Closed storage battery vacuumizing formation device

A chemical formation device and storage battery technology, applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc., can solve the problem of low acid addition efficiency of batteries, achieve the effect of improving acid addition efficiency and improving acid addition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

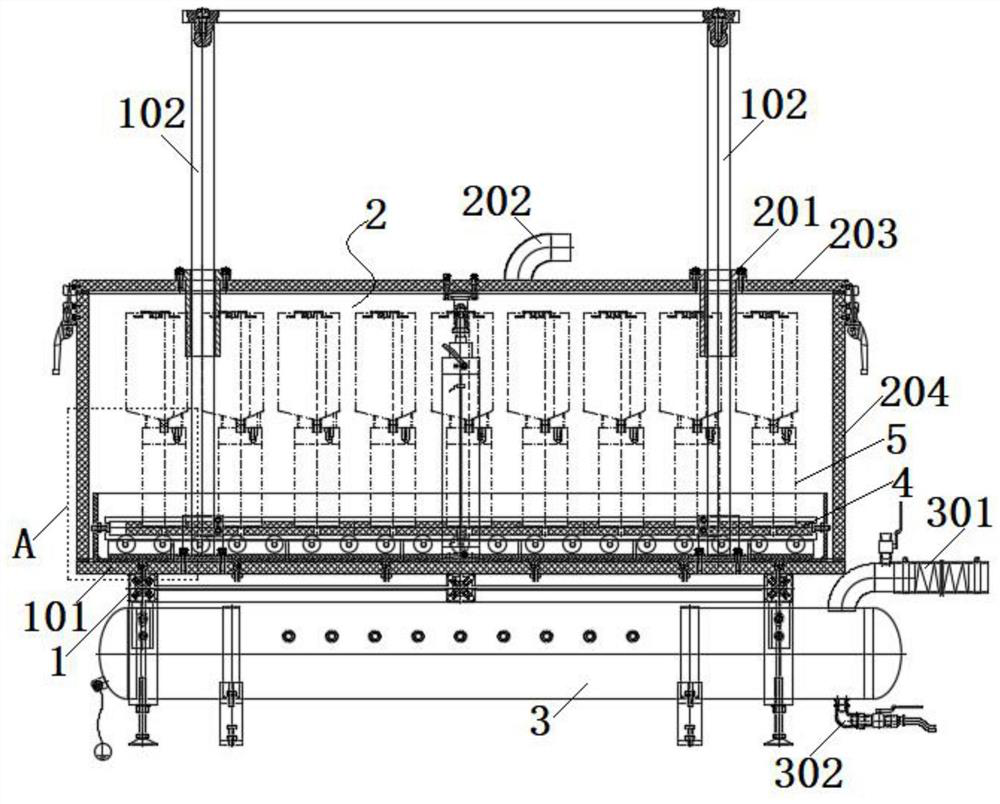

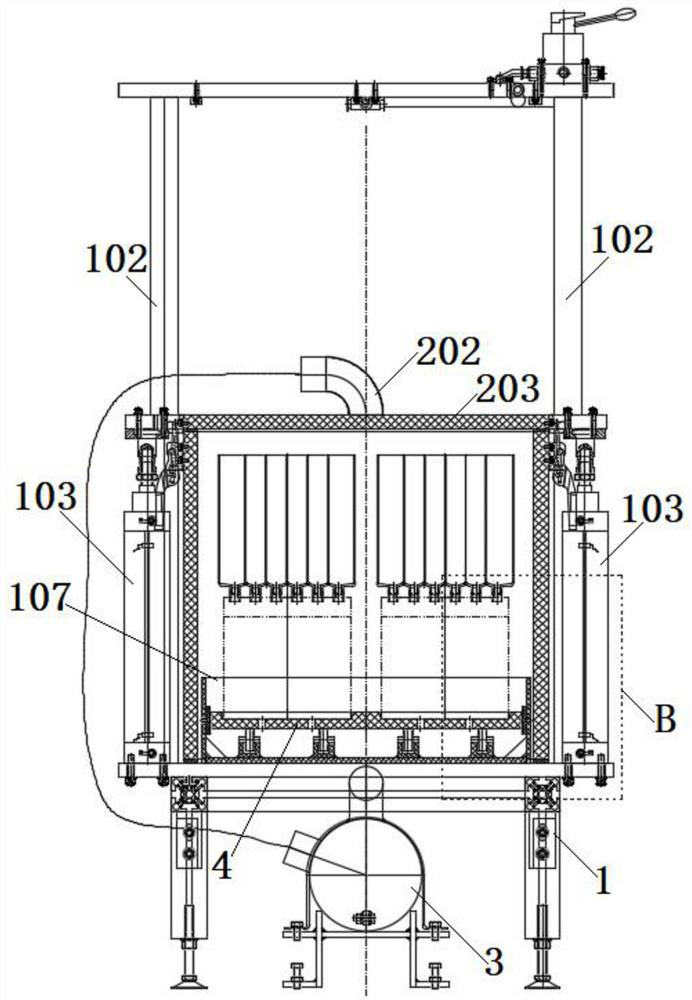

[0029] see Figure 1-4 As shown, the present invention is a vacuum forming device for a sealed storage battery, including a frame 1 , a sealed box 2 and a transfer tank 3 . The frame 1 is fixedly connected with a base plate 101 by welding or bolts; the upper surface of the base plate 101 is fixedly connected with two to four pairs of guide rods 102 and telescopic mechanisms 103, and the telescopic mechanisms 103 are air cylinders or hydraulic cylinders or electric telescopic rods.

[0030] The sealing box 2 is a box structure with an open bottom; the sealing box 2 is connected with a guide sleeve 201 cooperating with the guide rod 102, and the sealing box 2 is connected with the telescopic mechanism 103, which is used to drive the sealing box 2 to move up and down through the telescopic mechanism 103, And when the lower surface of the sealing box 2 is attached to the upper surface of the bottom plate 101, the sealing box 2 and the bottom plate 101 are enclosed to form a closed...

