Hoisting maintenance device for chemical mechanical equipment and installation method of hoisting maintenance device

A technology for chemical machinery and equipment, applied in the field of hoisting and maintenance devices for chemical machinery and equipment, which can solve problems such as potential safety hazards, failure of hoisting pre-inspection, and hoisting device without hoisting pre-inspection mechanism, etc., to achieve the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

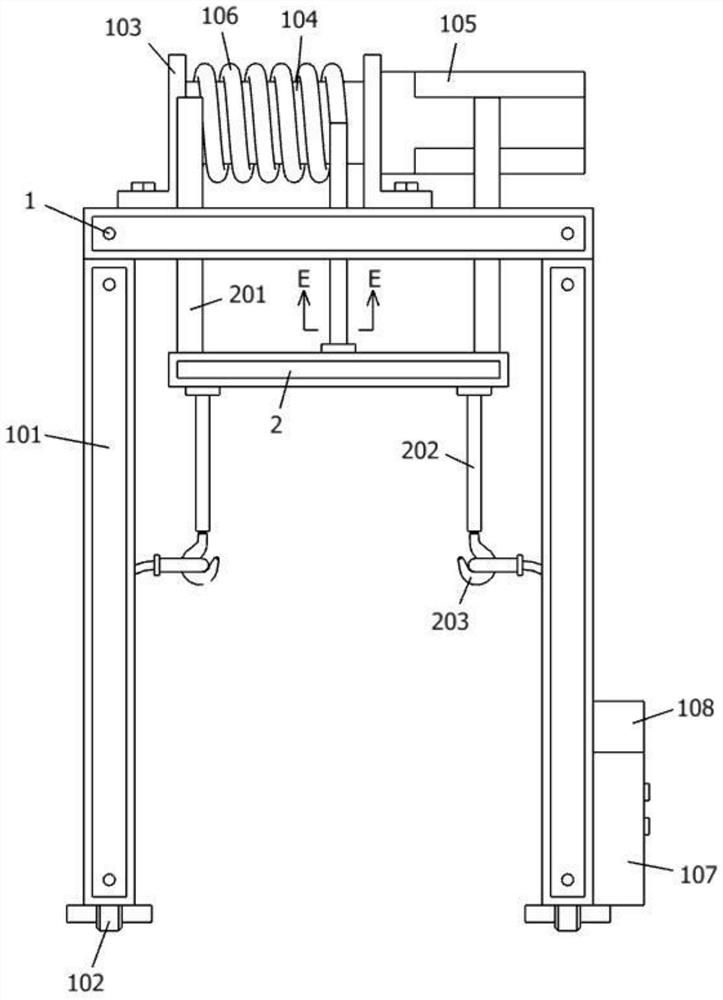

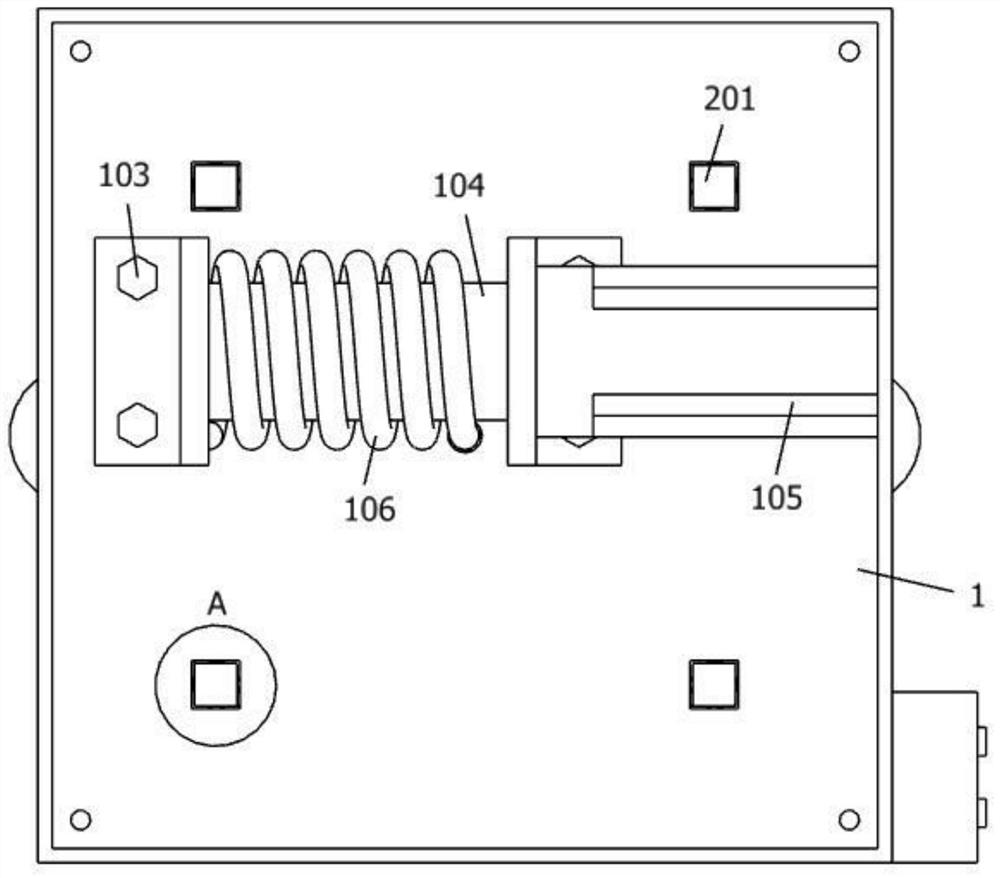

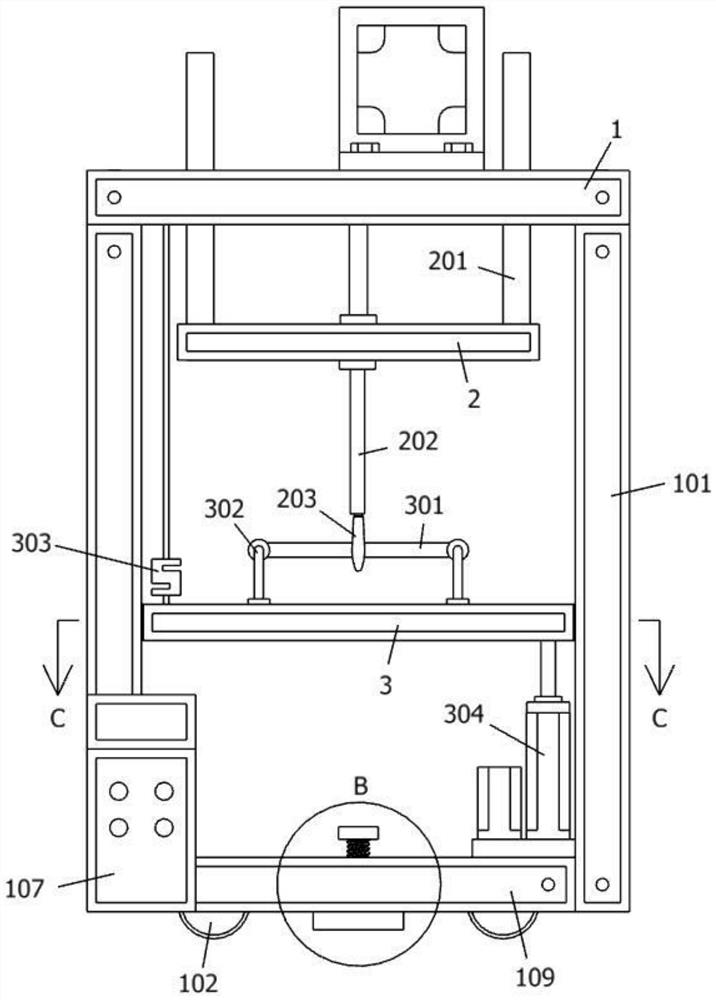

[0048] as attached figure 1 to attach Figure 8 Shown:

[0049] The present invention provides a device for hoisting and maintenance of chemical machinery equipment and its installation method, including: a bearing body 1; figure 1 As shown, the supporting body 2, the supporting body 2 has a square block structure as a whole, the supporting body 2 is located directly below the bearing body 1, the bearing body 1 has a square block structure as a whole, and the bearing body 1 includes: as attached figure 1 As shown, the supporting cylinder 101, the supporting cylinder 101 has a square column structure as a whole, and there are four supporting cylinders 101, and the four supporting cylinders 101 are fixedly installed on the corners of the four edges of the bottom end surface of the bearing main body 1; as attached image 3 As shown, the horizontal connecting column 109, the horizontal connecting column 109 has a square column structure as a whole, there are two horizontal conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com