Cage trolley

A technology of cage car and cage body, which is applied to trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of compression damage, heavy bearing weight and large extrusion force of the lower layer of goods, and achieve the effect of avoiding compression damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

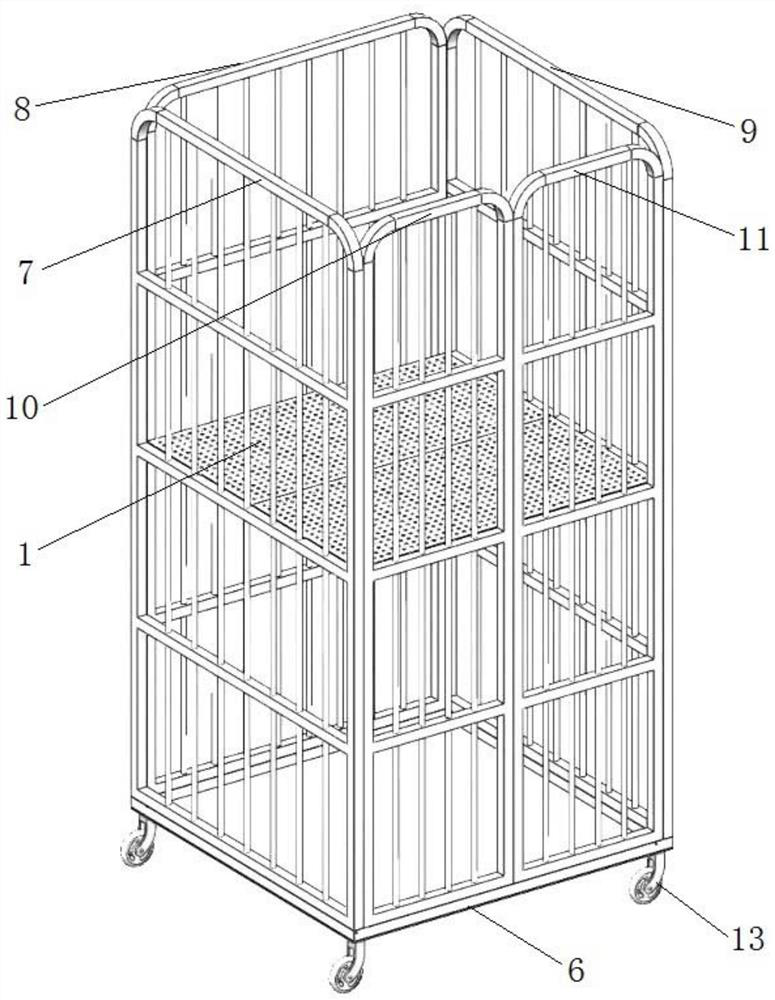

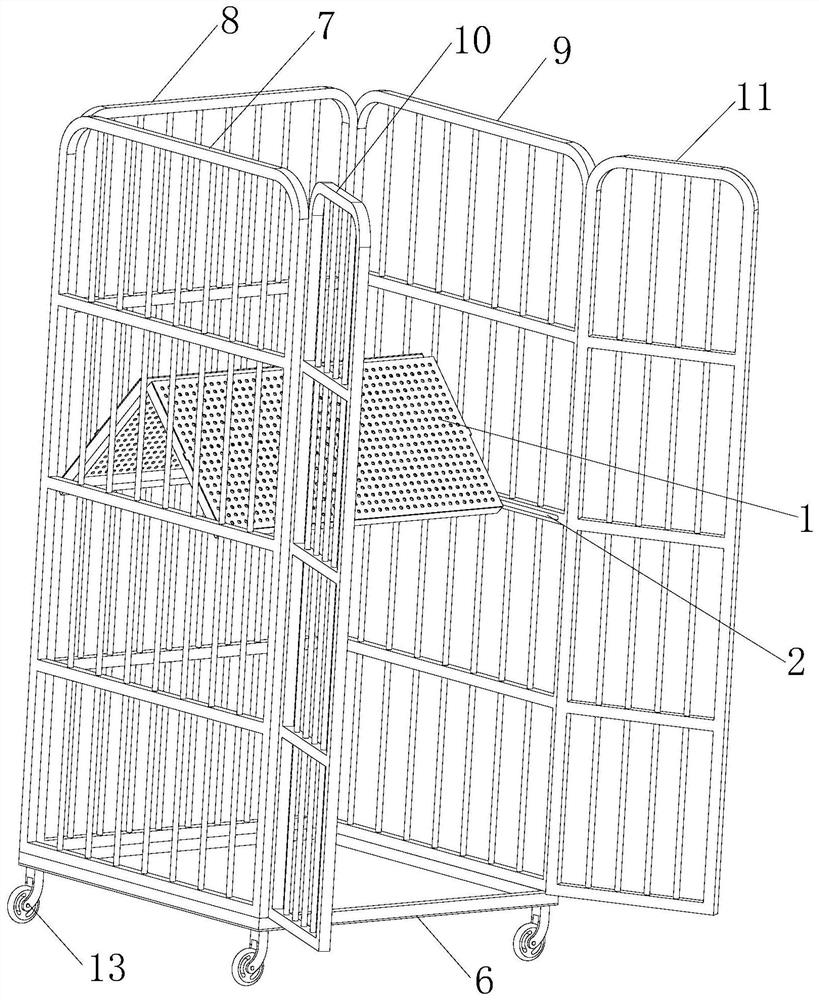

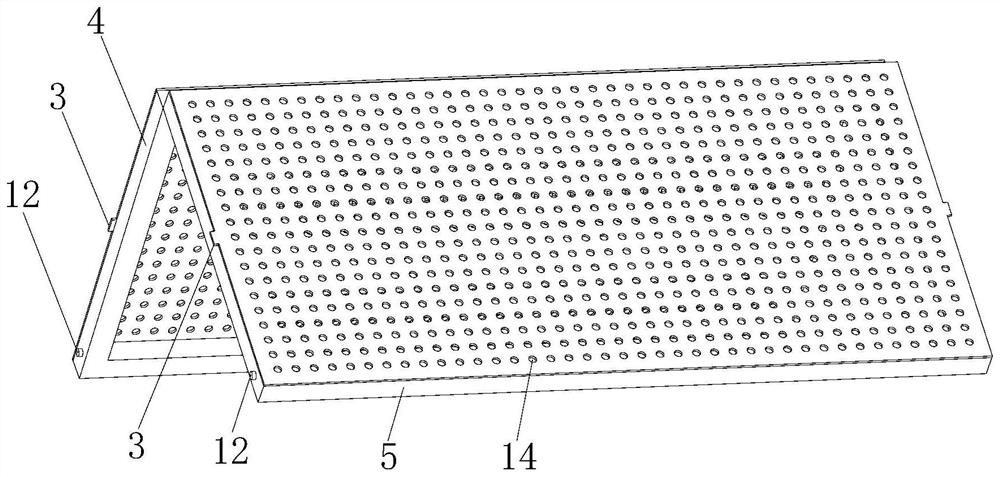

[0021] Such as Figure 1-Figure 3 As shown, the present embodiment provides a cage car, including a cage body, and a foldable support partition 1 is movable in the cage, and a ventilating mesh 14 is provided on the support partition 1, and the support partition Both sides of the plate 1 are provided with a sliding part, and the inner wall of the cage is provided with a limiting chute 2 adapted to the sliding part. The sliding part slides along the limiting chute 2 to realize the folding and unfolding function of the supporting partition 1 . When the supporting partition 1 is folded, the inner cavity of the cage has a storage chamber; when the supporting partition 1 is unfolded, the supporting partition 1 divides the inner cavity of the cage into two storage chambers. The goods in the two storage chambers are divided and limited by the support partition 1, which can avoid the problem that the goods are easily squeezed and damaged during loading and unloading. The invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com