Double-spiral-groove drill rod coated with optical fibers and communication drilling machine

A helical groove and double helix technology, which is applied in the field of double helical groove coated optical fiber drill pipes and communication drilling rigs, can solve the problems of unable to guarantee the safety of communication optical fibers, easy to squeeze and wear optical fibers, etc., to overcome the small signal capacity and the difficulty of processing Big, Applicable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

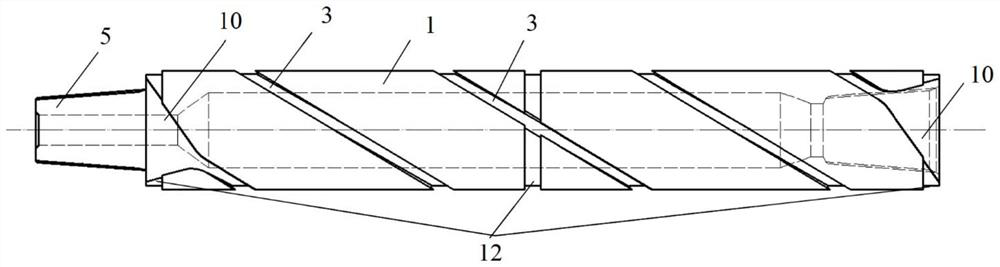

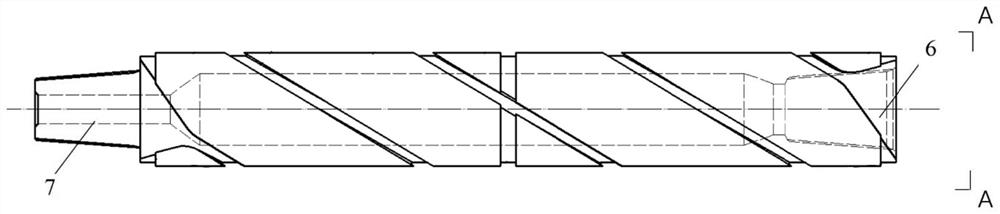

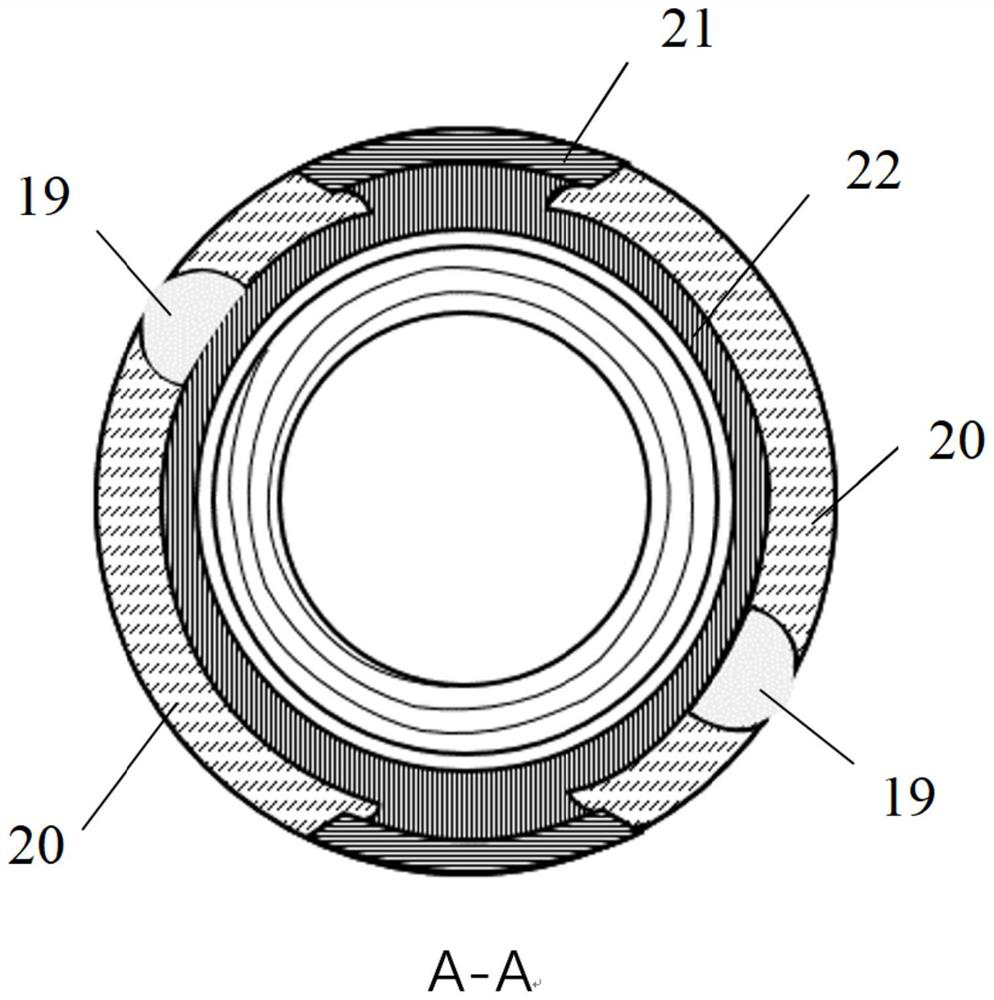

[0053] Follow the above technical solutions, such as Figure 1 to Figure 7 As shown, a double helical groove coated fiber optic drill rod comprises a helical groove drill rod 1 and a wire-passing drill rod joint 2 connected to one end of the helical groove drill rod 1, and the helical groove drill rod 1 spirals along its outer surface. A first helical trimming groove 3 is arranged, and the first helical trimming groove 3 is embedded in and penetrates the outer surface of the helical groove drill rod 1;

[0054] The wire-passing drill pipe joint 2 is spirally arranged with a second helical edge trimming groove 4 along its outer surface, and the second helical edge-receiving groove 4 is embedded in the outer surface of the wire-passing drill pipe joint 2;

[0055] The first helical edge trimming groove 3 and the second helical edge trimming groove 4 are provided through.

[0056] The first helical edge trimming groove 3 and the second helical edge trimming groove 4 are used for a...

Embodiment 2

[0100] Follow the above technical solutions, such as Figure 8 As shown in the figure, a communication drilling rig includes a drilling rig 16, on which the double helical groove outer-coated fiber optic drill rod as described in Embodiment 1 is installed; Signal instrument 18. Drilling rig 10 is used to provide power. The number of double helical groove outer-coated fiber optic drill rods installed on the drilling rig 10 may be multiple.

[0101]In specific use, select one or more sections of double helical groove covered fiber optic drill pipe according to the needs, install the drill pipe joints, drill bits and signal instruments through the wire, and snap the hole outside the double helical groove covered fiber optic drill pipe. Drilling spool, the optical fiber is led out of the hole, that is, the spool is clamped while drilling, and the optical fiber is connected to the signal instrument through the first spiral edge groove, the second spiral edge groove and the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com