Embodiment 2

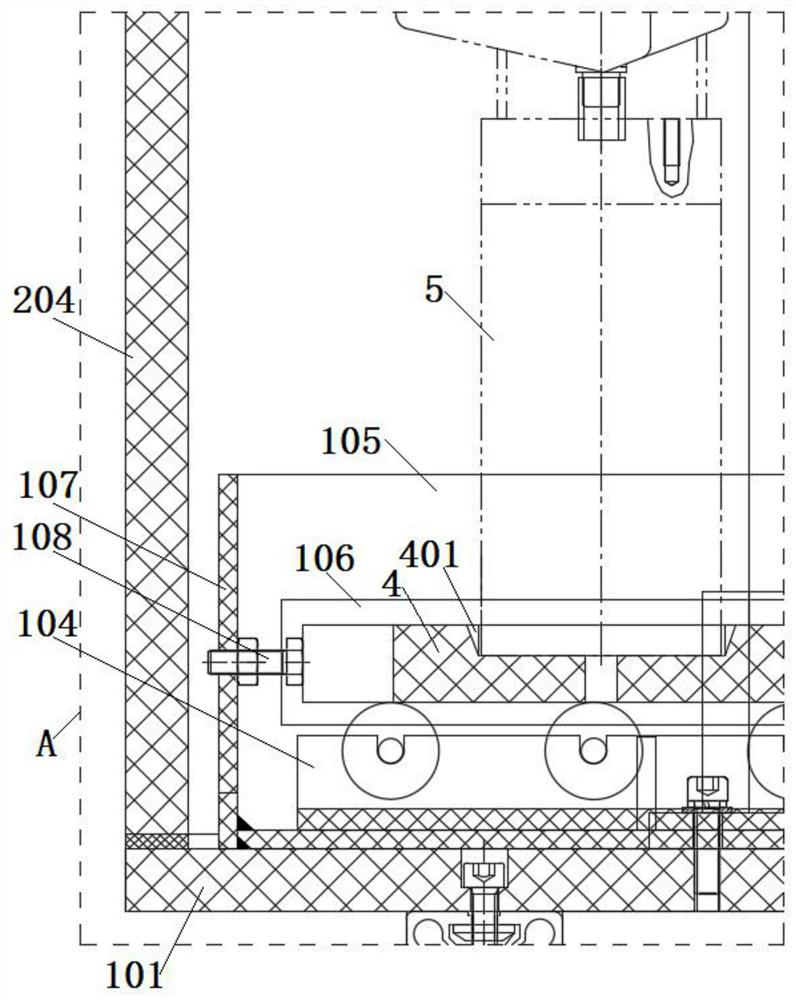

[0038] On the basis of Embodiment 1, a tray 4 is provided on the upper surface of the bottom plate 101, and several positioning grooves 401 distributed in pairs are opened on the upper surface of the tray 4, which are used to put the battery into the positioning groove 401, and the battery can be aligned through the positioning groove 401. Limit the location. By putting the accumulator 5 in acid addition into the positioning groove 401, multiple accumulators 5 can be transported and moved synchronously through the tray 4, which is beneficial to improve the convenience of use and production efficiency. Wherein, the inner bottom surface of the positioning groove 401 is provided with a through hole 402, through which the foreign matter or waste liquid accumulated in the positioning groove 401 can be removed to avoid accumulating in the positioning groove 401 and contaminating the battery.

[0039] At the same time, the upper surface of the bottom plate 101 is provided with two to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com