Urea injection system for reducing NOx discharge of engine and control method thereof

A technology of urea injection system and control method, which is applied in the field of engine exhaust purification system, can solve the problems of no thawing measures, no energy storage, no blockage, etc., and achieve the effect of preventing blockage and eliminating urea freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

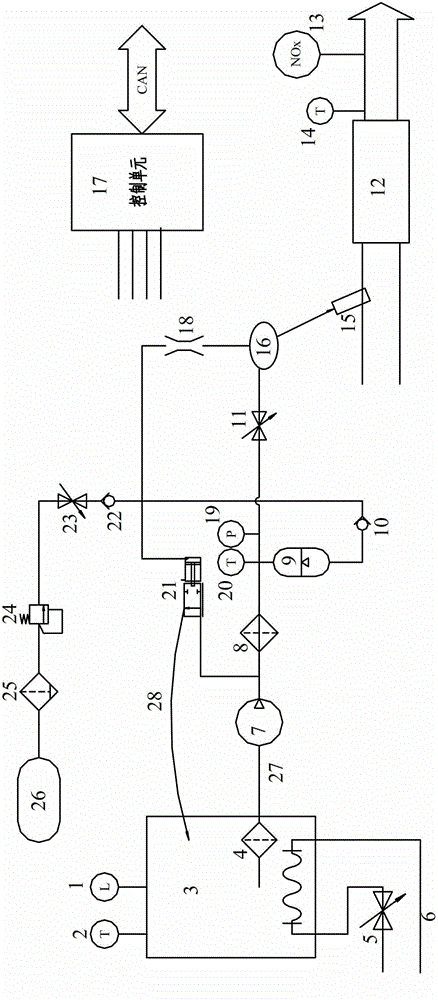

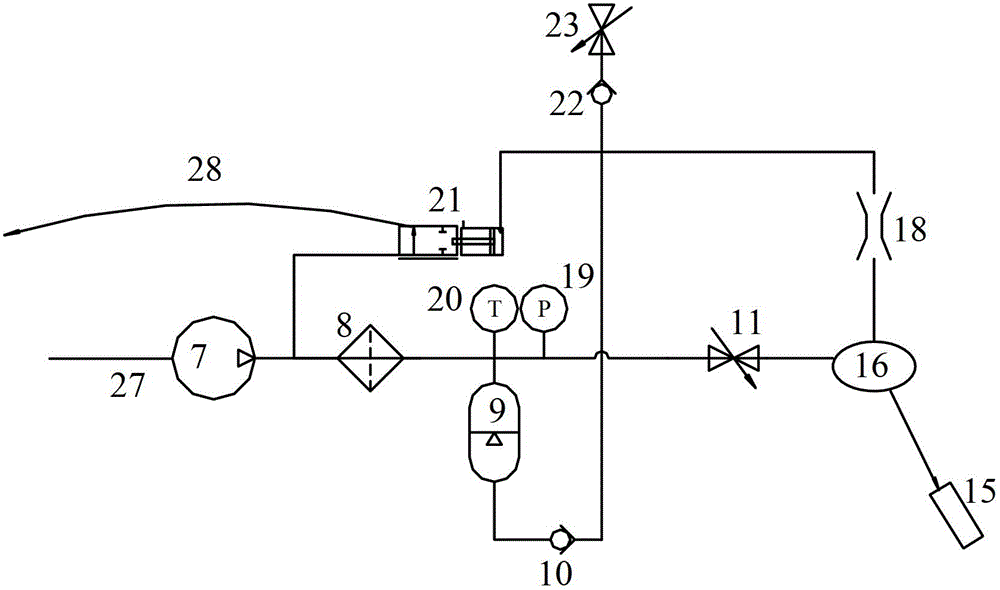

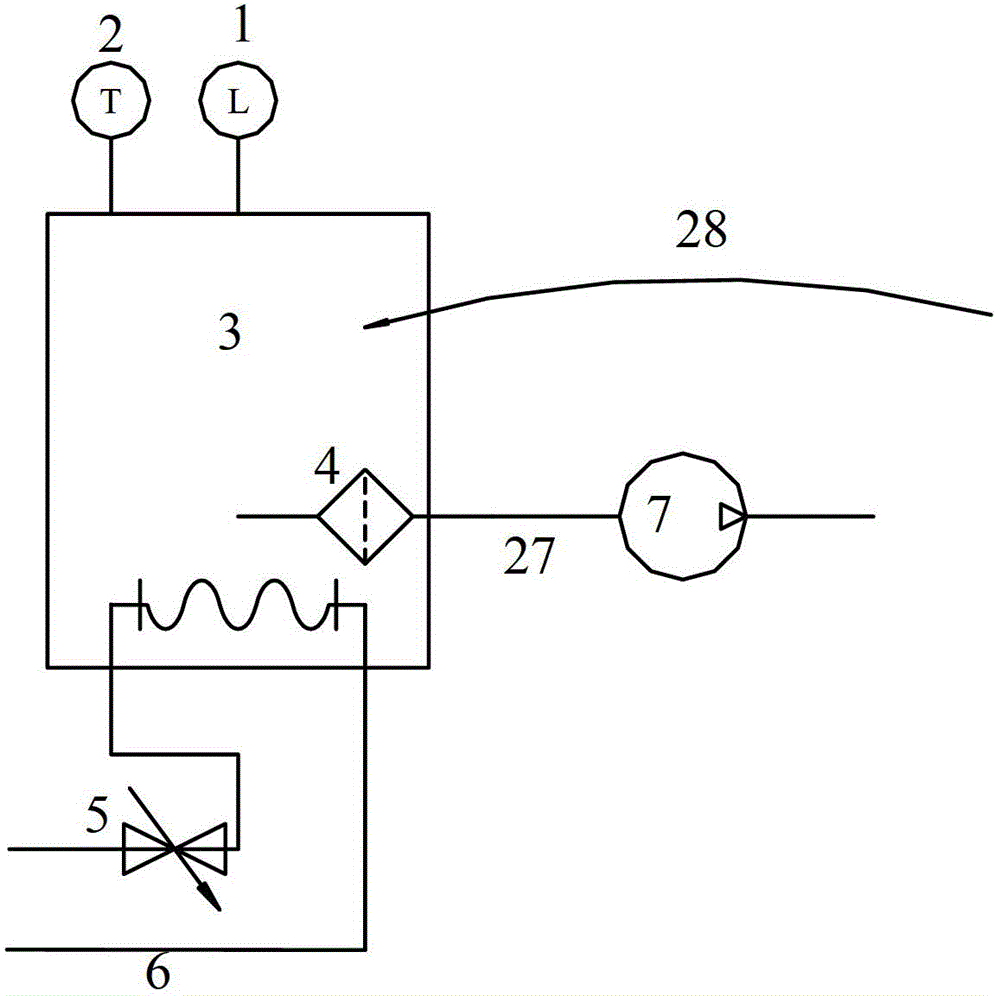

[0046] A urea injection system for reducing engine NOx emissions in the present invention mainly includes a urea supply unit, an injection unit, a thawing unit and a control unit. The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] like Figure 1-2 As shown, the urea supply unit in the system of the present invention mainly includes a urea DC pump 7, a secondary filter 8, an accumulator 9, a urea return air control valve 21, and a second one-way valve for air circuit control 22 and the second solenoid valve 23, the first solenoid valve 11 for urea supply control, the gas-liquid mixer 16, the pressure sensor 19 and the second temperature sensor 20 for monitoring the pressure and temperature of urea in the pipeline, etc.

[0048] like Picture 1-1 , the urea tank 3 is sequentially connected to the urea tank 3 through the first pipeline 27, the urea DC pump 7, the secondary filter 8, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com