Assembly type ground trunking structure and installation method thereof

A ground line and assembly technology, which is applied to the cable installation and cable installation in the ground conduit, can solve the problems that cannot exist independently, cannot be flexibly adjusted, and the floor trunking module does not have a leveling function, etc., to achieve Time-saving, simple and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

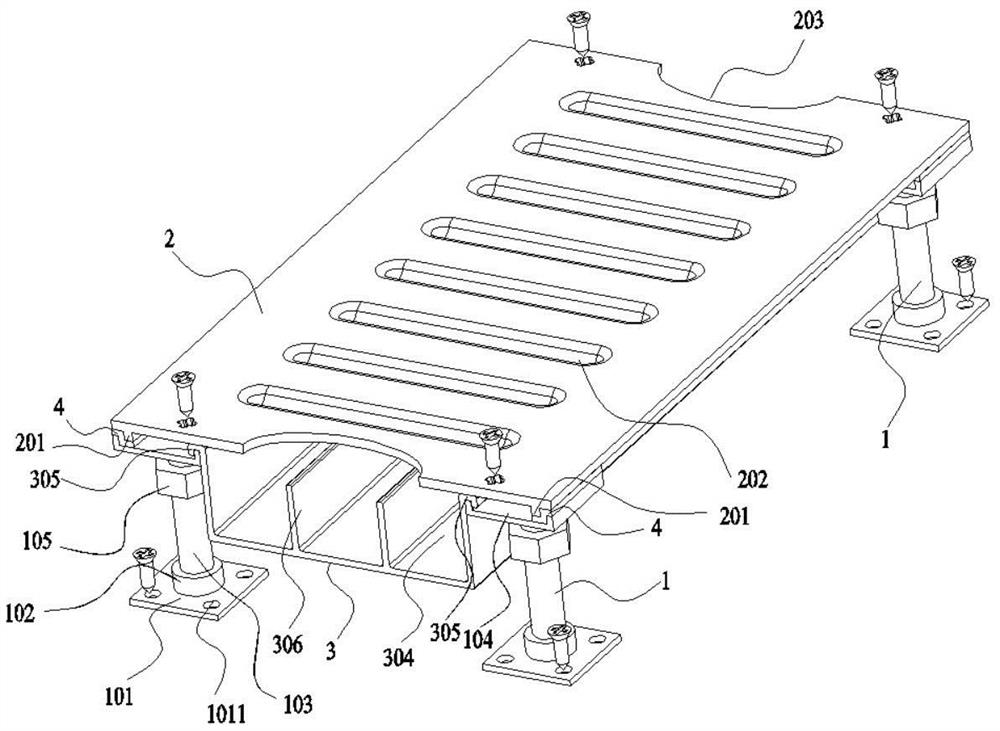

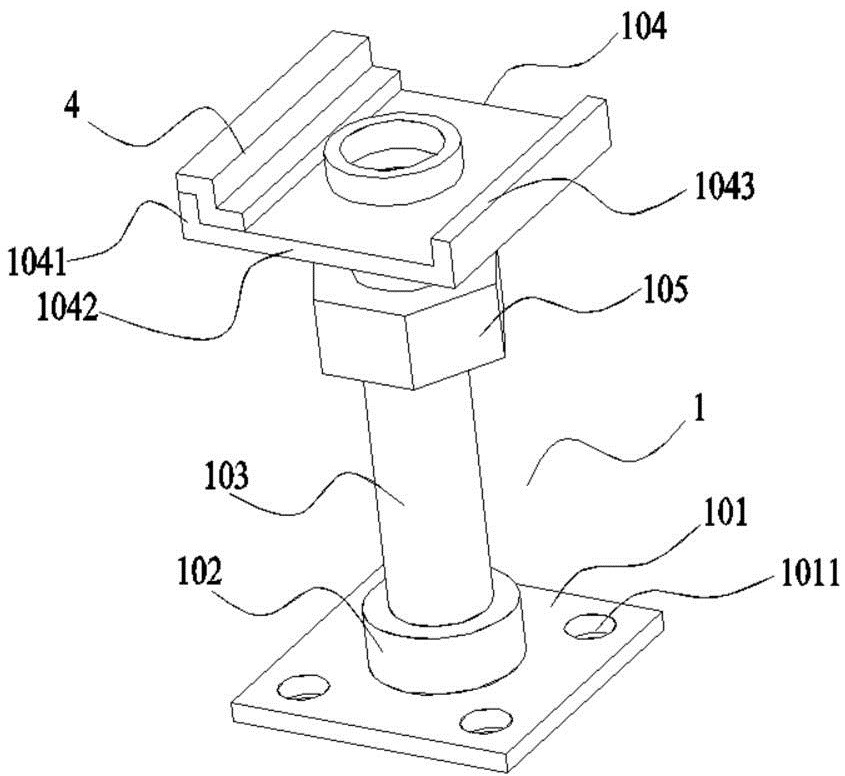

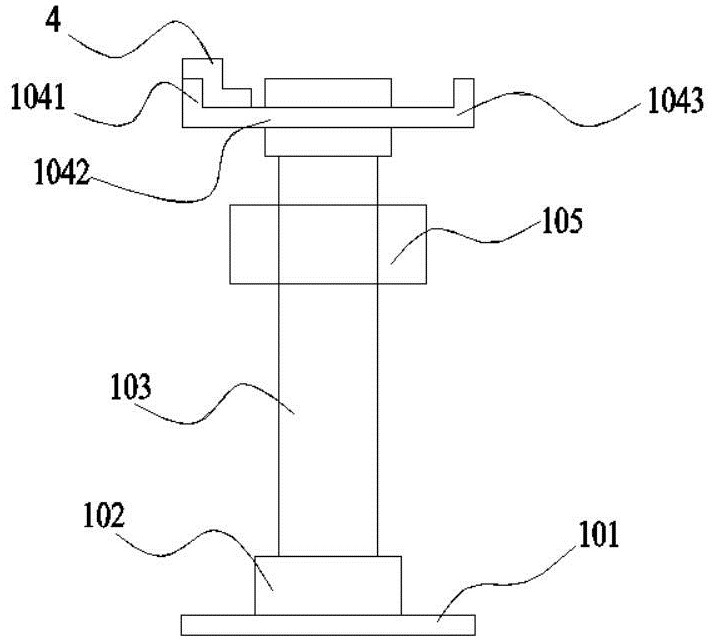

[0043] The embodiment of the present invention provides an assembled ground trunking structure, the structure is as follows Figure 1~Figure 7shown. An assembled ground trunking structure, including a leveling support 1, a floor trunking 3 and a trunking cover 2, the leveling support 1 is fixedly installed on the ground, and the leveling support 1 includes a support base 101 and a leveling Stud 103, the lower end of leveling stud 103 is screwed on the support base 101, the upper end of leveling stud 103 is fixedly connected with connection support 104, and connection support 104 is provided with first assembly part and second assembly part The floor trunking 3 is formed by connecting the first vertical plate 301, the first horizontal plate 302 and the second vertical plate 303 connected in a U shape, and the ends of the first vertical plate 301 and the second vertical plate 303 are provided with the first vertical plate 301 and the second vertical plate 303 The third assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com