An automatic acid adding device for lead-acid battery

A lead-acid battery, automatic acid addition technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems affecting battery performance, excessive acid addition, worker hazards, etc., to improve preparation accuracy and preparation safety, Effects of preventing excessive acid addition and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

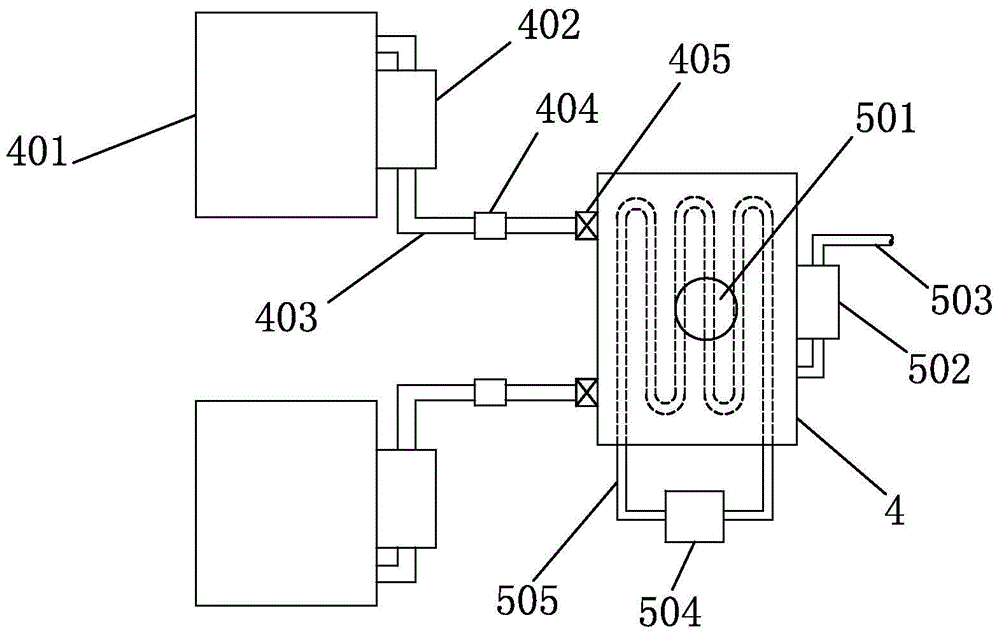

[0023] The invention relates to an automatic acid adding device for a lead-acid storage battery, comprising an electrolyte preparation device and an acid adding device for a lead-acid storage battery.

