Interstage separation device suitable for small-missile-diameter aircrafts

An inter-stage separation and aircraft technology, applied in the direction of self-propelled bombs, weapon types, projectiles, etc., can solve the problems of long separation time, small separation impact load, large separation impulse, etc., achieve fast thermal separation speed, and ensure connection stiffness. , the effect of small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

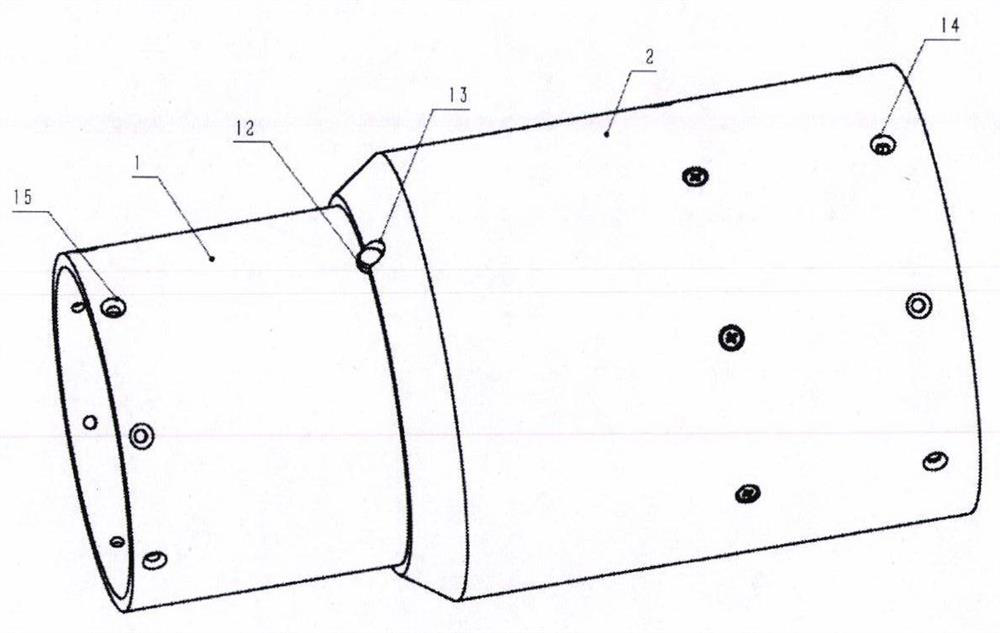

[0022] Such as figure 1 As shown, an interstage separation device suitable for small-diameter aircraft, the device is mainly through 1. The upper stage connecting cabin is tightly connected with the upper stage of the aircraft through radial screw holes, and 2. The lower connecting cabin and the lower stage of the aircraft pass through Radial screw holes fasten the connection to realize the connection between aircraft stages.

