Control mechanism and brake device

A control mechanism and control terminal technology, applied in the direction of brake transmission, control valve, air release valve, brake, etc., can solve the problems that the brake does not have anti-skid function, the anti-skid device does not have braking function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

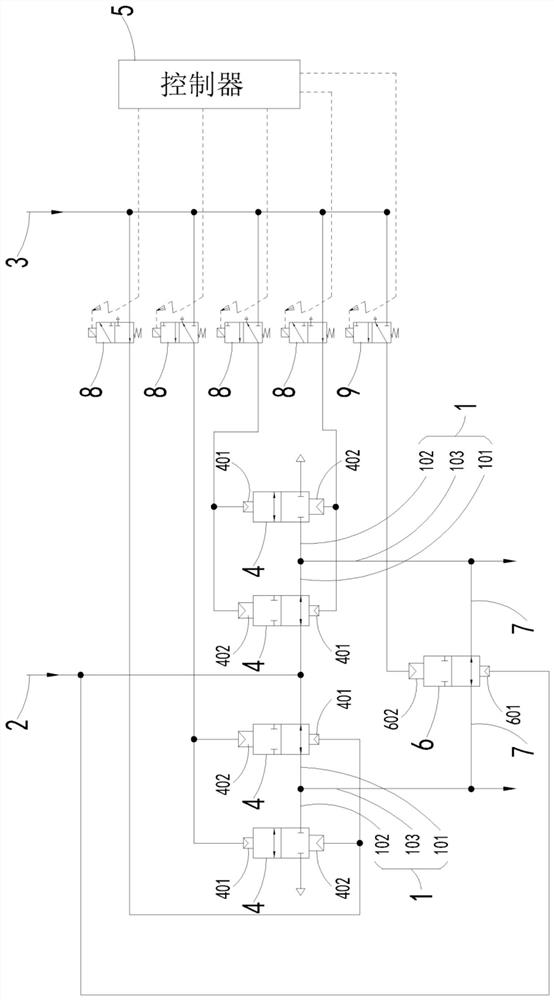

[0033] In this embodiment, a control mechanism is provided, including a three-way pipeline 1 and a first air source interface 2;

[0034] The three-way pipeline 1 is composed of a first pipeline 101, a second pipeline 102 and a third pipeline 103 in a three-way shape, and the first pipeline 101 and the second pipeline 102 are respectively connected to the valve chambers of a pair of control valves 4 One, the control end of any control valve 4 is at least controlled by the same controller 5 respectively;

[0035] The two control valves 4 connected to the same three-way pipeline 1 are restricted to alternative conduction by the controller 5 , and the valve chamber of one of the control valves 4 is connected to the first interface 2 of the gas source through the pipeline.

[0036] For ease of understanding, a pair of control valves 4 will be described in the form of the first control valve 4 and the second control valve 4;

[0037] Those skilled in the art should understand that...

Embodiment 2

[0088] In this embodiment, a control mechanism is provided; the control mechanism of this embodiment has the following differences from the control mechanism in the aforementioned embodiment 1:

[0089] The control valve 4 and the second control valve 6 are respectively provided as solenoid valves.

[0090] Adopt electromagnetic valve as control valve 4 and second control valve 6, can realize the braking function and anti-slip function to braking mechanism (clamp) equally; With respect to aforementioned embodiment 1, the control mechanism in this embodiment saves The number of solenoid valves used to control the pneumatic valve and the second pneumatic valve is actually less.

[0091] The rest of the structure of the control mechanism in this embodiment is the same as that of the aforementioned embodiment 1 except for the control valve 4 and the second control valve 6 , and will not be repeated here.

Embodiment 3

[0093] In this embodiment, a control mechanism is provided; the control mechanism of this embodiment has the following differences from the control mechanism in the aforementioned embodiment 1:

[0094] The control valve 4 is set as a solenoid valve, and the second control valve 6 is set as a pneumatic valve;

[0095] The electromagnetic valve 8 is adopted as the control valve 4, and the second control valve 6 is set as a pneumatic valve, which can also realize the braking function and anti-skid function for the braking mechanism (clamp); with respect to the foregoing embodiment 1, the present embodiment The control mechanism in the utility model saves the number of solenoid valves used to control the pneumatic valve, and the actual number of valves used is less.

[0096] The rest of the structure of the control mechanism in this embodiment is the same as that of the aforementioned embodiment 1 except for the control valve 4 , and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com