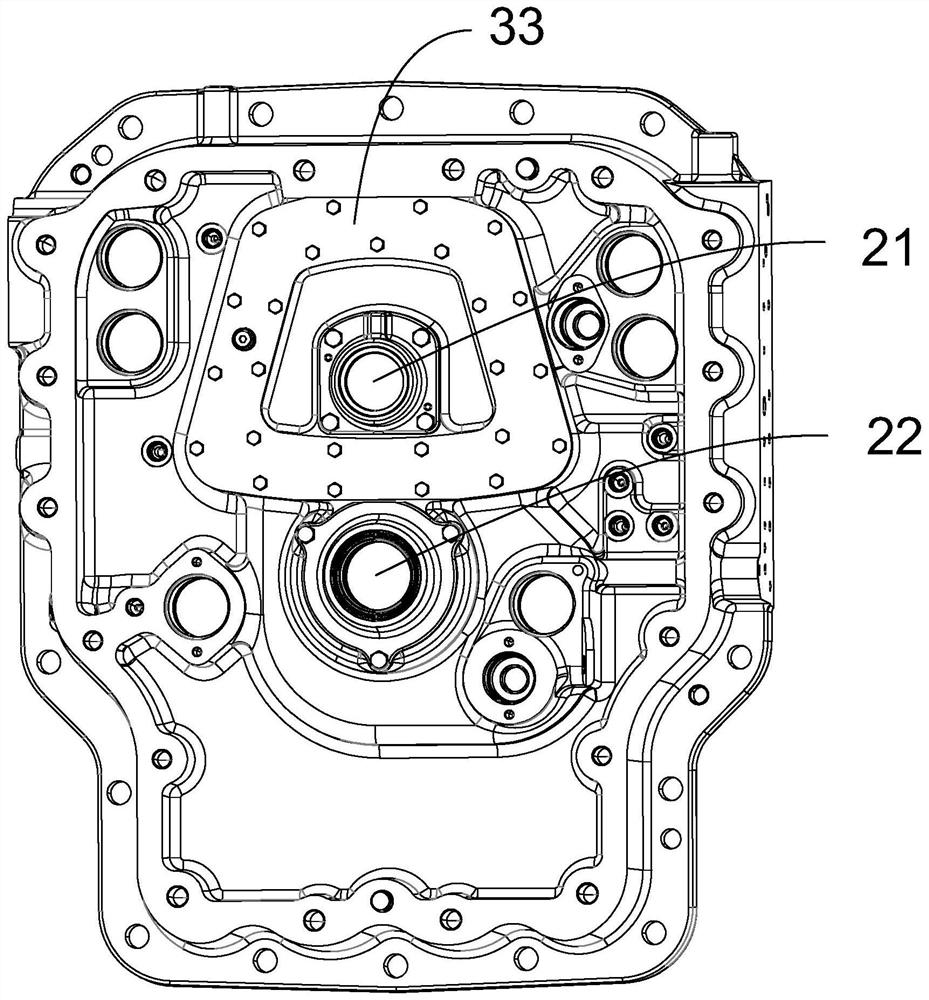

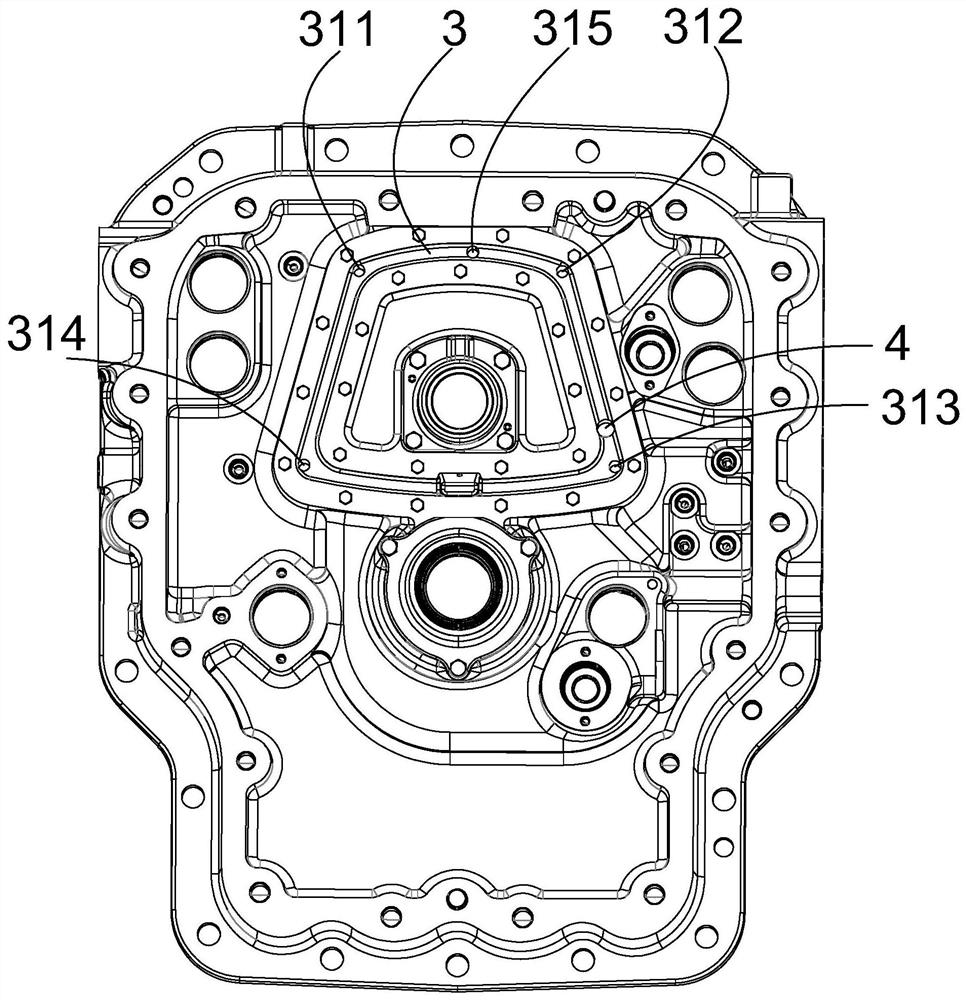

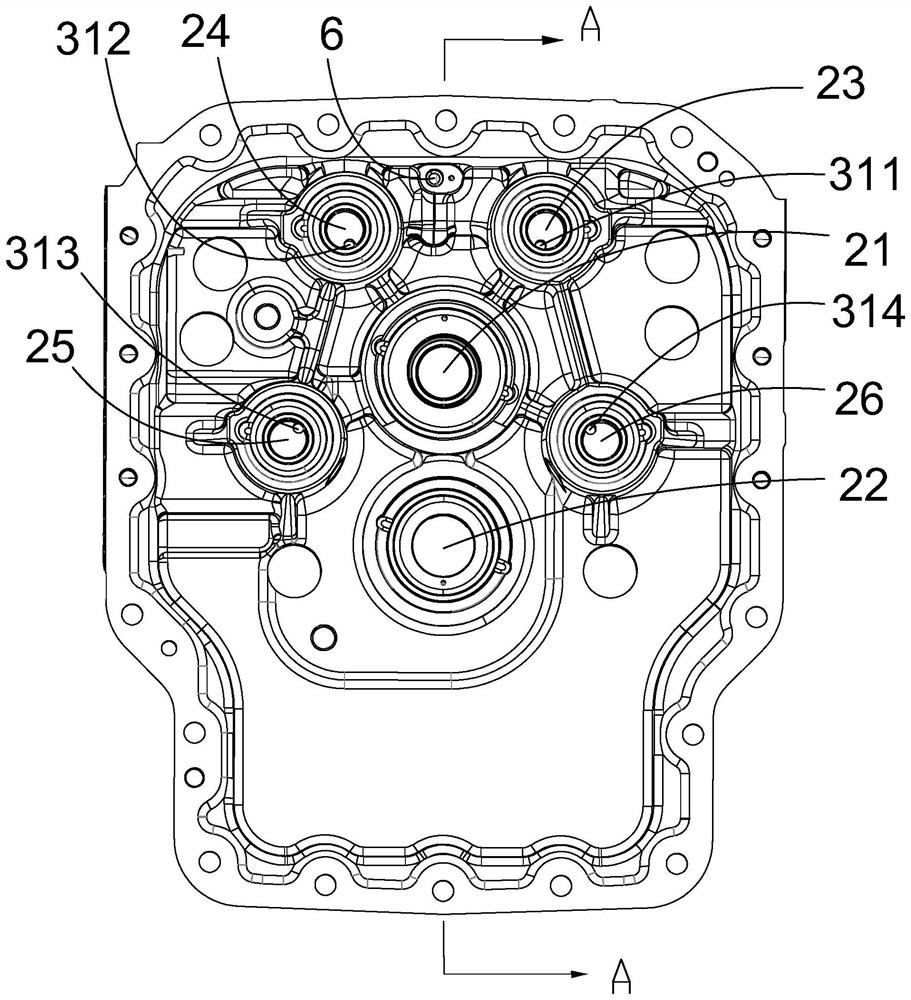

Lubricating pipe and transmission case

A lubricating oil pipe and lubricating oil technology, applied in the transmission box field, can solve the problems of unsatisfactory lubricating effect and limited injection range of the gearbox, and achieve the effects of enhancing the lubricating effect, optimizing the structure, and increasing the lubricating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] The overall structure of the transmission box and the lubricating oil pipe of the second embodiment is basically the same as that of the first embodiment, the difference is that the first slope 741 and the second slope 742 are both arc surfaces and the first slope 741 and the second slope 742 The center line is symmetrical with the intersection line 743 , and the first slope 741 and the second slope 742 extend along a direction away from the intersection line 743 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com