High-temperature heat pipe wick heat transfer limit experiment device and method

A high-temperature heat pipe and experimental device technology, which is applied in measurement devices, material thermal development, material thermal conductivity and other directions, can solve problems such as difficult observation, difficult direct observation, and limiting heat transfer power of heat pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now in conjunction with example, accompanying drawing, the present invention will be further described:

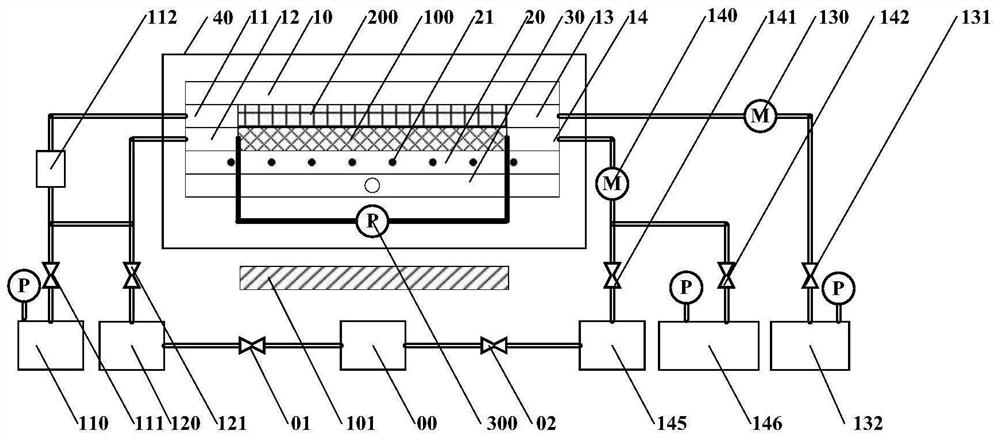

[0016] Such as figure 1 As shown, a high-temperature heat pipe liquid-absorbing wick heat transfer limit experiment device of the present invention includes an upper sealing plate 10, a heating plate 20, a lower sealing plate 30, a transparent side viewing plate 40, a left gas sealing plate 11, a left sealing liquid Plate 12, Right Gas Sealing Plate 13, Right Liquid Sealing Plate 14, Heating Wire 21, Liquid Absorbent Core Sample 100, Solid Sample 101, Compression Plate 200, Pressure Differential Transmitter 300, First Air Storage Chamber 110, The first gas storage valve 111, the gas preheater 112, the first servo pump 120, the first servo valve 121, the gas flow meter 130, the second gas storage valve 131, the second gas storage chamber 132, the flow meter 140, the second Servo pump 145, second servo valve 141, vacuum pump unit 146, vacuum pump valve 142, working m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap