Real-time focusing and centering adjustment method and device for in-situ test platform

An in-situ testing and real-time focusing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the optical microscope cannot automatically focus, follow the focus and track the sample, and achieve the effect of solving the sample out of focus and the deviation of the observation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

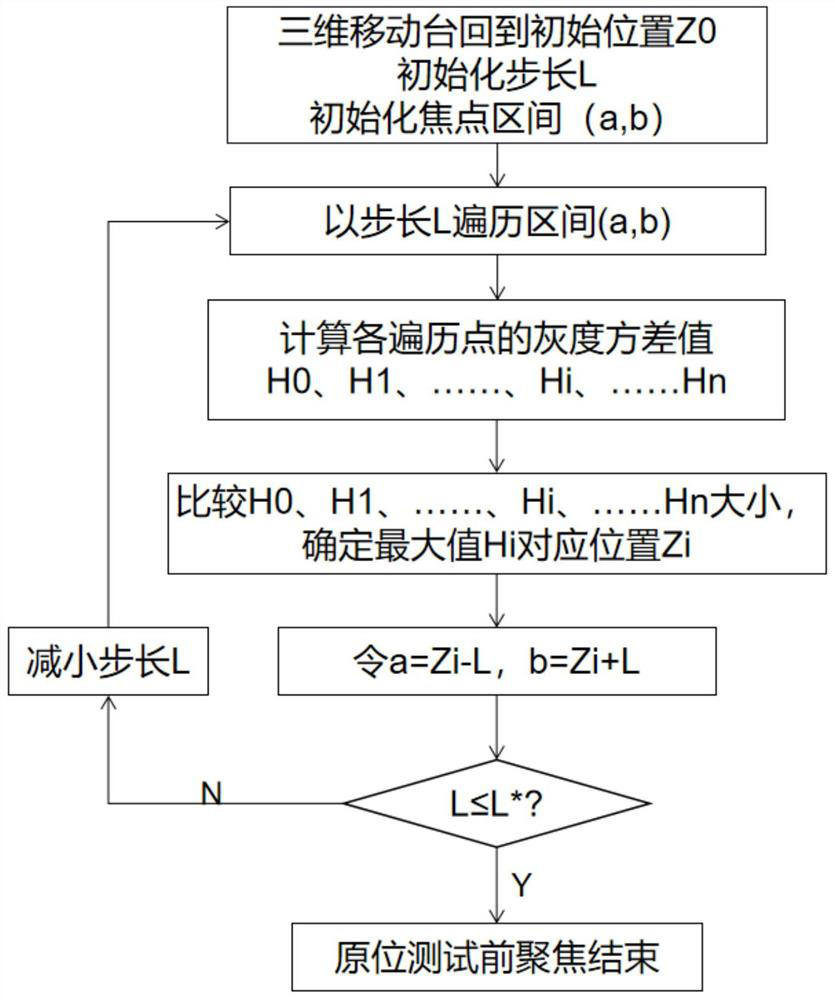

[0077] Embodiment 1 provides a real-time focusing and centering adjustment method facing the in-situ test platform. Before the in-situ test, the three-dimensional mobile platform is placed on the position of the stage in the optical microscope, and the three-dimensional mobile platform is installed above the three-dimensional mobile platform. To test the platform and samples in situ, connect the digital camera to the eyepiece of the optical microscope, and connect the host computer to the display screen, the digital camera, and the three-dimensional mobile platform respectively.

[0078] Before the in-situ test, the host computer executes the pre-test autofocus algorithm to obtain the first control information, and the three-dimensional mobile station controls the sample to move according to the first control information to obtain a clear sample image. The sample image frames the region of interest on the sample.