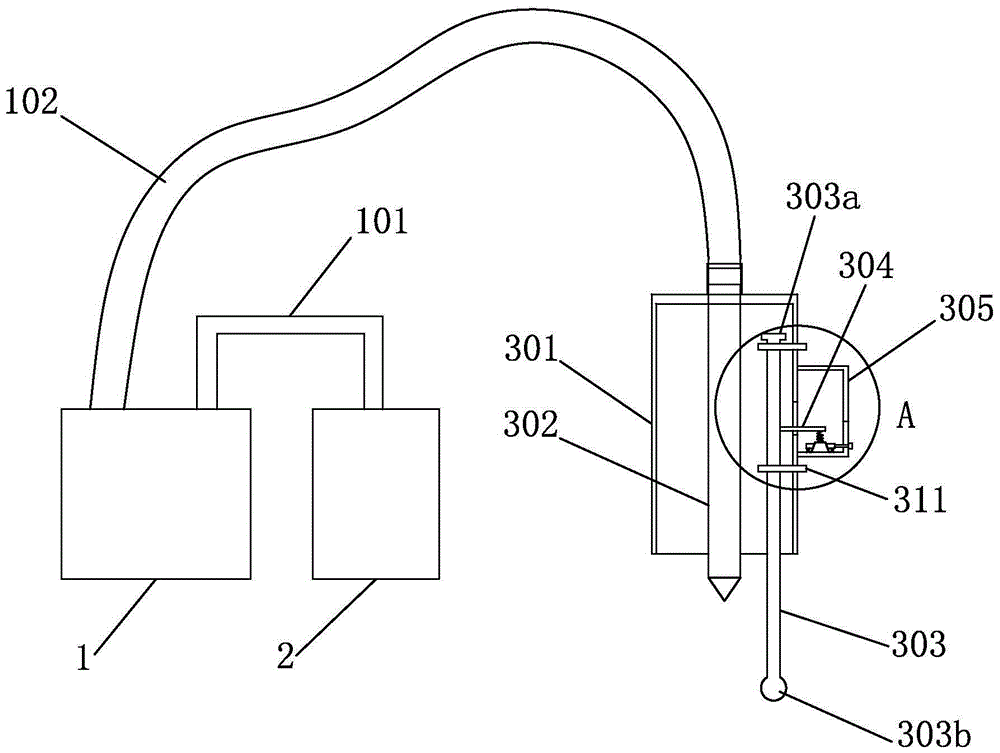

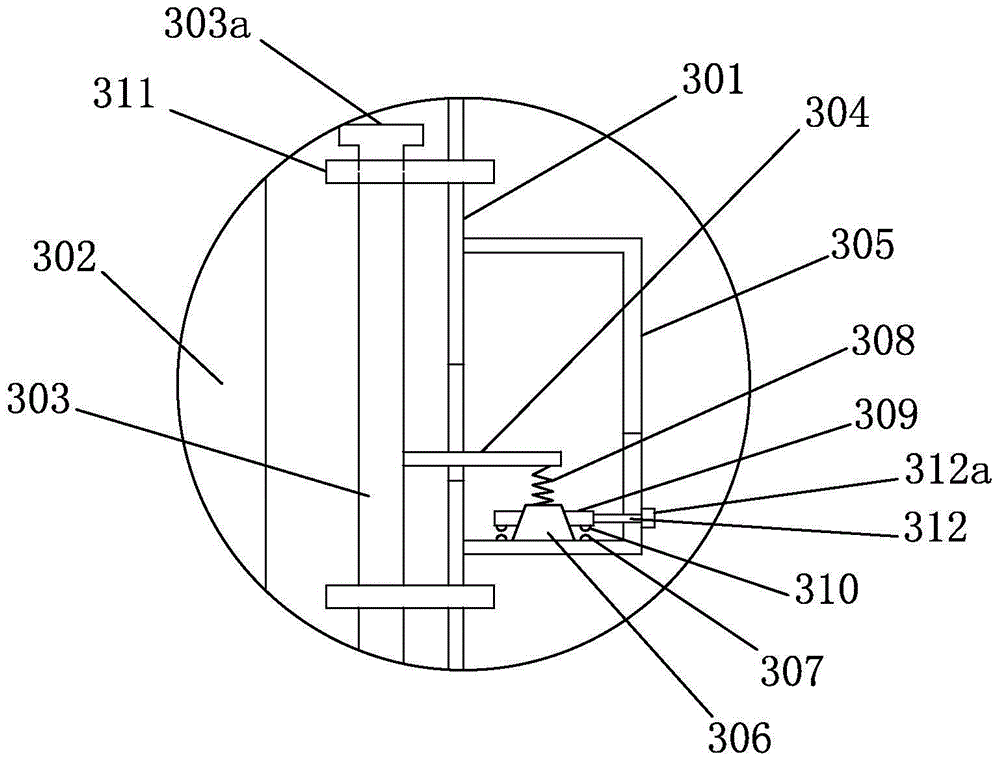

[0024] like figure 1 and figure 2 As shown, the lead-acid battery acid adding device includes an electric pump 1 and a liquid storage tank 2, the water inlet of the electric pump is connected to the water inlet pipe 101, and the other end of the water inlet pipe extends into the inner cavity of the liquid storage tank, and the electric pump The water outlet of the pump is connected to the water outlet pipe 102, and the other end of the water outlet pipe is connected to the acid injection head 3. The acid injection head includes a housing 301 that can be connected to the acid injection port of the battery at one end, and the aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com