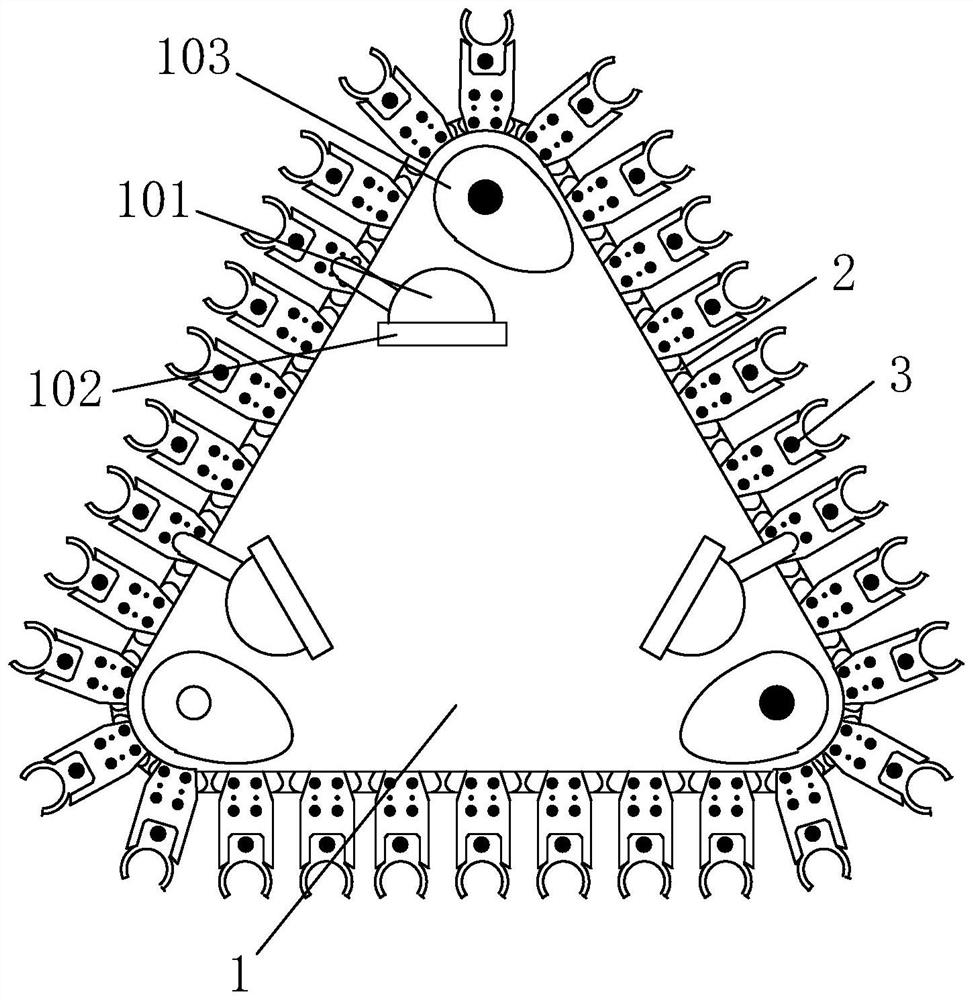

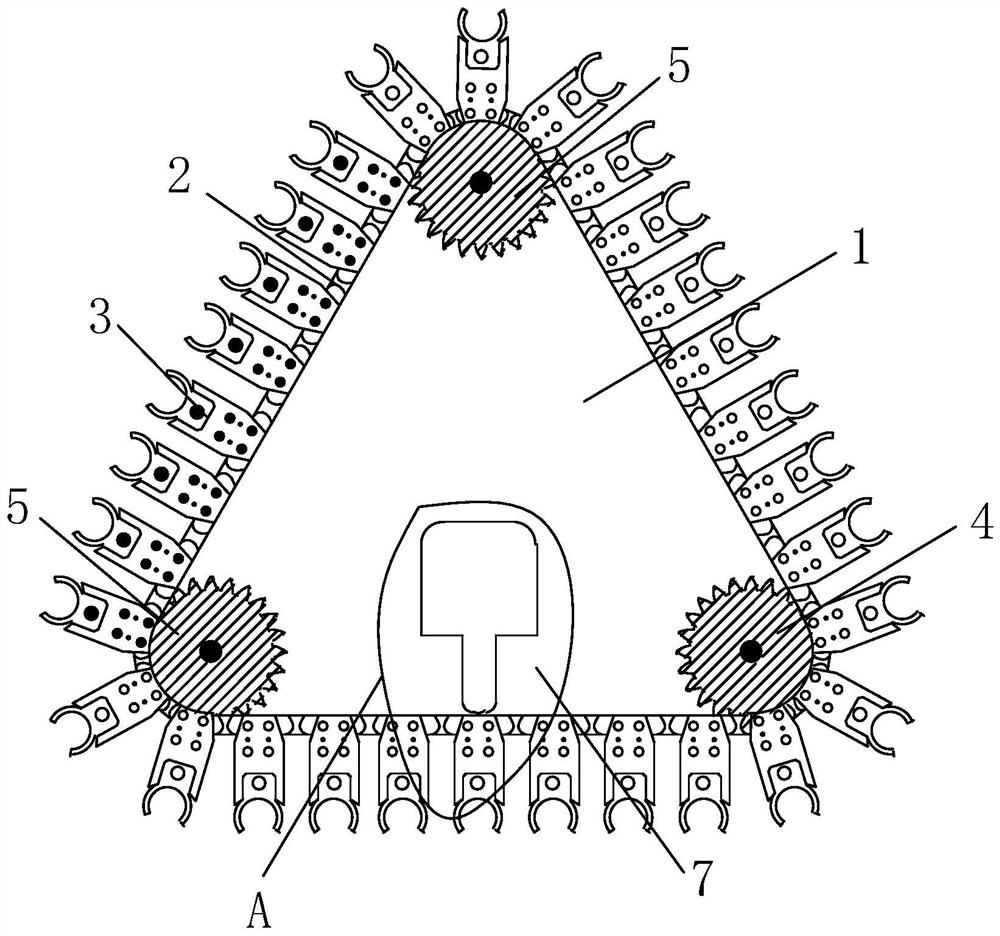

Chain type tool magazine

A chain-type tool magazine and chain technology, applied in the field of chain-type tool magazines, can solve problems such as affecting work efficiency, roughness and non-lubrication of chains and gears, chain breakage, etc., so as to improve work efficiency, increase lubrication area, and speed up flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

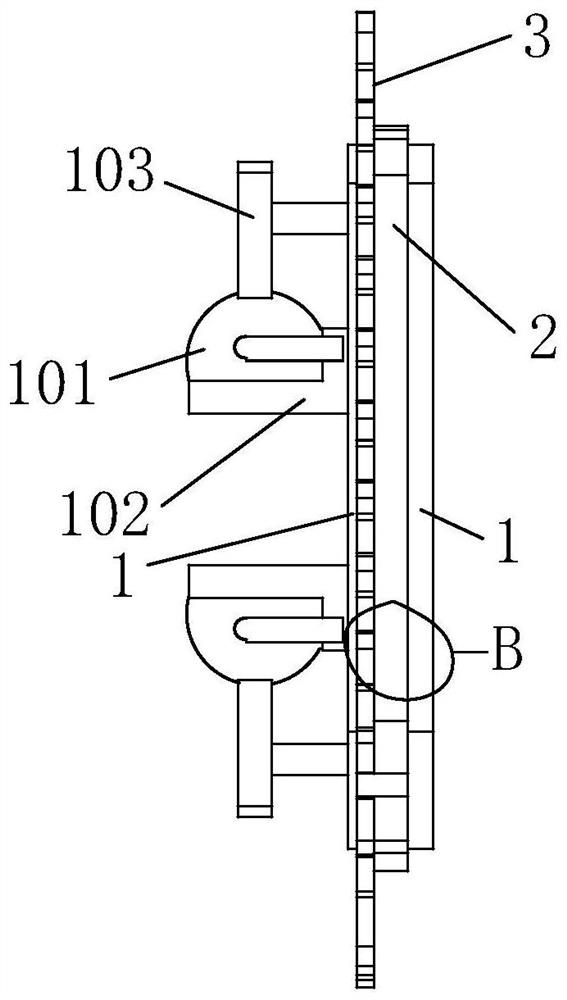

[0031] As a specific embodiment of the present invention, the diameter of the oil outlet hole 10 is smaller than the diameter of the ball 11, and the oil outlet hole 10 is closely attached to the ball 11;

[0032] The diameter of the oil outlet hole 10 in the lubricating device 7 is smaller than the diameter of the ball 11. When the ball 11 is placed on the oil outlet hole 10, a part of the ball 11 will protrude outside the oil outlet 10. Due to the self weight of the ball 11, the ball 11 and The oil outlet hole 10 will fit closely to prevent the lubricating oil from flowing out from the gap.

[0033] As a specific embodiment of the present invention, the ball 11 is provided with a support rod 1101, and the joint between the support rod 1101 and the ball 11 is provided with a first rotating rod 1102, and the ball 11 and the first rotating rod 1102 rotate connect;

[0034] As a specific embodiment of the present invention, grooves 901 are formed on both sides of the oil pipe 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com