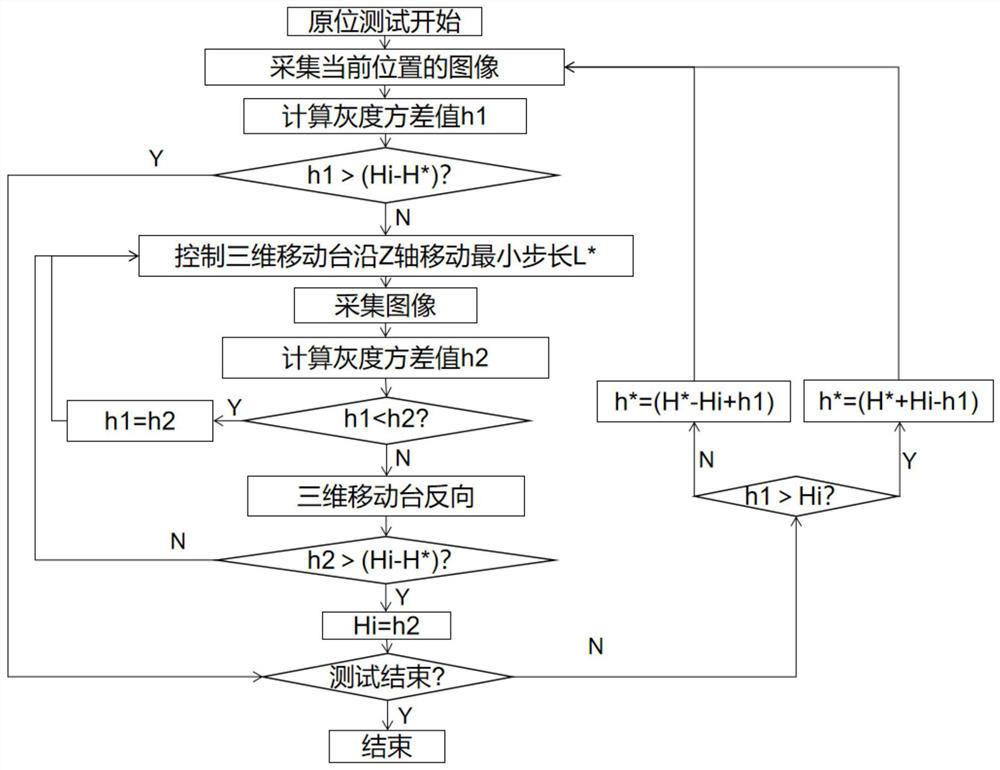

[0079]During the in-situ test, the host executes the in-situ t...

Embodiment 2

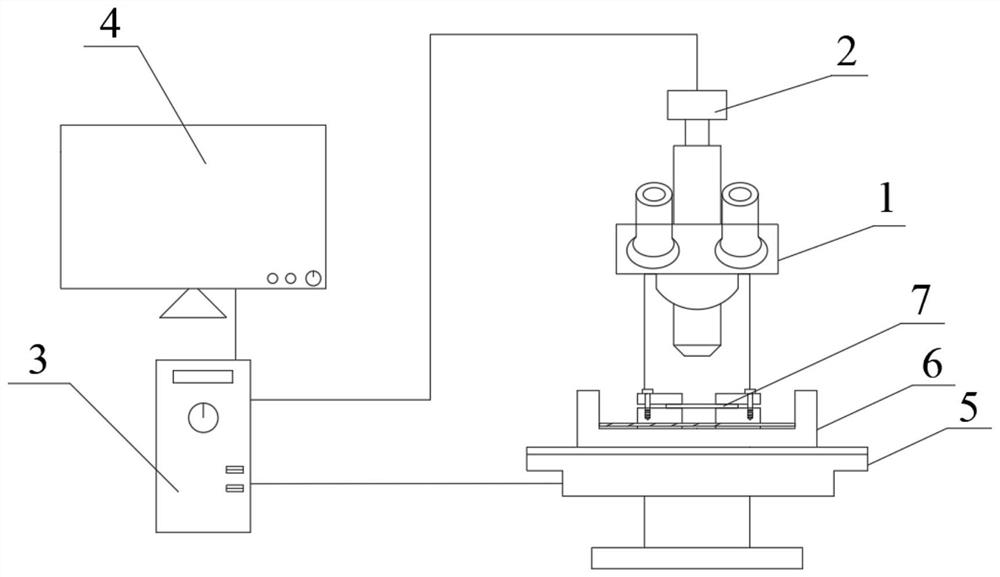

[0137] Embodiment 2 provides a real-time focusing and centering adjustment device for an in-situ test platform, see figure 1 , including: an ordinary optical microscope 1, a digital camera 2, a host computer 3, a display screen 4, a high-precision three-dimensional mobile platform 5 and an in-situ test platform 6. The three-dimensional mobile stage 5 is arranged at the position of the stage in the optical microscope 1, and the top of the three-dimensional mobile stage 5 carries the in-situ test platform 6 and the sample 7; the digital camera 2 and the optical microscope 1, the host computer 3 is connected to the display screen 4, the digital camera 2, and the three-dimensional mobile platform 5 respectively.

[0138] The optical microscope 1 is used to image the sample 7 through an optical system. The digital camera 2 is used to capture the image formed by the optical microscope 1 in real time, and transmit the image information to the host computer 3 . The host 3 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com