Mobile fast automatic control acid adding machine

An acid adding machine, a fast technology, applied in sustainable manufacturing/processing, lead-acid batteries, climate sustainability, etc. The acid rate can be adjusted automatically, the acid addition process is continuously controllable, and the effect of improving the acid addition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

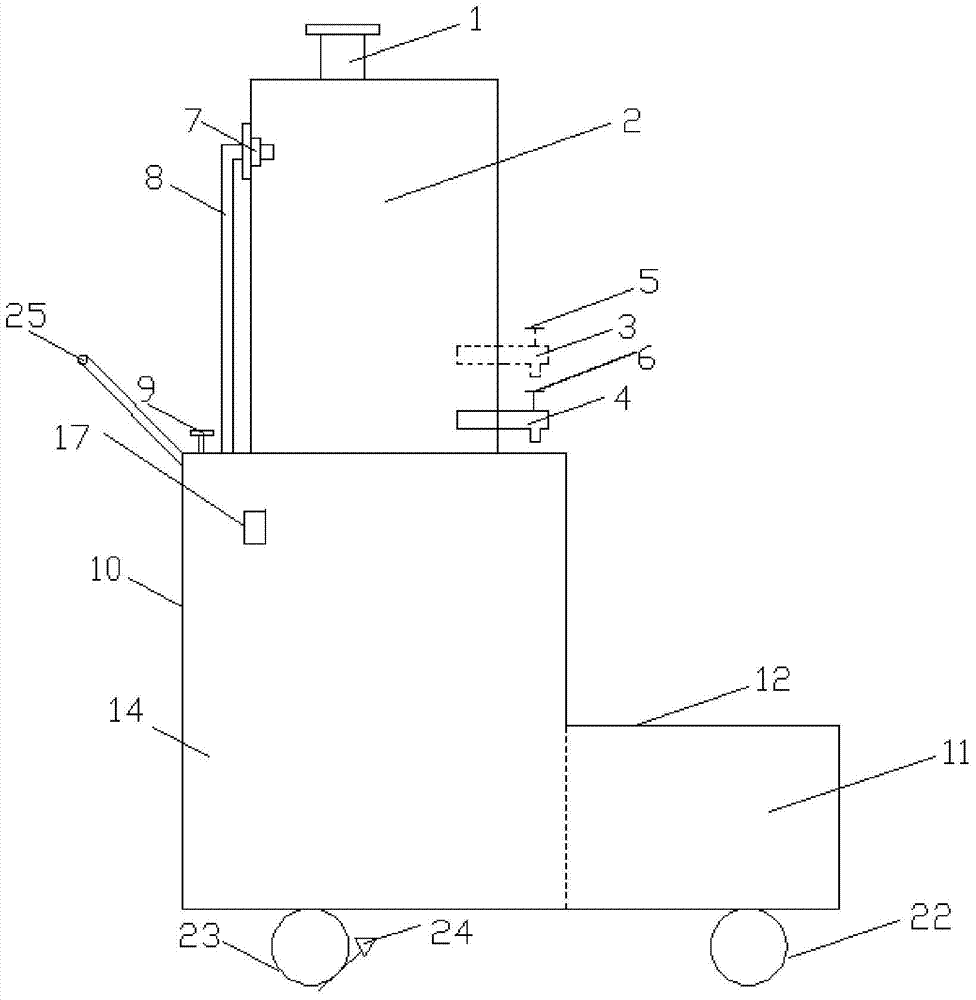

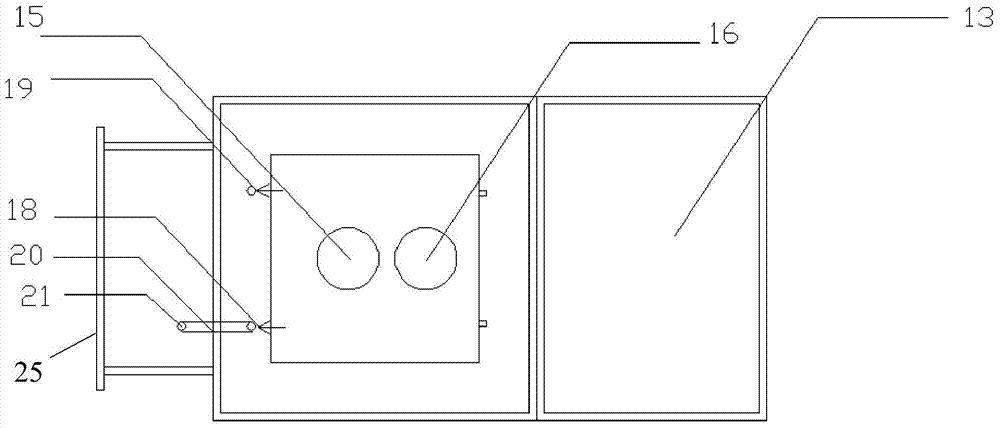

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0018] Such as figure 1 and figure 2 As shown, the movable fast self-control acid adding machine proposed by the present invention comprises a body 10 and a liquid storage tank 2 fixed on the top of the body 10, front wheels 22 and rear wheels 23 are installed at the bottom of the body 10, front wheels 22 and rear wheels The wheels 23 are used as the running mechanism of the body 10, which is convenient for the operator to promote the acid adding machine to move.

[0019] The machine body 10 includes an acid injection workbench 11 and a liquid suction workroom 14 for pumping in acid liquid; the acid injection workbench 11 is located at the front of the machine body 10 . The liquid pumping workshop 14 is located at the rear of the machine body 10 and is connected to the upper part of the liquid storage tank 2 through a conduit 8 .

[0020] When the acid liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com