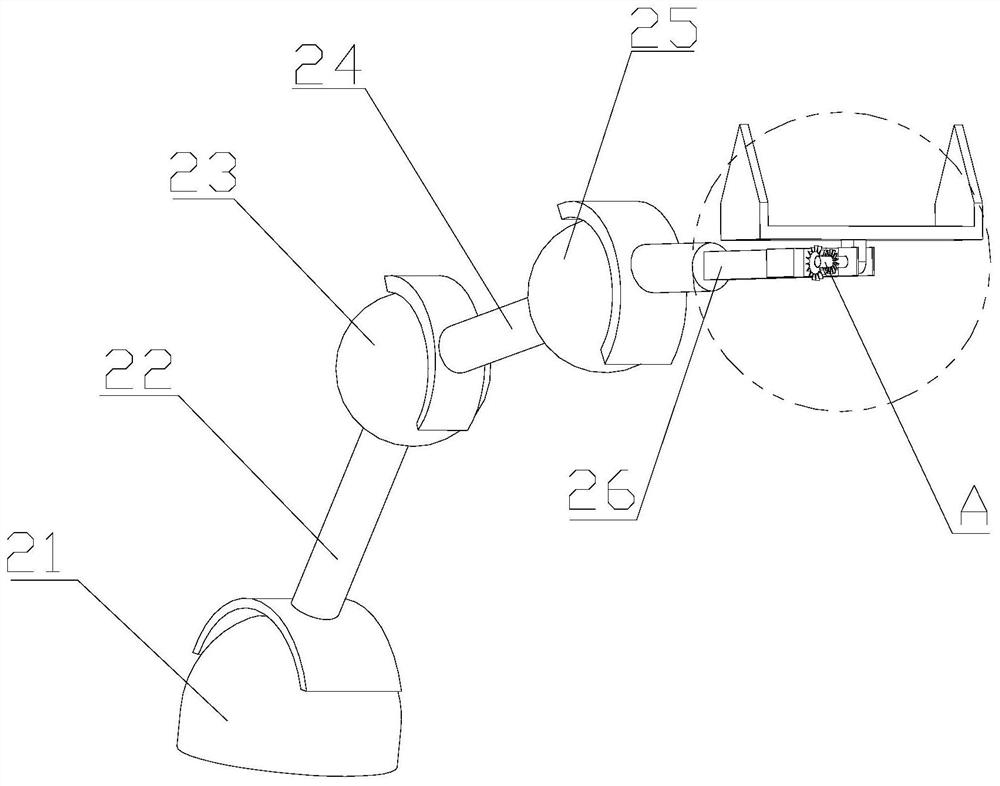

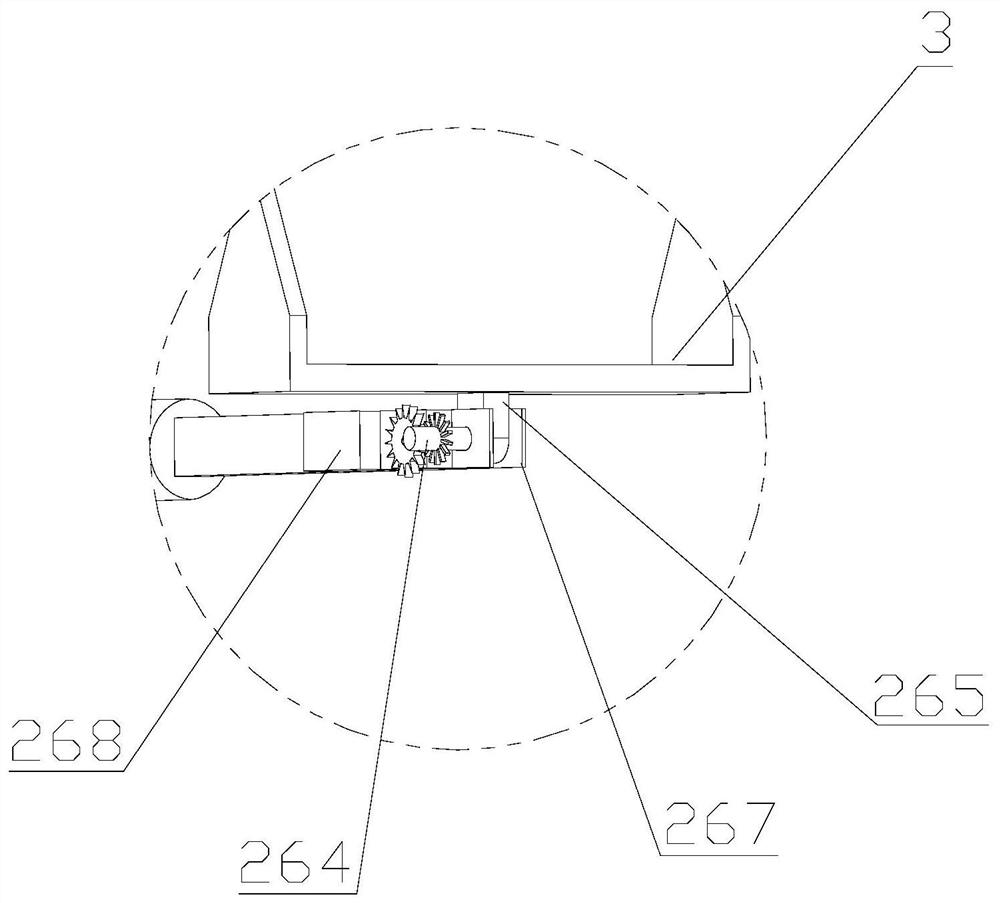

[0028] see Figure 1 to Figure 6 , the present invention provides a multi-axis rotation test box, the multi-axis rotation test box includes a main box 1, a multi-axis rotation arm 2 and a clamping claw 3, the inside of the main box 1 is provided with a partition 11, The partition board 11 divides the main box body 1 into a control room 12 and a test room, the inside of the control room 12 is provided with an electrical control device, and the inside of the test room is provided with a horizontal plate 13, and the horizontal plate 13 divides the test room into a test area 14 and an equipment area 15. The multi-axis rotating arm 2 is detachably connected to the horizontal plate 13 and is located inside the test are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com