Three-layer co-extrusion polyolefin infusion film and preparation method thereof

A three-layer co-extrusion, infusion film technology, applied in the field of infusion film, can solve the problems of high cost, complex process, many layers of infusion film, etc., achieve good compatibility and combination, and improve the effect of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

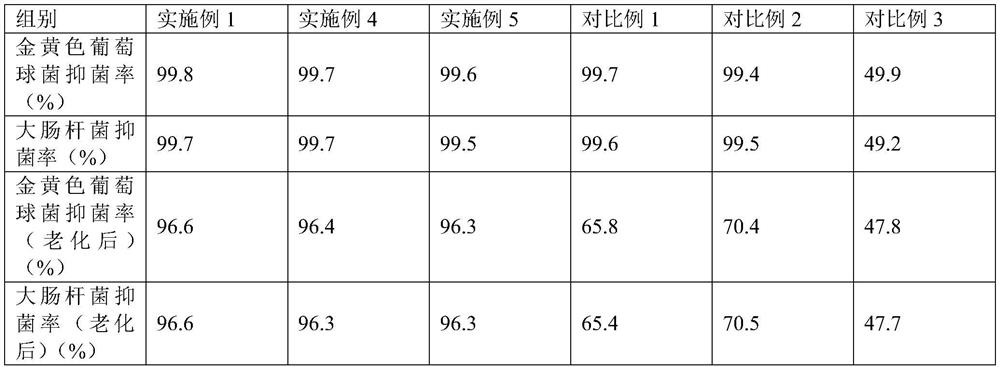

Examples

preparation example Construction

[0028] In addition, the preparation method of chitosan antibacterial modified polypropylene comprises the following steps: 4 ~10 5Mix and swell chitosan in lactic acid with a pH of 3-5, add 2-methyl-2-octenal and dimethyl sulfoxide and react at 30-50°C for 2-4 hours; adjust the pH to neutral , then add propylene monomer, sodium persulfate, polyoxypropylene ether and water to carry out polymerization reaction at 70-90°C for 3-5 hours, the polymerization pressure is 3-4MPaG, chitosan, 2-methyl-2-octene The mass ratio of aldehyde, propylene monomer, sodium persulfate and polyoxypropylene ether is 10-15:3-5:45-55:1-2:1-2; then methanol and saturated saline are added to break the emulsion, and then After filtering, washing and drying successively, the chitosan antibacterial modified polypropylene is obtained.

[0029] The preparation method of the above-mentioned three-layer co-extruded polyolefin infusion film comprises the following steps: the weather-resistant layer, the core ...

Embodiment 1

[0031] The three-layer co-extruded polyolefin infusion film includes a weather-resistant layer, a core layer and an inner sealing layer from outside to inside. The raw material of the weather-resistant layer includes polypropylene, and the thickness is 30 μm. The raw materials of the core layer include polyethylene, polypropylene and SEBS, and the thickness is 80 μm. The raw materials of the inner sealing layer include 43% chitosan antibacterial modified polypropylene and 57% SEBS, and the thickness is 70 μm. The total thickness of the prepared infusion film is 180 μm, and the materials such as polyethylene, polypropylene and SEBS are all medical grade materials, among which, the melting point of polypropylene is 140°C, and the melting point of polyethylene is 110°C; the styrene of SEBS is The block content is 32%.

[0032] In addition, the preparation method of chitosan antibacterial modified polypropylene comprises the following steps: the relative molecular weight is 8*10...

Embodiment 2

[0035] The three-layer co-extruded polyolefin infusion film includes a weather-resistant layer, a core layer and an inner sealing layer from outside to inside. The raw material of the weather-resistant layer includes polypropylene, and the thickness is 30 μm. The raw materials of the core layer include polyethylene, polypropylene and SEBS, and the thickness is 70 μm. The raw materials of the inner sealing layer include 35% chitosan antibacterial modified polypropylene and 65% SEBS, and the thickness is 65 μm. The prepared transfusion film has a total thickness of 165 μm, and the polyethylene, polypropylene, SEBS and other materials used are all medical grade materials, among which, the melting point of polypropylene is 140°C, and the melting point of polyethylene is 95°C; the styrene of SEBS is The block content was 17%.

[0036] In addition, the preparation method of chitosan antibacterial modified polypropylene comprises the following steps: the relative molecular weight i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap