Gasket assembling method and gasket assembler

An assembly method and assembler technology, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost of gaskets, vibration and noise, etc., and achieve the effect of reducing assembly costs and improving labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a gasket assembly method.

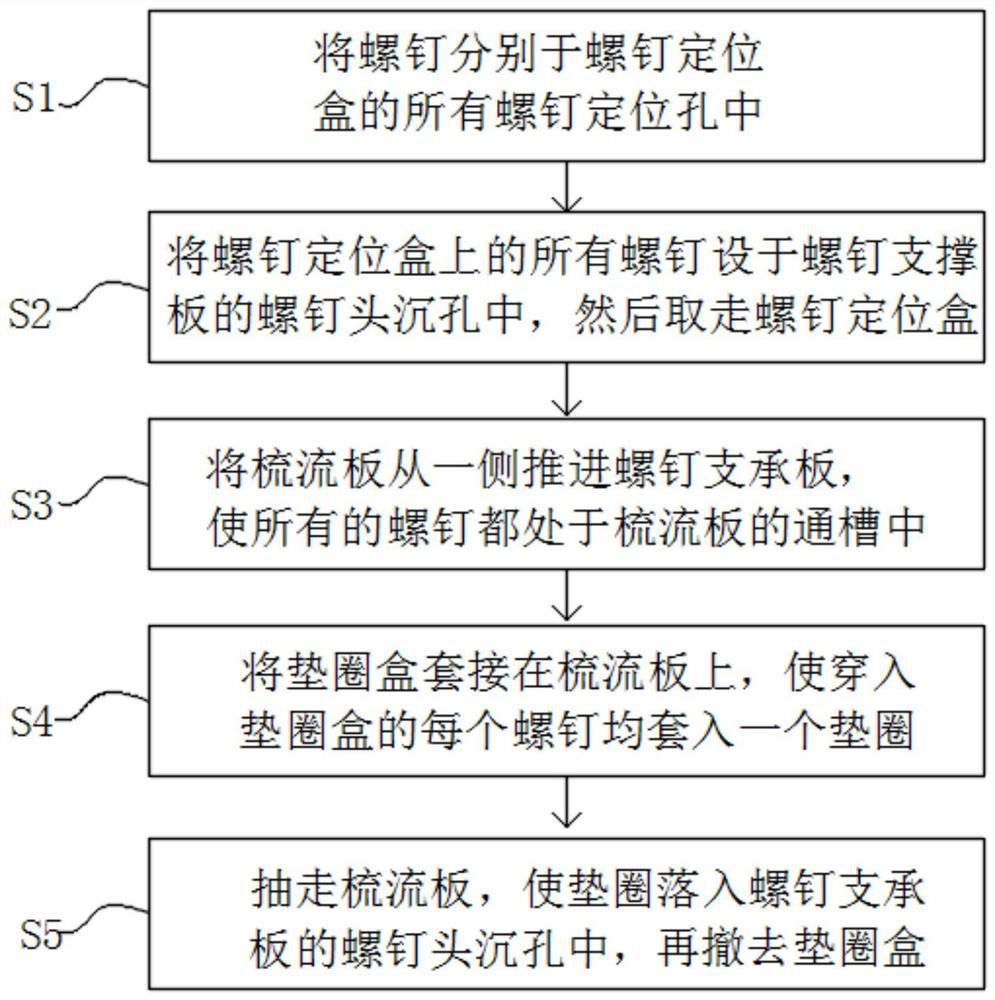

[0037] as attached figure 1 As shown, the gasket assembly method of the present embodiment includes the following steps:

[0038] S1: Set the screws 500 in all the screw positioning holes 101 of the screw positioning box 100;

[0039] Wherein, in this embodiment, step S1 specifically includes:

[0040] S11: Put the screws 500 into the screw positioning box 100, so that the screws 500 respectively fall into all the screw positioning holes 101 of the screw positioning box 100;

[0041] S12 : After all the screw positioning holes 101 have screws 500 , sweep out the screws 500 that do not fall into the screw positioning holes 101 from the gap of the screw positioning box 100 .

[0042] S2: set all the screws 500 on the screw positioning box 100 in the screw head counterbores 201 of the screw support plate 200, and then remove the screw positioning box 100;

[0043] Step S2 is specifically: insert the screw support plate 200 into...

Embodiment 2

[0052] Embodiment 2, a gasket assembler.

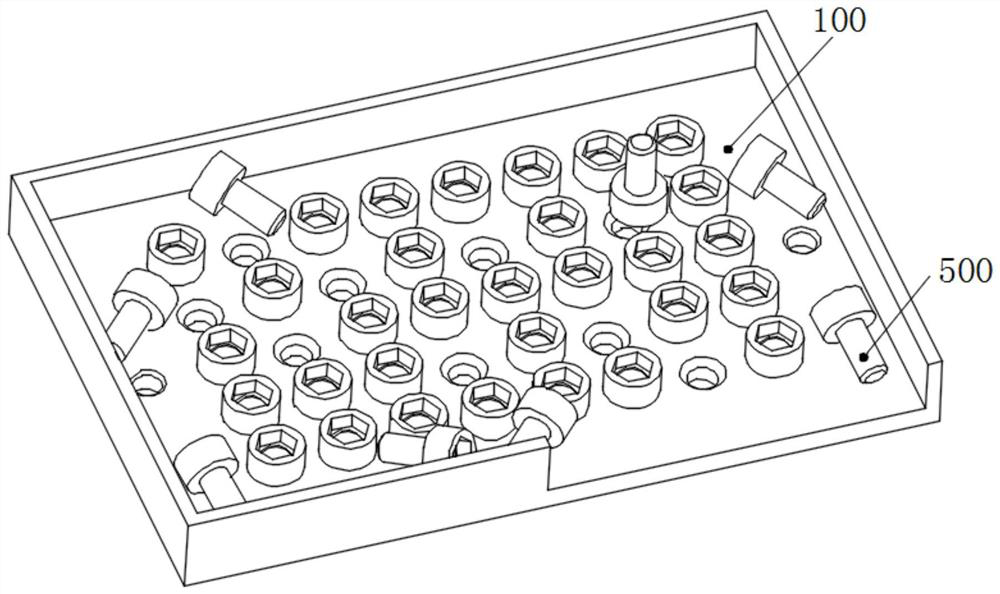

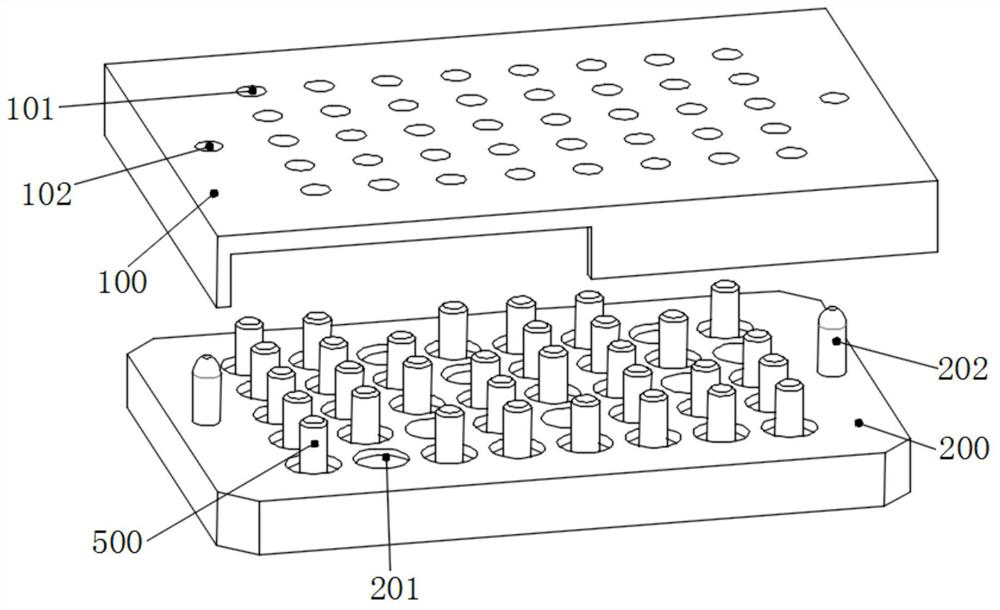

[0053] The washer assembler of this embodiment is applied to the assembly method described in Embodiment 1, and the washer assembler includes: a screw positioning box 100 , a screw support plate 200 , a comb plate 300 and a washer box 400 .

[0054] like figure 2 As shown, the bottom plate of the screw positioning box 100 of the present embodiment is provided with a plurality of screw positioning holes 101 for positioning the screws 500, and mounting holes 102 for socketing the screw support plate 200. The diameter of the screw positioning holes 101 is larger than The diameter of the threaded portion of a screw that is smaller than the diameter of the screw head.

[0055] Some screws 500 are put into the screw positioning box 100, and will be sifted or stirred by hand, and the screws 500 will finally fall into the screw positioning hole 101 of the screw positioning box 100, because the aperture of the screw positioning hole 101 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com