On-line detection method for automobile outer doorsill reinforcer

A detection method and reinforcement technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of scrap parts, affecting the qualified rate of products, and unqualified vehicles, so as to solve the problems of low efficiency, realize online automatic detection, and avoid unqualified products. Product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

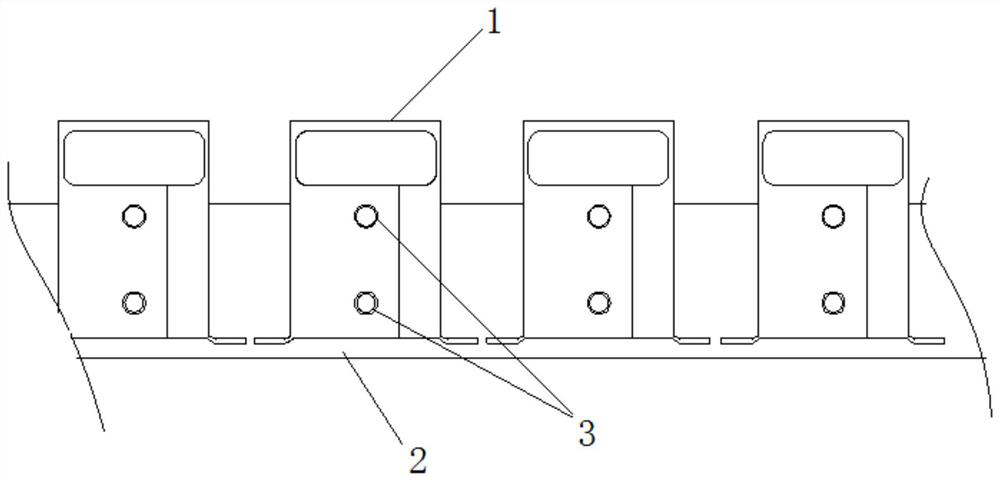

[0014] An on-line detection method for an automobile outer sill reinforcement. When the reinforcement 1 is clamped by a special fixture for the outer sill of the automobile and placed at the installation position of the outer sill 2, a color sensor is set on the fixture at the position corresponding to the positioning solder joint 3, and the color sensor is connected to The control system realizes online detection according to the color difference comparison between welding and non-welding.

[0015] figure 1 The positional relationship of reinforcement 1, outer sill 2, and positioning welding spot 3 is given in .

[0016] For the detection of unwelded reinforcements, the clamps are thrown into the waiting area, or sound and / or light alarms are processed manually; for the detection of welded reinforcements, the reinforcements and the outer threshold are welded.

[0017] As a preference, two color sensors are provided, corresponding to the two positioning welding spots 3 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com