Liquid distributor

A liquid distributor and liquid technology, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of fixed injection height and angle, and save installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A liquid distributor according to the present invention will be further described in detail through specific examples below.

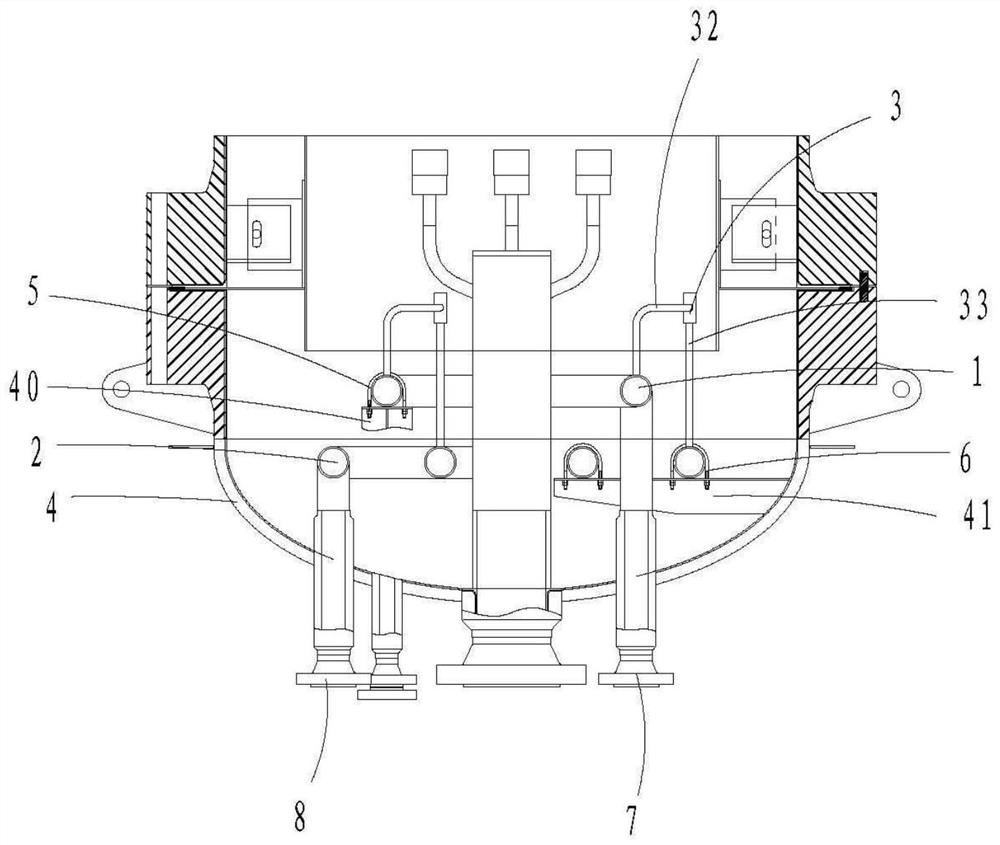

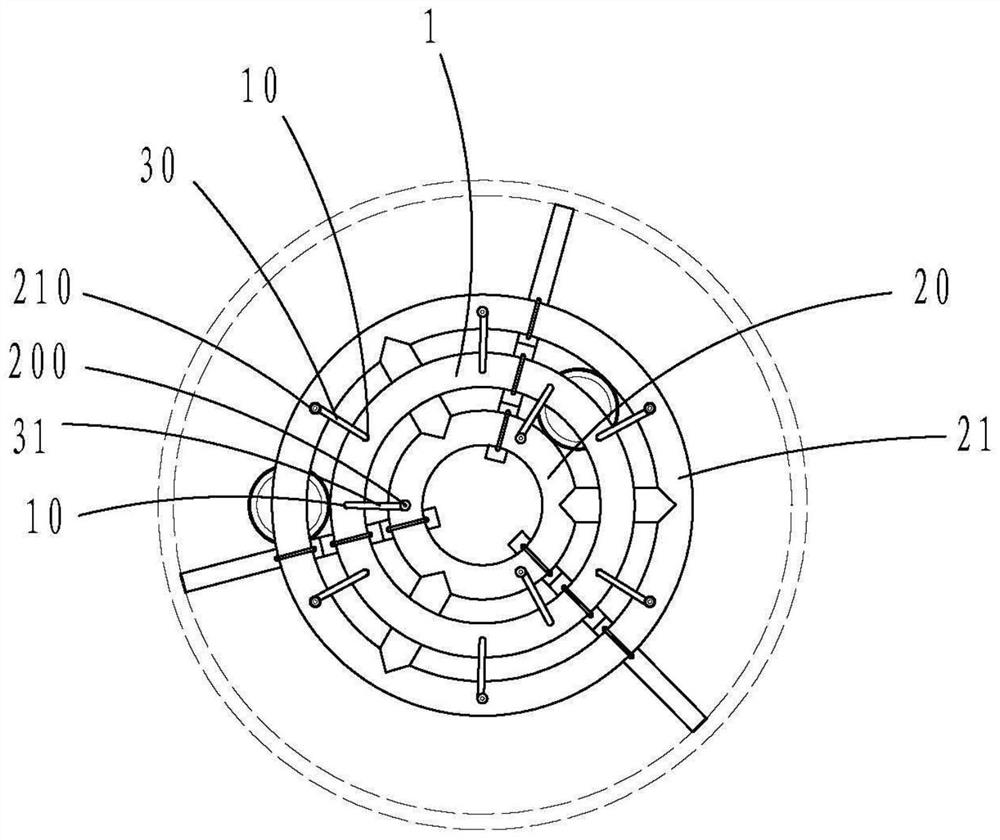

[0021] ginseng Figure 1 to Figure 5 As shown, a liquid distributor includes: an upper distribution ring pipe 1, a lower distribution ring pipe 2 and nine sets of row core pipe assemblies 3, and three uniformly arranged first connecting pieces are welded on the inner wall of the cylinder body 4 40 and three evenly arranged second connectors 41, the upper distribution ring pipe 1 is respectively installed on the three first connectors 40 through three first fixing parts 5, and the lower distribution ring pipe 2 is installed on the three first connectors 40 through three The two second fixing parts 6 are mounted on the three second connecting parts 41 respectively. In this embodiment, the first fixing parts 5 and the second fixing parts 6 are both U-shaped bolts and nuts.

[0022] The upper distribution ring pipe 1 is connected with the liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com