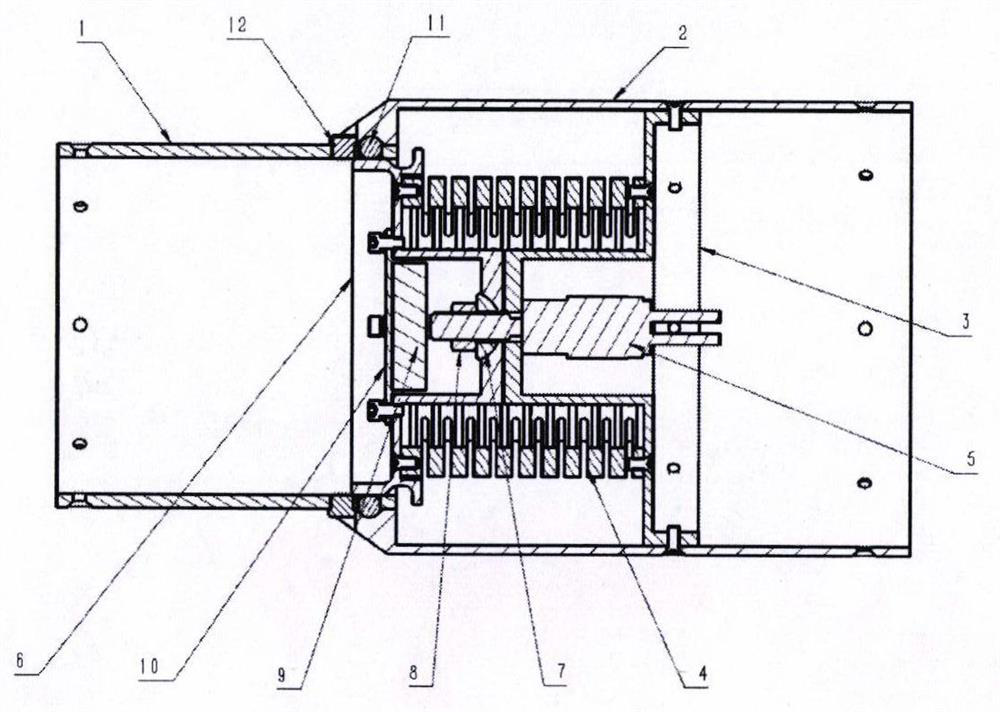

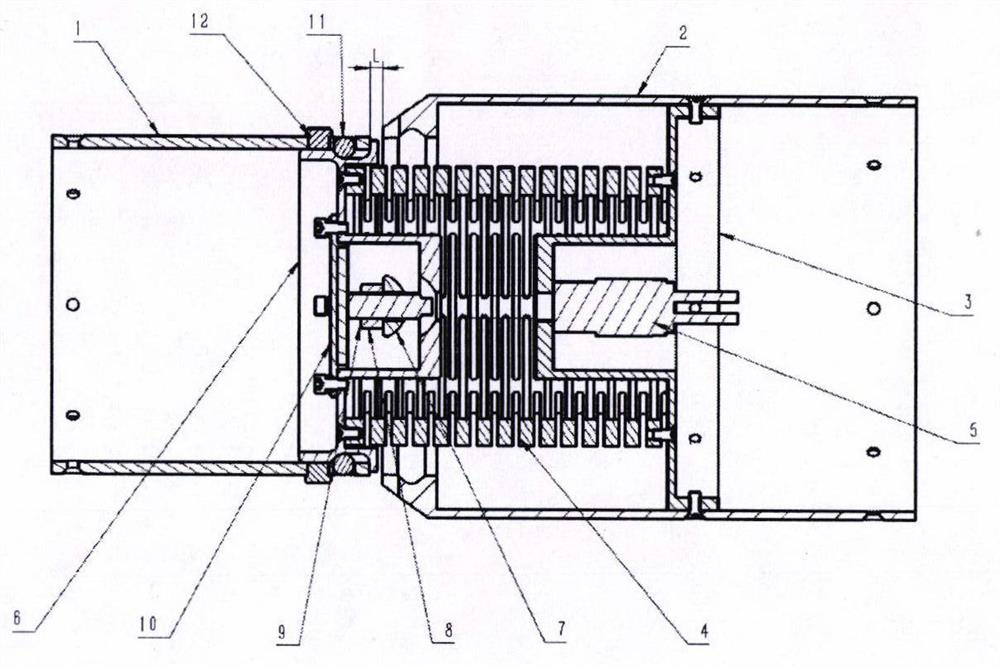

[0023] The locking connection of the inter-stage separation device suitable for small-diameter aircraft, such as figure 2 shown. 1. The upper-level connecting cabin and 2. The lower-level connecting cabin are nested with each other. 4. One side of the cylindrical spring is connected to 6. The unlocking top plate, and the other side is connected to 3. The mounting plate. 5. The explosion bolt passes through 6. Unlock the top plate and 3. Install the supporting plate, and lock with 7. Ball pad, 8. Lock nut. 5. The connection force of the explosive bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com